Académique Documents

Professionnel Documents

Culture Documents

Panchal Jatin D. Quality Control: Production Quality Related Issues

Transféré par

Samir ChaudharyDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Panchal Jatin D. Quality Control: Production Quality Related Issues

Transféré par

Samir ChaudharyDroits d'auteur :

Formats disponibles

PANCHAL JATIN D.

Mobile: 09930934936 ~ E-Mail: panchaljatin.d@gmail.com

A result-oriented professional with excellence in implementing quality mechanisms to deliver desired output, seeking

assignments in QUALITY CONTROL with an organisation of high repute

AN OVERVIEW

• Possess nearly 9 years of cross-functional experience in Quality Control, Auditing &

Inspections, Continual Improvements, Process Optimization as well as

Manufacturing Quality Control

• Currently associated with renowned manufacturing group in India - Godrej & Boyce Welding&Fabrication

Manufacturing Co. Ltd. as Deputy Manager – Quality (QC); actively involved in

performing inspection of Pressure Vessel, Column, Reactor and Heat Exchanger Testing &Inspections

• Adept in developing & instituting a framework of quality standards, procedures &

systems i.e. as per ISO / Kaizen; provided support in problem and defect analysis in Project Coordination

production quality related issues

Process Enhancements

• Education credentials included: TUV NORD Certified QMS ISO 9001-2008 Internal

Auditor Course; ASNT Certified NDT Level II in RT, UT, MT&PT,CSWIP 3.1 Auditing

Welding inspector.

• Demonstrated abilities in managing various operations as per the set parameters & Manufacturing

standards; steered efforts towards testing / inspection / corrosion / failure pattern Technical Documentation

all types of equipment necessary for evaluation

• Expertise in carrying out defect analysis in the product and rendering solutions to Team Management

production people for quality improvement; actively involved in project jobs like

erection in NDT systems as well as other quality related documentations

• Technical sound with codes &standards viz. ASME Sec. IIA, Sec. IIC, Sec. V, Sec. VIII

Div. I & II

• Focused & goal driven with a strong work ethics, continuously striving for improvement coupled with excellent administrative

aptitude with an eye for detail & commitment to offer quality work

CAREER CONTOUR

Since Aug’08: Godrej & Boyce Manufacturing Co. Ltd., Mumbai

Currently designated as Deputy Manager – Quality (QC)

Growth Path:

Aug’08-Jan’14 Assistance Manager – Manufacturing

Feb’14-Till Date Deputy Manager – Quality (Q.C.)

Key Result Areas:

Functional:

• Taking stringent quality measures including preparation of necessary documents to ensure compliance with above standards

& customer requirements

• Maintaining all high precision grade equipment/tools in safe custody & ensure all equipment are operated as per the

instructions and user manual

• Conducting internal audits periodically to assess the status of deployment of systems and take corrective measures for

achieving organisational objectives

• Planning & organizing required inspection, examination&tests;ensuring the completion and compliance of the same with code,

QAP and drawing

• Reviewing all stage inspection reports and accepting them prior to obtaining clearance from TPI; QAP and Procedures for

project requirements

• Preparing balance activity list for PWHT/Hydro/Dispatch and follow-up with subordinate

• Developing new process concepts for production optimization, yield improvement and developing guidelines for the

sequencing of manufacturing activities

• Conducting random online quality inspections to ensure that product quality standards are adhered to at all stages of the

manufacturing process

• Reviewing test certificates for raw material entailing Plates, Forging, Pressure Parts &Non-pressure Parts; getting it clear from

TIP/Clients

• Handling quality of the finished products, waste reduction during manufacturing and reducing the percentage of rejection

• Identifying scope for:

o Planning / implementing technological changes to enhance efficiency

o Modifications in equipment, process flow, working practices, consumables etc. for controlling & reducing conversion

cost per unit produced

• Implementing various techniques for cycle time / cost reduction, entailing identification of opportunities, analysis of data,

conducting tests, cost benefit analysis and implementation

• Directing and leading the technical personnel; imparting continuous on job training to the workforce for accomplishing greater

operational effectiveness / efficiency

Technical:

