Académique Documents

Professionnel Documents

Culture Documents

Vibration

Transféré par

Siva Kumar TutikaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Vibration

Transféré par

Siva Kumar TutikaDroits d'auteur :

Formats disponibles

CONTENTS

SL. TOPIC PAGE

NO. NO.

1. INTRODUCTION 1

2. FUNDAMANTALS OF VIBRATION 2

3. SOURCES OF VIBRATION 20

4. VIBRATION MEASUREMENT 44

5. VIBRATION ANALYSIS 66

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 1

1. INTRODUCTION

Everyone in the course of our daily life encounters the phenomenon of vl 'bration.

The effect of vibration is not only physically unpleasant but may also weaken the

structure. It must therefore be regarded as a most undesirable condition, which must be

eliminated for both comfort and safety.

On the contrary, the vibration is often useful and may be essential in some

application. Occasionally, for example vibration can be used to unmix things; as in

sieves and other sorting devices, for conveying grain from one place to another, concrete

will flow far -more readily into the furthermost recesses when it is poured into shuttering

if it is suitably vibrated. Also vibration has got application in medical practice. For

instance, it is used to massage away patients unwanted bulges and for removal of kidney

stones.

Large sums of money are spent nowadays on the study of various forms of

vibration. The subject of vibration has acquired considerable importance, with the

increasing pace of industrial and technological developments in the world over there has

been a phenomenal increase in the speed and power of industrial machines. All devices

which have mass and elasticity are capable of vibrating, however, rigid, they might seem.

Whether it is desired to use vibration as a tool for failure and maintenance

prediction or for using vibration control measure to avoid discomfort and failure, it is

necessary to have a proper understanding of the subject. -This course material is

concerned with fundamentals of vibration, sources of vibration, measurement of vibration

and vibration analysis of rotating machines.

PAGE 2

2. FUNDAMENTALS OF VIBRATION

2.0 INTRODUCTION

The study of vibration is concerned w' ith oscillatory motions of bodies and the

forces associated with them. All bodies possessing mass and elasticity are capable of

vibration. Thus most engineering machines and structures experience vibration to some

degree. The effects of vibration depend on the magnitude , frequency and duration of the

vibration. Also, some times the vibration of a system emits lot of noise, which is harmful

from human point of view.

PDF created with pdfFactory Pro trial version www.pdffactory.com

2.1 WHAT IS VIBRATION

Vibration is defined as the resp onse of an elastic system to a dynamic disturbance.

There are two general classes of vibrations - free and forced. Free vibration takes

place when a system oscillates under the action of forces inherent in the system itself, and

when external impressed forces are absent. The system under free vibration will vibrate

at one or more of its natural frequency, which is a property of dynamic system

determined by its mass and stiffness distribution.

Vibration that takes place under the excitation of external forces is called forced

vibration.

The simplest way to show vibration is to follow the motion of a weight suspended

at the end of a spring as shown in figure 2. I. This is typical of all machines since, they

too have weight and spring-like quality namely elasticity.

PAGE 3

Until a force is applied to the weight to cause it to move, we have no vibration.

By applying an upward force, the weight would move upward, compressing the spring.

If we release the weight, it would drop below its neutral position to some bottom limit of

travel, where the spring would stop the weight. The weight would travel upward through

the neutra position to tie top limit of motion, and then back again through the neutral

position. This is vibration! This motion will dampen with time unless force is applied

again.

PDF created with pdfFactory Pro trial version www.pdffactory.com

2.2 CHARACTERSTICS OF VIBRATION

A lot can be learned about a machine's condition and mechanical problems by

simply not'mg its vibration characteristics. Refem'ng to the weight suspended on a

spring, we can study the detailed,characteristics of vibration by plotting the movement of

the weight against time. This plot is shown in figure 2.2.

PAGE 4

The simplest form of vibration motion is simple harmonic motion. The motion of

the weight from its neutral position, to the top limit of travel back through the neutral

position to the bottom limit of travel, and its return to the neutral position, represents one

cycle of motion. This one cycle of motion has all the characteristics needed to measure

the vibration. Continued motion of the weight will simply be repeating these

characteristics. When the instantaneous displacement of the mass is plotted against time,

the motion takes sinusoidal form as shown in figure.

Fig: 2.2 CHARACTERSICS OF VIBRATION

As vibrations are movements of the machines around a rest point, they may be

quantified in terms of' displacement, velocity or acceleration. These characteristics of

vibration are measured to determine.the amount of severity of the vibration. The

displacement, velocity or acceleration of a vibration is often 17eferred to as the

'amplitude' of the vibration.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 5

In terms of the operation of the machine, the vibration amplitude is the indicator

used to determine how bad or good the operation of the machine may be. The greater the

amplitude, the more severe the vibration.

2.2.1 DISPLACEMENT (PEAK TO PEAK)

The total distance traveled by the vibrating part, from one extreme limit of travel

to the other extreme limit of travel is referred to as the 'peak-to-peak displacement'. In

Metric units, the peak-to-peak vibration displacement is usually expressed in microns,

where one micron equals one-thousandth of a millimeter (0.001-mm). Peak-to-peak

vibration displacement is sometimes expressed in mils, where 1 mil equals one

thousandth of an inch (0.001 inch).

2.2.2 VELOCITY (PEAK)

Since the vibrating weight shown in the figure.2.2 is moving, it miist be moving at

some speed- However, the speed of the weight is constantly changing. At the top limit of

the motion the speed is zero since the weight must come to a stop before it can go in the

opposite direction. The speed or velocity is greatest as the weight passes through the

neutral position. The velocity of the motion is definitely a characteristic of the vibration

but since it is constantly changing throughout the cycle, the highest or 'peak' velocity is

selected for measurement. In Metric units, vibration velocity is expressed in millimeters

per second peak. Vibration velocity is expressed in terms of inches per second peak for

English or imperial units.

2.2.3 VELOCITY (RMS)

The ISO in its work to establish internationally acceptable- units for measurement

of machinery vibration decided to adopt VELOCITY (RMS) (root mean square) as the

standard unit of measurement. This was decided in an

PAGE 6

attempt to derive criteria, which would determine an effective value for the varying

function of velocity. It should be noted that IRD Mechanalysis instruments may be

calibrated to read in -terms of VELOCITY (PEAK) or VELOCITY (RMS).

2.2.4 ACCELERATION

In discussing vibration velocity, we pointed out tfiat the velocity of the part

approaches zero at the extreme limits of travel. Of course, each time that the part comes

PDF created with pdfFactory Pro trial version www.pdffactory.com

to a stop at the limit of travel, it must 'accelerate' to pick-up speed as it travels towards the

other extreme limit of travel. Vibration acceleration is another important characteristic of

vibration. Technically, acceleration is the rate of change of velocity.

Referring to the motion plot, figure 2.2, the acceleration of the part is maximum at

the extreme limit of travel where the velocity is zero point 'A'. As the velocity of the part

increases, the acceleration decreases. At point 'B', (the neutral position) the velocity is

maximum and the acceleration is zero. As the part passes through the neutral point, it

must now 'decelerate' as it approaches the other extreme limit of travel. At point 'C',

acceleration is at peak.

Vibration acceleration is normally expressed in "g's" peak, where one is the

acceleration produced by the force of gravity at the surface of the C2 earth. By

international agreement, the value of 980.665 cm/se equals 386.087 C2

C2 inches/se also equals 32.1739 feet/se has been chosen as the standard acceleration due

to gravity.

