Académique Documents

Professionnel Documents

Culture Documents

JSA Additional Lamp Paiton 3

Transféré par

MarhendraCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

JSA Additional Lamp Paiton 3

Transféré par

MarhendraDroits d'auteur :

Formats disponibles

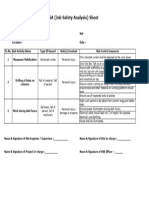

JOB SAFETY ANALYSIS

(RISK ASSESSMENT)

Area to be Access and/or Equipment Tag No. (KKS No.) : Chorination Building, WTP, Gate House No.3, Desalination Building, Battery Room, Mobile

Trash Rack System (see attached drawings)

Work to be Done : Provide and install additional lamp for some area within Paiton Unit 3 #PR148412

LOW HIGH Underwater Work Confined Space Excavation Hot Work

Risk Category Job :

Refer to Paiton Instruction : PI-05-03-01 Complex Lifting Work Working at High On Line Low & High Voltage

Work Order No. : Priority No. PAS Application No.

Work Period Date & Time Start Date & Time Finish

Operation

Applicant Health & Safety Work Parties Engineer

Supervisor

Signature :

Date : Time :

Ref. PI-05-03-01-F01 Page 1

Ref. PI-05-03-01-F01 Page 2

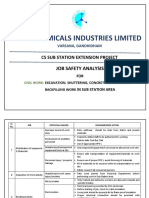

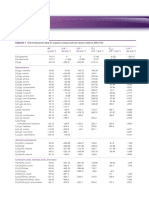

Work sequence Hazards Risk Control Measures

A. Prepartion

Mobilization tools, Good manual handling practices to be used (min. 2 person

equipment and materials Manual handling Musculoskeletal injuries lift); Use hand gloves

to the work place Use mechanical aids where required

Ensure all electrical equipment in good condition and

Electrical applies for knowing how to use properly

Electrical Shock Personal injury or death

equipment & lighting Ensure all electrical equipment has been checked before use

and has valid tagging

Install scaffolding by certificate scaffolder & tag by IPMOMI

Assembly of platform & Damage to exsisting facilities/

Scaffolding crumple safety officer. Always check regularly

scaffold on the ground equipment , personal injury

Secure existing facilities/equipment

Do not climb scaffold frame. Do not remove rails or bracing,

slip, fall or stepping through do not move scaffolding. Always close the hatch when

Personal injury or dead

open door hatch entering new level

Wear full body harness double lanyard

B. Working on the getting hit in the head from tools Know what is below and above you at all time. Use standard

scaffolding or equipment dropped from Personal injury safety helmet. Use safety rope where necessary to secure

above items

There is a dropping hazard. Take a minimum of equipment

Damage the installed equipment or

Dropped items and secure loose item. Use pocket, buckets, rope, or bags to

component below

keep item secure

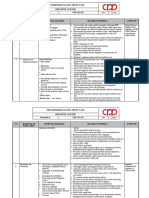

C. Conduit fabrication and

installtation

Cutting conduit Ensure the worker already got training and worm standard

PPE

Grinder wheel throws off sparks Put barricade around work area to prevent entry by

and hot bits of metal Skin & eyes injury unauthorized person

Ensure fire extinguisher has been prepare

Worm Safety gloves and eye protection

Worm v-shiled and long-sleeved clothes

Accidental contact with grinder Can cause bad cuts Workers will ensure the grinder’s guard is in place and fully

wheel operational before use.

Ensure the worker already got training and worm standard

Ref. PI-05-03-01-F01 Page 3

Work sequence Hazards Risk Control Measures

PPE

Ref. PI-05-03-01-F01 Page 4

Work sequence Hazards Risk Control Measures

Ensure all electrical equipment in good condition

Electrical Shock

Ensure all electrical equipment has been checked before use

Improper electrical

and has valid tagging

tools/equipment

can cause bad cuts Make sure cutting grinder disk speed / rpm greater than

equipment speed/rpm

Good manual handling practices to be used (min. 2 person

Manual handling Musculoskeletal injuries lift); Use hand gloves

Use mechanical aids where required

Ensure working tools in good condition and knowing how to

Conduit threading Beaten by working tools Personal injury

use properly

Sufficient rest period between jobs and avoid repetitious

Strains and sprains Personal injury

activity

D. Counduit installation & Use full body harness properly

Pulling Cable Work at heights Fall from height All scaffolding must be tagging by POMI safety officer

