Académique Documents

Professionnel Documents

Culture Documents

MODEL 7705 Flexible Coupling

Transféré par

Kalagan YadaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MODEL 7705 Flexible Coupling

Transféré par

Kalagan YadaDroits d'auteur :

Formats disponibles

7705 C-01

MODEL 7705 FLEXIBLE COUPLING

The Model 7705 Flexible Coupling is ideal for moderate pressure

pipeline applications where expansion, contraction and deflection

caused by temperature changes, seismic activity or other

vibrations are factors. The Model 7705 Flexible Coupling is

recommended for services up to 35 bar (500 psi) depending on

the size and schedule of the pipe being used. All Model 7705

couplings are comprised of two identical ductile iron housings

segments, EPDM rubber gasket and plated track bolts & nuts.

Housings segments are supplied with our standard painted

finishes, i.e. orange or RAL3000 red. Optional finishes such as

hot dipped zinc galvanized and custom epoxy coatings are

available.

MODEL 7705 FLEXIBLE COUPLING

Model 7705 Flexible Coupling

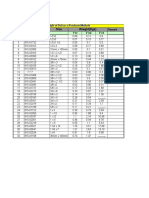

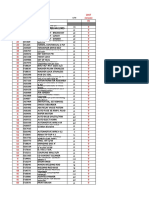

Max. Max. Pipe End Deflection Dimensions

Nom. Pipe Working End Separation Deg. Per Pipe Bolt

Size O.D. Pressure Load Coupling A B C Size Weight

o

mm mm Bar kN mm () mm/m mm mm mm mm Kgs

in in PSI Lbs in in/ft in in in in Lbs

25 33.4 35 3.0 0~1.6 2o - 45’ 48.0 57 100 46 M10 x 45 0.6

1 1.315 500 680 0~0.06 0.57 2.24 3.94 1.81 3/8 x 1-3/4 1.3

32 42.2 35 4.9 0~1.6 2o - 10’ 38.0 66 103 46 M10 x 55 0.7

1.25 1.660 500 1080 0~0.06 0.45 2.60 4.06 1.81 3/8 x 2-1/8 1.5

40 48.3 35 6.3 0~1.6 1o - 54’ 33.0 72 108 46 M10 x 55 0.7

1.5 1.900 500 1420 0~0.06 0.40 2.83 4.25 1.81 3/8 x 2-1/8 1.6

50 60.3 35 9.9 0~1.6 1o - 31’ 27.0 84 129 48 M10 x 55 0.8

2 2.375 500 2210 0~0.06 0.32 3.31 5.08 1.89 3/8 x 2-1/8 1.8

65 73.0 35 14.4 0~1.6 1o - 15’ 22.0 99 142 48 M10 x 55 0.9

2.5 2.875 500 3240 0~0.06 0.26 3.90 5.59 1.89 3/8 x 2-1/8 2.0

65 76.1 35 15.7 0~1.6 1o - 12’ 21.0 102 147 48 M10 x 55 1.0

2.5 3.000 500 3530 0~0.06 0.25 4.02 5.79 1.89 3/8 x 2-1/8 2.1

80 88.9 35 21.4 0~1.6 1o - 02’ 18.0 116 169 48 M12 x 75 1.3

3 3.500 500 4810 0~0.06 0.22 4.57 6.65 1.89 1/2 x 3 2.8

90 101.6 35 28.0 0~1.6 0o - 54’ 32.0 129 200 52 M12 x 75 1.5

3.5 4.000 500 6300 0~0.06 0.38 5.07 7.90 2.05 1/2 x 3 3.3

100 108.0 35 31.5 0~3.2 1o - 42’ 30.0 138 192 52 M12 x 75 1.9

4 4.250 500 7090 0~0.13 0.36 5.43 7.56 2.05 1/2 x 3 4.1

100 114.3 35 35.4 0~3.2 1o - 36’ 28.0 145 197 52 M12 x 75 1.9

4 4.500 500 7950 0~0.13 0.34 5.71 7.76 2.05 1/2 x 3 4.1

125 133.0 31 43.3 0~3.2 1o - 23’ 24.0 165 231 52 M16 x 90 2.3

5 5.250 450 9740 0~0.13 0.29 6.50 9.09 2.05 5/8 x 3-1/2 5.1