PAGE 7

2.3 CONVERSION OF AMPLITUDES

The displacement, velocity and acceleration of a vibration are directly related. If

the peak-to-peak displacement and frequency of a vibration are known, the velocity of

vibration can be found as follows: -

V Peak = 52.3D ( F / 1000 ) X 0.001

Where: -

V Peak = vibration velocity (mm/sec) peak

D = vibration displacement (microns) peak to peak

F = vibration frequency (CPM

Further to the above when it is required to calculate vibration acceleration, the

following formula can be used. -

G (Peak ) = 5.6 D ( F / 1000 )2 X.0001

Where: -

G (Peak ) = Vibration acceleration

D = Vibration displacement (microns) (peak-to -peak)

F = Vibration frequency (CPM)

PDF created with pdfFactory Pro trial version www.pdffactory.com

It is sometimes necessary to convert Metric measurement to Imperial, or the

converse. To convert velocity or displacement measurement from Metric to Imperial: -

Velocity (mm/sec)

Velocity (inches/sec) = 25.4

Displacement (microns)

Displacement (mils) = 25.4

PAGE 8

From Imperial to Metric: -

Velocity (mm/sec) = Velocity (inches/sec) X 25.4

Displacement (microns) = Displacement (mils) X 25.4

2.4 DISPLACEMENT, VELOCITY OR ACCELERATION WHICH SHOULD

WE USE?

Since the amplitude of vibration can be measured in terms of displacement, velocity

or acceleration, the obvious question is 'Which parameter should we use?

Vibration amplitude readings taken for checking overall machinery condition

indicate the severity of the vibration. But which is the best indicator of vibration

severity: displacement, velocity or acceleration? To answer this question, consider what

happens when a wire or piece of sheet metal is bent repeatedly back and forth.

Eventually, this repeated bending causes the metal to fai'i by fatigue in the area of the

bend. This is similar in many respects to the way a machine or machine component fail

from the repeated cycles of flexing caused by excessive vibration. Of course, the time

required to fail the wire or sheet metal can be reduced by: -

1. Increasing the amount of the bend (displacement). The further the metal is

bent each time, the more likely it is to fail.

2. By, increasing the rate of bending (frequency). Obviously, the more times

per minute the metal is flexed, the quicker it will fail.

Thus the severity of this bending action is a function of both how far the

metal is bent (displacement) and how fast the metal is bent (frequency). Vibration

severity then appears to be a function of displacement and frequency.

PAGE 9

PDF created with pdfFactory Pro trial version www.pdffactory.com

However, since vibration velocity is also a function of displacement and frequency

it is reasonable to conclude that a measure of vibration velocity is a direct measure of

vibration severity. Through experience we have found this to be basically true.

Vibration velocity provides the best overall indicator of machinery condition.

Displacement and acceleration readings are sometimes used to measure vibration

severity. However, when displacement or acceleration is used, it is also necessary to

know the frequency of the vibration. Charts like those shown in figure.2.3 and figure. 2.4

are often used to cross-reference the displacement or acceleration with frequency to

determine the level of severity. Note from figure 2.3 that a displacement of 25 microns

occurring at a frequency of 1200 CPM is in the 'GOOD' range, however, the same

displacement of 25 microns at a frequency of 20,000 CPM is in the 'VERY ROUGH'

range. Note also, that the diagonal lines dividing the zones of severity are constant

velocity lines. in other words, a velocity of 12.7 mms per second peak is in the 'ROUGH'

range regardless of the frequency of the vibration. Referring to the chart, figure 2.4, we

can note that an acceleration of 1.0 g at a frequency of 100,000 CPM is in the 'GOOD'

region of the chart; however, 1.0 g at a frequency of 18,000 CPM is in the 'SLIGHTLY

ROUGH' region.

So the real significance of the characteristics of vibration lies in the fact that they

are used to detect and describe the unwanted motion of a machine. Each of the

characteristics of vibration tells us something significant about the vibration. Therefore,

the characteristics might be considered to be symptoms used to diagnose inefficient

operation or impending trouble in a machine.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 10

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 11

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 12

2.5 VIBRATION FREQUENCY

Frequency is the number of complete cycle in unit time. From the figure 2.2, the

amount of time required to complete one cycle of vibration is the period of vibra@on. If

a period of one second is required to complete one cycle of vibration, then during one

minute the cycle will be repeated 50 times or 50 cycles per minute (CPM). The measure

of the number of cycle for a given interval of time is the frequency of vibration and

usually expressed in cycles per second or Hertz (CPS or Hz) or cycles per minute (CPM).

2.6 VIBRATION PHASE

Phase is defined as the position of a vibrating part at a given instant with reference

to a fixed part or another vibrating part. By measuring the phase we can

Ø Compare one vibration with another

Ø Determine how one part is vibrating relative to another part

Phase readings are normally expressed in degrees (00 to 3600) where one

complete cycle of vibration equeals 3600.

Phase angle of vibrations, like amplitude and frequency, is a useful parameter, for

analysis of vibrations. Measurement of phase and its analysis can help in the diagnosis of

a machinery problem.

Figure 2.5 shows the phase diagram of a vibrating object relative to a fixed

reference, which corresponds to the equilibrium position. The phase diagram gives the

phase angle @2, @3.......... corresponding to any position 2,3 ........... etc., as shown, as

measured from a datum.. Figure.2.6 shows the displacement time diagrams, A and B, of

two vibrating par't-s or objects.

PAGE 13

PDF created with pdfFactory Pro trial version www.pdffactory.com

Fig: 2.6 PHASE DIFFRERANCE BETWEEN TWO VIBRATING PARTS

The two reach their peaks or zero values, at different instants. The time difference,

being td, phase angle between the two vibrating objects is td X 3600, since the time

period corresponds to a full cycle or a phase of 360'.

In the case of a rotor, the phase angle gives the location of the rotor at any instant

e.g. it defines the location of the heavy spot of the rotor at each measurement point

relative to a fixed point and is useful for balancing.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 14

The phase may be measured with a stroboscope, as shown in figure 2.7. This is

shown for a rotor rotating at same speed. If the frequency of flash of the stroboscope

equals the running speed, any mark on the rotor appears stationary and the reading

against a fixed reference scale would give the phase difference.

2.7 VIBRATION SEVERITY

Since vibration amplitude (displacement, velocity or acceleration) is a measure of

the severity of the trouble in a machine, the next question may be; 'how much vibration is

too much?' To answer this question, it is important to keep in mind that our objective

should be to use vibration checks to detect trouble in its early stages for scheduled

correction. The goal is not to find out how much vibration a machine will stand before

failure, but to get a fair, warning of impending trouble so it can be eliminated before

failure.

PAGE 15

Absolute vibration tolerance or limits for any given machine are not possi 'ble.

That is, it is impossible to select a vibration limit which, if exceeded, wi ill result in

immediate machinery failure. The development of mechanical failure is just far

too,complex for such limits to exist. However, it would be impossible to effectivel utilise

vibration as an indicator of machinery condition y unless some guidelines are available

PDF created with pdfFactory Pro trial version www.pdffactory.com

and the years of experience of those familiar with machinery and machinery vibration

have provided some realistic guidelines.

The vibration velocity provides a direct measure of machinery condition for the,

intermediate vibration frequencies (600 to 60,000 CPM). The velocity values in figure

2.3 and figure, 2.4 are offered as a guide for overall unaltered velocity readings. When

vibration amplitude is measured in displacement or acceleration, the charts in figure 2.3

and figure 2.4 may be used as guides in selecting acceptable levels of machinery

vibration. Displacement and acceleration measurements applied to these charts should be

filtered readings only.

The guidelines offered in the above figures apply io machinery such as motors,

fans, blowers, pumps and general rotating machinery where vibration does not directly

influence the quality of a finished product. Amplitude readings should be those taken on

the bearings or structure of the machine.

Of course, the vibration tolerances suggested in these references will not be

applicable to all machines. For example, some machines such as hammer mills or rock

and coal crushers will inherently have high levels of vibration. Therefore, the values

selected using these guides should be used,' only so long as experience, maintenance

records and history proves them to be valid.