Have cedrtification TKBT 2 for working at heights

Sufficient rest period between jobs and avoid repetitious

Strains and sprains Personal injury

activity

All tools to be maintained in good condition

Tools to only be used for the task intended in line with

electrical tools to be insulated to 1000v

All tools to be appropriately stored to avoid damage

Use of hand tools Cuts and abrasions, flying objects

All damaged tools to be removed from use immediately

Appropriate PPE to be supplied and worn as identified

Condition and appropriate use of hand tools to be checked

during H&S inspections

Ref. PI-05-03-01-F01 Page 5

Work sequence Hazards Risk Control Measures

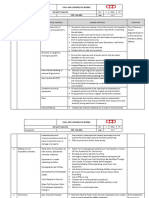

All tools to be maintained in good condition

Tools to only be used for the task intended in line with any

manufactures instructions

All tools to be inspected by the user prior to use

Cuts and abrasions, flying objects, Guards to be inspected regularly

Use of power tools

entanglement, electrocution Ensure that all cables are secured to avoid trip hazards

Prevent use of tools by unauthorized persons,

Appropriate PPE to be supplied and worn as identified

All tools to be appropriately stored to avoid damage

All damaged tools to be removed from use immediately

E. Lamp installation &

re-route cable line Injury to muscles, nerves, disc and Good manual handling practices to be used (min. 2 person

Manual handling : lifting &

ligaments of the low back lift); Use hand gloves

carrying

Low back stain, ligament sprain Use mechanical aids where required

Use full body harness properly

Work at heights Fall from height All scaffolding must be tagging by POMI safety officer

Have cedrtification TKBT 2 for working at heights

Working at hot area (heat) Dehydration Provide drinking water

Damage to exsisting facilities/

Working near electrically Conduct Tool Box meeting (area condition explanation),

equipment

energized equipment’s engineering ccontrols, provide solid barricade to cover

(electrical shock) equpiment

Personal injury

Noise Hearing injury Provide ear plug

Ensure work areas in communal areas are appropriately

Injury to workers around or cordoned off and safety signage is in place

Injury to others

operatives Good communication should be maintained with other trades

with regards to specific electrical hazard

Ref. PI-05-03-01-F01 Page 6

Work sequence Hazards Risk Control Measures

All tools to be maintained in good condition

Tools to only be used for the task intended in line with

electrical tools to be insulated to 1000v

All tools to be appropriately stored to avoid damage

Use of hand tools Cuts and abrasions, flying objects

All damaged tools to be removed from use immediately

Appropriate PPE to be supplied and worn as identified

Condition and appropriate use of hand tools to be checked

during H&S inspections

All tools to be maintained in good condition

Tools to only be used for the task intended in line with any

manufactures instructions

All tools to be inspected by the user prior to use

Cuts and abrasions, flying objects, Guards to be inspected regularly

Use of power tools

entanglement, electrocution Ensure that all cables are secured to avoid trip hazards

Prevent use of tools by unauthorized persons,

Appropriate PPE to be supplied and worn as identified

All tools to be appropriately stored to avoid damage

All damaged tools to be removed from use immediately

All cables to be taped down, covered or attached at a high

level to prevent trip hazards

Slips and trips Trips on trailing cables or materials materials and waste to be tidy or removed from site

Maintain good housekeeping standards and prevent trip

hazards

Sufficient rest period between jobs and avoid repetitious

Strains and sprains Personal injury

activity

In-appropriate tools & PPE

Ensure the correct tools & required PPEs are ready to use

cause hit by material & Personal injury

prior to carriying electrical isolation

equipment

Personal injury

F. Electrical isolation Unintended shutdown of other Identifity the equipment to be isolated and the safety overide

Damage to existing facilities/

equipment / system to be carried out prior to isolation

equipment

Ensure the isolation to be carried out by authorized electrical

Unauthorized isolation Personal injury

person only

Ref. PI-05-03-01-F01 Page 7

Work sequence Hazards Risk Control Measures

Identify & confirm the switchgear feeding electrical power to

Unauthorized energizing Electrical shock the equipment; isolate safety electrical isolation through

proper tools

G. Energized

Unintendend shutdown of other Personal injury install sign and do not operated without the permission from

equipment / system Damage to exsisting facilities/ engineering

equipment Ensure energized to be carried out by authorized person only

Dust mask for housekeeping crew when necessary

Dust dispersion Respiration system injury

Bundles bind or contained securely to prevent slippage

H. Housekeeping

Keep tools, equipment, extension cords, ropes etc. Out of

Disorganized tool & material Trip, slips, falls

walk ways

Additional Note :

1. Electrical isolation.

2. Normal work hour.

3.

