Académique Documents

Professionnel Documents

Culture Documents

NOVEC 1230 Total Flooding System EGEC Calculations Sheet

NOVEC 1230 Total Flooding System EGEC Calculations Sheet

Transféré par

Abdulqader MousaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

NOVEC 1230 Total Flooding System EGEC Calculations Sheet

NOVEC 1230 Total Flooding System EGEC Calculations Sheet

Transféré par

Abdulqader MousaDroits d'auteur :

Formats disponibles

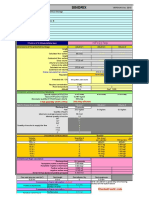

Computed By: Eng. H.

S

Project:

Checked By: Eng. M. Gamal

Date: Approved By: Dr. H. Soliman

NOVEC 1230 Total Flooding System Calculations

Hazard Area No.1

Protected Hazard Dimensions

Name of Protected Hazard Area Tel

Height 3.0 m

Area 100.0 m2 1076.4 ft2

Volume 300 m3

Volume of Fixed Structures

0.0 m3

Impervious to Agent vapor

Design Parameters

Class of Hazard Area A

Net Volume of Hazard Area 300.0 m3

Design Temperature in Hazard Area 20 C

o

Agent Specific Volume @ 1 Atm. pressure 0.072 m3/kg

Minimum Design Concentration 4.2 % per volume

Agent Design Concentration 5.4 % per volume

Tee Count of Piping System 6.0

Hazard Area Pressure 1.0 atm

Design Safety Factor 0.02

System Sizing ّ

Agent Net Capacity 243.0 kg 535.7 Ibs

Agent Net Capacity Percentage 67 % Accepted

Total Agent Flow Rate 24.3 kg/sec 53.6 Ibs/sec

Required No. of discharge Nozzels 3

Acual Flow per Nozzel 8.1 kg/sec 17.9 Ibs/sec

Nozzel and Branch Pipe Diameters 1 1/2 inch

Main Pipe Diameter 2 1/2 inch 3

Computed By: Eng. H.S

Project:

Checked By: Eng. M. Gamal

Date: Approved By: Dr. H. Soliman

Hazard Area No.2

Protected Hazard Dimensions

Name of Protected Hazard Area elect

Height 3.0 m

Area 50.0 m2 538.2 ft2

Volume 150 m3

Volume of Fixed Structures

0.0 m3

Impervious to Agent vapor

Design Parameters

Class of Hazard Area C

Net Volume of Hazard Area 150.0 m3

Design Temperature in Hazard Area 20 C

o

Agent Specific Volume @ 1 Atm. pressure 0.072 m3/kg

Minimum Design Concentration 4.2 % per volume

Agent Design Concentration 5.4 % per volume

Tee Count of Piping System 6.0

Hazard Area Pressure 1.0 atm

Design Safety Factor 0.02

System Sizing ّ

Agent Net Capacity 121.5 kg 267.8 Ibs

Agent Net Capacity Percentage 33 % Accepted

Total Agent Flow Rate 12.1 kg/sec 26.8 Ibs/sec

Required No. of discharge Nozzels 2

Acual Flow per Nozzel 6.1 kg/sec 13.4 Ibs/sec

Nozzel and Branch Pipe Diameters 1 1/2 inch

Main Pipe Diameter 2 inch 2 1/2

Computed By: Eng. H.S

Project:

Checked By: Eng. M. Gamal

Date: Approved By: Dr. H. Soliman

Combined System Sizing

Agent Total Net Capacity 364.5 kg 803.5 Ibs

Container Size Minimum Fill

Container Size Selection 900 Ib ###Ibs

455

Total Required No. of Containers 1

Agent Net Capacity in Each Container 364.5 kg

803.5 Ibs Accepted

Total Agent Flow Rate 36.4 kg/sec 80.4 Ibs/sec

Maximum Agent Flow Rate per Nozzel 9.07 kg/sec 20 Ibs/sec

Total Required No. of discharge Nozzels 5 Accepted

System Main Pipe Diameter 3 inch 3

Checking Agent Concentration in a Combind Space with Directional Valve

Name of Protected Hazard Area Tel

Height 3.0 m

Area 200.0 m2 2152.8 ft2

Volume 600 m3

Volume of Fixed Structures

0.0 m3

Impervious to Agent vapor

Design Parameters

Class of Hazard Area B

Minimum Design Concentration 4.2 % per volume

Net Volume of Hazard Area 600.0 m3

Design Temperature in Hazard Area 27 C

o

Agent Specific Volume @ 1 Atm. pressure 0.074 m3/kg

Tee Count of Piping System 6.0

Hazard Area Pressure 1.0 atm

Design Safety Factor 0.02

Agent Design Concentration 4.2 % Accepted

Computed By: Eng. H.S

Project:

Checked By: Eng. M. Gamal

Date: Approved By: Dr. H. Soliman

General Design Considerations

- Max. No. of Nozzels in the System 20

- Maximum Agent Flow Rate per Nozzel 9.07 kg/sec 20 Ibs/sec

- Maximum Discharge Time 10 sec

- Nozzel Maximum Coverage Radius 8.70 m 360o Nozzel Type

10.90 180o Nozzel Type

- Min. Nozzel Pressure 73 psi

- Maximum Ceiling Height 4.87 m

- Nozzel Max. Distance from Ceiling 0.30 m

- False Ceiling or Raised Floor Min. Height 0.30 m

- Space Min. agent percentage in combind system 10 %

- Beams that are less than 0.3 m below the slab need not be considered. Obstructions greater than 300 mm

(12”) can affect the distribution of agent and may require additional nozzles.

- The max. elevation difference between the container outlet and the furthest horizontal pipe run or

discharge nozzle (whichever is furthest) shall not exceed 9.1 m.

- The max. elevation difference between the furthest horizontal pipe runs or discharge nozzles (whichever is

furthest) shall not exceed 9.1 m.

- The agent design concentration shall be checked to insure that it is under NOAEL at maximum anticipated

temperature in the hazard space.

- Sizing is based on NFPA-2001

Vous aimerez peut-être aussi

- Hassantuk Wireless Fire Alarm System - V1.0Document13 pagesHassantuk Wireless Fire Alarm System - V1.0krishnakumarPas encore d'évaluation

- NOVEC 1230 Total Flooding System - EGEC Calculations SheetDocument14 pagesNOVEC 1230 Total Flooding System - EGEC Calculations SheetDesigner Forever100% (2)

- SEQUENCE OF OPERATION FOR NOVEC r1Document2 pagesSEQUENCE OF OPERATION FOR NOVEC r1Ahmed Sweet100% (1)

- Redbook Vol1part1 LPCBDocument755 pagesRedbook Vol1part1 LPCBvbgiri0% (1)

- Acuv SDocument32 pagesAcuv Sanoopkumar1231150Pas encore d'évaluation

- Typical Medical Equip Heat GainDocument1 pageTypical Medical Equip Heat GainMostafa AlaahobaPas encore d'évaluation

- Notifier Fire Alarm Battery CalculationDocument1 pageNotifier Fire Alarm Battery CalculationecodianPas encore d'évaluation

- Staircase Pressurisation Calculation Rev-04Document36 pagesStaircase Pressurisation Calculation Rev-04Anish KumarPas encore d'évaluation

- FlowCon Catalogue 06.2013Document214 pagesFlowCon Catalogue 06.2013steventcchanPas encore d'évaluation

- System Design: Total Flooding Extinguishing SystemDocument45 pagesSystem Design: Total Flooding Extinguishing SystemsureshkanuboyinaPas encore d'évaluation

- Chiller Diversity FactorDocument3 pagesChiller Diversity FactoraadsamudPas encore d'évaluation

- Stair Pressurization - Allied ConsultantDocument4 pagesStair Pressurization - Allied ConsultantTiefSeePas encore d'évaluation

- Atrium Natural Smoke CalculationsDocument5 pagesAtrium Natural Smoke CalculationsRamiAl-fuqahaPas encore d'évaluation