PAGE 16

For machines such as gr' ders and other precision machine tools where vibration

can affect the quality of a finished product, refer the 'Guide to Vibration Tolerance For

Machine Tools' provided in Table 2.1. Applying vibration tolerances to machine tools is

rather easy because they can be based on the machine's ability to produce a certain size or

finish tolerance. The values shown in the table are the result of years of experience with

vibration analysis of machine tools, and represent the vibration levels for which

satisfactory parts have been produced. Of course, these values may vary depending on

specific size and finish tolerances required. A comparison of the normal pattern of

vibration on the machine and the quality of finish, and size control required would reveal

what level of vibration is acceptable. The first time the quality of finish or size control

deteriorates, an unacceptable vibration level would be indicated. The initial values

selected from Table 2.1 can then be modified to the new, more realistic ones.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Another severity standard which is coming into increasing use is ISO 2372 (BS

4675) as given in Table 2.2. This standard differs somewhat to the general severity

standards referred to as it seeks to establish classifications of various types of machinery.

Annexure-A, which follows the standard, describes the machines covered in the

classification. To use ISO 2372 it is first necessary to classify the machine. Next reading

across the chart can correlate the severity of the machine condition. The severity of the

machine condition is indicated by the letter A 5 B, C or D.

Making the decision to correct a condition of vibration is often a very difficult one

indeed, especially when it involves downtime of critical machinery. Therefore, when

establishing acceptable levels of machinery vibration, e erience and factors such as

safety, labour costs downtime costs

PAGE 17

and the importance of a machine's operation to. the company's profits must be considered.

Table-2.1

TENTATIVE GUIDE TO VIBATION TOLERANCES FOR MACHINE TOOLS

TYPE OF MACHINE Displacement of vibration as read

with pickup on spindle bearing

housing in the direction of cut.

§ Grinders ___ Tolerance Range

Thread Grinder 0.25 to 1.5 microns

Profile of Contour Grinder 0.76 to 2.0 microns

Cylindrical Grinder 0.76 to 2.5 microns

Surface Grinder (vertical reading) 0.76 to 5.0 microns

Gardner or Besly Type 1.3 to 5.0 microns

Centreless 1.0 to 2.5 microns

§ Boring Machine 1.5 to 2.5 microns

§ Lathes 5.0 to 25.Omicrons

PAGE 18

PDF created with pdfFactory Pro trial version www.pdffactory.com

Table 2.2

ROLERANCES BASED ON B.s. 4675 : 1976

(ISO 2372)

'A BASIS FOR COMPARATIVE EVALUATION OF VIBRATION IN MACHINERY'

Velocity Class I Class II Class III Class IV

Velocity Velocity Ins/Sec M/C M/C M/C M/C

(mm/ s) RMS (mm/s) Peak Peak Small Medium Large Turboo

(1) (2) (3)

0.28 0.40 0.016

0.45 0.64 0.025 A

0.71 1.00 0.039 ------ A

1.12 1.58 0.062 B ------ A

1.80 2.54 0.100 ------ B ------ A

2.80 3.96 1.160 C ------ B ------

4.50 6.37 0.250 ------ C ------ B

7.10 10.00 0.390 D ------ C ------

11.20 15.80 0.620 D ------ C

18.00 25.40 1.000 D ------

28.00 39.60 1.560 D

45.00 63.70 2.500

A= Good B = Acceptable C = Still Acceptable D = Not Acceptable

PAGE 19

ANNEXURE-A

CLASSIFICATION EXAMPLES FROM BS 4675 (ISO 2372)

(For guidance purposes only)

In order to show how the recommended method of classification may be applied,

examples of specific classes of machines are given below. It should be emphasised,

however, that they are simply examples and it is recognised that other classifications are

possible and may be substituted in accordance with the circumstances concerned. As and

when circumstances permit, recommendations for acceptable levels of vibration severity

for particular types of machines will be prepared. At present experience suggests that the

following classes are appropriate for most applications

CLASS I

Individual parts of engines and machines integrally connected with the complete machine

in its normal operating condition. (Electrical motors of up to kw are typi@al examples of

machines in this category).

CLASS II

PDF created with pdfFactory Pro trial version www.pdffactory.com

Medium sized machines. (Typically electrical motors with 15 to 75 kw output)

without special foundations, rigidly mounted engines or machines (upto 300 kw) on

special foundations.

CLASS III

Large prime movers and other large machines with rotating masses mounted on

rigid and heavy foundations, which are, relatively stiff in the direction of vibration

measurement.

CLASS IV

Large prime movers and other large machines with rotating masses mounte( on

foundations which are relatively soft in the direction-of,vibration measurement (for

example turbo-generator sets, especially those with lightweight sub-structures).

PAGE 20

3. SOURCES OF VIBTRATION

3.0 INTRODUCTION

3.0 INTRODUCTION

In a machine, vibration is a result of minor faults that are the natural consequences

of manufacturing and material limitations. Common causes of vibration are as follows.

3.1. UNBALANCE:

This is a major contributor to vibration in rotating machinery. It is caused by

unequal distribution of mass in a rotating part. Points of unbalance produce additional

forces in the radial direction and the machine bearings restrain these forces resulting in

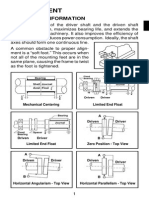

vibration. The unbalance can be static or dynamic as shown in figure 3. 1.

In either case the frequency of vibration equals the rotational frequency (IxRPM).

Amplitudes of vibrations are excessive in the radial directions. Phase measurement by a

stroboscope shows a single steady reference mark.

PAGE 21

PDF created with pdfFactory Pro trial version www.pdffactory.com

In the case of overhung rotors, vibrations in axial direction are also encountered due

to unbalance, in addition to those in radial directions. Vibrations at all bearings, in such a

case, would all be in phase.

Sometimes, reasons other than unbalance may also result in vibrations at rotational

frequency. In such cases, the unbalance as a possible cause should be confirmed by the

difference in phase between vibrations in the two radial directions - horizontal and

vertical. If the phase is 900,the cause of vibrations is unbalance. Defects like eccentric

pulleys may also cause vibrations at the frequency of rotational speed. In such a case, the

phase difference between vibrations, in the two directions, may not be 90' due to the

effect of reaction forces of the belt.

3.2 MISALIGNMENT

Like unbalance, misalignment is another common problem. Inspite of self-

aligning bearings and flexible couplings, it is difficult to align the shafts and their

bearings so that no force exists which will cause vibration. There are three possible types

of coupling misalignment as shown in figure 3.2

§ ·Angular the center line of the two shafts meet at an angle

§ Offset the shaft center lines are parallel but di 'laced from one another

§ A combination of angular and offset misalignment.

Misalignment, even with flexible, couplings, results in two forces, axial and radial,

which result in axial and radial vibrations. This is true even when the misalignment is

within the limits of flexibility of the coupling. The Magnitude of the forces and therefore

the amount of vibration generated will increase with increased misalignment. The

significant characteristic of

PAGE 22

vibration due to misalignment is that it will be in both the radial and axial directions.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Normally, the vibration frequency is lx RPM; however, when the misaligmnent is

severe, second order (2xRPM) and sometimes third order (3x RPM) vibration frequencies

may appear.

There can be a misalignment' not involving a coupling. The misalignment of a

bearing with its shaft is one example.

In the case of a misaligned sleeve type bearing, no vibration will result unless

there is also unbalance. In such a case radial vibration as well as an axial vibration will

be present due to the reaction of the misaligned bearing to the force caused by the

unbalance. If the real cause of this vibration is unbalance, then both the axial and radial

readings will be reduced when the part is balanced.