4.

5.

Ref. PI-05-03-01-F01 Page 8

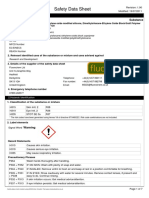

The following test are required to assess the atmospheric conditions in the nominated space :

Ref. PI-05-03-01-F01 Page 9

TEST REQUIRED

TEST FOR Permissible Exposure Limit (PEL)

YES NO

Ammonia Less than 25 ppm √

Carbon Dioxide Less than 5000 ppm √

Carbon Monoxide Less than 25 ppm √

Chlorine Less than 0.5 ppm √

Hydrogen Sulfide Less than 10 ppm √

Oxygen Greater than 19.5% & Less than 23.5% √

Ozone Less than 0.1 ppm √

Sulphur Dioxide Less than 2 ppm √

Hydrogen LEL = 4% & UEL = 75.6% √

LEL Less than/ ≤ 4% √

Note :

1. Reference (OSHA PEL – 2013)

2. For clarification on the test required to be carried out refer PI-05-03-02 (Testing of Confined Space)

Ref. PI-05-03-01-F01 Page 10

Vous aimerez peut-être aussi

- JSA Epoxy Coating Machine ShopDocument10 pagesJSA Epoxy Coating Machine ShopMarhendra100% (1)

- JSA Painting Aut Tranformer Unit 3 OutageDocument7 pagesJSA Painting Aut Tranformer Unit 3 OutageMarhendraPas encore d'évaluation

- JSA Crack Injection at Scruber Basin Unit 3Document6 pagesJSA Crack Injection at Scruber Basin Unit 3MarhendraPas encore d'évaluation

- Job Safety Analysis: (Risk Assessment)Document9 pagesJob Safety Analysis: (Risk Assessment)MarhendraPas encore d'évaluation

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- JSA Install Automatic Parking GateDocument6 pagesJSA Install Automatic Parking GateMarhendraPas encore d'évaluation

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailPas encore d'évaluation

- Builder Hoist Erection JSA HSE ProfessionalsDocument2 pagesBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDOPas encore d'évaluation

- JSA 12-Rev.02 - Pipe or Spool Erection by Using of Chain Blocks or Rope PulleyDocument3 pagesJSA 12-Rev.02 - Pipe or Spool Erection by Using of Chain Blocks or Rope PulleygolusinghdataPas encore d'évaluation

- Rebaring JSA HSE ProfessionalsDocument1 pageRebaring JSA HSE ProfessionalsSamadov 13Pas encore d'évaluation

- Fixing of Bracket in Cutout JSA HSE ProfessionalsDocument1 pageFixing of Bracket in Cutout JSA HSE ProfessionalsSamadov 13Pas encore d'évaluation

- Jsa Psa & GisDocument3 pagesJsa Psa & GisMohammed NouzalPas encore d'évaluation

- Job Safety Analysis: (Risk Assessment)Document12 pagesJob Safety Analysis: (Risk Assessment)MarhendraPas encore d'évaluation

- JSA Replace Exsisting Strainer at FGD 8Document8 pagesJSA Replace Exsisting Strainer at FGD 8MarhendraPas encore d'évaluation

- JSP For Electrical and HV TestingDocument4 pagesJSP For Electrical and HV TestingmohammedPas encore d'évaluation

- JSA Erection StructureDocument11 pagesJSA Erection StructureJAYESH JOSHIPas encore d'évaluation

- Job Safety Analysis New ReviseDocument12 pagesJob Safety Analysis New ReviseAnonymous YmINeSIFPas encore d'évaluation

- Fabrication Work Risk AssessmentDocument11 pagesFabrication Work Risk Assessmentstansilous100% (1)

- Structural Fabrication - Erection JSA HSE ProfessionalsDocument1 pageStructural Fabrication - Erection JSA HSE Professionalsm.rehanhsePas encore d'évaluation

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 pagesCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaPas encore d'évaluation

- Jsa FormatDocument6 pagesJsa FormatMohdHuzairiRusliPas encore d'évaluation

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- CS Sub Station JsaDocument4 pagesCS Sub Station JsaEHS Unit IIPas encore d'évaluation

