Académique Documents

Professionnel Documents

Culture Documents

Hto Eni

Transféré par

Chintan GondaliaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Hto Eni

Transféré par

Chintan GondaliaDroits d'auteur :

Formats disponibles

from eni research

choose the best

for industry

Via Laurentina, 449 - 00142 Rome

Tel.: + 39 06 5988.1

eni.com

agip lubricants

Edition December 2009

heat transfer technology comes alive

oils Via Laurentina

Tel.: + 39 06 5

eni.com

I_8246_380x190_ Heat_Transfer.indd 1 11/12/09 15:12

oils for heat transfer systems

The industrial heating of solids, liquids or gases is commonly carried out by a system of indirect heat transmission via a heat transfer

fluid that transfers heat from a heat source to the point of use.

The advantages of an indirect system are:

eni, through its Agip brand, is the leading company in the industrial lubricant market in Italy. > precision in temperature control

Technical and commercial leadership is maintained and reinforced by eni’s commitment to > uniformity of heating avoiding local overheating

technology, quality, environmental protection and technical customer support. > multiuse from one heat source

> maximum safety due to the separation of the user and the heat source.

technology

The internationally recognised advanced level of expertise and equipment at the San Donato Mineral heat transfer oils are used in modern plants for the industrial transmission of heat from a heat source to one or more users.

Milanese laboratories generate the development of products and processes for the most Mineral heat transfer oils has the following advantages:

modern production requirements.

> they function in a wide range of temperatures (from ambient temperature to 280 - 300°C)

quality > they may operate at atmospheric pressure, thus avoiding the necessity of high pressures which would require expensive plant

All plants in the lubricant production cycle operate in accordance to a certified quality > they provide excellent lubrication that ensures low wear on the pumps and valves

management system in conformity with standard ISO 9002.

> they have a protective capacity that ensures the absence of rust on metallic surfaces

environment > they have a low pour point that allows starting the plant in the cold

Attention to the environment is one of the main guiding principles in product development and > low vapour tension that reduces the risk of vapour formation

in the production cycle. All plants implement a certified environmental management system > use of a non-toxic, non-corrosive fluid that does not give collection or recovery problems.

in conformity with standard ISO 14001.

technical support

The highly qualified technical manpower are the highly dispersed global operations, ensured

outstanding technical back up support services to customers, security in total customers

satisfaction.

The industrial product line includes lubricants and special products to satisfy all the lubrication

requirements of any type of industrial plant at a qualitative level at the top of the market.

More information about application, characteristics and TDS is available on https://nalis.eni.it/Alis

and by e-mail alis@eni.it

I_8246_380x190_ Heat_Transfer.indd 2 11/12/09 15:13

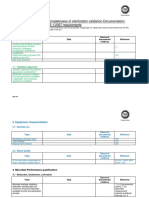

heat transfer oils properties ISO 67/43-12 classifications

The heat transfer fluids have the following characteristics:

> easy transmission of heat using relatively small quantities of fluid, which, from a thermodynamic point of view, means having a high

enough density, a good thermal conductibility and a high specific heat value typical

ISO - L type use temperature

> low vapour tension at the operating temperatures to allow use at low pressures in order applications

to avoid the development of vapours and the risk of cavitations or flow irregularities

> low viscosity in use to limit load leaks refined mineral oil open circuit open oil containers

> no aggressiveness with metallic and rubber materials QA or synthetic fluid for heating pieces

for heating of < 250°C

> good antifoam and air release properties mechanical components

> high flammability point.

refined mineral oil heat transfer fluid < 300°C

stability to cracking QB closed circuit

or synthetic fluid heating system

The term cracking means the breakdown of the oil molecule by the effects of temperature.

Unsaturated polymerised compounds leave carbonaceous deposits on the internal surfaces of tubes that increase cracking due closed circuit

refined mineral oil heat transfer fluid

to a decrease in the thermal exchange coefficient (K). It is fundamental to control the temperature of the oil in contact with the QC with forced 300 - 320°C

or synthetic fluid heating system

circulation

heating pipe and to avoid prolonged contact.

closed circuit

distillation range high stability heat transfer fluid > 320°C

QD with forced

synthetic fluid heating system

circulation

Mineral heat transfer oils consist of a mixture of hydrocarbons and are characterised by a distillation range rather than a distillation

temperature. In general reference is made to the temperature at the start of their distillation. This is a very important characteristic refined mineral oil

given that vapour sacs generated can cause cavitations in the pumps and alter the correct thermal exchange of the fluid and lead to QE or synthetic fluid cooling unit with hot flow

> - 30°C – < 200°C

cracking. In pressurised plant is possible to reach higher oil temperatures but only using low viscosity oils with narrow temperature low viscosity in circuits and/or cold flow

range of distillation and high cracking temperatures. the cold

resistance to oxidation

A high resistance to oxidation is another important characteristic of a heat transfer oil. It is advisable to maintain the temperature of

the oil, at points of contact with air (expansion vessel), below 50/60°C (the threshold under which oxidation is relatively low).

