Académique Documents

Professionnel Documents

Culture Documents

10 3138@cpp 2017-047 PDF

Transféré par

Marli CorreaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

10 3138@cpp 2017-047 PDF

Transféré par

Marli CorreaDroits d'auteur :

Formats disponibles

Prospects for Second-Generation

ethanol in canada: An Analysis of

economy-wide Impacts

hAwLey cAMPbeLL

Department of Resource Economics and Environmental Sociology, University of Alberta, Edmonton,Alberta

JAMeS rude

Department of Resource Economics and Environmental Sociology, University of Alberta, Edmonton,Alberta

MArtIN Luckert

Department of Resource Economics and Environmental Sociology, University of Alberta, Edmonton,Alberta

FArZAd tAherIPour

Agricultural Economics, Purdue University,West Lafayette, Indiana

Canadian Public Policy 2018.44:259-271.

La production canadienne d’éthanol est actuellement dérivée des céréales. L’éthanol est critiqué du fait

qu’il supplante la production alimentaire et n’apporte pas de réduction importante des gaz à effet de serre.

Selon ses promoteurs, l’éthanol de deuxième génération, tiré de matières lignocellulosiques comme les

arbres à croissance rapide, est plus efficace et réduit les gaz à effet de serre sans compromettre les appro-

visionnements alimentaires. Une industrie de l’éthanol de deuxième génération risque toutefois de ne pas

être rentable en ce qui a trait à la réduction des gaz à effet de serre. Les auteurs étudient les obstacles à la

commercialisation de l’éthanol de deuxième génération, son potentiel de succès et les conséquences, sur le

plan des politiques, de la promotion de la production canadienne d’éthanol de deuxième génération.

Mots clés : cultures énergétiques, éthanol cellulosique, politiques en matière de biocarburants

Canadian ethanol production is currently derived from grain. Ethanol is criticized for displacing food pro-

duction and not significantly reducing greenhouse gases. Second-generation ethanol from lignocellulosic

feedstocks, such as fast-growing trees, are promoted as being more effective at reducing greenhouse gases

without compromising food supplies. However, a second-generation ethanol industry may not be cost-

effective with regard to greenhouse gas reduction. This study examines obstacles to a commercial second-

generation ethanol industry, the potential for success, and the policy implications of promoting Canadian

second-generation ethanol production.

Keywords: cellulosic ethanol, energy crops, biofuel policies

Introduction fuels and alternative energy sources including electricity,

In 2016, Environment and Climate Change (ECC) Canada hydrogen, and renewable fuels. The current Canadian

began consultations with other levels of government and Renewable Fuels Regulations require an average renew-

stakeholders to create a national Clean Fuel Standard able content of at least 5 percent, based on the volume of

(CFS). The CFS is to be developed under the Canadian gasoline sold, and an average renewable fuel content of

Environmental Protection Act of 1999 (Government of Can- 2 percent for diesel and heating oil sold, also based on vol-

ada 1999) and build on the foundation set by the federal ume sold (ECC Canada 2010). The objective of the CFS is

Renewable Fuels Regulations (ECC Canada 2010). The CFS to achieve an annual reduction of 30 million metric tonnes

is to encourage the use of a broad range of lower carbon of greenhouse gas emissions by 2030 (ECC Canada 2017).

doi:10.3138/cpp.2017-047 © Canadian Public Policy / Analyse de politiques, September / septembre 2018

260 Campbell et al.

Currently, ethanol production contributes to more than intersectoral linkages among biofuels and crops, live-

80 percent of Canada’s renewable fuel production (USDA, stock, forestry, and the energy sector. Our approach is an

Foreign Agriculture Service 2016). To date, all Canadian applied general equilibrium model that simultaneously

ethanol production is sourced from agricultural grain addresses linkages across all sectors of the economy and

(CRFA 2011). Globally, these first-generation biofuels, is built around observed data. The basic elements include

especially ethanol, have been criticized for displacing modelling consumer and producer behaviour in as many

food production and escalating commodity prices while markets (factors, goods, and services) as will satisfy com-

making only modest contributions to GHG reductions plete macroeconomic market clearing across the economy.

(Searchinger et al. 2008). Second-generation biofuels, The Global Trade Analysis Project (GTAP) is a widely

produced using ligno-cellulosic feedstocks from woody used general equilibrium model (Hertel 1997). As a col-

biomass such as trees, grasses, and agricultural residues, laborative effort, parameters for and data on country-level

have been advocated on the basis that they should be more input–output, production, consumption, bilateral trade,

effective in reducing GHGs and do not compete with food tax, transport, and protection measures are collected for

supplies (Tilman et al. 2009). However, the commercial- each of the countries represented in the model. The struc-

ization of second-generation biofuels is proving difficult. ture, data sources, and parameters of GTAP are described

This study analyzes reasons why cellulosic ethanol has yet in several documents (e.g., Hertel 1997).

to be successfully commercialized in Canada, its future For our analysis, we make use of a modified version

potential, and the role that it can play in a national CFS. of the GTAP model, the GTAP-BIO-ADV (Taheripour

To understand the potential for success of second- et al. 2011). The model was developed to incorporate ad-

generation biofuels, the following factors need to vanced biofuels. The initial version of this model included

be considered: (a) production costs, relative to first- new US industries to produce ethanol from corn stover,

generation production; (b) government incentives for both miscanthus, and switchgrass. These industries use land,

the supply and demand of ethanol;1 (c) cross-sectoral spin- fertilizer, fuel, labour, capital, and transport services to

Canadian Public Policy 2018.44:259-271.

off benefits (e.g., employment, economic diversification, create feedstocks, which in turn are then used as inter-

and rural development) that could potentially justify the mediate inputs that are combined with value added to

use of subsidies; and (d) significant contributions to GHG produce ethanol. The ethanol is then combined with fossil

reductions (Moschini, Cui, and Lapan 2012). fuels to create transportation fuels that are used by other

This article examines whether these four factors for suc- industries, consumers, and government and are traded

cess are present in the development of second-generation internationally. Because these advanced biofuels are not

ethanol production in Canada. Although second-generation yet commercially available, the model is calibrated to

ethanol can be produced from a variety of feedstocks such produce very small volumes of advanced ethanol to solve

as trees, grasses, municipal waste, and agricultural residues, the complete model. Details on the process of construct-

we consider ethanol production in which the feedstock ing and calibrating the advanced biofuels component of

is derived from dedicated short-rotation tree crops (i.e., the model can be found in Taheripour et al. (2011). For

poplar) as an illustrative case.2 The analysis that underlies our purposes, the GTAP-BIO-ADV model was modified

this article is based on an economy-wide model that links to include Canadian hybrid poplar as a feedstock for

the agricultural sector to the rest of the economy and ac- cellulosic ethanol production in Canada. This modifica-

counts for feedback effects throughout the economy. This tion begins with Canadian cost estimates for producing

particular approach is attractive for studying cross-sectoral hybrid poplar (Campbell 2015), which are incorporated

effects because it accounts for competition for land across with the same process of constructing and calibrating

alternative uses in an explicit fashion and is able to capture the advanced biofuels component of the model used by

the economic impacts across the economy. This work builds Taheripour et al.

on an established model (Taheripour, Tyner, and Wang In our analysis, we are especially interested in model-

2011), with adaptations to account for second-generation ling land allocation to compare the interindustry impacts

ethanol production in Canada. of first- versus second-generation ethanol production in

We begin by outlining our analytical strategy. Then, Canada. GTAP-BIO-ADV includes explicit representation

we individually examine the four factors for success of of heterogeneous land productivity, which accounts for

second-generation ethanol in Canada. Finally, we con- differences across regions and adopts an agro-ecology

clude with a general discussion regarding the future of zoning method. Agro-ecological zones (AEZs) are sub-

second-generation ethanol production in Canada. divisions of land that are segmented according to their

agro-ecological features, whereby each AEZ has similar

Analytical Strategy land use potential (Lee et al. 2005). Land use competition

Understanding the potential of, and constraints on, the is modelled with two sequential stages. First, land is cat-

development of a commercially viable second-generation egorized as cropland, forestry, or pasture. In the second

ethanol sector requires a consideration of the complex stage, cropland is allocated across different uses.