- Ventilation Calculation UpdatedDocument1 pageVentilation Calculation Updatedbahaa ShehadehPas encore d'évaluation

- Corridor Pressurization Calculation 20170310Document1 pageCorridor Pressurization Calculation 20170310wow proPas encore d'évaluation

- Condensate TrapsDocument3 pagesCondensate Trapsalamdar321Pas encore d'évaluation

- Stair Pressurization CalculationDocument2 pagesStair Pressurization Calculationnaruto256100% (1)

- Fire Fighting Presentation Ali Hassan-Compressed-Pages-71-140Document70 pagesFire Fighting Presentation Ali Hassan-Compressed-Pages-71-140Crypto India100% (1)

- Fire Protection by Water Mist Systems: The View of Vds Vds 3188 Guideline For Planning and InstallationDocument20 pagesFire Protection by Water Mist Systems: The View of Vds Vds 3188 Guideline For Planning and InstallationGanpati techPas encore d'évaluation

- Integration - H VAC Fans and Smoke Control - Control EngineeringDocument5 pagesIntegration - H VAC Fans and Smoke Control - Control EngineeringMohamedAhmedFawzyPas encore d'évaluation

- Novec 1230 All CalculationsDocument5 pagesNovec 1230 All CalculationsKhyle Laurenz DuroPas encore d'évaluation

- System Design: Total Flooding Extinguishing SystemDocument45 pagesSystem Design: Total Flooding Extinguishing SystemJose Antonio LaraPas encore d'évaluation

- SPF Stair Case FanDocument2 pagesSPF Stair Case FanAla ShakerPas encore d'évaluation

- Pump Room Submersible Pumps CalcDocument1 pagePump Room Submersible Pumps CalcMohamed Adel ElBazPas encore d'évaluation

- Fire Engineering Approach PDFDocument36 pagesFire Engineering Approach PDFdescslamPas encore d'évaluation

- Flow Tech Louvers PDFDocument10 pagesFlow Tech Louvers PDFMoriyasuNguyenPas encore d'évaluation

- Superlon Technical SpecificationDocument8 pagesSuperlon Technical SpecificationSam Wing HongPas encore d'évaluation

- Guideline For TSP FM200 Systems Rev8Document12 pagesGuideline For TSP FM200 Systems Rev8binhhnPas encore d'évaluation

- DY - Series Zamil Duct SplitDocument23 pagesDY - Series Zamil Duct SplitAnwar SyedPas encore d'évaluation

- Staircase Pressurization Calculation SheetDocument4 pagesStaircase Pressurization Calculation SheetTariq AsgharPas encore d'évaluation

- VAV BrochureDocument28 pagesVAV BrochureMuralidharan SudhakarPas encore d'évaluation

- Novec 1230 DesignDocument8 pagesNovec 1230 Designnandeesh100% (1)

- N2 Generator CalculationDocument9 pagesN2 Generator CalculationBagus PrambudiPas encore d'évaluation

- Guideline For TSP FM200 Systems Rev6 PDFDocument13 pagesGuideline For TSP FM200 Systems Rev6 PDFeng_alaa1977100% (1)

- Pressure Drop Calculation Combined Steel and Mesonery Duct PDFDocument3 pagesPressure Drop Calculation Combined Steel and Mesonery Duct PDFsmcsamindaPas encore d'évaluation

- Foam CalculationsDocument8 pagesFoam CalculationsdheerajdorlikarPas encore d'évaluation

- Balancing Air Flow W FireSmoke DampersDocument3 pagesBalancing Air Flow W FireSmoke DampersNg KhanhPas encore d'évaluation

- The Sterling - Fire Protection System Contract 2016 PDFDocument7 pagesThe Sterling - Fire Protection System Contract 2016 PDFEr Dharmadurai RPas encore d'évaluation

- Grease Duct ManualDocument4 pagesGrease Duct Manualsaifi2004Pas encore d'évaluation