When an anti-friction bearing is misaligned with a shaft, then axial vibration will

exist even When the part is balanced. We have to install the bearing properly to

eliminate the vibration.

The misalignment of sheaves and sprockets used in V-belt drives and chain drives

results in high axial vibration. The angular and offset

PAGE 23

misalignment conditions result in destructive vibration and leading to accelerated wear of

sheaves, sprockets, chains and drive belts.

A bent shaft acts very much like angular misalignment, so its vibration.

characteristics are included with misalignment. We can suspect misalignment or a bent

shaft whenever the amplitude of axial vibration is greater than one-half of the highest

radial (horizontal or vertical).

2.3 MECHANICAL LOOSENESS

The causes of mechanical looseness could be loose mounting bolts, excessive

bearing clearance or a crack in' the structure of bearing pedestal.

For the vibration characteristic of mechanical looseness to occur, it needs some

other exciting force to cause it, say, unbalance or misalignment. But, when the looseness

is excessive, just - a small amount of unbalance or misalignment will result in large

vibrations. So, looseness simply allows more vibration to occur than would otherwise

appear. This does mean that if we can eliminate the unbalance or misaligmnent forces,

we can reduce the vibration, but it needs an extremely fine level of balance or alignment,

which may be impractical. So, removing the looseness is more practical.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Mechanical looseness leads to a heavy beating action and these cause a vibration at

a frequency of twice the rotating speed (2xRPM) and higher, orders of the loose' part.

The highest amplitude of vibration occurs at 2xRPM of the equipment.

The nature of mechanical looseness and the reason for the characteristic vibration at

2xRPM can be explained as follows in figure 3.3.

PAGE 24

Fig: 3.3 MECHANICAL LOOSENESS

There are two applied forces for each revolution of the shaft. One is applied by

the rotating unbalance, the other when the bearing drops against the pedestal. Therefore,

the vibration frequency is 2xRPM. We can view this with an oscilloscope attached to the

vibration analyzer.

Also there will be some clearances inherent in every' machine, and it is normal

that some vibration will occur at a frequency of 2xRPM whenever some unbalance or

misalignment is present.

Generally, we should suspect mechanical looseness to be the problem whenever

the seventy of vibration at 2xRPM is more than one half the severity of vibration at

rotating speed (lxRPM). Moreover, if we have great difficulty in eliminating the

vibration by balancing or realignment, we should verify whether there is any looseness.

3.4 BAD BELT DRIVES

V-belt drives are popular'for power transmission because of their capacity to

absorb shock and vibration. They are also quiet in operation when compared to chain or

gear drives. But, for machine tools where very low levels

PAGE 25

PDF created with pdfFactory Pro trial version www.pdffactory.com

of vibration must be maintained, they can be the source of vibration beyond limits. Such

problems are of two types.

• Belt reaction to other disturbing forces in the equipment

• Vibration due to actual belt problems.

When we see the whip and flutter of V-belts (the flexible strands between the

pulleys), we conclude that they are the source of vibration. Because of the ease with

which the belts could be changed and because the vibration of belt is readily visible than

other parts, belt replacement often happens to be the immediate solution. But

remember excessive unbalanced eccentric pulleys, is misalignment or mechanical

looseness, all these may result in belt vibration. The belt may be just an indicator of other

disturbances in the equipment. Hence, before replacing drive belts, make an analysis to

pinpoint the root causes.. Looking at the frequency of the vibration we can do this.

If the belt is reacting to other disturbing forces in the machine, the frequency of

belt vibration will most probably be the same as the disturbing frequency. When we

are using the strobe light of the analyser, that part of the machine, which is actually

generating the disturbing forces, will appear to stand still. For multi belt drives all belts

should have equal tension. If not, the slack belts may cause excessive vibration even for

very minor condition. Additional problems are belt slippage and rapid belt and pulley

wear. Vibration from actual belt defects will be at 1,2,3 & 4 times belt RPM. The

articular p frequency found would depend on the nature of the belt problem as well as

the number of pulleys and idlers over which the belt must pass.

To summarise, the vibration due to belt drives can -be reduced by the following

methodes.

PAGE 26

§ Make sure belts are in good physical condition

§ Check whether the number and size of belts meet the load

requirements

§ Use matched set of belts in multi-belt installations to get equal tension

§ Verify whether the pulleys and sheaves are round and accurately aligned with one

another

§ Check for wear of pulley grooves. Too much wear will allow the belt to ride in

the bottom of the groove, causing slippage and poor efficiency.

PDF created with pdfFactory Pro trial version www.pdffactory.com

§ Verify whether the belts are properly installed and adjusted to proper tension as

recommended by the manufacturer.

§ Keep other disturbing forces in the machine to a minimum.

3.5 ECCENTRICITY

Eccentricity means that the shaft (rotating) centerline is not the same as the rotor

(,geometric) centerline. It is not out-of-roundness or ovality. Eccentricity is a common

source of unbalance and results in more weight on one side of the rotating centerline than

on the other side. As an example, when the bore of the inner race is not concentric with

the inner race geometric centerline in an anti-friction bearing, an apparent unbalance in

the part mounted on the bearing will be introduced. If we balance the rotor, the forces

causing the vibration will be compensated and the vibration will disappear. That is why

balancing a rotor in its own bearing is recommended. Different sources of eccentricity

are, shown in figure 3.4.

PAGE 27

PDF created with pdfFactory Pro trial version www.pdffactory.com

Fi2: 3.4 SOURCES OF ECCENTRICITY

Though eccentricity can be corrected by routine balancing techniques, eccentricity

can also result in reaction forces, which may not be corrected by simple balancing. In

eccentric gear, the largest vibration will occur in the direction on a line through the

centers of the two gears, at a frequency equal to I XRPM of the eccentric gear. It is not

unbalance, though it will look like it.

Eccentricity of the V-belt sheaves will result in reaction forces similar to the

eccentric gear. Here, the largest vibration will occur in the direction of belt tension at a

frequency equal to lx RPM of the eccentric sheaves. Again, the vibration looks like

unbalance, but cannot be corrected by applying a balance correction.

PAGE 28

Eccentric fan, blower, pump and compressor rotors may also create forces, which

result in vibration. Here, the forces are unequal aerodynamic and hydraulic forces

against the rotor. These forces will be the greatest on the high side of the rotor, so will

resemble unbalance. For this equipment, there is no positive test for eccentricity except

that we can try to balance. If we get no results. verify if the impeller is concentric with

the shaft journals.

3.6 FAULTY ANTI-FRICTION BEARINGS

Rolling element bearings find many uses in today's machinery. They can be found

in motors, slow-speed rollers, gas turbines, pumps, and many other machines. Some of

the reasons for using the rolling element bearings are: low starting friction, low operating

friction, ability to support loads at low speed (even zero), lower sensitivity to lubrication

(compared to fluid film bearings so a simpler lubrication system can often be used) and

the ability to support both radial and axial loads in the same bearing.

Rolling element bearings have very little damping, so whenever a machine with.

rolling element bearings traverses a balance resonance, large vibration can result. Also,

compared to fluid film bearings, which generally have a long life, rolling element

bearings have a limited fatigue life due to the repeated stresses involved in their normal

use.

Rolling element bearings, regardless of type (ball, cylindrical, spherical, tapered, or

needle) consist of an inner and. outer race separated by the rolling elements, which are

usually held in a cage. Mechanical flaws may develop on any of these components.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Using the basic geometry of a bearing, the fundamental frequencies generated by these

flaws can be determined.

PAGE 29

The frequency of vibration caused by anti-friction is usually several times the

rotating speed of the part, but it is unlikely to be an even multiple of shaft RPM. So, if

we observe the rotating shaft with the strobe light, we may not see a stationary image (as.

it would for vibration caused by unbalance, misalignment or gears', which occur at even

multiples of shaft RPM) and also observe an unsteady frequency meter.