- Staircase and Walkways Railing Work JSA HSE ProfessionalsDocument1 pageStaircase and Walkways Railing Work JSA HSE ProfessionalsSamadov 13Pas encore d'évaluation

- Job Safety Analysis Sheet - Alluminium Door FixingDocument2 pagesJob Safety Analysis Sheet - Alluminium Door FixingNFRNPas encore d'évaluation

- 01 Job Safety Analysis HousekeepingDocument1 page01 Job Safety Analysis Housekeepingkhaja asifuddin100% (1)

- JSA For Construction of E - P WorkshopDocument5 pagesJSA For Construction of E - P Workshopm.rehanhsePas encore d'évaluation

- Project: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control MeasuresDocument3 pagesProject: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- 1st Aid Training Siemens ContractorDocument11 pages1st Aid Training Siemens ContractorTigor GurningPas encore d'évaluation

- 01 General Safety PDF PDFDocument1 page01 General Safety PDF PDFrichPas encore d'évaluation

- Appendix 18 Steam Blowing JSADocument3 pagesAppendix 18 Steam Blowing JSAzhang75% (12)

- Job Safety Analysis (Jsa)Document9 pagesJob Safety Analysis (Jsa)MohdHuzairiRusliPas encore d'évaluation

- 5.19.3 Job Safety Practices Installation of Cable TrayDocument3 pages5.19.3 Job Safety Practices Installation of Cable TrayBarkat UllahPas encore d'évaluation

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582Pas encore d'évaluation

- Structural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDocument2 pagesStructural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDarseen RPas encore d'évaluation

- JHSA For Temporary Plastic Septic TankDocument4 pagesJHSA For Temporary Plastic Septic TankAnna JisabaPas encore d'évaluation

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaPas encore d'évaluation

- Lesson Learned RegisterDocument2 pagesLesson Learned Registernasir habibPas encore d'évaluation

- Shuttring, Deshuttering, Steel Fixing, P.C.C and R.C.C Work JsaDocument5 pagesShuttring, Deshuttering, Steel Fixing, P.C.C and R.C.C Work JsaAKBAR ALIPas encore d'évaluation

- Assembly of Steel StructuresDocument2 pagesAssembly of Steel StructuresDelta akathehuskyPas encore d'évaluation

- Use of Power ToolsDocument3 pagesUse of Power ToolsNisanth ThulasidasPas encore d'évaluation

- Gas Cutting JsaDocument4 pagesGas Cutting JsaMohammed Minhaj100% (1)

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaPas encore d'évaluation

- Fixing of Glass at Bridge JSA HSE ProfessionalsDocument1 pageFixing of Glass at Bridge JSA HSE ProfessionalsViron BaxhiaPas encore d'évaluation

- Hard BarricationDocument3 pagesHard BarricationViron BaxhiaPas encore d'évaluation

- Job Hazard Analysis (Jha) Worksheet SPOC-433-CPF-JSA-ELEC-001Document2 pagesJob Hazard Analysis (Jha) Worksheet SPOC-433-CPF-JSA-ELEC-001asteway gonfaPas encore d'évaluation

- PT-03 JSA Dismantling of Slip Form (22-05-09)Document10 pagesPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibPas encore d'évaluation

- 5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionDocument3 pages5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionBarkat UllahPas encore d'évaluation

- Job Hazards AnalysisDocument1 pageJob Hazards AnalysisJane RoPas encore d'évaluation

- Ene Risk AssessmentDocument1 pageEne Risk AssessmentSanjeet SinghPas encore d'évaluation

- 03-F07 Job Safe Procedure Template - DAMMAM - NO. 01Document1 page03-F07 Job Safe Procedure Template - DAMMAM - NO. 01jawad khanPas encore d'évaluation

- JSP For AsphaltDocument8 pagesJSP For Asphaltmohammed tofiqPas encore d'évaluation

- JsaDocument13 pagesJsaArnold Roy Coballes Manalo100% (1)

- JSA - Field Instruments InstallationDocument4 pagesJSA - Field Instruments InstallationSagar PadhiyarPas encore d'évaluation

- JSA of CentrifugeDocument8 pagesJSA of CentrifugeGajanan NalegaonkarPas encore d'évaluation

- Shot Blasting Operation JSA HSE ProfessionalsDocument2 pagesShot Blasting Operation JSA HSE ProfessionalsSamadov 13Pas encore d'évaluation