© Canadian Public Policy / Analyse de politiques, September / septembre 2018 doi:10.3138/cpp.2017-047

Prospects for Second-Generation Ethanol in Canada:An Analysis of Economy-Wide Impacts 261

Land use data are organized by AEZ and land activity machinery, and season. Moreover, excessive removal of

(i.e., crops, livestock, and forestry). Allocated land is im- crop residues reduces soil fertility, and forest residues

mobile across AEZs but can be reallocated across activities may serve ecological functions.

within an AEZ depending on relative returns. The AEZ Dedicated energy crops, such as fast-growing grasses

categorization allows us to identify the most appropriate and trees, have the advantage of growing at high volumes

locations within Canada for hybrid poplar growth, limit- and high densities on marginal-quality land. In addition,

ing land reallocation to a semi-arid boreal climate zone as a dedicated perennial, poplar, with rotations of approxi-

(Lee et al. 2005). mately 20 years, offers additional environmental benefits

Investigating the feasibility of a potential advanced as a carbon sink (Jassala et al. 2013) while alleviating

biofuels industry requires a broad-brush approach. We pressures on food production. The idea is that dedicated

have chosen a computable general equilibrium model biomass feedstocks would be grown on private lands that

as an organizational tool to help discover potential are marginal for other productive uses. However, the ex-

unintended consequences of aggressive promotion of perience has been that significant government incentives

second-generation ethanol. Specifically, we use this ap- are required for these feedstocks to be economically viable,

proach as a quantitative method to assess direct and including subsidies for the establishment and maintenance

indirect land use changes, as well as potential impacts on of new dedicated biomass cropping systems, as well as

prices, production, and trade in closely related sectors. payments for the collection and harvest of existing bio-

This approach also allows us to assess whether broader mass resources (crop and forest residues) that currently

interindustry linkages are present. However, the model have no market (Carriquiry et al. 2011).

does not provide sufficient detail to address other relevant The US experience is particularly instructive with re-

factors that will influence the emergence of the industry, spect to Canadian potential for using marginal lands to

so additional information is introduced in the next two grow energy crops. The US Biomass Crop Assistance Pro-

sections, and then we return to describe the model results gram (BCAP) was introduced as part of the 2008 Farm Bill

Canadian Public Policy 2018.44:259-271.

to round out the analysis. (Food, Conservation, and Energy Act of 2008, Pub. L. 110-

234) to complement other incentive programs, including

Factors for Success of Second-Generation the Renewable Fuel Standard, and to encourage dedicated

ethanol Production biomass cropping systems on marginal land. To date, the

BCAP has a very low uptake rate for dedicated biomass

Production Costs plantings of just 49,000 acres of the available 911 million

There are several cost components to producing cellu- acres of farmland in the United States (USDA, National

losic ethanol in commercial refineries. Some of the major Agricultural Statistics Service 2017). Furthermore, only

considerations include the costs of feedstocks, the cost of 4–7 percent of all contracted land is marginal land, and

capital investment in new refineries, and the operating the remainder is taken from cropland (Barham, Mooney,

costs of maintaining ethanol refineries. We consider each and Swinton 2016).

of these economic obstacles here. Our analysis considers two scenarios in which we

double current Canadian ethanol production, for an addi-

Feedstock Constraints and Costs tional 1.8 billion litres of production. The first scenario

Depending on the conversion efficiency and applied tech- doubles current production of first-generation ethanol

nology in the United States, feedstock costs can account for produced from coarse grain; the second scenario uses

32–52 percent of total production costs for second-genera- hybrid poplar cellulosic feedstocks to produce the targeted

tion biofuels (Carriquiry, Du, and Timilsina 2011). There second-generation ethanol. Our model indicates that the

are two primary feedstock sources of cellulosic biomass: conventional biofuel route requires a total of 628,000

residues from agriculture and forestry and dedicated hectares of land (exclusively cropland), and the hybrid

energy crops. Residues from forestry and agriculture are poplar alternative requires 867,000 hectares of land. The

typically available at low densities across large regions, additional land necessary for hybrid poplar feedstock

making transportation costs high. Champagne (2007) production versus grain feedstock production reflects

estimates that Canada could annually produce 5.3 bil- the fact that land is tied up for longer growing periods to

lion litres of ethanol, based on the recoverable fraction produce a harvestable tree (i.e., 20 years) versus annual

of crop residues generated in 2001. However, although crop production. Approximately 570,000 hectares of the

these feedstocks show potential, the logistical problems land required for hybrid poplar production is drawn

(collection, storage, and preprocessing) and costs are from marginal land, and the remaining 297,000 hectares

considerable. Crop and forest residues are often widely predicted by the model must come from existing cropland.

distributed and have to be collected using an integrated Although cropland is still required for adequate hybrid

system at harvest. The collection and delivery methods poplar production, the 297,000 additional hectares are less

vary with the type of residue, location, terrain, available than half of the extra cropland (628,000 hectares) needed

doi:10.3138/cpp.2017-047 © Canadian Public Policy / Analyse de politiques, September / septembre 2018

262 Campbell et al.

to grow the incremental 1.8 billion litres of first-generation plant could be much lower, at approximately 245 million

ethanol. litres per year.

Although at first blush there would appear to be a On the basis of the current state of technology, second-

limitless supply of marginal land in the boreal regions of generation biofuels require high capital costs, more than

Canada, the actual available land mass is a thin border of five times that of similar-capacity starch-based ethanol

land between the treed and cropped zones of western Can- plants (Carriquiry et al. 2011). Wright and Brown (2007a),

ada, that is, a small area bordering public and privately using an engineering approach, estimate that a biochem-

owned land. For instance, in Alberta we calculate only ical cellulosic plant with 132-million-litre capacity would

approximately 1.5 million hectares of this marginal land cost US$294 million. In terms of actual expenditures, the

and assume a conservative amount (0.5 million hectares) two commercial cellulosic refineries operating in the

of additional marginal land available in the rest of the United States cost between US$200 (DuPont 2017) and

country. Using more than 40 percent of that marginal land US$275 million (Poet-DSM 2014).5 Conceptually, it is easier

for biofuels (in the case of Alberta) would have a signifi- to compare capital costs based on annual ethanol capacity.

cant impact on agricultural activities, such as pastureland For example, the DuPont cellulosic ethanol plant in Iowa

currently used to produce livestock. (which the company recently closed and announced it

There are several economic obstacles to converting plans to sell), cost about US$1.98 per litre (Hirtzner and

land to bioenergy crops, including the cost of produc- Renshaw 2017). As a point of reference, recent per-litre

tion of hybrid poplar. According to recent input cost capital expenditure for first-generation ethanol produc-

estimates, hybrid poplar production is around $100 per tion in the United States has been estimated to be US$0.33,

oven-dried tonne due to costly labour and capital and the whereas in Canada capital expenditures range from $0.60

expenses associated with rearing trees (authors’ calcula- to $0.95 per litre (Coad and Bristow 2011).