Take the case of a bearing having a flat spot on only one ball. As the ball rolls, the

flaw will intermittently come into contact with the bearing inner and outer races and will

result in vibration at 1, and possibly, 2-times ball rolling frequency. Because the rolling

frequency of the ball will be several times the RPM of the shaft, the resulting vibration

will be high compared to rotating speed frequency. The amplitude of the vibration will

depend on the extent of the bearing fault. In addition to the vibration occurring at or

multiples of ball rolling frequency, these momentary impacts may excite vibration at

natural frequency.

Every object has its own unique natural frequency. A flaw on a rotating element

of a bearing will produce the intermittent impacting type of force, which will cause the

various parts (inner and outer races, shaft, and bearing housing) to vibrate at their

respective natural frequencies. Normally, these will be high compared to the RPM of the

machine. Hence, these vibration frequencies measured from a faulty bearing will also be

high. Also, it is that these will be exact multiples of shaft RPM, Thus, the frequency of

unlikely bearing vibration will probably not be a direct multiple of shaft RPM. Finally,

there are many parts, hence many simultaneous vibration frequencies to varymg degrees,

which cause the frequency meter to be unsteady or moving.

PAGE 30

3.7 DEFECTIVE SLEEVE BEARINGS

High levels of vibration or noise in sleeve bearings generally result from excessive

bearing clearance (caused by wiping), looseness (babbitt loose in the housing), or

lubrication problems. A sleeve bearing with excessive clearance may allow a relatively

minor unbalance, misalignment or some other vibratory force to result in mechanical

looseness or pounding. Here the bearing is not the actual cause; it simply allows more

PDF created with pdfFactory Pro trial version www.pdffactory.com

vibration to occur than in the case where the bearing clearances were correct. A bearing,

which has been wiped, can often be detected by comparing the horizontal and vertical

amplitudes of vibration. Machines, which are securely mounted to a rigid foundation or

structure, will normally reveal slightly higher amplitude of vibration in the horizontal

direction. In several instances where the amplitude of vibration in the vertical direction

appeared usually high compared to the horizontal, a wiped bearing was found to be the

cause.

Oil whirl is another problem associated with sleeve-type bearings. This' vibration

occurs only on machines equipped with pressure-lubricated sleeve bearings and operating

at relatively high speed - normally above the second critical speed of the rotor. Oil whirl

vibration is often quite severe, but is easily recognized because the frequency is slightly

less (5% to 8%) than one-half the RPM of the shaft.

Under normal o eration, the shaft of the machine will rise up the side of p the

bearing slightly, depending on the shaft RPM, rotor weight and oil pressure. The shaft

operating at an eccentric position from the bearing center draws oil into a wedge to

produce a pressurized load-carrying film. If the eccentricity of the shaft within the

bearing is momentarily increased from its equilibrium position (say, as a result of a

sudden surge, an external shock load or other'

PAGE 31

transient condition), additional oil will immediately be pumped into fill the space vacated

by the shaft, thus increasing the oil film may drive the shaft into am pressure. This

additional force developed by the oil film may drive the shaft into a whirling path around

the bearing. . If the damping within the system is sufficient, the shaft will return to its

normal position in the bearing; otherwise, the shaft will continue in a whirling path.

Improper bearing design is normally attributed to the problem of oil whirl,

however, excessive bearing wear, an increase in lubrication oil pressure or a change in

oill viscosity are other possible causes. A temporary correction can some times be made

by changing the temperature (viscosity) of the lubricant. Increasing the loading on the

bearing by introducing a slight unbalance or misaligmnent is also some -crimes effective.

Scrapping the sides. of the bearing or grooving the bearing surface to disrupt the lubricant

wedge are also successful in some cases.

PDF created with pdfFactory Pro trial version www.pdffactory.com

There are several special sleeve-beanng configurations to reduce the possibility of

oil whirl. The axial-groove bearing is normally limited to smaller bearing applications

such as those used in light gas turbines and turbo-chargers. The three-lobed bearing

provides improved bearing stability against oil whirl. The three individual bearing

surfaces generate pressurized oil films that act to center the shaft, Axial grooves are

sometimes included at the intersection of the lobe segments to increase whirl resistance.

The tilting pad bearing is a common choice on larger high-speed industrial,

machinery. In a manner similar to the lobed-bearing, each segment or pad develops a

pressurized oil wedge, which tends to center the shaft in the bearing. - The tilting feature

allows each pad to follow the shaft, improving system damping and overall stability.

PAGE 32

Sometimes, a normal machine may exhibit oil whirl vibration. This may occur

when an external source transmits vibration to the machine through the foundation or

piping. If th is background vibration occurs at just the right frequency (ie. the probable

oil whirl frequency of the machine) oil whirl will likely occur-. This condition is referred

to as externally excited whirl.

In a similar manner, a normally stable machine may be excited into oil whirl by -a

foundation --or piping which is vibrating in resonance at a frequency equal to the

probable oil whirl frequency. The resonant vibration of the piping or foundation may be

the result of pulsation or flow turbulence. Oil whirl resulting from this condition is called

resonant whirl.

Whenever the vibration characteristic of oil whirl is found, we must carry out a

complete vibration survey, of the installation including background sources, foundation

and related piping to determine the true cause.

Another problem encountered on machines equipped with sleeve bearings is called

ffiction whirl or hysteresis whirl. It is similar to oil whirl except that'the vibration will

occur on rotors operating above their first critical speed and the frequency of the

vibration will always be the critical speed frequency of the rotor. For example, if a rotor

operates at 3000 RPM and the first rotor critical speed is 2000 RPM. As is obvious, this

vibration may not have the characteristic frequency of slightly less than 1/2 RPM

associated with oil whirl. However, for machines operating above or near their second

PDF created with pdfFactory Pro trial version www.pdffactory.com

critical speed, the frequency of hysteresis whirl may coincide with that of oil whirl

resulting in an extremely severe vibration problem.

In hysteresis or ffiction whirl, a rotor which, operates above critical speed will

tend to deflect or bow in a direction opposite the unbalance heavy spot. As

PAGE 33

a result, the internal friction damping (hysteresis damping) of the rotor, which normally

works to restrict deflection,. will be out of phase and this damping force will act to

further deflect the rotor. This condition is normally kept in check by the damping

provided by the bearings. However, if stationary damping is low,, compared to the

internal dampin of the rotor, trouble is likely to occur.

The usual solution. for hysteresis whirl is to increase stationary damping of the

bearings and structure. We can change to a tilting pad bearing or other special bearing

design. Sometimes, it can be solved by reduc'mg rotor damping for example, by

replacing a gear-type coupling with a frictionless coupling such as a flexible disk

coupling.

Improper lubrication can also cause vibration in a sleeve bearing. If the bearing

lacks lubrication or if the wrong lubricant is used, the result may be excessive ffiction

between the rotating shaft and stationary bearing. This friction serves to excite vibration

of the bearing and other related parts of the machine in a manner similar to the vibration

we can generate by simply moistening our finger and rubbing it over a pane of glass.

This vibration is called dry whip, is generally of high frequency and produces the

distinctive squeal as for a dry bearing. The vibration frequencies generated are not likel y

to occur at direct multiplies of-shaft RPM. Therefore, they will give no definite image

under the strobe light and the vibration is similar to that caused by a faulty anti-ffiction

bearing. Whenever vibration characteristic of dry whip is encountered, conduct an

inspection of the lubricant, lubrication system and bearing clearances. This condition has

been found on bearings with excessive and insufficient clearance.

PAGE 34

3.8 GEAR PROBLEMS

Common problems, which cause vibration in gear, are excessive gear wear, gear

tooth inaccuracies, faulty lubrication and dirt or foreign material trapped in the gear teeth.

