Académique Documents

Professionnel Documents

Culture Documents

Seal Gas Flow

Transféré par

oluwasolDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Seal Gas Flow

Transféré par

oluwasolDroits d'auteur :

Formats disponibles

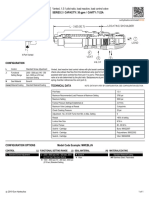

AMPLIFLOW

Flow Solutions Division

Contamination Prevention

for Dry Gas Sealing Systems

Flowserve’s AMPLIFLOW™ was developed to eliminate process

contamination, the number one cause of dry gas seal failures. The

AMPLIFLOW™ ensures the supply of clean filtered gas to the seals

by boosting supply gas pressure during periods of low compressor

pressure differential.

Configurations

Portable unit

Stand-alone panel

Integrated with Revolve dry gas seal

control panel

Integrated with Revolve Pre-filter panel

Possible Periods Pressure Gauge

of Low Differential

Volume Bottle

Pressure Pressurized Supply Gas 3.0 Liter

Start-up Drive Air Out

Idle

Recycle

Process sequence

Filtered Compressor

Discharge Gas

Shut-down Solenoid Valve

Pressure Gauge Pressure Control

Cool-down Valve

Slow-roll Filtered Drive Air In

Operating

Process Gas Boost

AMPLIFLOW™ provides a boost in gas pressure Characteristics

equal to 1.5 times the drive gas pressure (e.g., if air

is provided at 100 psig, the resultant seal supply

Figure 1: Drive Gas Consuption Versus

gas pressure boost is 150 psig).

Output Pressure

60

Drive Gas Consumption

Drive Gas (Air) Consumption (SCFM)

Figure 1 illustrates the drive gas consumption for

50

AMPLIFLOW™ to provide 70 SCFM of gas flow to

the seal, for various seal gas supply pressures.

40

Seal Gas Supply Flowrate 30

Figure 2 illustrates seal supply gas flow with and

without the use of AMPLIFLOW™. This graph is 20

300 600 900 1200 1500

for a natural gas transmission compressor with

Process Output Pressure (psig)

suction pressure of 700 psig and discharge

pressure of 880 psig.

Figure 2: Seal Gas Supply Flow Rate

120

Design Specifications

1. Pressurization

100

Flowrate Per Seal (SCFM)

Standard AMPLIFLOW™

Maximum Pressure: 1800 psig 80

2. Idle Warm-up

Maximum Flow Rate: 2.9 ACFM

60

Maximum Drive Gas

40

Consumption: 5.2 ACFM

Design Temperature: 300°F 20

3. Ramp-Up

Higher design pressures are also available.

0

0 10 20 30 40 50

Time (Min.) With AMPLIFLOW™

Without AMPLIFLOW™

Flowserve’s 50K Plus™ Program

50k Plus™ is a program designed to help ensure dry gas seal reliability in excess of

50,000 hours. Flowserve works with customers to minimize risks that contribute to

Flowserve FSD Corporation

seal failures by reviewing the entire system and operation. Compressor Seal Group

2100 Factory Street

Kalamazoo, MI 49001-4163

Phone: (1) 616-226-3400

Rev 09/00 USA FAX: (1) 616-226-3404 FSD160

Vous aimerez peut-être aussi

- Compressor ManturboDocument6 pagesCompressor ManturboSubhasish MitraPas encore d'évaluation

- Turboexpanders: CompressorsDocument4 pagesTurboexpanders: Compressorsdhanu_aquaPas encore d'évaluation

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsD'EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahPas encore d'évaluation

- DGS FailuresDocument37 pagesDGS FailuresAditya Shiva Appalla100% (2)

- Kaydon Dry Gas SealDocument12 pagesKaydon Dry Gas Sealxsi666Pas encore d'évaluation

- Dry Gas Seals SiemensDocument11 pagesDry Gas Seals Siemensahbabar808Pas encore d'évaluation

- Lubrication and Seal Oil Systems - Common Problems and Practical SolutionsDocument14 pagesLubrication and Seal Oil Systems - Common Problems and Practical SolutionsCALLESJPas encore d'évaluation

