Académique Documents

Professionnel Documents

Culture Documents

1000 KnaufPipeInsulation

Transféré par

kulov1592Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1000 KnaufPipeInsulation

Transféré par

kulov1592Droits d'auteur :

Formats disponibles

Knauf Data Sheet PE-DS-1 08-07

1000˚ Pipe Insulation

• The Knauf rotary

manufacturing process

produces insulation

with concentric inside

diameters and consistent

wall thicknesses.

• Knauf 1000° Pipe offers

an extended temperature

range—the best thermal

performance in the industry.

• Knauf’s “wind-up” forming

mandrel process prevents

gaps and inconsistent

densities, while making it

easy to cleanly notch out

sections.

• Knauf 1000° Pipe’s superior

compressive strength allows

for fast installation and a neat

finished appearance.

• Installed properly, the foil

vapor retarder with a

pressure-sensitive lap

assures a positive vapor

seal.

Facts at a glance • For all applications from 0°F to 1000°F.

• Excellent thermal performance.

• Superior fabrication properties.

• Manufactured in ISO 9001:2000 certified plant.

1000˚ Pipe Insulation

Description Easy Size Identification Temperature Range

Knauf 1000° Pipe Insulation is a molded, heavy- • Pipe size, wall thickness and Proto 25/50 Rated • Pipe operating temperatures from 0°F to 1000°F

density, one-piece insulation made from inorganic PVC fitting cover size are printed in a repeat (-18°C to 538°C). Water Vapor Transmission

glass fibers bonded with a thermosetting resin. It is pattern along the longitudinal lap. (ASTM E 96, Procedure A)

produced in 3’ lengths with or without a factory- • Easy identification at job site. • Jacket has a water vapor permeance of .02

applied jacket. The jacket is a white-kraft paper • Simplifies restocking. perms or less.

bonded to aluminum foil and reinforced with glass • After application, print is covered by the lap for a Corrosiveness (ASTM C 665)

fibers, and the longitudinal lap of the jacket is avail- neat appearance. • No greater than sterile cotton.

able with or without a self-sealing adhesive. A butt • Complies with ASTM C 795, MIL-I-24244C and

strip is furnished for each section. Specification Compliance

NRC 1.36.

In U.S.:

Application Puncture Resistance

• ASTM C 547; Type I, Grade A; Type IV,

Knauf 1000° Pipe Insulation is used in power, pro- (TAPPI Test T803) (Beach Units)

Grade A

cess and industrial applications and in commercial • Jacket minimum rating of 50 units.

• ASTM C 585

and institutional buildings where maximum fire Alkalinity (ASTM C 871)

• ASTM C 795

safety, resistance to physical abuse and a finished • Less than 0.6% as Na2O.

• ASTM C 1136 (jackets); Type I, II, III, IV

appearance are desired. Additional weather protec- • pH between 7.5 and 10.0.

tion is needed outdoors. • GREENGUARD Certification

Microbial Growth (ASTM C 1338)

• GREENGUARD For Children and Schools™ • Does not promote microbial growth.

Features and Benefits Certification

Energy Conservation Water Vapor Sorption (ASTM C 1104)

• HH-B-100B (jackets); Type I and II • Less than 0.2% by volume.

• Offers excellent resistance to heat loss or gain,

• HH-I-558C; Form D, Type III, Class 12; Class 13 Linear Shrinkage (ASTM C 356)

which saves energy and lowers operating costs.

(to 1000°F, 538°C) • Negligible.

• A low thermal conductivity of .23 at 75°F (24°C).

• MEA 325-83-M (City of New York Dept. of

Low-Cost Installation Product Forms amd Sizes

Buildings)

• Available with self-sealing lap, which eliminates Produced in 3' (914 mm) sections:

• MIL-I-22344D

need for staples, additional material and tools. • For iron pipe from ½" to 24" nominal pipesize

• MIL-I-24244C (ships)

• Fast, easy installation reduces labor costs. (13 mm to 610 mm).