tions; Campbell 2015).3 In addition, government policy

obstacles may influence feedstock supply. For example, Operating Costs

Canadian Public Policy 2018.44:259-271.

current provincial forest policies largely prevent the Given the optimal selection of plant location and size,

growing of non-native tree species (such as fast-growing a further major decision is the type of production pro-

hybrid poplar) on public lands (Anderson, Luckert, and cess. For cellulosic ethanol production, lignocellulosic

Campbell 2015), and there is uncertainty regarding the feedstocks must first be converted to sugars through

future of biofuel subsidy programs (Campbell, Anderson, a series of thermochemical or biochemical processes

and Luckert 2016). All of these considerations result in a (Sims et al. 2010). For the purposes of this discussion,

land supply function that is not very responsive to higher we consider only the biochemical process given that this

biofuel returns. Finding reliable sources of high-density currently appears to be the most popular method. The

woody feedstocks poses a significant challenge to second- success of cellulose-to-ethanol biochemical conversion

generation ethanol production. from lignocellulosic material feedstocks is generally a

function of fibre pretreatment, enzyme selection, and

Capital Costs operating conditions. The breakdown of cellulose into

The location of ethanol refineries is typically limited to sugar and then ethanol requires the use of expensive

within 50 miles of the feedstock (Balan 2014). Because enzymes. The enzyme cost to produce 1 litre of cellulosic

marginal land–based hybrid popular plantations would ethanol is US$0.26 (Markings 2017). Carriquiry et al.

not be located near existing first-generation ethanol re- (2011) find that operating costs associated with cellulosic

fineries, cellulosic ethanol plants would have to involve ethanol plants are between US$0.35 and US$0.45 per

greenfield investments in new locations. Harvesting, litre, but they see the potential to cut these costs by

treating, and transporting large volumes of biomass feed- as much as two-thirds with improvements in biofuel

stock to a refinery require careful logistical analysis before conversion technologies. When capital costs are added

plant investment and construction. The optimal size of to operating costs, it leads to an overall production cost

an ethanol plant is determined by the trade-off between of approximately US$0.79 per litre of cellulosic ethanol

increasing transportation costs for feedstocks and de- (Markings 2017).

creasing average plant costs as plant size increases. Given

the dearth of commercially viable second-generation Government Incentives

biorefineries, the only way to determine scale economies Recent estimates of biofuel production costs show that

is with engineering studies, which provide a fairly wide second-generation biofuels are two to three times more

range of estimates.4 Wright and Brown (2007b) estimate expensive than petroleum fuels on an energy-equivalent

that an optimal plant’s annual capacity should be appro- basis (Carriquiry et al. 2011). Given the significant chal-

ximately 1.35 billion litres for cellulosic ethanol versus lenges to procuring cellulosic feedstock to facilitate an

450 million litres for grain ethanol. Huang et al. (2009) emerging industry, the high capital costs, and the un-

suggest that optimal production for a cellulosic ethanol certainty around technology, some form of government

© Canadian Public Policy / Analyse de politiques, September / septembre 2018 doi:10.3138/cpp.2017-047

Prospects for Second-Generation Ethanol in Canada:An Analysis of Economy-Wide Impacts 263

incentive would likely be necessary to promote second- Similar federal programs were offered in subsequent

generation production. years. Currently, there are no capital expenditure sub-

Justifications for government support typically revolve sidies, but if past programs were to be renewed, then

around market failures. Multiple objectives are routinely second-generation capital costs could be as high as five

invoked to rationalize biofuels policies, ranging from to seven times the cost of recently built first-generation

finding secure supplies of alternatives to fossil fuels, re- plans (Stephen, Mabee, and Saddler 2012).

ductions in GHGs, and more broadly to promote economic Perhaps the most significant development for the

development. Canadian ethanol industry was the announcement of

The potential gamut of ways to support the emerging new federal and provincial mandates for renewable fuel

industry includes incentives to attract land for biomass mixtures (Renewable Fuels Regulations). This demand-

production, investment incentives to build refineries, side support effectively ensures that Canadian ethanol

incentives to increase the share of ethanol in gasoline producers have a market in which to sell their product.

blends, support for distribution infrastructure, and Five provinces have introduced blending mandates:

reduced taxes to encourage advanced biofuel consump- Alberta, British Columbia, and Ontario required a 5 per-

tion. Leach, Doucet, and Nickel (2011) highlight three cent ethanol blend in gasoline; Saskatchewan requires a

options for government financing of biofuels: production 7.5 percent blend, and Manitoba requires an 8.5 percent

subsidies, capital grants with no repayment conditions, blend.

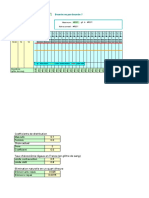

and repayable capital grants. Canadian federal and prov- Figure 1 shows the growth of first-generation pro-

incial governments have made use of all three of these duction, the level of subsidies, and targets for blending

financing options (Campbell et al. 2016). Early federal mandates. Since 2006, Canadian ethanol production has

and provincial programs included excise tax exemptions increased from approximately 0.3 to 1.8 billion litres

and investment incentives for ethanol plants. Later, direct (Campbell et al. 2016). The “biofuel boom” corresponds

supports and market-dependent loans were introduced to to a period with several government-backed low-interest

Canadian Public Policy 2018.44:259-271.

increase ethanol capacity. A complete list of government loans and grants for capital expansion, commercializa-

support for ethanol production in Canada is provided in tion, and volume-based subsidies to biofuel producers.

the Appendix. The beginning of this period also corresponds to a surge

In terms of investor incentives, the Canadian experi- in crude oil prices. The investment incentives and strong

ence started in 1992 with the National Biomass Ethanol crude oil prices stimulated the construction of biofuel

Program (Laan, Litman, and Steenblik 2009). The program refining plants, but it was the blending mandates that

offered loan guarantees up to a credit limit of $140 million. ensured expanded production by creating a legislated

2,500 0.30

2,000 0.25

0.20

$ per Litre

Millions of Litres

1,500

0.15

1,000

0.10

500

0.05

0 0.00

81 83 85 87 89 91 93 95 97 99 01 03 05 07 09 11 13 15

19 19 19 19 19 19 19 19 19 19 20 20 20 20 20 20 20 20

Cumulative Capacity National Target Subsidy Support

Figure 1: Canadian Ethanol Production, Blending Mandate, and Subsidy Support over Time

Source: Authors’ calculations.

doi:10.3138/cpp.2017-047 © Canadian Public Policy / Analyse de politiques, September / septembre 2018

264 Campbell et al.

market for ethanol and thereby providing assurances for There are several lessons here for future Canadian

future ethanol demand. policy. Second-generation ethanol plants cost more than

Conceptually, ethanol mandates can be thought of conventional biorefineries. More than just cost considera-

as an implicit subsidy on ethanol that encourages the tions inform the decision to invest in capital equipment.

substitution of biofuels in vehicle fuel blends (Lapan Investors face a risky technology and numerous uncer-

and Moschini 2012). By requiring ethanol to be mixed tainties with respect to markets and policies. Probably

with gasoline, government effectively creates a guaran- the best approach to stimulate investments to construct

teed market for ethanol mandating, which is an implicit second-generation plants is with a production mandate,

subsidy to the producers of ethanol. Within this context, which provides assurance as to the size of future ethanol

a relevant question is whether, and to what extent, the demand. Nonetheless, it is unlikely that an advanced

incentive effects of this guaranteed market pass upward ethanol sector will develop in Canada before one is firmly

through the supply chain to attract land for biomass established in the United States. The status of the US in-

feedstock production. dustry is still very much uncertain.