- Mhi Integrally Geared CompressorsDocument6 pagesMhi Integrally Geared CompressorscandharePas encore d'évaluation

- Gas SealsDocument38 pagesGas SealskbogeshwaranPas encore d'évaluation

- Dry Gas Seal ContaminationDocument1 pageDry Gas Seal Contaminationuak107080100% (1)

- John Crane Gas Seals: Gas Seals and Their Application For Maximum ReliabilityDocument41 pagesJohn Crane Gas Seals: Gas Seals and Their Application For Maximum ReliabilityDoctorObermanPas encore d'évaluation

- Trouble Shooting&SolutionsDocument21 pagesTrouble Shooting&SolutionsBaran ShafqatPas encore d'évaluation

- Dry SealDocument5 pagesDry SealGGUNAPas encore d'évaluation

- Dry Gas Seal ElliotDocument2 pagesDry Gas Seal ElliotFATHYPas encore d'évaluation

- Centrifugal Compressors MAN-GEDocument20 pagesCentrifugal Compressors MAN-GEIbc Cbs Ibc CbsPas encore d'évaluation

- R&P Material DetailsDocument20 pagesR&P Material DetailsinamPas encore d'évaluation

- Compressor Dry Gas SealsDocument12 pagesCompressor Dry Gas SealsRajeev Domble100% (3)

- The Consequences of Compressor Operation in Overload: by James M. SorokesDocument10 pagesThe Consequences of Compressor Operation in Overload: by James M. SorokesEdy AlamPas encore d'évaluation

- Choke - Surge - Anty-Surge - Stall: Nuovo PignoneDocument31 pagesChoke - Surge - Anty-Surge - Stall: Nuovo Pignoneadam yassine100% (2)

- Dry Gas Seal System ManualDocument44 pagesDry Gas Seal System ManualGeorge J AlukkalPas encore d'évaluation

- Seal Gas BoosterDocument2 pagesSeal Gas BoosterMatthieuPas encore d'évaluation

- Estudos de Casos - Revamps & Upgrades HOERBIGERDocument11 pagesEstudos de Casos - Revamps & Upgrades HOERBIGERJosePas encore d'évaluation

- Hoerbiger Oil Wiper PackingDocument4 pagesHoerbiger Oil Wiper PackingsaravananknpcPas encore d'évaluation

- Steam Amonia TurbineDocument21 pagesSteam Amonia TurbineLuis Alexandre MachadoPas encore d'évaluation

- Dry Gas Versus Wet Gas Compressor Seals PDFDocument5 pagesDry Gas Versus Wet Gas Compressor Seals PDFMANSIPas encore d'évaluation

- Article On Dry Gas Seals PDFDocument7 pagesArticle On Dry Gas Seals PDFanoopthazhath100% (1)

- Reciprocating CompressorsDocument5 pagesReciprocating CompressorsthirumalaiPas encore d'évaluation

- 6 Konitzer2Document32 pages6 Konitzer2mchramziPas encore d'évaluation

- T13151-176 Api 614 PDFDocument26 pagesT13151-176 Api 614 PDFpietroPas encore d'évaluation

- 5-DRY Dry Seal2Document45 pages5-DRY Dry Seal2Dang XmanPas encore d'évaluation

- TurboExpander ProcessDocument18 pagesTurboExpander ProcessdndudcPas encore d'évaluation

- Centrifugal Compressor System InteractionDocument6 pagesCentrifugal Compressor System Interactionshivajireturns100% (1)

- Centrifugal Compressors: Petroskills CourseDocument23 pagesCentrifugal Compressors: Petroskills CoursedeepikaPas encore d'évaluation

- Ge Dry Gas Seal RetrofitDocument4 pagesGe Dry Gas Seal RetrofitlubangjarumPas encore d'évaluation

- Article On Reciprocating CompressorDocument5 pagesArticle On Reciprocating CompressorKeith Contreras100% (2)

- Valves Overview Service enDocument12 pagesValves Overview Service enBalraj PadmashaliPas encore d'évaluation