Produced from paraffin oils, AGIP ALARIA are characterised by a better resistance to oxidation than aromatic or naphtha oils. agip alaria range

AGIP ALARIA is the range of very high quality AGIP heat transfer oils obtained from highly solvent refined paraffin mineral bases.

They are recommended for filling closed and open circuit diathermic plants and guarantee an excellent stability to cracking

and oxidation. These products are characterised by a restricted distillation interval and a very high initial distillation point.

Prandtl’s number

AGIP ALARIA heat transfer oils are available in various grades to allow the user to choose the most

Prandtl’s number is useful for calculating convective thermal transfer whether free or forced by heat transfer fluids. appropriate product for their operative requirements.

Cp.µ

Pr =

K

•Cp specific heat at constant pressure expressed in [kcal/kg °C]

•µ dynamic viscosity expressed in [cP]

•K thermal conductibility expressed in [kcal/m h °C]

I_8246_380x190_ Heat_Transfer.indd 3 11/12/09 15:15

3500

AGIP ALARIA 2 - 3 - 7

Oils composed of carefully selected paraffin bases, suitable for filling closed or open circuit of heat transfer systems. 3000

They are characterised by high stability to oxidation and high stability to thermal decomposition (cracking).

• Three viscosity gradations for a variety of types of use.

• Resistance to the formation of deposits and sludge at high temperatures. 2500

specific heat (joule/kg °C)

• Notable demulsivity and air separation capacity.

• High resistance to oxidation.

2000

AGIP ALARIA 3 HT

1500

A diathermic oil composed of a carefully selected and highly refined paraffin base. It is very stable to oxidation and thermal decomposition.

• Resistance to the formation of deposits and sludge at high temperatures.

AGIP ALARIA 2

• Notable demulsivity and air separation capacity. 1000

• High resistance to oxidation. AGIP ALARIA 3 - 3HT

500

For use wherever the maximum temperature leaving the heater is higher than the usual. AGIP ALARIA 7

0

0 50 100 150 200 250 300 350

temperature (°C)

operating conditions

AGIP ALARIA

(typical values) 2 3 3HT 7 Low viscosity oils are preferably used in plants operating at a high temperature, in particular in those pressurised by inert gas; firstly,

because they resist cracking more efficiently and secondly, because their high conductivity permits faster heat transmission and

starting the plant in a shorter time. More viscous gradations can be used in plants operating at a lower maximum temperature,

viscosity at 40°C mm2/s 16 31.3 30.4 95.3 normally non-pressurised, such as bitumen heating plants. Thermal conductibility (Q) increases with an increase in viscosity; however

viscosity at 100°C mm2/s 3.3 5.3 5.3 10.9 less viscous oil is often used as diathermic fluid despite a minor loss of heat load because it can be circulated faster, thus favouring

viscosity index - 105 103 107 97 faster heat transmission.

flash point P.M. °C 194 206 218 230

flash point c.o.c. °C 210 216 230 252

MAXIMUM WALL MAXIMUM MASS

pour point °C -12 -9 -12 -9 PRODUCTS

TEMPERATURE TEMPERATURE

neutralization number mg KOH/g ≤ 0.03 ≤ 0.03 ≤ 0.03 ≤ 0.03

conradson carbon residue %p 0.01 0.019 0.018 0.097

AGIP ALARIA 2 340°C 305°C

copper corrosion (3h at 150°C) - 1 1 1 1 AGIP ALARIA 3 320°C 305°C

dilatation coefficient m3/°C 0.00067 0.00066 0.00066 0.00064 AGIP ALARIA 3 HT 345°C 315°C

volumic mass kg/m3 856 870 860 889 AGIP ALARIA 7 315°C 300°C

I_8246_380x190_ Heat_Transfer.indd 4 11/12/09 15:16

Vous aimerez peut-être aussi

- Eni Turbine Oil BrochureDocument4 pagesEni Turbine Oil BrochureranjanguptPas encore d'évaluation

- FUOOTECH Series TY Vacuum Turbine Oil PurifierDocument15 pagesFUOOTECH Series TY Vacuum Turbine Oil PurifierKevin Chiang100% (1)

