Académique Documents

Professionnel Documents

Culture Documents

Meta-Xylene Isophthalic Acid (MX-IPA) - FLYER (2019 Program)

Transféré par

Mr KhosraviTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Meta-Xylene Isophthalic Acid (MX-IPA) - FLYER (2019 Program)

Transféré par

Mr KhosraviDroits d'auteur :

Formats disponibles

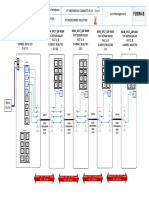

Technology and Costs

TECH 2019S10: meta-Xylene and Isophthalic Acid

meta-Xylene and Isophthalic Acid is one in a series of reports published as part of Nexant’s

2019 Technoeconomics – Energy & Chemicals (TECH) program.

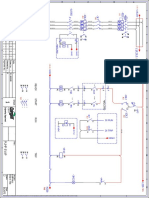

Overview Process Economics

Xylenes are C8 aromatics with methyl groups on the benzene Detailed cost of production estimates for various

ring. Although there is a market for mixed xylenes, mostly as technologies are presented for USGC, Western Europe,

a solvent, most demand is for individual isomers, primarily China, and Japan locations. Estimates are developed for

para- and ortho-xylene. meta-Xylene (MX) is obtained solely several production routes to MX & IPA. Sensitivity analyses

from mixed-xylenes separation and mainly used in Isophthalic on economy scale and feed pricing are also presented.

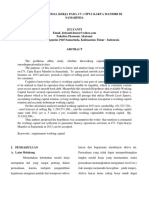

Acid (IPA) manufacture. The IPA market has grown both from Isophthalic Acid Production Costs

expansion of the PET industry and through increasing demand

1800

for adhesives and sealants.

1600

The IPA industry consists of a handful of players, with about 1400

nine producers in seven countries. The industry has mostly

1200

developed through the conversion of old PTA facilities and U.S. Dollars per Ton

U.S. Dollars per Ton

1000

swing PTA/IPA operation.

800

This TECH report provides an updated overview of the

600

technological, economic, and market aspects of MX and IPA.

400

The following issues are addressed in this report:

200

What are the major technologies for MX/IPA

production? Who are the major technology holders? 0

Player 10

Player 11

Player 12

Player 13

Player 1

Player 2

Player 3

Player 5

Player 6

Player 7

Player 8

Player 9

What are some of the developing or alternative

technologies? Region 2 Region 3 Region 4

How do the process economics compare across Net Raw Materials Utilities Direct Fixed Costs Allocated Fixed Costs Depreciation ROCE

processes and different geographic regions?

What are the major applications for MX and IPA? Commercial Overview

How does growth compare in different regions?

Where is most of the supply centered? Which IPA accounts for 83 percent of MX demand, while minor

regions have merchant MX and IPA? end uses include component in color pigments and dyes.

Production Technologies Global IPA consumption was approximately 1.27 million

tons in 2018, with PET bottle resin being the largest end-

MX is recovered from mixed xylenes through selective use. Demand is expected to grow at 4.4 percent annual to

adsorption and crystallization. UOP and MGC have both 2024, driven by increasing PET bottle resin production and

commercialized a process. IPA is produced by an oxidation UPR in China.

process that largely parallels that for making purified

Recently, the IPA industry has been concerned with limited

terephthalic acid: liquid oxidation of MX followed by

MX availability, which has constrained plant operations

hydrogenation purification step.

globally. This tightness is anticipated to be resolved in the

Most existing plants use this conventional processes. forthcoming years. However, significant IPA capacity additions

Routes to IPA with lower oxidation reactor conditions and have also been announced, which, if commissioned, will put

without the hydrogenation step have been developed but pressure on MX supply and global IPA operating rates in the

have not been commercialized. Process technology for MX forecast period.

and IPA is available for license. Yet, some technology

An overview of the supply, demand, and trade of IPA on a

holders do not consider licensing their process at this stage. global and regional (North America, Europe, Asia Pacific)

The meta-xylene and IPA technology is mature and basis is provided in this report.

developments have focused on better separation and

increased recovery of solvent and catalyst. Green routes

efforts remain at embryonic stage.