• NFPA 90A and 90B

Condensation Control • For copper tube from ⅝" to 6 ⅛" (16 mm to

• NRC Reg. Guide 1.36

• Installed properly, the foil vapor retarder and 156 mm).

pressure-sensitive lap assure a positive vapor • USCG 164.109/4/0 (plain, unjacketed only)

• Wall thicknesses from ½" to 6" (13 mm to

seal. In Canada:

152 mm) in single layer (for most sizes).

UL Classified • CAN/ULC S102-M88

• All insulation inner and outer diameters comply

• All Knauf Pipe Insulation, plain or jacketed, • CCG F1-304 (plain only)

with ASTM C 585.

meets the fire and smoke safety requirements of • CGSB 51-GP-9M

most federal, state and local building codes. • CGSB 51-GP-52M (jacket) Packaging

• Four convenient carton sizes for easy ordering,

Technical Data inventory tracking and storage.

Surface Burning Characteristics • Unique sesame tape reinforced carton hand

• UL Classified. holds for superior strength and easy handling.

• Does not exceed 25 Flame Spread, 50 Smoke • Color-coded labels to easily identify pipe sizes

Developed when tested in accordance with by wall thickness.

ASTM E 84, CAN/ULC S102-M88, NFPA 255

• Easy to access butt strips.

and UL 723.

Precautions

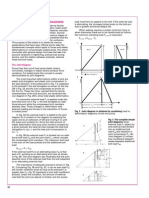

Thermal Efficiency (ASTM C 335) Hot Pipe

• May be installed while the system is in

Mean Temperature k k (SI)

.70 .101 operation, at all temperatures up to 1000°F

75°F (24°C) .23 .033

Thermal Conductivity (SI Units) (W/m• °C)

(538°C).

Thermal Conductivity (BTU-in./hr •ft 2•°F)

.60 .087

100°F (38°C) .24 .035 .50 .072 • Knauf recommends, for insulation

200°F (93°C) .28 .040 .40 .058

thicknessesgreater than 6” (152 mm) the

.30 .043

temperature must be increased from 500°F

300°F (149°C) .34 .049

.20 .029

(260°C) to maximum temperature at a rate

400°F (204°C) .42 .061 .10 .014

not exceeding 100°F (56°C) per hour.

500°F (260°C) .51 .074 .00

0 100 200 300 400 500 600 (˚F ) • During initial heat-up to operating

-18 38 93 149 204 260 316 (˚C)

600°F (316°C) .62 .089 Mean Temperature temperatures above 350°F (177°C), a slight

odor and some smoke may be given off as

a portion of the bonding material used in the

Minimum Pipe Insulation (In.)a insulation begins to undergo a controlled

(to meet ASHRAE 90.1 Requirements)

decomposition.

Insulation Conductivity Nominal Pipe Diameter (in.) • If natural convection is not adequate in

Fluid Design Conductivity confined areas, forced ventilation should

Operating Range Mean be provided in order to protect against any

Temperature BTU-in./ Temperature Runoutsb 1& 1¼ 2½

Range, °F (hr∙ft3∙°F) Rating, °F up to 2 less to 2 to 4 5&6 8 & up harmful fumes and vapors that might be

generated.

Heating Systems (Steam, Steam Condensate and Hot Water)

• Care must also be taken when using

Above 350 32-34 250 1½ 2½ 2½ 3 3½ 3½

sealants, solvents or flammable adhesive

251-350 29-31 200 1½ 2 2½ 2½ 3½ 3½ during installation.

201-250 27-30 150 1 1½ 1½ 2 2 3½ • A maximum of 6” (152 mm) wall thickness

141-200 25-29 125 ½ 1½ 1½ 1½ 1½ 1½ is recommended.

105-140 24-28 100 ½ 1 1 1 1½ 1½ Cold Pipe

• Use a continuous vapor retarder on piping

Domestic and Service Hot Water Systemsc

operating below ambient temperatures.