• Held accountable for:

o Releasing the job for PWHT/Hydro/Dispatch after ensuring the completion of all prior stages

o Witnessing of Equipment Loading &Unloading for PWHT in Furnace or Local PWHT

o Getting signed NDE reports & Heat Treatment Charts from TPI

• Inspection of Pressure Vessel, Column, Reactor and Heat Exchanger

• Performing stage wise inspection in fabrication of Pressure Vessel, Reactor &Column as per QAP, Drawing and Code

Requirements;releasing them by signing the inspection reports from TPI /QC

• Taking care of inter-pass temperature, welding parameters and welding consumables as per WPS

• Carrying out:

o Visual Test, Penetrant Test, PMI, Ferriete, Hardness Test, Pneumatic Test and Hydraulic Test

o Final dimension inspection of the equipment

o Blasting, Painting and Pickling & Passivation Inspection

• Following welding process, non-destructive testing, destructive testing, fabrication, casting, raw material inspection, heat

treatment, painting, fabrication, machining, etc.

• Preparing work instructions / test descriptions / inspection plans and revising / updating them as and when required

• Conducting regular inspection and tests to ensure the performance capacity of various machines and equipments to ensure

smooth operations

SCHOLASTICS

Bachelors’ in Mechanical Engineeringin 2008

LokmanyaTilak College of Engineering, Mumbai with 66%

IT Skills: Conversant with MS Office (Word, Excel & PowerPoint) and Internet Applications

PERSONAL SNIPPETS

Date of Birth: 16th December, 1985

Address: F 7/41, Godrej Hill Side Colony,Vikhroli West, Mumbai-400079

Nationality: Indian

Marital Status: Married

No. of Dependants: 5

Passport No.: K0966865 (Valid Up to 23/11/2021)

Driving License No.: MH03 20110032258 (Valid Up to 24/05/2031)

Visa Status: NA

Language Known: English, Gujarati, Hindi & Marathi

Vous aimerez peut-être aussi

- Subramanyan CV QC EngineerDocument5 pagesSubramanyan CV QC EngineerSubramanyan Amruthum100% (3)

- Arun ResumeDocument3 pagesArun ResumeMelissa MurrayPas encore d'évaluation

- Quality Control and Quality AssuranceDocument22 pagesQuality Control and Quality AssurancejswldeepPas encore d'évaluation

- BridgeDocument25 pagesBridgeamit kandpalPas encore d'évaluation

- Wk8 Laura Martin REPORTDocument18 pagesWk8 Laura Martin REPORTNino Chen100% (2)

- R1.P1.T1.Crouhy Ch.1,2,4 v5SDocument6 pagesR1.P1.T1.Crouhy Ch.1,2,4 v5SNurul Amalina ZulkifliPas encore d'évaluation

- UCC Article 2-PocketGuideDocument2 pagesUCC Article 2-PocketGuidesuperxl2009Pas encore d'évaluation

- QAQC Engineer Rev 00Document2 pagesQAQC Engineer Rev 00DanielPas encore d'évaluation

- Vinay ResumeDocument4 pagesVinay Resumenaveen yadavPas encore d'évaluation

- Handramohan Akshmipathy: ENIOR Quality Professional - Nearly 26 Years of ExperienceDocument5 pagesHandramohan Akshmipathy: ENIOR Quality Professional - Nearly 26 Years of ExperienceANIL PLAMOOTTILPas encore d'évaluation

- Rajender Singh - ResumeDocument4 pagesRajender Singh - ResumeBaljeetPas encore d'évaluation

- Saravana Kumar.M ResumeDocument6 pagesSaravana Kumar.M ResumeHariPas encore d'évaluation

- Usman CV Qaqc 1Document2 pagesUsman CV Qaqc 1Digital InfoPas encore d'évaluation

- Usama Tamboli CV QDocument3 pagesUsama Tamboli CV QUsamah TPas encore d'évaluation

- Curriculum Vitae: Khermache MokhtarDocument4 pagesCurriculum Vitae: Khermache MokhtarMokhtar KhermachePas encore d'évaluation

- Usman CV Piping Inspector 11Document3 pagesUsman CV Piping Inspector 11Digital InfoPas encore d'évaluation

- Quality EngineerDocument3 pagesQuality Engineerapi-777738350% (1)

- Usman CV QC Work SDocument3 pagesUsman CV QC Work SDigital InfoPas encore d'évaluation

- Rahul Ghotekar (CV) - 2023Document3 pagesRahul Ghotekar (CV) - 2023Ashok ShelkePas encore d'évaluation