For more information please contact

Technology@nexant.com or www.nexantsubscriptions.com

Technology and Costs

TECH 2019S10: meta-Xylene and Isophthalic Acid

Subscribe to TECH

The TECH program (formerly known as PERP) is globally recognized as the industry standard source of process evaluations

of existing, new and emerging of interest to the energy and chemical industries.

TECH’s comprehensive studies include detailed technology analyses, process economics, as well as commercial overviews

and industry trends. Reports typically cover:

Trends in chemical technology

Strategic/business overviews

Process Technology:

Chemistry

Process flow diagrams and descriptions of established/conventional, new and emerging processes

Process economics – comparative costs of production estimates for different technologies across various

geographic regions

Overview of product applications and markets for new as well as established products

Regional supply and demand balances for product, including capacity tables of plants in each region

Regulatory and environmental issues where relevant

Subscription Options

A subscription to TECH comprises:

PDF reports including detailed technology analyses, process economics, as well as commercial overviews and

industry trends

Cost of production tables in spreadsheet format

Consultation time with the project team

An annual subscription to TECH includes twenty reports published in a given program year. Reports can also be

purchased on an individual basis, including reports from previous program years

For more information please contact

Technology@nexant.com or www.nexantsubscriptions.com

Nexant Subscriptions and reports provide clients with comprehensive analytics, forecasts and insights for the chemicals, polymers,

energy and cleantech industries. Using a combination of business and technical expertise, with deep and broad understanding of

markets, technologies and economics, Nexant provides solutions that our clients have relied upon for over 50 years.

Technology and Costs comprises the Technoeconomics – Energy & Chemicals (TECH) program (formerly known as PERP), the

Biorenewable Insights program (BI), the Sector Technology Analysis, and the new Cost Curve Analysis. These programs provide

comparative economics of different process routes and technologies in various geographic regions.

Nexant serves its clients from over 30 offices located throughout the Americas, Europe, the Middle East, Africa and Asia.

Corporate Headquarters Americas Europe, Middle East & Africa Asia Pacific

Tel: +1 415 369 1000 Tel: +1 914 609 0300 Tel: +44 20 7950 1600 Tel: +662 793 4600

101 2nd St Suite 1000 44 S Broadway, 1 King’s Arms Yard 22nd Floor, Rasa Tower I

San Francisco 5th Floor White Plains London EC2R 7AF 555 Phahonyothin Road

CA 94105-3651 NY 10601-4425 United Kingdom Kwaeng Chatuchak

USA USA Khet Chatuchak

Bangkok 10900

Thailand

For more information please contact

Technology@nexant.com or www.nexantsubscriptions.com

Vous aimerez peut-être aussi

- Sound Recording Studio Revenues World Summary: Market Values & Financials by CountryD'EverandSound Recording Studio Revenues World Summary: Market Values & Financials by CountryPas encore d'évaluation

- MFMS MIS Reports KeonjharDocument26 pagesMFMS MIS Reports KeonjharAvijitSinharoyPas encore d'évaluation

- H 8 / 3 0 0 A N D H 8 / 3 0 0 L: 8 - B I T MicrocontrollersDocument43 pagesH 8 / 3 0 0 A N D H 8 / 3 0 0 L: 8 - B I T MicrocontrollersEdwin Alex Ovando SaavedraPas encore d'évaluation

- Spare Parts Catalogue: Handling Systems - Counter Balance Forklift TruckDocument12 pagesSpare Parts Catalogue: Handling Systems - Counter Balance Forklift TruckFalgon IslamPas encore d'évaluation

- Nov Dec '21 Racquet Sports Industry MagazineDocument72 pagesNov Dec '21 Racquet Sports Industry MagazineLiya DavidovPas encore d'évaluation

- HL-5340D 5350DN 5350DNLT 5370DW 5370DWT 5380DN Parts LSTDocument36 pagesHL-5340D 5350DN 5350DNLT 5370DW 5370DWT 5380DN Parts LSTNebi aktaşPas encore d'évaluation

- Brother 8065 Parts List and LayoutDocument40 pagesBrother 8065 Parts List and LayoutNischit Kunwar ChhetriPas encore d'évaluation