The first-generation production subsidies that stimu-

lated the rapid expansion of Canadian ethanol production Model results and Interindustry effects

are now expiring, because the targets for meeting the Our analysis considers a doubling of ethanol produc-

current blending mandates have been reached. If the tion in Canada, which would increase ethanol content to

desire is to change the direction of the ethanol industry approximately 10 percent, an amount that matches the

toward cellulosic ethanol, then new types of subsidies “blend-wall,” or the maximum amount of ethanol that

are needed to replace the current cohort. These subsidies most vehicles can safely use given current vehicles. The

might include new incentives for plant construction and model of the GTAP database used is the 2004 version 7.

commercialization. However, given the increased costs as- Although the data appear dated, commodity prices for this

sociated with second-generation production, the previous period are remarkably close to recent prices since 2015.6

Canadian Public Policy 2018.44:259-271.

level of support is not likely to lead to sufficient product- The basic elements of consumer and producer behaviour

ive capacity to satisfy the increased demand associated are described with 43 goods (10 primary agriculture) and

with any increase in mandates. The CFS will eventually 19 regions. The standard assumptions of the GTAP model

subsume the current renewable fuel regulations. Because (Hertel 1997) apply, including a static model with perfectly

CFS emission reduction requirements are on a life-cycle competitive markets. First-generation ethanol is assumed

basis, second-generation ethanol production may be more to be produced entirely from corn.7

effective in reducing carbon emissions. Simply increasing Mechanically, the model is solved by forcing ethanol

the blending requirement without additional policies will production to double and asking what implicit ethanol

result in more first-generation ethanol production (see subsidy is required to support this production. The model

“Model Results and Interindustry Effects”). At this time, keeps adjusting until there is sufficient incentive to achieve

it is difficult to predict the exact incentives for second- the increase in ethanol production. When the additional

generation production without knowing the specifics of ethanol production is fulfilled with conventional first-

how CFS regulations will be implemented. Alternative generation ethanol, we find the required subsidy to be

incentives could include a call by biofuel industry stake- $0.63/litre. When the increased production is met through

holders for exemptions for cellulosic ethanol from federal cellulosic ethanol from hybrid poplar feedstock, a much

and provincial fuel taxes. larger subsidy is required: $0.27/litre as a direct produc-

The US experience is in line with the high costs of tion subsidy plus $0.87/litre as an implicit or blending

increasing cellulosic ethanol in our simulations and subsidy. The much higher subsidy rate for cellulosic

also helps to illustrate a potential outcome of Canadian ethanol accounts for the additional incentives required

efforts to create incentives for the construction of to attract land for biomass production.

second-generation plants. The major incentive for the Our model can address some of the broader issues of

construction of US biorefineries has been loan guaran- economic development that are sometimes used to jus-

tees from the US Department of Energy (DOE) and the tify biofuel expansion. Justifications for first-generation

US Department of Agriculture. The DOE loan program ethanol policies include support for agriculture and rural

guaranteed the construction of six commercial-scale development. Because ethanol (and most biodiesel) is

biorefineries (Hayes 2013). Of the six plants, only one, made from agricultural crops, there is a solid link between

Poet-DSM, is currently commercially viable, and it re- farmers and the biofuel industry. Increased biofuel pro-

ceived a loan guarantee of $80 million on a US$275 million duction would therefore increase demand for agricultural

investment. Subsequently, Poet-DSM declined the DOE production. In general, the modelling results indicate that

loan guarantee, but received an additional US$100 mil- if biofuel mandates were doubled with first-generation

lion in grants to support the costs of engineering and production, interindustry impacts would be negligible

construction (Poet-DSM 2014). beyond the primary agriculture and forest sectors, with

© Canadian Public Policy / Analyse de politiques, September / septembre 2018 doi:10.3138/cpp.2017-047

Prospects for Second-Generation Ethanol in Canada:An Analysis of Economy-Wide Impacts 265

little or no induced consumption effects driving the rest simulation in which the additional production comes via

of the economy. cellulosic feedstocks. Doubling ethanol production via

One of the primary arguments for supporting cellulosic first- versus second-generation processes yields markedly

ethanol is that biomass feedstock can alleviate some of different outcomes for coarse grains (corn and barley) and

the cropland pressures that first-generation feedstocks ruminant (cattle) production. Coarse grain production

have caused. When we consider doubling ethanol pro- increases by 9 percent with first-generation production,

duction with second- versus first-generation feedstocks, with a 6 percent increase in price, whereas it contracts by

more wheat and oilseed acreage is taken away for first- just over 1 percent with second-generation production

generation production than with cellulosic ethanol. The with a price increase of less than 1 percent. In this case,

shift in acreage is due to a GTAP-BIO-ADV assumption the popular land is being drawn from marginal land that

that first-generation ethanol is sourced from coarse-grain does not affect cereal production but does affect cattle

feedstocks.8 Coarse-grain-based ethanol production re- grazing. Cattle production declines by 1.5 percent, with a

quires higher quality land, unlike cellulosic feedstock, price increase of 2 percent, because of second-generation

which can use lower quality marginal land. However, production, whereas it declines just more than a quarter

although hybrid poplar can be grown on marginal lands, of percentage point with conventional production. This

the total land required to support a 100 percent increase in difference can again be attributed to the fact that the model

ethanol production is greater than that required by grains shifts marginal-quality land previously used for livestock

to produce the same amount. to accommodate hybrid poplar production to produce

Table 1 shows the results of our GTAP-BIO-ADV second-generation ethanol. Changes in exports reflect the

simulation analysis in percentage of change relative to the changes in production but are larger in percentage terms

baseline. Two scenarios are considered, a first-generation given that not all grain is exported.

simulation in which all of the additional production comes Other grains and oilseed production decrease as land

via starch-based feedstocks and a second-generation is drawn away for biofuels production. However, second-

Canadian Public Policy 2018.44:259-271.

generation production is able to mitigate the production

loss by 20–25 percent between scenarios. Qualitatively,

table 1: Simulation Results the results for both scenarios follow the same direction,

% but the orders of magnitude are smaller with second-

generation production. The impacts for non-ruminants

Price Output Net Export (hogs and poultry), forestry, and oil and gas are all small.

Simulation Change Change Change The impacts for an aggregate other industry and services

First-generation simulation sector are not different from zero.

Wheat 0.58 −3.01 −2.56 An additional motivation for government support of

Coarse grains 6.11 8.97 −21.13 ethanol is to increase economic opportunities for rural

Oilseeds 0.83 −2.41 −2.37

communities, although this is often defined by govern-

ments in vague terms. In agricultural communities,

Other ag goods 1.12 −2.03 −5.38

increases in farm income seldom translate into rural

Forestry 0.00 −0.02 1.49

development; that depends on broader issues such as

Ruminant 0.29 −0.29 −3.45

infrastructure and the attractiveness of living in the com-

Non-ruminant 0.30 −0.33 −0.47

munity (OECD 2010). The location of ethanol refineries

Other industries and services −0.01 −0.02 0.27 will be at least partially determined by infrastructure,

Welfare change −$937,053,156 but the development of the industry will also determine

Second-generation simulation the development of infrastructure. Indeed, most North

Wheat 0.40 −2.24 −1.92 American ethanol production facilities are located in rural

Coarse grains 0.80 −1.15 −2.12 communities near agricultural feedstock sources. In the

Oilseeds 0.64 −1.91 −1.94 United States, the dense concentration of facilities in the

Other ag goods 0.37 −0.81 −1.68 Midwest allows ethanol producers to take advantage of

Forestry −0.08 0.00 4.08

shared infrastructure and gain agglomeration effects.