Misaligmnent or a bent shaft can also be at fault. This is easy to identify because the

PDF created with pdfFactory Pro trial version www.pdffactory.com

vibration normally occurs at a frequency equal to gear meshing frequency (the number of

gear teeth x the RPM of the faulty gear). In complex gear arrangements where several

meshing frequencies are possible, we have to examine the drawing of the gear box to

determine the RPM and number of teeth on the various gears to identify which gear or

gears are most likely at fault.

However, if the axial vibration occurring at motor RPM frequency is relatively

high on the gearbox and motor, misalignment may be the source of trouble. In this case,

this misalignment condition should be corrected first; this may also eliminate the high

frequency gear vibration.

Sometimes, vibration at a frequency and equal to gear meshing frequency may be

produced; for example, if a gear has only one broken or deformed tooth, a vibration at lx

gear RPM may result. Viewing the vibration waveform on an oscilloscope connected to

the analyzer will enable to differentiate this problem from unbalance because of the

spike-like signal caused by a faulty gear tooth. If more than one tooth is deformed, a

vibration frequency equal to the number of deformed teeth x gear RPM may result.

An eccentrically mounted gear will also cause vibration at 1 x gear RPM, similar

to unbalance. Where eccentricity is the problem, any attempt to balance in-situ will not

be fruitful. Eccentricity, unbalance ind bent shafts have also caused gear vibration at sub-

multiple frequencies of actual gear meshing frequency.

PAGE 35

The vibration amplitude and frequency from gears may also be erratic sometimes.

This occurs with gears, which are operating under a very light load alcondition where the

load may randomly shift back and forth from one gear to another. The impacts, which

occur as the load is shifted, will excite the natural to frequencies of the gears, bearings

and associated machine components. However, we can detect this gear vibration readily

at two or more points on the machine and, thus we can distinguish from the bearing

vibration which is predominate at the point of the faulty bearing. Because of the

characteristic high frequency, gear vibration is also a common source of objectionable

noise. For this reason, if we correct gear faults and other disturbances to reduce

excessive gear vibration, noise level also will be reduced.

3.9 ELECTRICAL PROBLEMS

PDF created with pdfFactory Pro trial version www.pdffactory.com

Vibration of rotating electrical machinery can be mechanical or electrical in origin.

We have already seen mechanical problems. Electrical problems normally consist of

unequal magnetic forces acting on the rotor or stator. These y unequal magnetic forces

may be due to

• Rotor not round

• Eccentric armature journals

• Rotor and stator misaligned (rotor not centered in the sta,tor)

• Elliptical stator bore

• Broken bar

• Open or shorted windings

The frequency of vibration will be lxRPM, and will appear similar to unbalance.

An easy way to identify this source of vibration is to observe the change of vibration

amplitude; the instant electrical power is disconnected from the unit. Make this check

with the analyzer filter on the out position. If the

PAGE 36

vibration disappears the instant power is shut off; the vibration is likely due to electrical

problems. If so, conventional, electrical testing procedures can be carried out to. pinpoint

the true cause of the problem. If it decreases only gradually after power is removed, the

problem is probably mechanical in nature.

Electrical problems with induction motors often cause swinging or pulsating

amplitude in nature. The blasting noise and vibration is caused by the slip frequency,

characteristic of this type. Slip frequency = motor RPM synchronous frequency of the

rotating magnetic field. The synchronous frequency is always equal to or an exact sub

multiple of the AC. line frequency Therefore, if the motor has both electrical and

mechanical problems such as unbalance, there will actually be two different vibration

frequencies present. Since these two are close, their amplitudes will alternately add

together and then subtract at a rate equal to the difference between their frequencies. The

result will be a noticeable with steady beat as well as the corresponding swing of the

amplitude meter.

If the amplitude of this pulsating vibration is excessive, we must correct it. If we

observe the amplitude meter, the instant the power is shut off, we can decide whether it is

mechanical or electrical cause. The pulsation may not be detrimental to the performance

PDF created with pdfFactory Pro trial version www.pdffactory.com

of the machine, but a pulsating noise is more noticeable than a steady one and affects the

personnel psychologically.

Electric motors have inherent vibration due to torque pulses. These torque pulses

are generated as the motor's rotating magnetic field energizes the poles in the stator. The

frequency of vibration resulting from torque pulses will be 2 times the AC line frequency

powering the motor. Thus, if AC line frequency is 50 Hz (50 cycles per second) or 3000

CPM, torque pulse frequency will be 6000 CPM. This is rarely troublesome except

where

PAGE 37

extremely low vibration levels are required, or if the torque pulses should behappen to

excite a resonant condition in the machine or structure. If resonance is excited, this can

also result in excessive noise.

In eccentric motor armature though the armature itself may be balanced or in

terms of rotor weight distribution, a lxRPM force is generated between the armature and

stator because of varying magnetic attraction between the eccentric armature and motor

poles. Increased load increases the magnetic field strength and results in increased

vibration.

To check this, measure the vibration, with the motor operating under power. Then, turn

the power off and observe what happens to the amplitude of vibration. If the amplitude

decreases gradually as the motor coasts down, the problem is likely unbalance.

On the other hand, if the vibration amplitude disappears the instant power is turned

off, the problem is electrical and possibly due to armature eccentricity. Other electrical

problems causing vibration are shorted windings, broken rotor bars, or a rotor, which is

not properly centered in the stator. A visual inspection using standard motor testing

procedures will reveal the nature of the electrical problem.

3.10 RESONANCE

We already know that every object and every part of a machine has natural frequency. If

we strike a bell, it vibrates at its own natural frequency. This continued vibration, called

free vibration, will eventually diminish because of inherent damping In addition to free

vibration, there are forced vibrations where the frequency depends on the frequency of

the driving force applied to the machine or structure. For example, the driving force of

rotor unbalance

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 38

may cause the forced vibration of a motor. In such case, the frequency of this forced

vibration is determined by the speed (RPM) of the motor.

To confirm whether or not a part is vibrating in resonance, we can apply the bump

test. . With the machine shut down, simply bump the machine or structure with a force

sufficient to cause it to vibrate. Since an object 'will undergo free vibration at its natural

frequency when bumped or struck, the frequency of free vibration generated in this way

will be indicated on the analyzer's frequency meter. The analyzer's filter must be in the

out position for this test. If the vibration diminishes very quickly, it may be necessary to

bump the machine several times in succession m order to sustain free vibration long

enough to register on the frequency meter.

We can also record the amplitude and phase of vibration versus the rotating speed

of the machine. We can use FFr analysis or make@ a similar plot by operating the

machine at a number of selected speeds and plotting the amplitude and phase of vibration

for each speed. If resonant conditions do exist, they will be clearly identified by a

characteristic peak vibration and by a large phase shift (around 180').

There are several ways to correct a resonance problem. We can change the

frequency of the exciting force so that it no longer coincides with the natural frequency of

the machine or structure. Either increasing or decreasing the RPM of the machine can do

this. If the exciting frequency cannot be changed, change the natural frequency - by

increasing or decreasing the stiffness or mass of the, object.

PAGE 39

3.11 AERODYNAMIC AND HYDRAULIC FORCES

Machine which handle fluids will have vibration and noise due to the reaction of

the vanes or blades on the irnpeller striking the fluid. This type of vibration is common

on pumps, fans and blowers. The frequency will be equal to the number of vanes or

blades on the impeller times the RPM of the machine.

Aerodynamic and hydraulic vibrations are rarely troublesome unless they excite

some part of the machine, piping or ductwork to vibrate at resonance. When we

encounter this type of vibration, carry out the tests for resonance to determine which part

of the machine is causing the problem. If no resonance condition can be found, the

problem may be due to improper design of the machine or related piping or du'ctwork.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Obstructions in the path of the gas or liquid. or sharp 90' turns in the direction of flow

may cause this vibration.