- S07 Tank Project - JSA - Erection of Scaffolding 2nd LevelDocument6 pagesS07 Tank Project - JSA - Erection of Scaffolding 2nd LevelKrishVy KumærPas encore d'évaluation

- Sika Injection 201 CE Part A - MSDSDocument9 pagesSika Injection 201 CE Part A - MSDSMarhendraPas encore d'évaluation

- Sikaflex - 221Document2 pagesSikaflex - 221MarhendraPas encore d'évaluation

- Technical Clarification Form-PR171982Document11 pagesTechnical Clarification Form-PR171982MarhendraPas encore d'évaluation

- SikaGrout 215 SDS en - MYDocument9 pagesSikaGrout 215 SDS en - MYMarhendraPas encore d'évaluation

- Sika Injection 201 CE Part B - MSDSDocument10 pagesSika Injection 201 CE Part B - MSDSMarhendraPas encore d'évaluation

- BA - KLARIFIKASI PR171982 Effluent Water New Piping System Line To Boiler 78 - PPMDocument4 pagesBA - KLARIFIKASI PR171982 Effluent Water New Piping System Line To Boiler 78 - PPMMarhendraPas encore d'évaluation

- Schedule Booster FanDocument1 pageSchedule Booster FanMarhendraPas encore d'évaluation

- 1.LINE 1,2 GANewSealBoosterAirFanDocument1 page1.LINE 1,2 GANewSealBoosterAirFanMarhendraPas encore d'évaluation

- Schedule Booster FanDocument1 pageSchedule Booster FanMarhendraPas encore d'évaluation

- 3.LINE 1,2 S9129 InletDuctingSketchDocument1 page3.LINE 1,2 S9129 InletDuctingSketchMarhendraPas encore d'évaluation

- 2.LINE 1,2 GAExistingSealBoosterAirFanDocument1 page2.LINE 1,2 GAExistingSealBoosterAirFanMarhendraPas encore d'évaluation

- Design Calculation Rail 350 X 175 For PTW PreparationDocument9 pagesDesign Calculation Rail 350 X 175 For PTW PreparationMarhendraPas encore d'évaluation

- Access Gate Fence Pole FoundationDocument1 pageAccess Gate Fence Pole FoundationMarhendraPas encore d'évaluation

- This constructi-WPS OfficeDocument1 pageThis constructi-WPS OfficeMarhendraPas encore d'évaluation

- JSA Install Automatic Parking GateDocument6 pagesJSA Install Automatic Parking GateMarhendraPas encore d'évaluation

- Desain Rak PerlengkapanDocument1 pageDesain Rak PerlengkapanMarhendraPas encore d'évaluation

- Job Safety Analysis: (Risk Assessment)Document12 pagesJob Safety Analysis: (Risk Assessment)MarhendraPas encore d'évaluation

- JSA Replace Exsisting Strainer at FGD 8Document8 pagesJSA Replace Exsisting Strainer at FGD 8MarhendraPas encore d'évaluation

- BoQ of Additional Lamps For Some P3 Area 2020 - R1Document3 pagesBoQ of Additional Lamps For Some P3 Area 2020 - R1MarhendraPas encore d'évaluation

- Additional Drawing Excitation Spare Trafo Rev01-1Document1 pageAdditional Drawing Excitation Spare Trafo Rev01-1MarhendraPas encore d'évaluation

- Sow To Provide Additional Lamp On Some Area of Paiton 3 - 2020 R1Document21 pagesSow To Provide Additional Lamp On Some Area of Paiton 3 - 2020 R1MarhendraPas encore d'évaluation

- JSA Replace Exsisting Strainer at FGD 8Document6 pagesJSA Replace Exsisting Strainer at FGD 8MarhendraPas encore d'évaluation

- AtoZ PicsDocument7 pagesAtoZ PicsMarhendraPas encore d'évaluation

- Tabel Baja Profil WF PDFDocument7 pagesTabel Baja Profil WF PDFErwin d'Adventura63% (19)

- JSA Building Paving FactoryDocument12 pagesJSA Building Paving FactoryMarhendraPas encore d'évaluation

- Access Gate FoundationDocument1 pageAccess Gate FoundationMarhendraPas encore d'évaluation

- Formulation Development and Evaluation of Unit Moulded Herbal Semisolid Jelly Useful in Treatment of Mouth UlcerDocument9 pagesFormulation Development and Evaluation of Unit Moulded Herbal Semisolid Jelly Useful in Treatment of Mouth UlcerLaeeq R MalikPas encore d'évaluation