Canada, however, presently lacks the critical mass of

Ruminant 2.00 −1.53 −26.97

ethanol facilities to see any agglomeration effects; there

Non-ruminant 0.16 −0.47 −0.22

are relatively few small-sized refineries, which are spread

Other industries and services 0.01 −0.02 −0.89

across the country.

Welfare change −$1,526,400,330

Regardless, even in the case of doubled ethanol

Note: Ruminants include cattle; non-ruminants include hogs and

production in Canada, direct job creation from refinery es-

poultry. Ag = agricultural.

tablishment in rural communities would be minimal. The

Source: Authors’ calculations.

Canadian Renewable Fuels Association has estimated that

doi:10.3138/cpp.2017-047 © Canadian Public Policy / Analyse de politiques, September / septembre 2018

266 Campbell et al.

645 direct jobs would result from approximately 2 billion gasoline. In 2015, Canada’s reported CO2 equivalent was

litres of annual production (Office of the Auditor General 722 megatonnes (ECC Canada 2016); the calculated emis-

of Canada 2007). Our model produces a similar value of sion reductions represent 0.19 percent and 0.46 percent of

approximately 655 direct jobs.9 Indirect and induced jobs Canada’s total emissions.

have been estimated to be much higher—approximately The cost-effectiveness of biofuels as a method of re-

6,000 jobs (Office of the Auditor General of Canada 2007). ducing GHG emissions has recently been questioned. It

On the basis of our analysis, this appears to be an overesti- is important to remember that it is not just the technology

mation. Indirect jobs from ethanol production are likely behind the production of biofuels that influences these

to be negligible, based on our results, given the small costs; it is also the policies that stimulate biofuel produc-

interindustry impacts associated with ethanol production. tion that greatly influence the cost efficacy of biofuels in

Welfare effects in GTAP-BIO-ADV are measured reducing carbon emissions. For example, both historic

as equivalent variation.10 Not surprisingly, the overall renewable fuels standards and emerging carbon taxes will

welfare implications of increased ethanol production affect the adoption of biofuels. Canada’s Ecofiscal Com-

in Canada appear to be minuscule on a gross domestic mission (2016) estimates that Canadian ethanol policies

product (GDP) basis. In the case of doubling production are a costly means to reduce GHG emissions, ranging from

with first-generation ethanol, welfare is reduced by ap- $180 to $185 per tonne. Our simulations produce similar

proximately $1.5 billion, or 0.09 percent of total GDP. With results, with first-generation ethanol production of 1.8 bil-

ethanol produced from hybrid poplar biomass, welfare lion litres costing about $190 per tonne. Second-generation

declines by approximately $2.5 billion, or 0.15 percent of ethanol, however, is much costlier, at approximately $345

total GDP. These welfare decreases can be attributed to the per tonne of CO2 reduced.

necessity of government subsidies to create incentives for As for emerging carbon tax policies, one question is

production, which create inefficiencies in the market and whether a carbon tax would improve the economics of

move the economy away from its equilibrium, reducing biofuels. A carbon tax would have negative economy-

Canadian Public Policy 2018.44:259-271.

welfare. wide impacts on the costs of production, especially for

fossil fuel–producing and energy- and carbon-intensive

reducing Greenhouse Gas emissions manufacturing industries. These effects, in turn, would

The most prevalent rationale for promoting biofuels is reduce the total demand for all fuels. Because ethanol is

arguably that they help reduce a negative externality blended with other fossil fuels, its demand could decrease

that is generated from carbon emissions associated with as well. However, the carbon tax could spur increased

burning fossil fuels. According to NRCAN (2016a), first- demand for biofuels with lower GHG emissions to be

generation ethanol achieved approximately 35 percent blended with gasoline. In the short run, this increase

less carbon dioxide (CO2) emissions relative to gasoline. would likely be limited to approximately 10 percent (the

Alternatively, advanced biofuels (including cellulosic blend wall of most current vehicles), although over time

ethanol from hybrid poplar) are defined as biofuels that an increase in flex-fuel vehicles could emerge, allowing

achieve at least a 50 percent GHG emission reduction higher biofuel percentages. Note that a carbon tax would

(Advanced Biofuels Canada 2017). Indeed, studies find have to be implemented such that the ethanol content in a

that advanced biofuels reduce GHG emissions of up to gasoline blend is recognized as being a less polluting fuel.

80 percent (McCarl 2008). There are several estimates of If, however, the carbon tax was applied as a flat rate across

how much GHG reduction is provided by Canadian bio- both components of the fuel, then ethanol producers

fuel production. According to the Office of the Auditor would be at a disadvantage given that production costs

General of Canada (2007), 2 billion litres of ethanol pro- exceed those of gasoline. A carbon tax could also lead to

duction would reduce GHG emissions by approximately a further increase in ethanol utilization if all or part of the

2.9 megatonnes. Similarly, an Ecofiscal Commission report revenue from the carbon tax is used to subsidize biofuels.

on Canadian biofuel production asserts that ethanol pro- With the implementation of a carbon tax, the net

duction reduced annual GHG emissions (CO2 equivalent) impact, therefore, is an empirical question regarding

by 2.2 megatonnes between 2010 and 2015 (Canada’s whether the economy-wide depressed use of all fuels

Ecofiscal Commission 2016). On the basis of our analysis, is greater or less than substitutions of biofuels for fos-

doubling ethanol production and displacing an additional sils fuels (again, this is highly dependent on how the

1.8 billion litres of gasoline with first-generation ethanol carbon tax is imposed on biofuels versus fossil fuels).

could reduce CO2 emissions by approximately 1.4 mega- Our model considers a $30 per tonne revenue-neutral

tonnes.11 These emission reductions were calculated using carbon tax that is applied equally across all fuel com-

the CO2 emissions from gasoline and ethanol estimated ponents and broadly across the economy. Our results

by NRCAN (2016b). By doubling ethanol production with indicate a negligible increase in ethanol utilization after

second-generation ethanol, CO2 emissions are estimated the carbon tax is implemented. However, similar model-

to be reduced up by to 3.3 megatonnes per year relative to ling approaches indicate that, if instead of compensating

© Canadian Public Policy / Analyse de politiques, September / septembre 2018 doi:10.3138/cpp.2017-047

Prospects for Second-Generation Ethanol in Canada:An Analysis of Economy-Wide Impacts 267

taxpayers, 10 percent of the carbon tax is reinvested as likely to be significant if part of the taxes are invested in

an ethanol production subsidy, then ethanol utilization subsidizing ethanol. So other, hopefully complement-

would increase by almost 7 percent (Timilsina, Csordas, ary, objectives are necessary to motivate governments to

and Mavel 2011). intervene sufficiently to ensure the commercial success of

second-generation ethanol.

overall Assessment and conclusions It is possible that commercial volumes of second-

The road to a national clean fuel standard involves generation ethanol production will create positive

several choices. The range of low-carbon fuel choices economic spinoffs that help to justify the necessary

includes electricity, hydrogen, and biofuels (ethanol and government support. There is both good news and bad

biodiesel). Biofuels are currently attractive because they news on this front. First, the good news is that the distor-

are renewable, they are compatible with current vehicle tions caused by subsidized production do not have very

infrastructure, and the energy is storable. However, chan- large negative impacts on other sectors in the economy.