- Calculation Sheet: Oil Interceptor SizingDocument4 pagesCalculation Sheet: Oil Interceptor Sizingcoolth2Pas encore d'évaluation

- A Method of Damper Control For Corridor Ventilation and Smoke ExtractionDocument15 pagesA Method of Damper Control For Corridor Ventilation and Smoke ExtractionrasheedillikkalPas encore d'évaluation

- Nuaire Commercial Useful InfoDocument10 pagesNuaire Commercial Useful InfoYaser AkarPas encore d'évaluation

- Design Fire Fighting Systems CO2 CalculationDocument3 pagesDesign Fire Fighting Systems CO2 Calculationantonalmeida100% (1)

- Design Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionDocument1 pageDesign Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionpsjjoshiPas encore d'évaluation

- Solar Heaters DM FormatDocument1 pageSolar Heaters DM Formatanas shehabiPas encore d'évaluation

- QCDD BP GuidelinesDocument6 pagesQCDD BP Guidelines남광연0% (1)

- Mechanical CommentsDocument6 pagesMechanical Commentspsn_kylmPas encore d'évaluation

- Smoke Mang HonywellDocument12 pagesSmoke Mang HonywellyasserismailPas encore d'évaluation

- Meyerfire - Hydraulic Calculation Tipsheet February 2021Document1 pageMeyerfire - Hydraulic Calculation Tipsheet February 2021Eugene BeangkePas encore d'évaluation

- Tyco - Ultra Low Flow Aquamist AM30Document2 pagesTyco - Ultra Low Flow Aquamist AM30cosmynns100% (1)

- Sustainability & Smoke ControlDocument11 pagesSustainability & Smoke ControlmpwasaPas encore d'évaluation

- Fahu CalculationDocument1 pageFahu CalculationArul SankaranPas encore d'évaluation

- ESP CAlDocument1 pageESP CAlMohammed Sayeem ShabuddinPas encore d'évaluation

- Bill of Quantities & Schedule For Fire Detection, Fire Protection & Security SystemDocument15 pagesBill of Quantities & Schedule For Fire Detection, Fire Protection & Security SystemMd. Mominul IslamPas encore d'évaluation

- Volume 1 Fire Protection Systems Testing and Commissioning ProceduresDocument7 pagesVolume 1 Fire Protection Systems Testing and Commissioning ProceduresAbdalrahman AntariPas encore d'évaluation

- Monitoring RoomDocument8 pagesMonitoring RoomMohammed TalebPas encore d'évaluation

- Archive Room2Document8 pagesArchive Room2Mohammed TalebPas encore d'évaluation

- One Dimensional Consolidation Properties: (Oedometer)Document2 pagesOne Dimensional Consolidation Properties: (Oedometer)Siti MaimunahPas encore d'évaluation

- Total Flooding System: Drwazah Engineering Consultant & SafetyDocument1 pageTotal Flooding System: Drwazah Engineering Consultant & SafetyaakoglanisPas encore d'évaluation

- Control Room Flow CalcDocument8 pagesControl Room Flow Calckarim3samirPas encore d'évaluation

- 6.2 NOVEC-HFC227 Quick Calc Tool With FIA Flaps DEC13 - 1Document856 pages6.2 NOVEC-HFC227 Quick Calc Tool With FIA Flaps DEC13 - 1Worrapan KaewprajobPas encore d'évaluation

- Chapter 1Document45 pagesChapter 1Abdulqader MousaPas encore d'évaluation

- List of FigDocument1 pageList of FigAbdulqader MousaPas encore d'évaluation

- CO2 System CalculationsDocument1 pageCO2 System CalculationsAbdulqader MousaPas encore d'évaluation

- Mep CV 3 PDFDocument3 pagesMep CV 3 PDFAbdulqader MousaPas encore d'évaluation

- A Completely Real Time Approach To Process Control Education PDFDocument4 pagesA Completely Real Time Approach To Process Control Education PDFkayePas encore d'évaluation