- Case 52 Problems With A Blocked-In Centrifugal PumpDocument2 pagesCase 52 Problems With A Blocked-In Centrifugal Pumphwang2Pas encore d'évaluation

- Type PR Online Assurance Program: Success StoryDocument2 pagesType PR Online Assurance Program: Success Storyvarun sharmaPas encore d'évaluation

- Vacuum Condenser Drainage - Proper Design & Installation GuideDocument3 pagesVacuum Condenser Drainage - Proper Design & Installation Guidenirmal_subudhiPas encore d'évaluation

- Hydroseal Relief Valve Threaded High CapacityDocument4 pagesHydroseal Relief Valve Threaded High Capacitytxlucky80Pas encore d'évaluation

- Dry Gas Seal1Document8 pagesDry Gas Seal1anshug1016100% (1)

- 002 - Reciprocating CompressorDocument16 pages002 - Reciprocating CompressorMuhammad TariqPas encore d'évaluation

- DGS NewDocument20 pagesDGS NewKanishk KothariPas encore d'évaluation

- Hydrocarbon Turbo ExpandersDocument20 pagesHydrocarbon Turbo ExpandersPakde NdokPas encore d'évaluation

- Compressor Tech 12 2014Document68 pagesCompressor Tech 12 2014Tiffany Johnson100% (1)

- Dry Gas Seal DesignDocument26 pagesDry Gas Seal DesignCALLESJ100% (1)

- Troubleshooting Centrifugal Gas Compressor Shaft Oil SealsDocument33 pagesTroubleshooting Centrifugal Gas Compressor Shaft Oil SealsMuhammad afzal100% (1)

- JOhnCrane Dry Gas Seal Pumps PF - 2874Document2 pagesJOhnCrane Dry Gas Seal Pumps PF - 2874Mohammed Al-BrashdiPas encore d'évaluation

- PIL140 Dry Gas Face Seals Rev 12aDocument13 pagesPIL140 Dry Gas Face Seals Rev 12ampiumettiPas encore d'évaluation

- GG 01 01 2017 26Document5 pagesGG 01 01 2017 26Shaban RabiePas encore d'évaluation

- Dry Gas Seal System StandarDocument8 pagesDry Gas Seal System StandarRonny AjaPas encore d'évaluation

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationD'EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationPas encore d'évaluation

- Phase Equilibria: Basic Principles, Applications, Experimental TechniquesD'EverandPhase Equilibria: Basic Principles, Applications, Experimental TechniquesPas encore d'évaluation

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineD'EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineÉvaluation : 5 sur 5 étoiles5/5 (1)

- Hose Pressure Test Pump (Air-Powered) : Part No DC27530Document2 pagesHose Pressure Test Pump (Air-Powered) : Part No DC27530omernoumanPas encore d'évaluation

- CompressorDocument6 pagesCompressorAbdul MalikPas encore d'évaluation

- Compressed Air System: MLN Block 405, Algeria Operator TrainingDocument6 pagesCompressed Air System: MLN Block 405, Algeria Operator TrainingGUESSOUMAPas encore d'évaluation

- Mooney Flowgrid Brochure 8-12 FDocument8 pagesMooney Flowgrid Brochure 8-12 FmiltonPas encore d'évaluation

- CPE 75 150 CPVS 100 150 Instruction Manual 6230579365Document24 pagesCPE 75 150 CPVS 100 150 Instruction Manual 6230579365CPP EI DSpPas encore d'évaluation

- HVACR 10 Module 1 (FINAL)Document56 pagesHVACR 10 Module 1 (FINAL)Homer R. MagistradoPas encore d'évaluation

- Argohytoslr PDFDocument874 pagesArgohytoslr PDFdonnyPas encore d'évaluation

- Sabz QT For Piston SealDocument2 pagesSabz QT For Piston SealAsim IbrahimPas encore d'évaluation

- 5 - Southern Cross - Iso Pump - 65 X 50 - 160 - 1410-2890 RPMDocument1 page5 - Southern Cross - Iso Pump - 65 X 50 - 160 - 1410-2890 RPMBryan ChaiPas encore d'évaluation