- Heating Elements Thermostats & Controls Heating Systems & UnitsDocument11 pagesHeating Elements Thermostats & Controls Heating Systems & UnitsabcPas encore d'évaluation

- CATALOGUE COMP - 2935043820 ZRZT 55-90 (FF) & ZRZT 75-90 VSD (FF) Oil-Free Rotary Scre...Document16 pagesCATALOGUE COMP - 2935043820 ZRZT 55-90 (FF) & ZRZT 75-90 VSD (FF) Oil-Free Rotary Scre...abduPas encore d'évaluation

- MENERGA System OverviewDocument20 pagesMENERGA System OverviewΠροσλαλιά διαχ.Pas encore d'évaluation

- Caadox: ChemerronDocument35 pagesCaadox: Chemerrondon timoPas encore d'évaluation

- Heating Ventilation Air Conditioning Units BrochureDocument20 pagesHeating Ventilation Air Conditioning Units BrochureMlayeh MohamedPas encore d'évaluation

- Texatherm Texaco PDFDocument4 pagesTexatherm Texaco PDFJayath BogahawattePas encore d'évaluation

- ZR ZT 55-90 16p Brochure 2017 0602 LR InekoDocument16 pagesZR ZT 55-90 16p Brochure 2017 0602 LR InekolennyPas encore d'évaluation

- MilitaryAeroTherm 6003595Document8 pagesMilitaryAeroTherm 6003595shahinPas encore d'évaluation

- Thermax Single Effect Hot Water Driven ChillerDocument12 pagesThermax Single Effect Hot Water Driven ChillerKetan ChandravadiyaPas encore d'évaluation

- Brochure Honeywell HTSDocument12 pagesBrochure Honeywell HTSIngeniero Proyectos 1Pas encore d'évaluation

- Engineers Nova Scotia: Detailed Engineering Experience RecordDocument1 pageEngineers Nova Scotia: Detailed Engineering Experience Recordndoan_44Pas encore d'évaluation

- TF8550 Merino Laminates Case StudyDocument2 pagesTF8550 Merino Laminates Case Studyemperor_vamsiPas encore d'évaluation

- 143 484 Crushing Malaxing EngDocument12 pages143 484 Crushing Malaxing EngWAFAPas encore d'évaluation

- General Catalogue - Process Product Guide - CopieDocument566 pagesGeneral Catalogue - Process Product Guide - CopieghilesPas encore d'évaluation

- Products Catalog - ACORE Filtration Co - LTDDocument22 pagesProducts Catalog - ACORE Filtration Co - LTDMauricio RaúlPas encore d'évaluation

- Model ESTD1 Lab Spray Dryer PDFDocument2 pagesModel ESTD1 Lab Spray Dryer PDFeidPas encore d'évaluation

- Wynns 2Document8 pagesWynns 2fulltransmissionPas encore d'évaluation

- Short Path Film Evaporation Distillation SpduDocument25 pagesShort Path Film Evaporation Distillation SpduisepcontrolPas encore d'évaluation

- 485 Leaf Removal Washing EngDocument8 pages485 Leaf Removal Washing EngEpilefSantiagoPas encore d'évaluation

- Oel Gas E 03 2015Document24 pagesOel Gas E 03 2015Dennis Koay GMPas encore d'évaluation

- Shorter Cycle Times and Greater Cleaning Performance: WD 200 / WD 250 / WD 290Document20 pagesShorter Cycle Times and Greater Cleaning Performance: WD 200 / WD 250 / WD 290Luis Mario JuarezPas encore d'évaluation

- Chemical Engineering Magazine Feb 2015 PDFDocument76 pagesChemical Engineering Magazine Feb 2015 PDFMaje Dioses PedreraPas encore d'évaluation

- Catalogue AC enDocument194 pagesCatalogue AC enKA plusPas encore d'évaluation

- TEAM004 Heat Treating Brochure 0219 WEBDocument3 pagesTEAM004 Heat Treating Brochure 0219 WEBram0629Pas encore d'évaluation

- Ring Design GuideDocument48 pagesRing Design GuideFathy MostafaPas encore d'évaluation

- Advance 2011 3 enDocument30 pagesAdvance 2011 3 enrojas_giancarloPas encore d'évaluation

- Texatherm: Industrial Heat Transfer OilDocument2 pagesTexatherm: Industrial Heat Transfer OilCharith LiyanagePas encore d'évaluation

- Benefits of Oil Free Chiller Technology FinalDocument2 pagesBenefits of Oil Free Chiller Technology FinalAnurag KumbharePas encore d'évaluation