105 and Greater 24-28 100 ½ 1 1 1½ 1½ 1½

• Seal all joints, surfaces, seams and fittings to

Cooling Systems (Chilled Water, Brine, Refrigerant)d

prevent condensation.

40-55 23-27 75 ½ ½ ½ 1 1 1 • On below-freezing applications and in

Below 40 23-27 75 1 1 1½ 1½ 1½ 1½ high-abuse areas, the ASJ jacket shall be

a For minimum thicknesses of alternative insulation types, see 9.4.8.2, ASHRAE 90.1. protected with a PVC vapor retarding outer

b Runouts to individual terminal units not exceeding 12 ft. in length. jacket. In addition, exposed ends of insula-

c Applies to recirculating sections of service or domestic hot water systems and first 8 ft. from storage tank for non-recirculating systems.

d The required minimum thicknesses do not consider water vapor transmission and condensation. Additional insulation, vapor retarders, or both, may be tion shall be sealed with vapor barrier mastic

required to limit water vapor transmission and condensation. installed per the mastic manufacturer’s

instructions. Vapor seals at butt joints shall

be applied at every fourth pipe section

joint and at each fitting to isolate any water

incursion.

• On chilled water systems operating in high- • Fittings should be insulated to same thickness as • Faced insulation should not have a facing

humidity conditions, it is recommended that the the adjoining insulation. temperature above 150°F (66°C).

same guidelines be followed as listed above for • Apply fittings per manufacturer’s instructions.

Recommended Thicknesses

below-freezing applications. • When required by specification, a hard insert

The minimum thicknesses (see chart on page 5)

• Exterior hanger supports are recommended. of sufficient length should be used to avoid

are based on ASHRAE 0.1-1989 standards and do

Outside Application compression of the insulation.

not necessarily represent the Economic Thickness

• Do not expose pipe insulation to weather. It must Caution of Insulation or the thickness required for proper

be covered with appropriate jacketing, mastic or Fiber glass may cause temporary skin irritation. condensation control. Rather, they serve as mini-

vapor retardant adhesives. Wear long-sleeved, loose-fitting clothing, head mum recommendations for commercial applications.

• All exposed surfaces must be protected. Proto® covering, gloves and eye protection when handling For recommended Economic Thickness, install

Indoor/Outdoor PVC Jacketing is recommended. and applying material. Wash with soap and warm according to Knauf or NAIMA ETI programs or as

See Knauf Guide Specifications for recom- water after handling. Wash work clothes separately specified.

mended PVC jacketing application guidelines. and rinse washer. A disposable mask designed for

• Apply jacketing, mastics or vapor retardant nuisance type dusts should be used where sensitiv- Fiber Glass and Mold

adhesives per manufacturer’s instructions. For ity to dust and airborne particles may cause irritation Fiber glass insulation will not sustain mold growth.

metallic jackets, factory-applied and condensate to the nose or throat. However, mold can grow on almost any material

retarders are recommended. when it becomes wet and contaminated with organic

Application Guidelines materials. Carefully inspect any insulation that has

ASJ-SSL

Storage been exposed to water. If it shows any sign of mold

• Keep adhesive and contact surfaces free from

• Protect insulation from water damage or other it must be discarded. If the material is wet but shows

dirt and water, and seal immediately once

abuse, welding sparks and open flame. no evidence of mold, it should be dried rapidly and

adhesive is exposed.

• Cartons are not designed for outside storage. thoroughly.

• Apply when ambient and insulation temperatures

Preparation If it shows signs of facing degradation from wetting,

are between 0°F and 130°F (-18°C and 54°C).

• Apply only on clean, dry surfaces. it should be replaced.