- DLP SeminarDocument27 pagesDLP SeminarJitendraKalerPas encore d'évaluation

- Exploded View and Spare Part ListDocument1 pageExploded View and Spare Part ListJose Enrique Sanchez ThompsonPas encore d'évaluation

- Difference Between Silica Fume and Fly AshDocument14 pagesDifference Between Silica Fume and Fly AshSohail Anwar100% (1)

- ZS-648R & ZS-658R: Ceiling Mount SpeakersDocument2 pagesZS-648R & ZS-658R: Ceiling Mount SpeakersAtgProyek AvilaPas encore d'évaluation

- HPGR Faq PDFDocument9 pagesHPGR Faq PDFfran01334Pas encore d'évaluation

- Higer PeopleDocument64 pagesHiger PeoplemivanoPas encore d'évaluation

- SAROVA - E BrochureDocument25 pagesSAROVA - E BrochureDeepu ReddyPas encore d'évaluation

- Brosur Permaleum & Tough ZoneDocument9 pagesBrosur Permaleum & Tough Zoneariffyan101Pas encore d'évaluation

- ISO 45001 Guide Final - Mar2018Document8 pagesISO 45001 Guide Final - Mar2018Ishumael BurayayiPas encore d'évaluation

- CATALOGO EN Opt PDFDocument138 pagesCATALOGO EN Opt PDFMalcolm GingellPas encore d'évaluation

- MQ303B Manual (Ver1.3)Document7 pagesMQ303B Manual (Ver1.3)이상우Pas encore d'évaluation

- Medical Certificate PDFDocument1 pageMedical Certificate PDFFAIQPas encore d'évaluation

- Maersk Line Container Equipment Guide PDFDocument4 pagesMaersk Line Container Equipment Guide PDFfahrie_manPas encore d'évaluation

- Research Proposal - ICTDocument8 pagesResearch Proposal - ICTSuresh Kumar RaiPas encore d'évaluation

- 9.1740.xx - XXX TDL14 V3.12 EngDocument30 pages9.1740.xx - XXX TDL14 V3.12 EngdotronganhtuanPas encore d'évaluation

- Technical Education Department: Academic Year: 2019 - 2020Document10 pagesTechnical Education Department: Academic Year: 2019 - 2020John Michael ReyesPas encore d'évaluation

- Service Manual: Boiler Steam Iron Provapor GC 6022Document6 pagesService Manual: Boiler Steam Iron Provapor GC 6022pukymottoPas encore d'évaluation

- Optsim AppnotesDocument458 pagesOptsim AppnotesParthesh Mankodi0% (1)

- Flam BICC CatalogueDocument32 pagesFlam BICC Catalogueahmed saberPas encore d'évaluation

- LEED ZeroDocument16 pagesLEED ZeroDaniel Nuñez HernandezPas encore d'évaluation

- Historical GIS Research in CanadaDocument347 pagesHistorical GIS Research in Canadamvojnovic66Pas encore d'évaluation

- SAP FICO (Finance and Controlling) : SAP R/3 Systems Introduction To ERPDocument4 pagesSAP FICO (Finance and Controlling) : SAP R/3 Systems Introduction To ERPibmangiPas encore d'évaluation

- Om 05145 01Document40 pagesOm 05145 01Franco bucciarelliPas encore d'évaluation

- Multimedia Terminals.: Top Class Patient EntertainmentDocument8 pagesMultimedia Terminals.: Top Class Patient EntertainmentDorin SimioanaPas encore d'évaluation

- Design and Performance Estimation of Fir Filter Using Null Convention LogicDocument12 pagesDesign and Performance Estimation of Fir Filter Using Null Convention LogicavnishPas encore d'évaluation

- Nextel Motorola I680 Brute ManualDocument193 pagesNextel Motorola I680 Brute ManualWireflyPas encore d'évaluation

- Allight Hl8whd A CatDocument2 pagesAllight Hl8whd A CatAlbert AloepchaPas encore d'évaluation

- Session 4 - LeanStartupDocument32 pagesSession 4 - LeanStartupvinay mouryaPas encore d'évaluation