ges in technology, consumer acceptance, and government Interindustry effects of doubling ethanol production

policy will ultimately determine what role biofuels will from either first- or second-generation ethanol would be

play in the mix of low-carbon fuels. largely confined to agriculture and forestry sectors. The

To date, first-generation (starch-based) ethanol has bad news is that spillovers are so small that they cannot

dominated renewable fuel production. However, large have a positive impact on other sectors of the economy.

opportunity costs with respect to land use changes that The only real hope for economic development in rural

penalize food production and a very heavy reliance on communities, especially in northern regions and com-

government support have led researchers and policy- munities hit hard by a contraction in the forestry sector,

makers to search for an alternative. The long-promised is that second-generation ethanol incentives would spur

commercialization of second-generation ethanol produc- investment and employment in rural areas with sluggish

tion offers potential improvements over first-generation economic activity. However, commercial ventures will

Canadian Public Policy 2018.44:259-271.

ethanol. The objective of this article is to assess the po- have to optimize utilization costs through selection of

tential for success of a poplar-based second-generation plant locations and sizes that may not benefit these com-

ethanol industry in Canada. munities. Unlike Iowa, current low production intensities

Success depends on controlling production costs and in Canada make it unlikely that first- and second-gener-

encouraging investment in biorefineries and the associ- ation refineries will coexist with existing infrastructure

ated infrastructure. Controlling production costs involves and the associated synergies. Even if such joint facilities

maintaining a reliable source of feedstocks at low cost and become feasible, it is not known whether they would be

controlling operating costs. Capital investment depends located in disadvantaged communities and utilize woody

on future expected profitability relative to costs. Investors biomass as a feedstock.

also face a risky technology that has not been proven in Although second-generation ethanol does not compete

commercial ventures and numerous uncertainties with directly with food, dedicated cellulosic energy crops

respect to markets and policies. To date, ethanol produc- would still compete for scarce agricultural land. In Can-

tion in North America has relied on government support, ada, doubling current production with second-generation

and development of second-generation ethanol will no ethanol from dedicated energy crops is estimated to

doubt require continued support, with the open question displace production on 297,000 hectares of cropland and

being how much. 570,000 hectares of grazing land. The implicit subsidy that

Government policies may improve incentives for would be required to double ethanol production would

investments in a second-generation industry, but ap- be costly, whether that production comes from first- or

proaches undertaken vary greatly with respect to how second-generation biofuels.

well they will explicitly address tangible market failures. Clearly, obstacles must be overcome before second-

Certainly, reducing environmental externalities is the generation ethanol is able to establish a dominant role

primary justification. There has been a certain amount in the mix of low-carbon fuels necessary to establish a

of excitement about the potential for second-generation national clean fuel standard. Governments have to choose

ethanol to significantly reduce carbon emissions. We find wisely before aggressively promoting the sector.

that if 1.8 billion litres of Canadian gasoline were to be

replaced with ethanol, CO2 emissions could be reduced Acknowledgements

by up to 3.3 megatonnes per year. However, the cost- This work was supported by a research grant from Bio-

effectiveness of this approach is questionable because of fuelNet. The authors have no other relevant affiliations

the subsidies necessary to compensate for the cost dis- or financial involvement with any organization or entity

advantages of second-generation ethanol. Carbon taxes with a financial interest or a financial conflict with the

have the potential to create incentives to increase the use subject matter or materials discussed in the article apart

of ethanol, but results indicate that this increase is only from those disclosed.

doi:10.3138/cpp.2017-047 © Canadian Public Policy / Analyse de politiques, September / septembre 2018

268 Campbell et al.

Notes International Scholarly Research Notices: Biotechnology

1 Note that production costs of cellulosic ethanol and govern- 2014:463074. https://doi.org/10.1155/2014/463074.

ment support for the industry are not mutually exclusive. Barham, B.L., D.F. Mooney, and S.M. Swinton. 2016.

Indeed, government support will become unnecessary as “Inconvenient Truths about Landowner (Un)Willingness

production costs in the industry decrease. to Grow Dedicated.” Choices 31(4):1–7. At http://www.

2 Gonzalez et al. (2012) compare the financial returns of choicesmagazine.org/choices-magazine/submitted

woody fibers with switchgrass and corn stover. They found articles/inconvenient-truths-about-landowner

woody fibers more attractive. Maung et al. (2013) discuss unwillingness-to-grow-dedicated-bioenergy-crops.

the substitutability between alternative feedstuffs and Campbell, H. 2015. “Ethanol Production from Hybrid

found that many of the same issues occur across feedstocks. Poplar in Canada: A General Equilibrium Analysis.”

Therefore, many of our results generalize to other purpose MSc thesis, University of Alberta, Edmonton. At https://

grown feedstocks. era.library.ualberta.ca/items/02c699d1-e7d4-4185

3 We assume a 20-year rotation period with costs compound- 9498-77ad3b647c15/view/bba351a8-29e1-4673-982e

ed to year 20 (Campbell 2015). 77e799b170c4/Campbell_Hawley_N_201509_MSc.pdf.

4 There are no commercial-sized cellulosic ethanol plants in Campbell, H., J. Anderson, and M.K. Luckert. 2016. “Public

Canada. In the United States, there are currently only two Policies and Canadian Ethanol Production: History and

cellulosic ethanol plants producing more than 2 million gal- Future Prospects for an Emerging Industry.” Biofuels 7(2):

lons per year (“US Ethanol Plants” 2017). 117–30. https://doi.org/10.1080/17597269.2015.1122312.

5 A third commercial-sized refinery that produces 25 million Canada’s Ecofiscal Commission. 2016. “Course Correction:

gallons per year was constructed in Hugoton, Kansas, by It’s Time to Rethink Canadian Biofuels Policies.” Montreal:

the Spanish company Abengoa Bioenergy. Plant construc- Canada’s Ecofiscal Commission. At https://ecofiscal.ca/

tion cost US$500 million (Gies 2014). In 2016, Abengoa Bio- wp-content/uploads/2016/10/Ecofiscal-Commission-

energy went into bankruptcy, and the plant is not currently Course-Correction-Biofuels-Report-October-2016.pdf.

operating (Sapp 2017). Canadian Renewable Fuels Association (CRFA). 2011.

6 For instance, there is a 4 percent difference between crude “Ethanol: Key Issues.” Ottawa: Canadian Renewable

Canadian Public Policy 2018.44:259-271.

oil prices and recent prices and a 5 percent difference for Fuels Association. At http://ricanada.org/wp-content/

broader commodity prices. uploads/2014/11/ethanol-fact-sheet-august102011.pdf.