- Venkatesh GDocument2 pagesVenkatesh GArunanandPas encore d'évaluation

- Kiran Krishnan K: Resume - Qa/Qc Inspector E&IDocument6 pagesKiran Krishnan K: Resume - Qa/Qc Inspector E&IDelfin DavidPas encore d'évaluation

- Roles Ansn Responsibilities of QC Engineer/Manager ResponsibilitiesDocument4 pagesRoles Ansn Responsibilities of QC Engineer/Manager ResponsibilitiesEngr Primus ChinonyePas encore d'évaluation

- J4nmo n8kb6Document2 pagesJ4nmo n8kb6UMESHPas encore d'évaluation

- Milin M Patel: Curriculum ViateDocument3 pagesMilin M Patel: Curriculum Viatedevendra singhPas encore d'évaluation

- Qualification ValidationDocument29 pagesQualification ValidationmrugeshjPas encore d'évaluation

- Resume Rajkiran Updated - GenDocument4 pagesResume Rajkiran Updated - GenRaj KiranPas encore d'évaluation

- Bechtel QAQC AdvisorDocument5 pagesBechtel QAQC Advisoryoonchankim0911100% (1)

- Naukri AbhijitKhot 4408175 - 10 00 - 1Document4 pagesNaukri AbhijitKhot 4408175 - 10 00 - 1Mayuri DhaktodePas encore d'évaluation

- Qa - QC ManagerDocument14 pagesQa - QC Managermunawar hussainPas encore d'évaluation

- CV For The AutomobileDocument4 pagesCV For The AutomobileArpita PithvaPas encore d'évaluation

- Suresh Kumar K: QA/QC Engineer-MEPDocument4 pagesSuresh Kumar K: QA/QC Engineer-MEPVipin Kumar ParasharPas encore d'évaluation

- Muhammad Salem: Top Level AssignmentsDocument5 pagesMuhammad Salem: Top Level AssignmentsMPas encore d'évaluation

- May 28 20 QA QCDocument172 pagesMay 28 20 QA QCChristine PaulinePas encore d'évaluation

- Sundar GDocument2 pagesSundar GRazvan GheorghiesPas encore d'évaluation

- Curriculum Vitae: Muhammad AmmarDocument3 pagesCurriculum Vitae: Muhammad Ammarammar mughalPas encore d'évaluation

- Wa0000.Document5 pagesWa0000.oguaputaezijPas encore d'évaluation

- E&i QC Inspector Resum and DocumentsDocument24 pagesE&i QC Inspector Resum and DocumentsIrfan 786pakPas encore d'évaluation

- Mech Welding QA QC CVDocument13 pagesMech Welding QA QC CVMohammed Abdul ParwezPas encore d'évaluation

- Curriculum Vitae Of: Correspondence/Permanent Address: EmailDocument19 pagesCurriculum Vitae Of: Correspondence/Permanent Address: EmailsojeckPas encore d'évaluation

- QA QC-ManagerDocument2 pagesQA QC-ManagerMuhammad Abubakar SheikhPas encore d'évaluation

- KhalidDocument3 pagesKhalidMuhammad FarooqPas encore d'évaluation

- CV General ReferenceDocument5 pagesCV General ReferenceOscar Perez YaraPas encore d'évaluation

- Quality Inspection EngineerDocument2 pagesQuality Inspection EngineerEswara Rao BodduPas encore d'évaluation

- Mr.D.ramesh Babu CV 16.10.2018Document9 pagesMr.D.ramesh Babu CV 16.10.2018RamboPas encore d'évaluation

- Responsibilities of QC EngineerDocument3 pagesResponsibilities of QC EngineerHafis HSEPas encore d'évaluation

- Ravi Lead AuditorDocument11 pagesRavi Lead AuditorRonanki RaviPas encore d'évaluation

- A Study of Quality Control and Quality Assurance at Construction SiteDocument19 pagesA Study of Quality Control and Quality Assurance at Construction Sitetapan12345100% (14)

- Kanda Payment Screen ShotDocument9 pagesKanda Payment Screen ShotRamboPas encore d'évaluation

- National Institute of Construction Management and ResearchDocument14 pagesNational Institute of Construction Management and Researchsimple_aniPas encore d'évaluation

- Ayman Shehata 2022 (9 10 2022)Document5 pagesAyman Shehata 2022 (9 10 2022)ayman sobhyPas encore d'évaluation