• If stored below 0°F or above 130°F, allow

• Pipe or vessel should be tested and released

insulation cartons to stand within recommended Notes

before insulation is applied.

temperature range for 24 hours prior to The chemical and physical properties of Knauf

General Guidelines

application. 1000° Pipe Insulation represent typical average

• All sections should be firmly butted.

• Do not store product below -20°F (-29°C) or values determined in accordance with accepted test

• Seal circumferential joint with a minimum 3"

above 150°F (66°C). methods. The data is subject to normal manufactur-

(76 mm) wide butt strip.

• When using Knauf’s SSL closure system, make ing variations. The data is supplied as a technical

• Jackets, coating and adhesives should have a service and is subject to change without notice.

sure the longitudinal and circumferential joints

comparable F.H.C. rating. References to numerical flame spread ratings are

are properly sealed by rubbing the closure

firmly with a squeegee. Use of staples is not • Factory-applied jacket can be painted with latex not intended to reflect hazards presented by these

recommended. or water-based paint. Solvent-based paints or any other materials under actual fire conditions.

should not be used. Check with your Knauf Insulation sales representa-

• When using Knauf SSL Pipe Insulation, the

surface temperature of the insulation should be • Do not expose factory-applied jacket to tive to assure information is current.

between -20°F and 150°F (-29°C and 66°C) chemicals or liquid water.

during the life of the insulation. • All piping should have continuous insulation.

Fittings and Hangers • Position longitudinal lap downward to avoid dirt

• Use Proto 25/50 Rated (ASTM E 84) PVC Fitting and moisture infiltration.

Covers, applying PVC fittings per Proto’s Data • Do not expose pipe insulation to excessive

Sheet. vibration or physical abuse.

For more information call (800) 825-4434, ext. 8283

or visit us online at www.knaufinsulation.us

Knauf Insulation GmbH

One Knauf Drive

Shelbyville, IN 46176

Sales and Marketing (800) 825-4434, ext. 8283

Technical Support (800) 825-4434, ext. 8212

Fax (317) 398-3675

Information info.us@knaufinsulation.com

World Wide Web www.knaufinsulation.us

©2007 Knauf Insulation GmbH.

Knauf 1000° Pipe Insulation products are leed Eligible Product

certified for indoor air quality as a low emitting Use of this product may help building projects meet green

product by The GREENGUARD Environmental In- building standards as set by the Leadership in Energy and

stitute™ to both the GREENGUARD Certification Environmental Design (LEED) Green Building Rating System.

ProgramSM and the more stringent GREENGUARD Credit 4.1 - 4.2 Recycled Content

For Children and Schools™ standard. Credit 5.1 - 5.2 Regional Materials

www.greenguard.org.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- E112Document3 pagesE112kulov1592Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- RAiNA2023-Literature Review Report-Rainscreen Performance (RDH-Straube, Smegal)Document67 pagesRAiNA2023-Literature Review Report-Rainscreen Performance (RDH-Straube, Smegal)kulov1592Pas encore d'évaluation

- Qsun and Quv ComparisonDocument16 pagesQsun and Quv Comparisonnikopigni2Pas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Janssen2016-Experimental Study of Dynamic Effects in Moisture Transfer in Building MaterialsDocument13 pagesJanssen2016-Experimental Study of Dynamic Effects in Moisture Transfer in Building Materialskulov1592Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Belic2015-HVAC Control Methods - A Review-COOOLDocument8 pagesBelic2015-HVAC Control Methods - A Review-COOOLkulov1592Pas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- 03 OsmosisDocument44 pages03 OsmosispankajPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- EPA2008-Indoor Air Vapor Intrusion Mitigation ApproachesDocument49 pagesEPA2008-Indoor Air Vapor Intrusion Mitigation Approacheskulov1592100% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Bolted Connection DesignDocument25 pagesBolted Connection Designkulov1592Pas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- E177 13 Standard Practice For Use of The Terms Precision and Bias in ASTM Test MethodsDocument10 pagesE177 13 Standard Practice For Use of The Terms Precision and Bias in ASTM Test MethodsmatsergyPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Thermo NotesDocument381 pagesThermo NotespondoraPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- BeyerLeveque1992-Analysis of A One-Dimensional Model For The Immersed Boundary MethodDocument34 pagesBeyerLeveque1992-Analysis of A One-Dimensional Model For The Immersed Boundary Methodkulov1592Pas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Bolt Joint-DiagramsDocument6 pagesBolt Joint-Diagramskulov1592Pas encore d'évaluation