- Globaltherm Omnipure Product Information SheetDocument4 pagesGlobaltherm Omnipure Product Information SheetMalek MahmoudPas encore d'évaluation

- Cetus DE: Ultra High Performance Synthetic Air Compressor LubricantDocument2 pagesCetus DE: Ultra High Performance Synthetic Air Compressor LubricantAymanSayedElantableePas encore d'évaluation

- TF ENG 01 HTF Selection GuideDocument11 pagesTF ENG 01 HTF Selection GuidehasrunizraPas encore d'évaluation

- Oil Filtering Whitepaper 2017Document10 pagesOil Filtering Whitepaper 2017Brayan MejiaPas encore d'évaluation

- ZRZT 55-90 (VSD) (FF)Document25 pagesZRZT 55-90 (VSD) (FF)Erick GuzmanPas encore d'évaluation

- Lubricants For Steel Industry: CondatDocument2 pagesLubricants For Steel Industry: CondatAlstome PowerPas encore d'évaluation

- Impregnation Technology: Stronger Electrical MotorDocument8 pagesImpregnation Technology: Stronger Electrical MotorAnselmo Aguado cortesPas encore d'évaluation

- Tectrol Kaltreiniger EngDocument1 pageTectrol Kaltreiniger EngkarlocikovicPas encore d'évaluation

- Drosrite: Maximizing Aluminum Recovery Salt-FreeDocument2 pagesDrosrite: Maximizing Aluminum Recovery Salt-FreeSrinivasan ReddyPas encore d'évaluation

- Fire & Smoke DamperDocument24 pagesFire & Smoke Dampershahin msPas encore d'évaluation

- Thermoengineering Brochure ENGDocument6 pagesThermoengineering Brochure ENGaliPas encore d'évaluation

- Tray DryerDocument22 pagesTray DryerHari KishorePas encore d'évaluation

- Commercial Air Conditioning Systems: Hcac-Ca-Gbx01Document10 pagesCommercial Air Conditioning Systems: Hcac-Ca-Gbx01Ian OsorioPas encore d'évaluation

- White Paper SemiconductorDocument1 pageWhite Paper SemiconductorEric DunnPas encore d'évaluation

- Advancingindustry 40 Inplasticswithhydraulicfluids 1540892358026Document14 pagesAdvancingindustry 40 Inplasticswithhydraulicfluids 1540892358026Sly LumbaPas encore d'évaluation

- FM 200 Data Centre ApplicationDocument1 pageFM 200 Data Centre ApplicationSwaraj BiswasPas encore d'évaluation

- D Series: 75 kW-160 KW Oil-Free Rotary Screw Compressors Fixed & Regulated Speed (RS)Document16 pagesD Series: 75 kW-160 KW Oil-Free Rotary Screw Compressors Fixed & Regulated Speed (RS)Luran JuPas encore d'évaluation

- DX Domina PlusDocument16 pagesDX Domina PlusOsama Ben DawPas encore d'évaluation

- Self-Cleaning and Robust: Thin Film TechnologiesDocument8 pagesSelf-Cleaning and Robust: Thin Film TechnologiesParvinder KaurPas encore d'évaluation

- Life Cycle of The Refrigerating SystemDocument27 pagesLife Cycle of The Refrigerating SystemRuben SantillanPas encore d'évaluation

- IMI Critical Engineering Brochure DownloadDocument24 pagesIMI Critical Engineering Brochure DownloadArun Babu0% (1)

- 7econ Industries - Fact Sheet - VacuDryDocument2 pages7econ Industries - Fact Sheet - VacuDryOgunranti RasaqPas encore d'évaluation

- Oilgasenergymeetings PresentDocument98 pagesOilgasenergymeetings PresentRamy HusseinPas encore d'évaluation

- ScrubberDocument8 pagesScrubberRS50% (2)

- IPF Sample 2017 PDFDocument40 pagesIPF Sample 2017 PDFJaymin KothariPas encore d'évaluation

- List Chemtech 2015 Exhibitors DirectoryDocument410 pagesList Chemtech 2015 Exhibitors Directoryindusexposium100% (1)

- Manufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesD'EverandManufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowD'EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowÉvaluation : 4 sur 5 étoiles4/5 (1)

- Legaledge Test Series: Mock Common Law Admission Test 2024 Mock Clat - 03Document40 pagesLegaledge Test Series: Mock Common Law Admission Test 2024 Mock Clat - 03Ashutosh MalviyaPas encore d'évaluation