- Basic Rules and Regulations For A QA - QC EngineerDocument76 pagesBasic Rules and Regulations For A QA - QC EngineerNazrul Obayed JabedPas encore d'évaluation

- Module 3 CPM-3Document20 pagesModule 3 CPM-3YogeshPas encore d'évaluation

- Rupak Choudhary: Work ExperienceDocument5 pagesRupak Choudhary: Work ExperiencePradhipta W NurrobbiPas encore d'évaluation

- Application CV-Nguyen Ba SonDocument2 pagesApplication CV-Nguyen Ba SonHoàng Vỹ PhạmPas encore d'évaluation

- Quality Manager & Production Manager CompetencyDocument6 pagesQuality Manager & Production Manager CompetencyManoj MehraPas encore d'évaluation

- Quality Management/ R D / Product Development Professional: Arun Kumar ShrivastavaDocument4 pagesQuality Management/ R D / Product Development Professional: Arun Kumar ShrivastavaArunPas encore d'évaluation

- CV of Muhammad Adeel RajputDocument4 pagesCV of Muhammad Adeel RajputFarhan SaghirPas encore d'évaluation

- Shah Zaman - QAQC Mechanical EngineerDocument8 pagesShah Zaman - QAQC Mechanical EngineerShah ZamanPas encore d'évaluation

- Calibration of EquipmentDocument80 pagesCalibration of EquipmentVivek Sagar100% (3)

- Construction Quality Control & Odit ProposelDocument7 pagesConstruction Quality Control & Odit ProposelHamayet RaselPas encore d'évaluation

- Qa EngineerDocument2 pagesQa EngineerNhữ HuyPas encore d'évaluation

- IEP For BrendonDocument1 pageIEP For BrendonSamir ChaudharyPas encore d'évaluation

- HydroDocument4 pagesHydroSamir ChaudharyPas encore d'évaluation

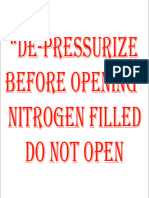

- DEPR (4)Document1 pageDEPR (4)Samir ChaudharyPas encore d'évaluation

- Competency Matrix - Tech TemplateDocument7 pagesCompetency Matrix - Tech TemplateSamir ChaudharyPas encore d'évaluation

- Flat Bottom Tank Inspection Checklist - LinkedinDocument9 pagesFlat Bottom Tank Inspection Checklist - LinkedinSamir ChaudharyPas encore d'évaluation

- Code & Standard Linkedin.Document34 pagesCode & Standard Linkedin.Samir ChaudharyPas encore d'évaluation

- CV LinkedinDocument3 pagesCV LinkedinSamir ChaudharyPas encore d'évaluation

- Samir Hasan Chaudhary: ContactDocument2 pagesSamir Hasan Chaudhary: ContactSamir ChaudharyPas encore d'évaluation

- CV - Linkedin 5Document9 pagesCV - Linkedin 5Samir ChaudharyPas encore d'évaluation

- CV - Linkedin 4Document6 pagesCV - Linkedin 4Samir ChaudharyPas encore d'évaluation

- CV - Linkedin 3Document5 pagesCV - Linkedin 3Samir ChaudharyPas encore d'évaluation

- CV - Linkedin 2Document5 pagesCV - Linkedin 2Samir ChaudharyPas encore d'évaluation

- CV - Linkedin 1Document5 pagesCV - Linkedin 1Samir ChaudharyPas encore d'évaluation

- Procedure - Designer QualificationDocument5 pagesProcedure - Designer QualificationSamir ChaudharyPas encore d'évaluation

- Klingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingDocument2 pagesKlingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingSamir ChaudharyPas encore d'évaluation

- Specialty Complete Catalog BWDocument13 pagesSpecialty Complete Catalog BWSamir ChaudharyPas encore d'évaluation

- SB - 622 PDFDocument10 pagesSB - 622 PDFSamir ChaudharyPas encore d'évaluation

- Liquid Penetrant Examination Report: PO No.&Document2 pagesLiquid Penetrant Examination Report: PO No.&Samir Chaudhary100% (2)

- Dish InspectionDocument1 pageDish InspectionSamir ChaudharyPas encore d'évaluation

- Pipe Schedule ChartDocument16 pagesPipe Schedule ChartSamir ChaudharyPas encore d'évaluation