- AC71Document4 pagesAC71kulov1592Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Sound PowerDocument12 pagesSound Powerkulov1592Pas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Bolted Connection DesignDocument25 pagesBolted Connection Designkulov1592Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- CH01-Pressure, Potentials and The GradientDocument20 pagesCH01-Pressure, Potentials and The Gradientkulov1592Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Waterhammer-Student Note-COOL PDFDocument8 pagesWaterhammer-Student Note-COOL PDFkulov1592Pas encore d'évaluation

- Boiling Heat Transfer - Annurev - Fluid.30.1Document37 pagesBoiling Heat Transfer - Annurev - Fluid.30.1agnotts09Pas encore d'évaluation

- Cavitation in Valves 7-22-08Document6 pagesCavitation in Valves 7-22-08Keivn SimiyuPas encore d'évaluation

- Cavitation in Valves 7-22-08Document6 pagesCavitation in Valves 7-22-08Keivn SimiyuPas encore d'évaluation

- MTF270-Turbulence Modeling-Large Eddy Simulations PDFDocument29 pagesMTF270-Turbulence Modeling-Large Eddy Simulations PDFkulov1592Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Gowri2009-Infiltration Modeling Guidelines For Commercial Building Energy Analysis (USDOE PNNL-18898) PDFDocument24 pagesGowri2009-Infiltration Modeling Guidelines For Commercial Building Energy Analysis (USDOE PNNL-18898) PDFkulov1592Pas encore d'évaluation

- ACCA2011-Manual J-Residential Load Calculation-Outdoor Design Conditions PDFDocument52 pagesACCA2011-Manual J-Residential Load Calculation-Outdoor Design Conditions PDFkulov159257% (7)

- TCP IP Protocol Suite Chap-01 IntroDocument13 pagesTCP IP Protocol Suite Chap-01 IntroRahul RajPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Lecture2 PDFDocument20 pagesLecture2 PDFPinjala AnoopPas encore d'évaluation

- Dust CollectionDocument6 pagesDust Collectionkulov1592Pas encore d'évaluation

- Dust CollectionDocument43 pagesDust Collectionkulov1592100% (1)

- Infiltec-DM4-Dual Digital Micro Manometers PDFDocument3 pagesInfiltec-DM4-Dual Digital Micro Manometers PDFkulov15920% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- CMHC1998-Testing of Air Barrier Systems For Wood Frame WallsDocument4 pagesCMHC1998-Testing of Air Barrier Systems For Wood Frame Wallskulov1592Pas encore d'évaluation

- TECTITE-Explanation of Blower Door Terms and Results PDFDocument6 pagesTECTITE-Explanation of Blower Door Terms and Results PDFkulov1592Pas encore d'évaluation

- Dirty Dozen List of Endocrine DisruptorsDocument4 pagesDirty Dozen List of Endocrine DisruptorsMariuszPas encore d'évaluation

- Electronic Fetal MonitoringDocument4 pagesElectronic Fetal MonitoringMauZungPas encore d'évaluation

- JOHARI Window WorksheetDocument2 pagesJOHARI Window WorksheetAnonymous j9lsM2RBaIPas encore d'évaluation

- Z0109MN Z9M TriacDocument6 pagesZ0109MN Z9M TriaciammiaPas encore d'évaluation

- Gut Health Elimination Diet Meal Plan FINALDocument9 pagesGut Health Elimination Diet Meal Plan FINALKimmy BathamPas encore d'évaluation