125 139.7 31 47.6 0~3.2 1o - 19’ 23.0 170 233 52 M16 x 90 2.6

5 5.500 450 10690 0~0.13 0.28 6.69 9.17 2.05 5/8 x 3-1/2 5.7

125 141.3 31 48.6 0~3.2 1o - 18’ 23.0 172 234 52 M16 x 90 2.6

5 5.563 450 10930 0~0.13 0.27 6.77 9.21 2.05 5/8 x 3-1/2 5.7

150 159.0 31 61.4 0~3.2 1o - 09’ 20.0 190 253 54 M16 x 90 3.0

6 6.250 450 13800 0~0.13 0.24 7.48 9.96 2.13 5/8 x 3-1/2 6.6

150 165.1 31 66.4 0~3.2 1o - 07’ 19.0 196 261 54 M16 x 90 3.1

6 6.500 450 14930 0~0.13 0.23 7.72 10.28 2.13 5/8 x 3-1/2 6.8

150 168.3 31 69.0 0~3.2 1o - 05’ 19.0 200 268 62 M16 x 90 3.2

6 6.625 450 15500 0~0.13 0.23 7.87 10.55 2.44 5/8 x 3-1/2 7.0

200 JIS 216.3 31 114.0 0~3.2 0o - 51’ 15.0 254 348 62 M20 x 120 5.8

8 8.516 450 25620 0~0.13 0.18 10.00 13.70 2.44 3/4 x 4-3/4 12.8

200 219.1 31 116.9 0~3.2 0o - 50’ 15.0 260 350 64 M16 x 90 5.8

8 8.625 450 26280 0~0.13 0.18 10.24 13.78 2.52 5/8 x 3-1/2 12.8

C-01-1 Rev. A 120505

7705 C-01

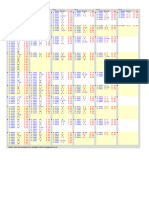

Model 7705 Flexible Coupling

Max. Max. Pipe End Deflection Dimensions

Nom. Pipe Working End Separation Deg. Per Pipe Bolt

Size O.D. Pressure Load Coupling A B C Size Weight

o

mm mm Bar kN mm () mm/m mm mm mm mm Kgs

in in PSI Lbs in in/ft in in in in Lbs

250 JIS 267.4 24 134.6 0~3.2 0o - 41’ 12.0 337 420 64 M20 x 120 8.0

10 10.528 350 30450 0~0.13 0.14 13.27 16.54 2.52 3/4 x 4-3/4 17.6

250 273.0 24 141.3 0~3.2 0o - 40’ 12.0 343 425 64 M20 x 120 8.2

10 10.750 350 31750 0~0.13 0.14 13.50 16.73 2.52 3/4 x 4-3/4 18.0

300 JIS 318.5 24 192.2 0~3.2 0 - 35’

o 10.0 389 478 64 --- 10.4

12 12.539 350 43200 0~0.13 0.12 15.31 18.81 2.52 7/8 x 6-1/2 22.9

300 323.9 24 198.8 0~3.2 0o - 34’ 10.0 390 467 64 --- 10.8

12 12.750 350 44660 0~0.13 0.12 15.35 18.39 2.52 7/8 x 6-1/2 23.8

MODEL 7705H (VdS approved)

Model 7705H Flexible Coupling

Nom.l Pipe Max. Max. Pipe Deflection Dimensions

Size O.D. Working End End Degree Per Pipe Bolt Weight

Pressure Load Separation Coupling A B C Size

o

mm mm Bar kN mm () mm/m mm mm mm mm Kgs

in in PSI Lbs in in/ft in in in in Lbs

200 219.1 35 116.9 0~3.2 0o - 50’ 15.0 266 343 63 M20 x 120 7.5

8 8.625 500 29200 0~0.13 0.18 10.47 13.50 2.48 3/4 x 4-3/4 16.5

MODEL 7705 MATERIAL SPECIFICATIONS

• Housing: reduced by incremental increases in temperature. Additional

Ductile Iron to ASTM A536, Gr. 65-45-12, min. tensile strength factors that affect gasket life and performance include

448MPa (65,000 psi). temperature, fluid medium (air, water, air with water… etc.) and

the continuous or intermittent use of the piping system. For

specific applications over 200oF (93oC), please consult Shurjoint

• Surface Finish: for recommendations.

Standard painted finishes in orange or RAL3000 red.