Cavitation, recirculation and flow turbulence is other problems that have similar

vibration characteristics. Vibration and noise resulting from these problems will be

random in nature Unlike steady state vibration from unbalance or misalignment, random

vibration and noise has no discreet frequency and / or amplitude characteristics. For

example, the vibration and noise caused by cavitation in a pump may cover a rather broad

frequency range where individual amplitudes and frequencies are constantly changing.

Cavitation normally occurs when a pump is operating with excess capacity or low

suction pressure. Since the pump is starved, the fluid coming into the pump will literally

be pulled apart in attempt to fill the void, which exists. This creates highly unstable

pockets or cavities of nearly perfect vacuum, which collapse or implode very quickly.

Because of their impactive nature,these implosions serve to excite the local natural

frequencies of the pump housing, impeller and other related parts. Since these

implosions may

PAGE 40

occur at random intervals at various locations within the pump or piping, the resulting

vibration and noise will also be random in amplitude and frequency.

In some cases, where the fluid undergoes a substantial pressure drop at a valve, in

the pump or at changes in piping diameter, dissolved gases may be released or the liquid

may boil. This is also called cavitation and has the same random vibration amplitude and

frequency characteristics.

Re-circulation normally occurs when a pump is operating at low capacity or high

suction pressure. In other words, restricting the capacity of the pump causes the excess

fluid to return from the discharge to the impeller. This reverse flow and the mixing of

fluids moving in opposite directions results in random noise and vibration similar to

cavitation.

Flow turbulence is the result of resistance to the normal flow of liquid, or gas.

This resistance may be caused' by obstructions, sharp turns or simply surface friction

between the fluid and the duct or piping. Another cause of flow turbulence is the mixing

of high velocity and low velocity fluids. A good example of this is the et engine where

PDF created with pdfFactory Pro trial version www.pdffactory.com

high velocity exhaust gases are mixed with the outside air. Only minor engine vibration

is created, since this mixing takes place outside the engine.

Some random noise and vibration from flow turbulence may be inherent in the

normal operations of fans, blowers, pumps, compressors and gas turbines. Where these

are excessive, an inspection of the system together with, noise or vibration readings taken

along the machine and related piping and ductwork will usually pinpoint the problem.

Sometimes you may have to redesign, say, the fan duct work - changing the sharp right

angle turn to two 45' sections together with turning vanes.

PAGE 41

3.12 RECIPROCATING FORCES

Reciprocating compressors, piston pumps, gasoline and diesel engines will have

vibrations because of the reciprocating motion inherent in the design and operation of the

machine. These are the result of inertia of the reciprocating parts plus the varying

pressures on the pistons, which cause torque variations.

Vibration and noise analysis of reciprocating machines are complex because of the

many frequencies found, such as, those at 1 and 2 times RPM; however, frequencies

at.higher orders are also common depending on the number of pistons and their

relationship to one another. A six cylinder 4-cycle engine may have three power

impulses for each revolution of the crankshaft, which will result in a vibration at 3xRPM.

An 8-cylinder engine with four Ises per revolutio power impu will show a vibration at

4xRPM.

The higher order frequencies found on reciprocating machines are inherent in the

machine and will rarely be a cause for concern unless they excite a resonant condition in

the machine or structure.

The problems with reciprocating machines can be either mechanical or operational

problems. The mechanical problems include unbalance, misalignment, bent shafts,

looseness and faulty bearings. Operational problems include blow-by, leaking or sticking

valves, and injector or ignition problems. Often, both will be nearly the same. So, it is

sometimes difficult to pinpoint the exact problem without further evaluation of analysis

data.

PDF created with pdfFactory Pro trial version www.pdffactory.com

There are several possible ways. For example, an operational problem such as

faulty ignition will normally be accompanied by a significant decrease in the efficiency

of the machine as well as excessive vibration. A mechanical

PAGE 42

problem like unbalance may show little or no change in overall efficiency. In addition,.

operational problems tend to increase unequal reciprocating forces and, thus may show a

much greater increase in vibration in a direction parallel to the reciprocating motion but

only a small increase in vibration in the direction perpendicular to this motion.

Mechanical problems such as unbalance or misalignment will normally show a

substantial increase in two or more directions.

3.13 RUBBING

Rubbing between the stationary and rotating parts of a machine may cause the

vibration to have a frequency at twice rotating speed, in addition to the rotating speed

frequency. If the rubbing is continuous, no particular vibration characteristics are likely.

However, a very high frequency of vibration and noise may be present due to friction

exciting natural frequencies of the system.

Rubbing in the seals of a steam turbine or a similar large machine will cause

changes in amplitude and phase from one run to the next when no changes have been

made to the system. For example, a steam turbine running at 3000 RPM may have a

steady amplitude and phase of vibration at rotating speed frequency. However, reducing

the speed to, say 1500 RPM and then increasing the speed again to 3000 RPM will often

produce a new amplitude and or phase of vibration. This seems to indicate that the point

at which rubbing occurs changes from one run to the next. Of course this condition must

be corrected before balancing could be carried out.

Rubbing is usually the result of a bent shaft, broken or damaged parts, or distortion

of the system that will usually be revealed by other vibration characteristics.

PAGE 43

3.14 BEAT VIBRATION

A noticeable beat or pulsation may be the result of a single exciting force, which is

continuously changing in amplitude or frequency. However, more often a pulsating

vibration and noise results from the interaction of two or more steady-state-sources of

unequal frequency,

PDF created with pdfFactory Pro trial version www.pdffactory.com

The pulsating noise and vibration often associated with induction type electric

motors is one example of beat. One force occurs at electrical frequency and another at

the slightly lower rotational frequency. We have referred to this slip frequency

characteristic earlier.

Pulsating noise and vibration can also occur where two or more individual

machines are involved. Consider two machines mounted side-by-side on the same

structure with one machine operating at 1500 RPM and the other at 1400 RPM. If the

vibration or noise amplitudes are significant at these two frequencies, their interaction

will result in a noticeable beat. The two forces alternately and continuously coming in-

phase and then out of phase with one another produce the beat or pulsation. When the

two are in phase, their amplitudes will add together to give a maximum resultant

vibration or noise amplitude and when the two forces are out of phase, their amplitudes

subtract or cancel one another to give the minimum overall amplitude. The beat

frequency will be equal to the difference between the two exiting force frequencies. For

the example above, the beat will occur at 1500 CPM - 1400 CPM @ 100 CPM.

Sometimes, a beating will occur at a frequency equal to the sum of the two exciting force

frequencies for our example, 1500 CPM-+ 1400 CPM = 2900 CPM. The higher beat

frequency is usually less noticeable than the low frequency beat except perhaps where a

resonant frequency of the machine or structure is being excited.

PAGE 44

4. VIBRATION MEASUREMENT

4.0 INTRODUCTION

Vibration motion is usually desired to be recorded against time. This is done by a

measurement system, which is functionally similar to that for any other physical variable,

as in figure.4.1

Physical

Variable Transducer Signal Display or

Element conditioning Recording Output

Element Element

Fig.4.1 FUNCTIONAL ELEMENTS OF A MEASURING INSTRUMENT

The three essential functional elements are 1. Transducer element 2. Signal

conditioning element and 3. Display or recording element.

PDF created with pdfFactory Pro trial version www.pdffactory.com

The transducer element converts the variable to be measured, in a usableform e.g.

vibratory signal is converted to an electrical signal, by an electromechanical transducer.

The signal conditioning elements include amplifiers or filters or differentiators,

integrators etc. and convert the signal so that it is recorded or displayed, according to the

requirements.