- Parts Reference List: Model: HL-2030/2040/2070NDocument19 pagesParts Reference List: Model: HL-2030/2040/2070NantoniojfsPas encore d'évaluation

- Fin S06 07Document2 pagesFin S06 07hidyPas encore d'évaluation

- MockCAT 2007Document22 pagesMockCAT 2007Sunil GangwaniPas encore d'évaluation

- Ntroduction To ARM7 LPC2148 MicrocontrollerDocument5 pagesNtroduction To ARM7 LPC2148 MicrocontrollercaseguysPas encore d'évaluation

- M01 Day 01 Session 02Document10 pagesM01 Day 01 Session 02PraveenGowda K SPas encore d'évaluation

- ARM7 Based LPC2148 MicrocontrollerDocument4 pagesARM7 Based LPC2148 MicrocontrollerPalani PicoPas encore d'évaluation

- How To Start Programming For ARM7 Based LPC2148 MicrocontrollerDocument5 pagesHow To Start Programming For ARM7 Based LPC2148 Microcontrollerrudra_1Pas encore d'évaluation

- The End of An Era in Processor EvolutionDocument17 pagesThe End of An Era in Processor EvolutionSantiNeiraPas encore d'évaluation

- Radio FM Con RDS Un Proyecto HAT Superior para Raspberry Pi PDFDocument8 pagesRadio FM Con RDS Un Proyecto HAT Superior para Raspberry Pi PDFAndres AlegriaPas encore d'évaluation

- TC2005en-Ed17 SIP Providers Supported On OpenTouch and OmniPCX EnterpriseDocument13 pagesTC2005en-Ed17 SIP Providers Supported On OpenTouch and OmniPCX EnterpriseChathura DalugodaPas encore d'évaluation

- Py BoardDocument9 pagesPy BoardKazalište ArušaPas encore d'évaluation

- EN SpecGuide PalcoInOut.Document9 pagesEN SpecGuide PalcoInOut.Wellington Suzini Aquino JuniorPas encore d'évaluation

- Alignment Sheet ONGC 2Document1 pageAlignment Sheet ONGC 2SaravananPas encore d'évaluation

- OBE Based DSD Lab Manual Updated1 PDFDocument101 pagesOBE Based DSD Lab Manual Updated1 PDFAbdullahPas encore d'évaluation

- GP340 ExDocument18 pagesGP340 Exali mohibPas encore d'évaluation

- AgateOnyx Service Training V1.3 03 20 2019Document80 pagesAgateOnyx Service Training V1.3 03 20 2019Wi ChiPas encore d'évaluation

- Fuji Frontier 350 370 Parts List Fourth Edition PDFDocument173 pagesFuji Frontier 350 370 Parts List Fourth Edition PDFOMPRAKASH100% (2)

- Ricoh 6000Document2 pagesRicoh 6000Dương Minh PhụngPas encore d'évaluation

- Doc1132 PDFDocument9 pagesDoc1132 PDFLeonardoMartinPas encore d'évaluation

- Grabadora Olympus ManualDocument18 pagesGrabadora Olympus ManualcasperllPas encore d'évaluation

- Nokia n8 Service ManualDocument12 pagesNokia n8 Service ManualtecsupportPas encore d'évaluation

- Saunier Duval M37480M2T-XXXSP-Mitsubishi PDFDocument97 pagesSaunier Duval M37480M2T-XXXSP-Mitsubishi PDFadel berguiPas encore d'évaluation

- PM - HL 4150CDN 4570CDW 4570CDWTDocument42 pagesPM - HL 4150CDN 4570CDW 4570CDWTleo_lnetoPas encore d'évaluation

- 6800 Parts ListDocument36 pages6800 Parts Listmeocon234100% (1)

- Visio-Flowcore Feeder Milala 2Document3 pagesVisio-Flowcore Feeder Milala 2Indah SyafaniPas encore d'évaluation

- Visio-Flowcore Feeder Milala 2Document3 pagesVisio-Flowcore Feeder Milala 2Indah SyafaniPas encore d'évaluation