Hot dip zinc galvanized (Option). (Option) Grade “T” Nitrile (Color code: Orange stripe)

Epoxy Coatings in RAL3000 red or other colors (Option) Recommended for petroleum products, air with oil vapors,

vegetable and mineral oils within the specified temperature

range. Also good for water services under +66oC

• Rubber Gasket: (+150oF).

To assure maximum life for the service intended, proper gasket Temperature range: -29 oC to +82 oC (-20 oF to +180 oF).

selection and specification in ordering is essential. Failure to Do not use for HOT WATER above +66 oC (+150 oF) or

select the proper gasket compound may result in personal injury, HOT DRY AIR above +60 oC (+140 oF)

property damage, joint leakage or joint failure.

Other options: Grade “O” - Fluoroelastomer.

Grade “E” EPDM (Color code: Green stripe) Good for cold & hot Grade “L” - Silicone.

water up to +230oF (+110oC). Also good for services for water For additional details contact Shurjoint.

with acid, water with chlorine, deionized water, seawater and

waste water, dilute acids, oil-free air and many chemicals. Not

recommended for petroleum oils, minerals oils, solvents and • Bolts & Nuts:

aromatic hydrocarbons. Heat treated carbon manganese steel track bolts to ASTM

Maximum Temperature Range: -29oF (-34oC) to +230oF A449-83a (or A183 Gr. 2), minimum tensile strength 758 MPa

(+110oC)* (110,000 psi), Zinc electroplated, with heavy-duty hexagonal nuts

*For hot water application between 200oF - 230oF extreme to ASTM A563.

caution should be used as the life of the gasket can be greatly

General Notes:

z Pressure ratings listed are CWP (cold water pressure) or maximum working pressure within the service temperature range of the gasket

used in the coupling. This rating may occasionally differ from maximum working pressures listed and/or approved by UL, ULC, and/or FM

as testing conditions and test pipes differ. For additional information contact Shurjoint..

z Maximum working pressures and end loads listed are total of internal and external pressures and loads based on Sch. 40 steel pipe with

roll grooves to ANSI/AWWA C606-97 specifications. For information on other pipe schedules contact Shurjoint..

z For one time field test only the maximum joint working pressure may be increased 1-1/2 times the figures shown.

z Warning: Piping systems must always be depressurized and drained before attempting disassembly and or removal of any components.

z Shurjoint reserves the right to change specifications, designs and or standard equipment without notice and without incurring any

obligations.

C-01-2 Rev. A 120505

Vous aimerez peut-être aussi

- Grooved Fittings - ShurjointDocument7 pagesGrooved Fittings - ShurjointitskittylimPas encore d'évaluation

- Memoria de Calculo Desague - MH - Rev0Document5 pagesMemoria de Calculo Desague - MH - Rev0Junior Diaz VenturaPas encore d'évaluation

- G-01 Model K-9 Rigid Coupling Rev-LDocument3 pagesG-01 Model K-9 Rigid Coupling Rev-LMohammed NiqrisPas encore d'évaluation

- Memoria de Calculo Desague - MH - Rev0Document5 pagesMemoria de Calculo Desague - MH - Rev0Junior Diaz VenturaPas encore d'évaluation

- Hydraulic CalculationDocument49 pagesHydraulic CalculationNguyên Trịnh CaoPas encore d'évaluation

- Product Specifications: Hole-Cut SystemDocument1 pageProduct Specifications: Hole-Cut SystemErickPas encore d'évaluation

- Argco Fig 403 - Mec TeeDocument3 pagesArgco Fig 403 - Mec TeeFIRE RL SYSTEMSPas encore d'évaluation

- SCH 80Document20 pagesSCH 80precillaPas encore d'évaluation

- C-01 Model 7705 Standard Flexible CouplingDocument4 pagesC-01 Model 7705 Standard Flexible CouplingDaniel SanPas encore d'évaluation

- Victaulic Couplings Data TableDocument4 pagesVictaulic Couplings Data Tablejlinhares.engPas encore d'évaluation

- 25 Wires TableDocument1 page25 Wires TableMohamedPas encore d'évaluation

- Catalogo Da TEEJETDocument22 pagesCatalogo Da TEEJETRodrigoPas encore d'évaluation