- Influence of Soil Structure Interaction On Seismic Demands - 2019 - EngineeringDocument15 pagesInfluence of Soil Structure Interaction On Seismic Demands - 2019 - Engineeringabubaker ahmedPas encore d'évaluation

- Agnihotra Seminar Brochure FinalDocument14 pagesAgnihotra Seminar Brochure Finalarvind351Pas encore d'évaluation

- Faculty of Engineering Technology Civil Engineering Department Soil LaboratoryDocument11 pagesFaculty of Engineering Technology Civil Engineering Department Soil LaboratoryAnas Abu-shawishPas encore d'évaluation

- Work, Energy and PowerDocument56 pagesWork, Energy and PowerAnu MakhijaPas encore d'évaluation

- Dwnload Full Introduction To Environmental Geology 5th Edition Keller Test Bank PDFDocument35 pagesDwnload Full Introduction To Environmental Geology 5th Edition Keller Test Bank PDFgilmadelaurentis100% (12)

- At Oxyrhynchus: Mary BeardDocument36 pagesAt Oxyrhynchus: Mary BeardsalisoftPas encore d'évaluation

- Steel Design 5 May 2022Document3 pagesSteel Design 5 May 2022tous les joursPas encore d'évaluation

- Factoring Using Common Monomial FactorDocument26 pagesFactoring Using Common Monomial FactorHappyPas encore d'évaluation

- EP Printables: Levels 1-4: Earth ScienceDocument35 pagesEP Printables: Levels 1-4: Earth ScienceArle CambalPas encore d'évaluation

- 2008 - An Optical, EPR and Electrical Conductivity Study of Blue Barium TitanateDocument8 pages2008 - An Optical, EPR and Electrical Conductivity Study of Blue Barium TitanateBeh NaatPas encore d'évaluation

- Global Demography: SubtitleDocument32 pagesGlobal Demography: SubtitleEneb De OcampoPas encore d'évaluation

- Daily Practice Problem Sheet 109: Gaurav AroraDocument3 pagesDaily Practice Problem Sheet 109: Gaurav AroraKushant BaldeyPas encore d'évaluation

- MOSFET - Working, Types, Operation, Advantages & ApplicationsDocument28 pagesMOSFET - Working, Types, Operation, Advantages & ApplicationsgezahegnPas encore d'évaluation

- Email EnglishDocument65 pagesEmail EnglishNghi NguyễnPas encore d'évaluation

- Amity International School, Pushp Vihar English Worksheet - Class 12Document3 pagesAmity International School, Pushp Vihar English Worksheet - Class 12ViplavPas encore d'évaluation

- Standard Operating Procedure Handover File - enDocument7 pagesStandard Operating Procedure Handover File - enrebka mesfinPas encore d'évaluation

- Ce121 Lec5 BuoyancyDocument18 pagesCe121 Lec5 BuoyancyPetForest Ni JohannPas encore d'évaluation

- CrashUp Surface TensionDocument33 pagesCrashUp Surface TensionSameer ChakrawartiPas encore d'évaluation

- Methods of Curriculum IntegrationDocument3 pagesMethods of Curriculum IntegrationApril Rose BaratoPas encore d'évaluation

- Normal Probability DistributionDocument17 pagesNormal Probability DistributionGladzangel LoricabvPas encore d'évaluation

- Learning Activity Sheet 2 Principles of Radio Broadcasting: Background Information For LearnersDocument3 pagesLearning Activity Sheet 2 Principles of Radio Broadcasting: Background Information For LearnersYuta's HousewifePas encore d'évaluation

- Project ReportDocument16 pagesProject Reportshaqib71% (7)

- OralCom q1 Mod3 Barrierstocommunciation v5Document33 pagesOralCom q1 Mod3 Barrierstocommunciation v5KryssssPas encore d'évaluation

- Int Fire Alarm - CPL Okems Tu (HND)Document80 pagesInt Fire Alarm - CPL Okems Tu (HND)NjitnumPas encore d'évaluation

- LAC Reflection JournalDocument6 pagesLAC Reflection JournalEDITHA QUITO100% (1)

- 11 RP SP Equipment SpecificationDocument39 pages11 RP SP Equipment SpecificationRobby KurniawanPas encore d'évaluation

- C.O.A of Liquid FlavourDocument4 pagesC.O.A of Liquid FlavourjagadeeshPas encore d'évaluation

- Sterilization Review Questionnaire ETODocument5 pagesSterilization Review Questionnaire ETOsaberPas encore d'évaluation

- 5 SLS RequiermentsDocument13 pages5 SLS RequiermentssuniljayaPas encore d'évaluation