- MarketingDocument5 pagesMarketingnash MadlaPas encore d'évaluation

- Marketing Mix For Insurance IndustryDocument7 pagesMarketing Mix For Insurance IndustryReema NegiPas encore d'évaluation

- CCPStatement 1Document3 pagesCCPStatement 1Kristina WoodPas encore d'évaluation

- Anna University - B.Tech - BIOTECHNOLOGY Syllabus - GE1451 Total Quality Management 1. IntroductionDocument79 pagesAnna University - B.Tech - BIOTECHNOLOGY Syllabus - GE1451 Total Quality Management 1. IntroductionSakib ShaikhPas encore d'évaluation

- At The Hotel - BusuuDocument5 pagesAt The Hotel - BusuuAida TeskeredžićPas encore d'évaluation

- 4.theories of EDocument19 pages4.theories of EManish Nasha100% (1)

- Australian/New Zealand Standard: Wet Area MembranesDocument7 pagesAustralian/New Zealand Standard: Wet Area MembranesGopi KrishnanPas encore d'évaluation

- Ch01 TB RankinDocument9 pagesCh01 TB RankinAnton VitaliPas encore d'évaluation

- You Tube Time To Charge UsersDocument7 pagesYou Tube Time To Charge UsersgalingpriyatnaPas encore d'évaluation

- Electronic Payment Systems: MBA EX 9607 - Managing E-BusinessDocument32 pagesElectronic Payment Systems: MBA EX 9607 - Managing E-BusinessAshutosh SinghalPas encore d'évaluation

- Buying ArvindDocument21 pagesBuying ArvindVaibhav SrivastavaPas encore d'évaluation

- PriceAdjustment GOs ampCircularsRabdB DepartmentDocument41 pagesPriceAdjustment GOs ampCircularsRabdB DepartmentV Venkata Narayana50% (4)

- Generator Service 0750614536Document3 pagesGenerator Service 0750614536Digital pallet weighing scales in Kampala UgandaPas encore d'évaluation

- Nalli Silk Saree Was Established in 1928Document5 pagesNalli Silk Saree Was Established in 1928Rahul KrishnetPas encore d'évaluation

- Introducción A Las MicrofinanzasDocument21 pagesIntroducción A Las MicrofinanzasNitzia VazquezPas encore d'évaluation

- Syllabus Labor Law Rev Plus CasesDocument219 pagesSyllabus Labor Law Rev Plus CasesMarivicTalomaPas encore d'évaluation

- Omer FarooqDocument3 pagesOmer FarooqomerfarooqscribdPas encore d'évaluation

- Syllabus: Digital Media Economics at UNC School of Journalism and Mass CommunicationDocument9 pagesSyllabus: Digital Media Economics at UNC School of Journalism and Mass CommunicationRyan Thornburg100% (1)

- Industrial Training ReportDocument63 pagesIndustrial Training ReportMohamed Shamal77% (13)

- Chapter 6 Supply Chain ManagementDocument25 pagesChapter 6 Supply Chain ManagementMỹ DuyênPas encore d'évaluation

- Smit Questionnaire On JewelleryDocument3 pagesSmit Questionnaire On JewelleryamitPas encore d'évaluation

- (English (Auto-Generated) ) Ethics Case Study - Do Not Let Your Friends Suffer (DownSub - Com)Document3 pages(English (Auto-Generated) ) Ethics Case Study - Do Not Let Your Friends Suffer (DownSub - Com)Bình LưuPas encore d'évaluation

- Value Added Tax (VAT)Document1 pageValue Added Tax (VAT)Parth UpadhyayPas encore d'évaluation

- Stock Market Indicators: S&P 500 Buybacks & Dividends: Yardeni Research, IncDocument11 pagesStock Market Indicators: S&P 500 Buybacks & Dividends: Yardeni Research, IncchristiansmilawPas encore d'évaluation

- Cost - Estimation Chem PlantDocument39 pagesCost - Estimation Chem PlantriffPas encore d'évaluation

- Bath and Shower in India PDFDocument8 pagesBath and Shower in India PDFVishal SinghPas encore d'évaluation

- Lion Air Eticket Itinerary / ReceiptDocument2 pagesLion Air Eticket Itinerary / ReceiptMuzakkir SyamaunPas encore d'évaluation