For measurement of motion or vibration of an object, there are basically two types

of transducers.

1 Fixed reference types as shown in figure 4.2 where the motion of the moving

object is measured relative to a fixed datum (earth).

2 Seismic type transducer is shown in figure 4.3. These are used in practical

situations where a fixed datum is not available. For

PAGE 45

example, for measurement of vibrations in a moving vehicle, a bridge or of a machine

located in. an industrial environment where the disturbance due to surrounding equipment

results in no availability of the fixed datum. In such cases, the seismic transducer has to

be attached to the vibrating object. Inside the transducer is a mass mounted on a spring

and damper and the relative motion of the mass Z relative to the frame of the instrument,

is a measure of the unknown vibration "x", the relation depending on the frequency of

vibration.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 46

4.1 VIBRATION TRANSDUCERS

A transducer or pickup is a device which converts vibratory or shock motion into an

optical or a mechanical or more commonly an electrical signals that is proportional to a

parameter. of the motion. Of course one of the most widely used vibration sensors is the

human fingertip. When accessibility and temperature allow, this is often the first sensor

to be applied in diagnosing machine vibration.

The following factors are usually borne in mind while making a choice of a

vibration transducer

* Whether a seismic or a fixed reference type of transducer is required

in the situation under consideration.

* Whether the magnitude of motion is very sm all (microns), medium (mm) or

large (cm).

* Frequency range over which vibrations are likely to be encountered and over

which the transducer is expected to have a linear frequency response.

* Whether the output of the transducer is desired to be proportional to

displacement, velocity or acceleration.

* Whether the transducer is to be of contact type or proximity type.

* Whether the transducer is of self - generating type or an external supply is

required.

PAGE 47

* The type of associated circuit and its complexity, which would also determine

its cost.

There are several types of transducers available for measurement of vl 'bration a

few commonly used is discussed below.

4.1.1 ELECTRODYNAMIC TYPE

This is a fixed reference transducer has its magnet fixed and the core with a

number of coils is attached to the vibrating object. The reverse is also possible and the

core may be fixed and the magnet attached to the vibrating object. Relative motion

induces an electrical voltage in the coil, proportional to the velocity of the vibrating

object. Integrating and differentiating circuits are needed if displacement and

PDF created with pdfFactory Pro trial version www.pdffactory.com

acceleration respectively, are desired. This is a self generating and contact type of

transducer, which is shown in figure 4.4.

PAGE 48

4.1.2 PHOTOELECTRIC DISPLACEMENT GAUGES

Another useful displacement measuring device may be constructed by using a

light source and a photoelectric cell. A photocell is, essentially a current generating

device for which the amount of current generated is proportional to the amount of light

falling on it. Hence, if the light falling on the cell can. )e made proportional to the

displacement, the photocell becomes a displacement transducer. A schematic sketch is

shown in figure 4.5a.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 49

The photo tube consists of a cathode coated with a material (such as lithium)

which emits electrons when struck by light. If this electron emitter is connected in circuit

as shown in figure4.5b, the emitted electrons flow to the anode. and through the load

resistance (RL).

The potential across the load (EL) is proportional to the current (or electron) flow

(EL= IRL) and hence to the light falling on the photo cathode. Since the current from a

photocell is very small, a photo multiplier tube is usually used.

4.1.3 LINEAR VARIABLE DIFFERENTIAL TRANSFORMER

LVDT (Linear Variable Differential Transducer) is of contact type, whose core is

attached to the vibrating object and the coils are f xed. There is a

PAGE 50

primary coil ((P3,), supplied with AC, carrier supply (Fig.4.6). The two secondary coils

are connected in series opposition so that the output is zero when the core is in the,

middle. Vibratory motion'; increases the inductance of one coil and decreases that of the

other, producing and output which varies fairly linearly with displacement over a wide

range..

4.1.4 HAND VIBROGRAPH

The hand vibrograph is a mass-spring type of mechanical device, which measures

vibration displacement and produces a hard copy record of the displacement. The

instrument is held so that a sensing tip touches the vibrating body. The displacement of

this body is imparted to the tip, which is attached to a writing stylus through a system of

PDF created with pdfFactory Pro trial version www.pdffactory.com

levers. A strip of recording paper is moved under the stylus at constant speed producing

a plot of instantaneous tip position vs time. It is shown in figure 4.7.

PAGE 51

The high frequency response is limited by the inertia of the mechanical lever

system. Typical, limits are: Maximum frequency response - 250 cps, Low frequency

limit 5 cps, maximum displacement 0.125 inches and resolution

0.0002

4.1.5 EDDY CURRENT PROBES

Eddy current probes are primarily used to detect vibration in rotating machines, to

monitor shaft axial position or thrust wear and to measure relative expansion between

rotor and casing of a machine. It is also a proximity probe.

The probe uses the eddy current principle to measure the distance from the coil (on

the tip of the probe) to the surface of the shaft. This is accomplished by the generation of

a small radio frequency in the proximitor (driver). The RF signal escapes into the area

surrounding the probe tip. When no conductive material is within range of the signal,

virtually all of the power released to the surrounding area is returned to the probe tip. As

a conductive surface approaches the tip, the RF sets up small eddy currents on this

surface. This eddy current creates a power loss in the RF signal and is measurable. The

nearer the target material, the greater the eddy current loss. The losses of an eddy current

system appear as a parabolic curve when measurements are made at various gap

distances. Therefore, it is necessary that the probe have a linear voltage output as a

PDF created with pdfFactory Pro trial version www.pdffactory.com

function of gap. This is normally provided in the proximitor by internal compensation.

The output of the proximitor is a d.c. voltage which varies as the gap distance varies, thus

providing the average gap distance from the probe tip to the target surface plus vibration

excursion level in both frequency and, amplitude of observed motion

PAGE 52

An inherent feature of eddy current measurement is that it is not disturbed by non-

conductive material in the gap between the probe and its observed surface, so that oil,

steam, gases and so forth, do not adversely affect the measurement. Special probes are

available for high vacuum, high pressure and high temperatures. Other models are

designed for use in water and saturated steam and some models for gaseous/liquid

oxygen.

The proximitor signal output voltage, when used to observe a rotating body such as

a turbine shaft, gear shaft or coupling indicates the vibration amplitude and frequency on

the same plane as the probe (vertical probe/vertical plane etc.) When two probes are

mounted in an XY configuration (vertical and horizontal or otherwise 900 angularly

separated) at the same lateral location, the total shaft relative radial motion is observed.

The output of the transducer system, as a varying d.c. voltage can be displayed on an

oscilloscope to pictorially represent the exact shaft motion with respect to probe

mounting, this is very useful for malftmction diagnosis.

The following things are to be noted while using an eddy current probe.

1. It is important to, know the material of the shaft, as the surface electrical

resistance will be factor in determining the amount of energy transferred and

thus the distance between the probe tip and target.

2. The probe must be positioned so that no metal is near to the tip other than the

'target' metal surface. The mounting hole should be chamfered or counter

bored, if necessary

3. The original distance between probe tip and target must be known.

PAGE 53

Depending upon the use, standard probes are available in ranges of 5 mils to 50

mils having sensitivities from 200 mV/mil (8 mV/micron) to 100 mV/mil (4mV/micron).

Standard probes are usable at temperature up to 200'F or 350'F. The frequency response

is from DC to 5 KHz. The eddy current probe is susceptible to changes in shaft surface

PDF created with pdfFactory Pro trial version www.pdffactory.com

e.g. mechanical run out, electrical run out (residual magnetic field), shaft finish, and

coatings of different conductivity. Submerence in water can be troublesome unless well

seated in ceramic.

4.1.6 CAPACITANCE PROBE

The capacitive transducer is a contact free displacement sensitive pick up. It finds