- TablessssDocument6 pagesTablessssEVA BUENAFEPas encore d'évaluation

- Pages From Design of Fluid Systems-Hook-Ups, Spirax Sarco 4Document1 pagePages From Design of Fluid Systems-Hook-Ups, Spirax Sarco 4Ujwal KhandokarPas encore d'évaluation

- 3 Valvula Modular Serie 01Document42 pages3 Valvula Modular Serie 01Leandro AguiarPas encore d'évaluation

- 0743674-2 6 PDFDocument11 pages0743674-2 6 PDFAlexandru AlexPas encore d'évaluation

- 14 Air Condition Inicial A320 Alfa SCDocument85 pages14 Air Condition Inicial A320 Alfa SCPiloto TrujillanoPas encore d'évaluation

- 295-5490 Filter Cart Group (Continued) Essential Tool: Model: Diesel Fuel Engines Warranty: Six MonthsDocument2 pages295-5490 Filter Cart Group (Continued) Essential Tool: Model: Diesel Fuel Engines Warranty: Six Monthsricardo manriquezPas encore d'évaluation

- FMM - Unit V QBDocument51 pagesFMM - Unit V QBThiruvasagamoorthy Ka0% (1)

- Hydraulic Oil Iso VG 46Document1 pageHydraulic Oil Iso VG 46KarthikeyanPas encore d'évaluation

- Technical Documentation Engine Spare Parts CatalogueDocument337 pagesTechnical Documentation Engine Spare Parts CatalogueHakan BalcıPas encore d'évaluation

- Non-Dimensional Aerodynamic Design of A Centrifugal Compressor ImpellerDocument12 pagesNon-Dimensional Aerodynamic Design of A Centrifugal Compressor ImpellerSubhash PadmanabhanPas encore d'évaluation

- Valve Sizing: Cepde AssignmentDocument15 pagesValve Sizing: Cepde AssignmentVRUSHABHPas encore d'évaluation

- Ayvaz Rubber Expansion JointsDocument5 pagesAyvaz Rubber Expansion JointsThanhPas encore d'évaluation

- BE 2019 TurbomachinaryDocument5 pagesBE 2019 TurbomachinarySuyash Shinde.Pas encore d'évaluation

- NTT Data JKT3 Delivery (At Site) 20200602.REV.7Document1 pageNTT Data JKT3 Delivery (At Site) 20200602.REV.7agung sudarsonoPas encore d'évaluation

- CPP Schematic Diagram Duplex Complete 9 Jan 2019Document1 pageCPP Schematic Diagram Duplex Complete 9 Jan 2019BdSulianoPas encore d'évaluation

- High Performance Fieros Turbocharger Compressor CalculatorDocument4 pagesHigh Performance Fieros Turbocharger Compressor Calculatorjameel babooramPas encore d'évaluation

- Hydraulic SystemDocument29 pagesHydraulic SystemCaliche Guerra100% (1)

- Sun Hydraulics MWEB-LJN Technical SpecificationsDocument1 pageSun Hydraulics MWEB-LJN Technical SpecificationsJustinPas encore d'évaluation

- Types of SeparatorsDocument9 pagesTypes of Separatorsvijayi dhansarPas encore d'évaluation

- ExcelDocument65 pagesExcelrendalop ujtaPas encore d'évaluation

- Ejercicios AliviosDocument20 pagesEjercicios AliviosPaola ChavezPas encore d'évaluation

- Chapter 7: Hydraulic Machines (Pumps)Document6 pagesChapter 7: Hydraulic Machines (Pumps)Syahid MuhammadPas encore d'évaluation

- Desc 1569254035000 1026809Document5 pagesDesc 1569254035000 1026809jose GilPas encore d'évaluation

- Man B&W: Relief ValveDocument15 pagesMan B&W: Relief ValveRobert LuuPas encore d'évaluation

- 950 GC Main Controle ValveDocument23 pages950 GC Main Controle ValveAbdellahPas encore d'évaluation

- BS 6759-Part 3 Safety ValvesDocument49 pagesBS 6759-Part 3 Safety ValvesPrafulla SupekarPas encore d'évaluation