- Completions and WorkoverDocument309 pagesCompletions and WorkoverFan Jack67% (3)

- Test1 Goc & Poc Tough by S.K.sinha See Chemistry Animations atDocument3 pagesTest1 Goc & Poc Tough by S.K.sinha See Chemistry Animations atmyiitchemistry100% (1)

- Gas Chromatography AmmoniaDocument10 pagesGas Chromatography AmmoniacurlychemPas encore d'évaluation

- Pulse GerminationDocument21 pagesPulse GerminationChetan KambojPas encore d'évaluation

- MasterCast 140Document4 pagesMasterCast 140robin rezkPas encore d'évaluation

- Pharmacognostical and Preliminary Phytochemical Screening On Leaves of Trianthema Decandra Linn.Document3 pagesPharmacognostical and Preliminary Phytochemical Screening On Leaves of Trianthema Decandra Linn.anto_pharma7784Pas encore d'évaluation

- Waste Management Write-UpDocument5 pagesWaste Management Write-UpGounassegaraneDuraisamy100% (1)

- National Waste Management Strategy 2019-2023Document64 pagesNational Waste Management Strategy 2019-2023Chikondi KanamaPas encore d'évaluation

- 01-0019-01 Flame Methods Manual For AADocument117 pages01-0019-01 Flame Methods Manual For AARobert Larry Cordova DiazPas encore d'évaluation

- What Pipeliners Need To Know About Induction Bends PDFDocument20 pagesWhat Pipeliners Need To Know About Induction Bends PDFmarcos2dami2o2de2azePas encore d'évaluation

- Construction Safety ProgramDocument108 pagesConstruction Safety Programalvin100% (3)

- Atkins & de Paula Elements of Physical Chemistry 5th TXTBK (Dragged) 2Document7 pagesAtkins & de Paula Elements of Physical Chemistry 5th TXTBK (Dragged) 2Roselle Mea EderPas encore d'évaluation

- Models - Bfc.li Battery Thermal 2d AxiDocument16 pagesModels - Bfc.li Battery Thermal 2d AxijehadyamPas encore d'évaluation

- Redox EquilibriaDocument2 pagesRedox Equilibriafunkykid80Pas encore d'évaluation

- Carbon and Its Compounds - Shobhit NirwanDocument17 pagesCarbon and Its Compounds - Shobhit NirwanBhaskar 8287Pas encore d'évaluation

- Hydro Silk Fluid Englisch 06 2020Document1 pageHydro Silk Fluid Englisch 06 2020Saman KhalidPas encore d'évaluation

- A Brief Introduction To Pressure Vessels: (Clarification Needed)Document3 pagesA Brief Introduction To Pressure Vessels: (Clarification Needed)daniPas encore d'évaluation

- Thermo Scientific Taq Dna Polymerase With KCL Buffer: DescriptionDocument3 pagesThermo Scientific Taq Dna Polymerase With KCL Buffer: DescriptionCHIRANJEEVIPas encore d'évaluation

- Chemical Bonding and Molecular Structure - Lecture NotesDocument51 pagesChemical Bonding and Molecular Structure - Lecture NotesEdith EatonPas encore d'évaluation

- Everyday Science PDFDocument101 pagesEveryday Science PDFMahmood SyedPas encore d'évaluation

- Introduction To Water Chemistry in FreshwasterDocument4 pagesIntroduction To Water Chemistry in FreshwasterpomodoroPas encore d'évaluation

- (En GB) DBE 821 - 1.00Document7 pages(En GB) DBE 821 - 1.00Enio Miguel Cano LimaPas encore d'évaluation

- Yanmar BulletinsDocument10 pagesYanmar BulletinsBill Carter100% (2)

- Calculations in Furnace TechnologyDocument277 pagesCalculations in Furnace Technologysakthivel100% (2)

- Hyperbaric Oxygen TherapyDocument7 pagesHyperbaric Oxygen Therapy18juni1995Pas encore d'évaluation

- Presenters Post16 Tcm18-118246Document18 pagesPresenters Post16 Tcm18-118246Kamariah IsmailPas encore d'évaluation

- Density MethodDocument5 pagesDensity MethodMajed DawaPas encore d'évaluation

- Are Red Flowers Really Red?Document4 pagesAre Red Flowers Really Red?Mikaella CapiralPas encore d'évaluation

- 3.AcidBases FinalDocument35 pages3.AcidBases FinalSoham RanePas encore d'évaluation