- CUT40 Plasma Protel SchematicDocument1 pageCUT40 Plasma Protel SchematichosseinarevanPas encore d'évaluation

- CRB BR enDocument5 pagesCRB BR enRatnakar GuravPas encore d'évaluation

- 15.351 Managing Innovation and Entrepreneurship: Mit OpencoursewareDocument40 pages15.351 Managing Innovation and Entrepreneurship: Mit OpencoursewareChristinePas encore d'évaluation

- Op IFDocument12 pagesOp IFdesignPas encore d'évaluation

- Gs30a01f20-01en 010Document8 pagesGs30a01f20-01en 010mehdi mPas encore d'évaluation

- J-11 Programmers Reference Jan82Document54 pagesJ-11 Programmers Reference Jan82dusanzalarPas encore d'évaluation

- BROCHUREDocument33 pagesBROCHURElegend guraraPas encore d'évaluation

- EP-51658-P-CAE-0201 (00) Phase A TG CEDocument3 pagesEP-51658-P-CAE-0201 (00) Phase A TG CEG Bill AlphaPas encore d'évaluation

- LPC2148 GPIO Tutorial (LED, Switch Interfacing) - EmbeTronicXDocument13 pagesLPC2148 GPIO Tutorial (LED, Switch Interfacing) - EmbeTronicXAkshay Jadhav100% (1)

- So Do Nguyen Ly Mach Do DuongDocument2 pagesSo Do Nguyen Ly Mach Do DuongLhthang KtvPas encore d'évaluation

- Üzemanyag Monitor Szűrő - Bulletin - Page - 05Document2 pagesÜzemanyag Monitor Szűrő - Bulletin - Page - 05Ben YusPas encore d'évaluation

- PENALTIES Wftda Statsbook A4Document2 pagesPENALTIES Wftda Statsbook A4rogerdeflPas encore d'évaluation

- PP3 D714e4Document169 pagesPP3 D714e4Alvaro AlcaláPas encore d'évaluation

- Axial AOF AOF: DimensionsDocument2 pagesAxial AOF AOF: DimensionsAblayePas encore d'évaluation

- Ormar1-PLC: Trakasti Filter 1Document1 pageOrmar1-PLC: Trakasti Filter 1Vedran MarkanovićPas encore d'évaluation

- HL 2540-5240L 5250DN 5270DN Part ListDocument38 pagesHL 2540-5240L 5250DN 5270DN Part ListPaoloPas encore d'évaluation

- 8 Bit Microcontroller - H/W Architecture, Instruction Set and ProgrammingDocument44 pages8 Bit Microcontroller - H/W Architecture, Instruction Set and ProgrammingprashantvlsiPas encore d'évaluation

- Specification INPUT: 100-240V AC (50/60Hz)Document1 pageSpecification INPUT: 100-240V AC (50/60Hz)Federico UrquizaPas encore d'évaluation

- FUJI FRONTIER 550 - 570 - PartsListDocument264 pagesFUJI FRONTIER 550 - 570 - PartsListvitprint22100% (4)

- DOL Wiring 11 KW PDFDocument1 pageDOL Wiring 11 KW PDFDella Fitri AndiniPas encore d'évaluation

- Tribhuvan University Institute of Engineering Pulchowk, Lalipur A Lab Report On Embedded SystemDocument24 pagesTribhuvan University Institute of Engineering Pulchowk, Lalipur A Lab Report On Embedded SystemSaroj Katwal0% (1)

- SUF557 Skid Mounted Power Pack Electrical System: Left Side ViewDocument2 pagesSUF557 Skid Mounted Power Pack Electrical System: Left Side ViewGilvan JuniorPas encore d'évaluation

- Resep Tofu Rica RicaDocument1 pageResep Tofu Rica Ricandutz004Pas encore d'évaluation

- Diagrama Electrico Motor Cat C9Document2 pagesDiagrama Electrico Motor Cat C9Ramón José Aponte Franco100% (4)

- CABE Space - A Guide To Producing Park and Green Space Management PlansDocument48 pagesCABE Space - A Guide To Producing Park and Green Space Management PlansbenconnolleyPas encore d'évaluation