7 The GTAP-BIO-ADV model only uses corn to produce eth- Carriquiry, M., X. Du, and G. Timilsina. 2011. “Second-

anol. This is the case for 78 percent of Canadian-produced Generation Biofuels: Economics and Policies.” Energy

ethanol, but the remainder is produced from wheat. This Policy 39(7):4222–34. https://doi.org/10.1016/j.enpol.

is not a drastic assumption because the alternative feed- 2011.04.036.

stock is feed wheat. Producers typically do not intention- Champagne, P. 2007. “Feasibility of Producing Bio-Ethanol

ally set out to produce feed wheat, so increased ethanol from Waste Residues: A Canadian Perspective: Feasibility

mandates would not necessarily cause more wheat to be of Producing Bio-Ethanol from Waste Residues in

produced. Canada.” Resources, Conservation and Recycling 50(3):

8 If the model were adjusted to incorporate wheat feedstocks, 211–30. https://doi.org/10.1016/j.resconrec.2006.09.003.

the reduction in wheat acreage might be slightly mitigated. Coad, L., and M. Bristow. 2011. “Ethanol’s Potential

9 This number includes direct jobs in the biofuels sector and Contribution to Canada’s Transportation Sector.” Ottawa:

does not net out the minimal job losses in other sectors as Conference Board of Canada.

the economy adjusts through factor reallocation. DuPont. 2017. “Cellulosic Ethanol Plant - Nevada, Iowa:

10 It is important to note there are a number of other externali- Overview.” At https://www.pp.dupont.com/products

ties that these calculations do not consider. These include and-services/industrial-biotechnology/advanced

potential environmental benefits associated with ethanol biofuels/cellulosic-ethanol/nevada-iowa-cellulosic

production, as well as additional economic changes that ethanol-plant.html.

could change the policy landscape for renewable fuels. Environment and Climate Change (ECC) Canada. 2010.

11 Note that the GHG emissions accounted for in the GTAP- “Renewable Fuels Regulations, Environment and Climate

BIO-ADVF model are only CO2 emissions associated with Change Canada.” At http://www.ec.gc.ca/lcpe-cepa/

the combustion of fossil fuels. eng/regulations/detailReg.cfm?intReg=186.

Environment and Climate Change (ECC) Canada. 2016.

“Greenhouse Gas Emissions.” At https://www.canada.

references ca/content/dam/eccc/documents/pdf/cesindicators/

Advanced Biofuels Canada. 2017. “Advanced Biofuels.” At greenhouse-gas-emissions/greenhouse-gas-emissions-en.

https://advancedbiofuels.ca/advanced-biofuels/. pdf

Anderson, J., M. Luckert, and H. Campbell. 2015. “Potential Environment and Climate Change (ECC) Canada. 2017.

Policy Reforms for a ‘More Exotic’ Canadian Forest Sector: “Clean Fuel Standard: Discussion paper.” Accessed 23 July

Comparing Canada’s Plantation Policies with Those in 2017. https://www.ec.gc.ca/lcpe-cepa/D7C913BB-13D0

Australia, New Zealand and the United States.” Forestry 42AF-9BC7-FBC1580C2F4B/CFS_discussion_paper_2017

Chronicle 91(5):560–72. https://doi.org/10.5558/tfc2015-095. 02-24-eng.pdf.

Balan, V. 2014. “Current Challenges in Commercially Food, Conservation, and Energy Act of 2008, Pub. L. 110-234,

Producing Biofuels from Lignocellulosic Biomass.” 122 Stat. 923.

© Canadian Public Policy / Analyse de politiques, September / septembre 2018 doi:10.3138/cpp.2017-047

Prospects for Second-Generation Ethanol in Canada:An Analysis of Economy-Wide Impacts 269

Gies, E. 2014. “For Cellulosic Ethanol Makers, The Road McCarl, B.A. 2008. “Bioenergy in a Greenhouse Gas

Ahead Is Still Uphill.” Yale Environment 360, 2 November. Mitigating World.” Choices: The Magazine of Food,

At https://e360.yale.edu/features/for_cellulosic_ethanol_ Farm and Resource Issues 23(1):31–3. At http://www.

makers_the_road_ahead_is_still_uphill. choicesmagazine.org/2008-1/theme/2008-1-09.htm.

Gonzalez, R., J. Daystar, M. Jett, T. Treasure, H. Jameel, Moschini, G., J. Cui, and H. Lapan. 2012. “Economics of

R. Venditti, and R. Phillips. 2012. “Economics of Cellulosic Biofuels: An Overview of Policies, Impacts and Prospects.”

Ethanol Production in a Thermochemical Pathway for Bio-Based and Applied Economics 1(3):269–96. https://doi.

Softwood, Hardwood, Corn Stover and Switch Grass.” org/10.13128/BAE-11143.

Fuel Processing Technology 94(1):113–22. https://doi. Natural Resources Canada (NRCAN). 2016a. “Ethanol.” At

org/10.1016/j.fuproc.2011.10.003. http://www.nrcan.gc.ca/energy/alternative-fuels/fuel

Government of Canada. 1999. Canadian Environmental facts/ethanol/3493?attr=8.

Protection Act, 1999 (S.C. 1999, c. 33). At http://laws-lois. Natural Resources Canada (NRCAN). 2016b. “Learn the Facts:

justice.gc.ca/eng/acts/c-15.31/. Fuel Consumption and CO2.” At http://www.nrcan.

Hayes, D. 2013. “Second-Generation Biofuels: Why They Are gc.ca/energy/efficiency/transportation/cars-light-trucks/

Taking So Long.” WIREs Energy and Environment 2(3):304– buying/16770.

34. https://doi.org/10.1002/wene.59. Office of the Auditor General of Canada. 2007.

Hertel, T. 1997. Global Trade Analysis: Modeling and “Environmental, Social and Economic Impacts of Biofuel

Applications. Cambridge: Cambridge University Press. Production in Canada.” At http://www.oag-bvg.gc.ca/

Hirtzner, M., and J. Renshaw. 2017. “DuPont to Sell Cellulosic internet/English/pet_205_e_28941.html.

Ethanol Plant in Blow to Biofuel.” Reuters, 2 November. Organisation for Economic Co-operation and

At https://www.reuters.com/article/us-dowdupont Development (OECD). 2010. “Agricultural Policies

ethanol/dupont-to-sell-cellulosic-ethanol-plant-in-blow and Rural Development—A Synthesis of Recent OECD

to-biofuel-idUSKBN1D22T5. Work.” Paris: OECD. At https://www.oecd.org/

Huang, H., S. Ramaswamy, W. Al-Dajani, U. Tschirner, and agriculture/44561502.pdf.

R. Cairncross. 2009. “Effect of Biomass Species and Plant Poet-DSM. 2014. “First Commercial-Scale Cellulosic Ethanol

Canadian Public Policy 2018.44:259-271.

Size on Cellulosic Ethanol: A Comparative Process and Plant in the U.S. Opens for Business.” At http://poet-dsm.

Economic Analysis.” Biomass and Bioenergy 33(2):234–46. com/pr/first-commercial-scale-cellulosic-plant.

https://doi.org/10.1016/j.biombioe.2008.05.007. Sapp, M. 2017. “Abengoa Bioenergia’s Brazilian Arm Files for

Jassala, R.S., T.A. Black, C. Arevalo, H. Jones, J.S. Bhatti, and Bankruptcy Protection.” Biofuels Digest, September 26. At

D. Sidders. 2013. “Carbon Sequestration and Water Use https://www.biofuelsdigest.com/bdigest/2017/09/26/

of a Young Hybrid poplar plantation in north-central abengoa-bioenergias-brazilian-arm-files-for-bankruptcy

Alberta.” Biomass and Bioenergy 56:323–33. https://doi. protection/.

org/10.1016/j.biombioe.2013.05.023. Searchinger, T., R. Heimlich, R.A. Houghton, F. Dong, A.

Laan T., T. Litman, and R. Steenblik. 2009. “Biofuels—At What Elobeid, J. Fabiosa, S. Tokgoz, D. Hayes, and T. Yu. 2008.

Cost? Government Support for Ethanol and Biodiesel “Use of U.S. Croplands for Biofuels Increases Greenhouse

in Canada.” Winnipeg, MB: International Institute for Gases through Emissions from Land-Use Change.”

Sustainable Development. At https://www.iisd.org/ Science 319(5867):1238–40. https://doi.org/10.1126/

pdf/2009/biofuels_subsidies_canada.pdf. science.1151861.