- Diplomate Course and Conferment RequirementsDocument1 pageDiplomate Course and Conferment Requirementsabigail lausPas encore d'évaluation

- Culturally Safe Classroom Context PDFDocument2 pagesCulturally Safe Classroom Context PDFdcleveland1706Pas encore d'évaluation

- WP DeltaV Software Update Deployment PDFDocument8 pagesWP DeltaV Software Update Deployment PDFevbaruPas encore d'évaluation

- Msds Aluminium SulfatDocument5 pagesMsds Aluminium SulfatduckshaPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Schools Division of Roxas CityDocument4 pagesSchools Division of Roxas CityHuge Propalde EstolanoPas encore d'évaluation

- 4 - Mixing Equipments Used in Flocculation and CoagulationDocument27 pages4 - Mixing Equipments Used in Flocculation and Coagulationhadeer osmanPas encore d'évaluation

- Anti-Bribery and Corruption PolicyDocument2 pagesAnti-Bribery and Corruption PolicyAJAY PatilPas encore d'évaluation

- InfertilityDocument8 pagesInfertilityrivannyPas encore d'évaluation

- Science Form 3 2020 (Notes, PBD, Exercise) : Chapter: 8 RadioactivityDocument19 pagesScience Form 3 2020 (Notes, PBD, Exercise) : Chapter: 8 Radioactivitysakinah100% (1)

- MPSI OverviewDocument15 pagesMPSI OverviewZaqee AlvaPas encore d'évaluation

- Hotel Transportation and Discount Information Chart - February 2013Document29 pagesHotel Transportation and Discount Information Chart - February 2013scfp4091Pas encore d'évaluation

- Maxs AdultDocument1 pageMaxs Adultclark lopezPas encore d'évaluation

- Maternal and Child Health Nursing 7 BulletsDocument4 pagesMaternal and Child Health Nursing 7 BulletsHoneylie PatricioPas encore d'évaluation

- Purpose in Life Is A Robust Protective Factor of Reported Cognitive Decline Among Late Middle-Aged Adults: The Emory Healthy Aging StudyDocument8 pagesPurpose in Life Is A Robust Protective Factor of Reported Cognitive Decline Among Late Middle-Aged Adults: The Emory Healthy Aging StudyRaúl AñariPas encore d'évaluation

- MN - 2019 01 29Document28 pagesMN - 2019 01 29mooraboolPas encore d'évaluation

- 2012 U.S. History End-of-Course (EOC) Assessment Field Test Fact SheetDocument2 pages2012 U.S. History End-of-Course (EOC) Assessment Field Test Fact SheetswainanjanPas encore d'évaluation

- Protection Solutions: Above-the-NeckDocument42 pagesProtection Solutions: Above-the-NeckMatt DeganPas encore d'évaluation

- Your Marathon Training PlanDocument16 pagesYour Marathon Training PlanAndrew Richard ThompsonPas encore d'évaluation

- Course Syllabus MGTP 31206 31207Document12 pagesCourse Syllabus MGTP 31206 31207NamitBhasinPas encore d'évaluation

- Creative An Inclusive ClassroomDocument3 pagesCreative An Inclusive Classroommuneeba zafarPas encore d'évaluation

- PP Aaa PP1 141Document30 pagesPP Aaa PP1 141Rabah AmidiPas encore d'évaluation

- Respiratory Examination - Protected 1Document4 pagesRespiratory Examination - Protected 1anirudh811100% (1)

- Babok Framework Overview: BA Planning & MonitoringDocument1 pageBabok Framework Overview: BA Planning & MonitoringJuan100% (1)

- Resume - Arun BhartiDocument3 pagesResume - Arun BhartiArun AbPas encore d'évaluation

- Financial Markets & Institutions: Lecture Notes #3Document90 pagesFinancial Markets & Institutions: Lecture Notes #3Joan MaduPas encore d'évaluation