- Birhane, E. 2014. Agroforestry Governance in Ethiopa Report WP 5Document50 pagesBirhane, E. 2014. Agroforestry Governance in Ethiopa Report WP 5woubshetPas encore d'évaluation

- Activity 1 Which Is WhichDocument1 pageActivity 1 Which Is WhichRhanna Lei SiaPas encore d'évaluation

- Kinematic Tool-Path Smoothing For 6-Axis Industrial Machining RobotsDocument10 pagesKinematic Tool-Path Smoothing For 6-Axis Industrial Machining RobotsToniolo LucaPas encore d'évaluation

- Case Study TemplateDocument4 pagesCase Study Templateapi-355498849Pas encore d'évaluation

- DS ClozapineDocument3 pagesDS ClozapineMiggsPas encore d'évaluation

- The Fat Cat Called PatDocument12 pagesThe Fat Cat Called PatAlex ArroPas encore d'évaluation

- Republic of The Philippines: Paulene V. Silvestre Personal DevelopmentDocument3 pagesRepublic of The Philippines: Paulene V. Silvestre Personal DevelopmentPau SilvestrePas encore d'évaluation

- Real Number System.Document7 pagesReal Number System.samuel1436Pas encore d'évaluation

- Karbohidrat: Gula, Pati & SeratDocument20 pagesKarbohidrat: Gula, Pati & SeratAlfi Syahrin SiregarPas encore d'évaluation

- Missions ETC 2020 SchemesOfWarDocument10 pagesMissions ETC 2020 SchemesOfWarDanieleBisignanoPas encore d'évaluation

- EDUC307 BEED CurriculumDocument9 pagesEDUC307 BEED CurriculumPaula Antonette L. CelizPas encore d'évaluation

- Fontenot Opinion and OrderDocument190 pagesFontenot Opinion and OrderInjustice WatchPas encore d'évaluation

- Artikel Andi Nurindah SariDocument14 pagesArtikel Andi Nurindah Sariapril yansenPas encore d'évaluation

- Chapter One A CellDocument46 pagesChapter One A CellLeon MarkoPas encore d'évaluation

- Project Documentation - Sensorflex 30G Data SheetDocument15 pagesProject Documentation - Sensorflex 30G Data SheetOmar HectorPas encore d'évaluation

- Cb-3 Mech'l Plans 05.06.22Document12 pagesCb-3 Mech'l Plans 05.06.22Mark Vincent MoraPas encore d'évaluation

- Manual GPS Trimble Portugues CFX-750 / FM-750Document246 pagesManual GPS Trimble Portugues CFX-750 / FM-750José Luis Mailkut Pires100% (5)

- Gonzales Cannon Feb 28 IssueDocument40 pagesGonzales Cannon Feb 28 IssueGonzales CannonPas encore d'évaluation

- Kuis 4Document10 pagesKuis 4Deri AntoPas encore d'évaluation

- Kebutuhan Modal Kerja Pada Cv. Cipta Karya Mandiri Di SamarindaDocument7 pagesKebutuhan Modal Kerja Pada Cv. Cipta Karya Mandiri Di SamarindaHerdi VhantPas encore d'évaluation

- Case Study: Direct Selling ConceptDocument20 pagesCase Study: Direct Selling Conceptbansi2kk0% (1)

- HOPE 2A MODULE 1 Introduction To SportsDocument11 pagesHOPE 2A MODULE 1 Introduction To SportsChristian Ray Lucnagan ReyesPas encore d'évaluation

- Control Work.: ..... Is A Typical ..... DishDocument4 pagesControl Work.: ..... Is A Typical ..... DishАндрій ХомишакPas encore d'évaluation

- Eliminate Zombie Nouns and Minimize Passive Voice: Plain LanguageDocument2 pagesEliminate Zombie Nouns and Minimize Passive Voice: Plain LanguagePădure IonuțPas encore d'évaluation

- Tucker CarlsonDocument4 pagesTucker CarlsonDai ZPas encore d'évaluation

- Articles On Philippine Obligation and ContractsDocument114 pagesArticles On Philippine Obligation and ContractsKriz Batoto100% (1)