Lapan, H., and G. Moschini. 2012. “Second-Best Biofuel Sims, R., W. Mabee, J. Saddler, and M. Taylor. 2010. “An

Policies and the Welfare Effects of Quantity Mandates Overview of Second-Generation Biofuels Technologies.”

and Subsidies.” Journal of Environmental Economics and Bioresource Technology 101(6):1570–80. https://doi.

Management 63(2):224–41. https://doi.org/10.1016/j. org/10.1016/j.biortech.2009.11.046.

jeem.2011.10.001. Stephen, J., W. Mabee, and J. Saddler. 2012. “Will Second-

Leach, A., J. Doucet, and T. Nickel. 2011. “Renewable Fuels: Generation Ethanol Be Able to Compete with First-

Policy Effectiveness and Project Risk.” Energy Policy Generation Ethanol? Opportunities for Cost Reduction.”

39(7):4007–15. https://doi.org/10.1016/j.enpol.2011. Biofuels, Bioproducts & Biorefining 6(2):159–76. https://doi.

02.020. org/10.1002/bbb.331.

Lee, H., T.W. Hertel, B. Sohngen, and N. Ramankutty. 2005. Taheripour, F., W. Tyner, and M. Wang. 2011. “Global Land

Towards an Integrated Land Use Data Base for Assessing Use Changes due to the U.S. Cellulosic Biofuel Program

the Potential for Greenhouse Gas Mitigation. Global Trade Simulated with the GTAP Model.” Paper presented at the

Analysis Paper No. 25, Purdue University, West Lafayette, 14th Annual Conference on Global Economic Analysis.

Indiana. At https://docs.lib.purdue.edu/gtaptp/26/. Pittsburgh, PA; 24–26 July. At https://econpapers.repec.

Markings, S. 2017. “The Disadvantages of Cellulose Biofuel.” org/paper/agsaaea11/103559.htm.

At https://sciencing.com/disadvantages-cellulose Tilman, D., R. Socolow, J.A. Foley, J. Hill, E. Larson, L. Lynd,

biofuel-5906.html. S. Pacala, J. Reilly, T. Searchinger, C. Somerville, et al. 2009.

Maung, T., C. Gustafson, B. McCarl, D. Ripplinger, and D. “Beneficial Biofuels—The Food, Energy, and Environment

Saxowsky. 2013. “Economics of Biomass Feedstocks Trilemma.” Science 325(5938):270–71. https://doi.org/

and Biofuels.” In Biofuel Crop Sustainability, ed. B.P. 10.1126/science.1177970.

Singh, 402–27. Oxford, UK: Wiley; https://doi. Timilsina, G.R., S. Csordas, and S. Mavel. 2011. “When Does a

org/10.1002/9781118635797.ch13. Carbon Tax on Fossil Fuels Stimulate Biofuels?” Ecological

doi:10.3138/cpp.2017-047 © Canadian Public Policy / Analyse de politiques, September / septembre 2018

270 Campbell et al.

Economics 70(12):2400–15. https://doi.org/10.1016/j. “U.S. Ethanol Plants.” 2017. Ethanol Producer Magazine. At

ecolecon.2011.07.022. http://ethanolproducer.com/plants/listplants/US/

US Department of Agriculture (USDA), Foreign Agriculture Operational/All/page:1/sort:platform/direction:asc.

Service. 2016. Canada—Biofuels Annual—2016. GAIN Wright, M., and R. Brown. 2007a. “Comparative Economics

Report No. CA16038. Washington, DC: USDA Foreign of Biorefineries Based on the Biochemical and

Agricultural Service. At https://gain.fas.usda.gov/ Thermochemical Platforms.” Biofuels, Bioproducts &

Recent%20GAIN%20Publications/Biofuels%20Annual_ Biorefining 1(1):49–56. https://doi.org/10.1002/bbb.8.

Ottawa_Canada_8-9-2016.pdf. Wright, M., and R. Brown. 2007b. “Establishing the Optimal

US Department of Agriculture (USDA), National Agricultural Sizes of Different Kinds of Biorefineries.” Biofuels,

Statistics Service. 2017. “Farms and Land in Farms 2016 Bioproducts & Biorefining 1(3):191–200. https://doi.org/

Summary.” Washington, DC: USDA National Agricultural 10.1002/bbb.25.

Statistics Service.

Canadian Public Policy 2018.44:259-271.

© Canadian Public Policy / Analyse de politiques, September / septembre 2018 doi:10.3138/cpp.2017-047

Prospects for Second-Generation Ethanol in Canada:An Analysis of Economy-Wide Impacts 271

Appendix

Table A.1: Summary of Canadian Ethanol Support

Jurisdiction Duration Program Amount

Provinces Mid-1990s–present Excise tax exemption Time periods vary by province and exemptions vary

from $0.09/L–$0.25/L.

Alberta 2007–2011 Biorefining Commercialization and Grants ($54 million) to support renewable bioenergy

Market Development Program, Bioenergy projects.

Infrastructure Development Program

2007–2016 Bioenergy Producer Credit Program Between 2007 and 2011, $38 million was disbursed to

bioenergy producers.

British Columbia Mid-1990s–2010 Excise tax exemption $0.145/L.

Federal 1992–2008 Excise tax exemption $0.085/L to $0.10/L.

2003–2007 Ethanol Expansion Program 7-year interest-free loans for plant construction

or expansion. Estimated subsidy value of

$2.5–$11.4 million/year.

2006–2008 Biofuels Opportunities for Producers Funding for business plan creation.Total subsidy value

Initiative of $10 million.

2007–2012 ecoAgriculture Biofuels Capital Repayable loans for building or expansion of biofuel

plants. Estimated subsidy value of $2.3–$12.3 million

per year.

2008–2017 ecoENERGY for Biofuels Program Available to any existing or proposed renewable fuel

Canadian Public Policy 2018.44:259-271.

producers who applied by 31 March 2010; $0.08/L for

2011–2012 (declining rate over life of the program).

Total of $1 billion available.

Manitoba 2008–2015 Ethanol Fund Grant Regulation Available for licensed ethanol producers in Manitoba;

$0.15/L (declining rate over life of the program).

Ontario 2007–2017 Ontario Ethanol Growth Fund Subsidy amount depends on the market price of

ethanol, corn, and crude oil; maximum of $0.11/L;

maximum of $0.10/L capital grant.Total of

$520 million available for the program.

a

Excise tax exemptions were available in Alberta, British Columbia, Manitoba, Ontario, and Quebec.

Source: Adapted from Campbell et al. (2016).

doi:10.3138/cpp.2017-047 © Canadian Public Policy / Analyse de politiques, September / septembre 2018

Vous aimerez peut-être aussi

- EthanolDocument47 pagesEthanolLe SaodienPas encore d'évaluation

- Chapitre1555-Alcanes AlcoolsDocument6 pagesChapitre1555-Alcanes AlcoolsHassan HAMKAPas encore d'évaluation

- AlcootestDocument6 pagesAlcootestAlamine DieyePas encore d'évaluation

- ترموديناميكDocument23 pagesترموديناميكFati TiimochaPas encore d'évaluation

- Modèle de Calcul de PatenteDocument6 pagesModèle de Calcul de PatenteChiara TindoPas encore d'évaluation

- Spub 137 0107Document9 pagesSpub 137 0107Henrimup100% (1)

- Questionnaire Audit FRDocument3 pagesQuestionnaire Audit FRSamy AkesbiPas encore d'évaluation