- Canada Immigration Forms: E33106Document6 pagesCanada Immigration Forms: E33106Oleksiy Kovyrin100% (1)

- Monthly Film Bulletin: 1T1IcqDocument12 pagesMonthly Film Bulletin: 1T1IcqAlfred_HitzkopfPas encore d'évaluation

- Rockonomics: Book Non-Fiction US & Canada Crown Publishing (Ed. Roger Scholl) UK & Comm John Murray (Ed. Nick Davies)Document2 pagesRockonomics: Book Non-Fiction US & Canada Crown Publishing (Ed. Roger Scholl) UK & Comm John Murray (Ed. Nick Davies)Natasha DanchevskaPas encore d'évaluation

- Hero Found: The Greatest POW Escape of the Vietnam WarD'EverandHero Found: The Greatest POW Escape of the Vietnam WarÉvaluation : 4 sur 5 étoiles4/5 (19)

- Sully: The Untold Story Behind the Miracle on the HudsonD'EverandSully: The Untold Story Behind the Miracle on the HudsonÉvaluation : 4 sur 5 étoiles4/5 (103)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureD'EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureÉvaluation : 5 sur 5 étoiles5/5 (125)

- The Fabric of Civilization: How Textiles Made the WorldD'EverandThe Fabric of Civilization: How Textiles Made the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (58)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachD'EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachÉvaluation : 3.5 sur 5 étoiles3.5/5 (6)

- The Future of Geography: How the Competition in Space Will Change Our WorldD'EverandThe Future of Geography: How the Competition in Space Will Change Our WorldÉvaluation : 4 sur 5 étoiles4/5 (6)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyD'EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyPas encore d'évaluation

- Four Battlegrounds: Power in the Age of Artificial IntelligenceD'EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceÉvaluation : 5 sur 5 étoiles5/5 (5)

- The End of Craving: Recovering the Lost Wisdom of Eating WellD'EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellÉvaluation : 4.5 sur 5 étoiles4.5/5 (82)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaD'EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaPas encore d'évaluation

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreD'EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreÉvaluation : 4.5 sur 5 étoiles4.5/5 (33)

- The Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeD'EverandThe Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeÉvaluation : 4.5 sur 5 étoiles4.5/5 (99)

- Mini Farming: Self-Sufficiency on 1/4 AcreD'EverandMini Farming: Self-Sufficiency on 1/4 AcreÉvaluation : 4 sur 5 étoiles4/5 (76)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- System Error: Where Big Tech Went Wrong and How We Can RebootD'EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootPas encore d'évaluation

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationD'EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationÉvaluation : 4.5 sur 5 étoiles4.5/5 (46)

- Highest Duty: My Search for What Really MattersD'EverandHighest Duty: My Search for What Really MattersPas encore d'évaluation

- Pale Blue Dot: A Vision of the Human Future in SpaceD'EverandPale Blue Dot: A Vision of the Human Future in SpaceÉvaluation : 4.5 sur 5 étoiles4.5/5 (588)

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindD'EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindPas encore d'évaluation

- Reality+: Virtual Worlds and the Problems of PhilosophyD'EverandReality+: Virtual Worlds and the Problems of PhilosophyÉvaluation : 4 sur 5 étoiles4/5 (24)

- The Knowledge: How to Rebuild Our World from ScratchD'EverandThe Knowledge: How to Rebuild Our World from ScratchÉvaluation : 3.5 sur 5 étoiles3.5/5 (133)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerD'EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerÉvaluation : 4.5 sur 5 étoiles4.5/5 (54)

- Process Plant Equipment: Operation, Control, and ReliabilityD'EverandProcess Plant Equipment: Operation, Control, and ReliabilityÉvaluation : 5 sur 5 étoiles5/5 (1)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerD'EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerÉvaluation : 4.5 sur 5 étoiles4.5/5 (122)

- A Place of My Own: The Architecture of DaydreamsD'EverandA Place of My Own: The Architecture of DaydreamsÉvaluation : 4 sur 5 étoiles4/5 (242)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestD'EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestÉvaluation : 4 sur 5 étoiles4/5 (28)