- Measurement Conversion Tables: Inches Fractions To Decimals, CM & MM Inches To Cm. & MMDocument2 pagesMeasurement Conversion Tables: Inches Fractions To Decimals, CM & MM Inches To Cm. & MMKhaled MeraashliPas encore d'évaluation

- Tension Force Calculation Sheet For Steel Bolts PDFDocument1 pageTension Force Calculation Sheet For Steel Bolts PDFVỸ TRẦNPas encore d'évaluation

- Conversion & Thread Tables PDFDocument2 pagesConversion & Thread Tables PDFjakariyaPas encore d'évaluation

- Balls BallsDocument2 pagesBalls BallsOm PurandarePas encore d'évaluation

- Greenfield Tap Drill Recommendations PDFDocument1 pageGreenfield Tap Drill Recommendations PDFSan Ban CastroPas encore d'évaluation

- Shackles: 5150 - Nut & Bolt Bow ShackleDocument1 pageShackles: 5150 - Nut & Bolt Bow ShackleAlthaf R100% (1)

- Weight Bolt-Nut & WasherDocument6 pagesWeight Bolt-Nut & Washerrahul surendranPas encore d'évaluation

- C-02 Model 7707 Heavy Duty Flexible Coupling - Rev-UDocument3 pagesC-02 Model 7707 Heavy Duty Flexible Coupling - Rev-UDaniel SanPas encore d'évaluation

- Typical AWG Wire SizesDocument2 pagesTypical AWG Wire SizesMitha VivekPas encore d'évaluation

- Inch - MM Conversions: Revised Feb 2011Document1 pageInch - MM Conversions: Revised Feb 2011kamaldhar007Pas encore d'évaluation

- Estes Engine Chart Model RocketDocument1 pageEstes Engine Chart Model RocketJohn ByerPas encore d'évaluation

- Sorf Flange Detail S.No NB Class Size in Inch Fastners Size Bolt Length IN MMDocument17 pagesSorf Flange Detail S.No NB Class Size in Inch Fastners Size Bolt Length IN MMAnonymous XzGgqTPas encore d'évaluation

- Eye Bolt 1Document1 pageEye Bolt 1Adi SutardiPas encore d'évaluation

- Starrett ChartDocument2 pagesStarrett ChartVictor Monteagudo100% (2)

- STARRETT Decimal Chart PDFDocument2 pagesSTARRETT Decimal Chart PDFVictor MonteagudoPas encore d'évaluation

- Decimal Equivalent Card Bulletin 1317Document2 pagesDecimal Equivalent Card Bulletin 1317FabekPas encore d'évaluation

- Pipe Properties and DimensionsDocument6 pagesPipe Properties and DimensionsJanzxhel Alva OlazoPas encore d'évaluation

- Pipes Dimension PropertiesDocument6 pagesPipes Dimension PropertiesJanzxhel Alva OlazoPas encore d'évaluation

- Ampacities and Mechanical Properties of Rectangular Copper Busbars: Table 1. Ampacities of Copper No. 110Document4 pagesAmpacities and Mechanical Properties of Rectangular Copper Busbars: Table 1. Ampacities of Copper No. 110Kiran KarthikPas encore d'évaluation

- Starrett Decimal Equivalent Card (Bulletin 1317)Document2 pagesStarrett Decimal Equivalent Card (Bulletin 1317)Franz CorasPas encore d'évaluation

- Estes Engines ChartDocument1 pageEstes Engines ChartArindam MahantaPas encore d'évaluation

- Bolt, Nut, WasherDocument9 pagesBolt, Nut, WasherAndri EkoPas encore d'évaluation

- 2.2 Ricwil Pre-InsulatedDocument6 pages2.2 Ricwil Pre-InsulatedAHMAD HAFIZAL MOHD YAMINPas encore d'évaluation

- Class NotesDocument2 pagesClass NotesrayafellowsjrPas encore d'évaluation

- Forged Machinery Eye Bolts: See Application and Warning InformationDocument1 pageForged Machinery Eye Bolts: See Application and Warning InformationHasrul SunPas encore d'évaluation

- Steel Section DLDocument1 pageSteel Section DLenggPas encore d'évaluation

- RoofDek D46 Load TableDocument1 pageRoofDek D46 Load TableQadir MohideenPas encore d'évaluation

- BUL 4462 Product Overview Hose Bulletin UK MainDocument4 pagesBUL 4462 Product Overview Hose Bulletin UK MainTuan buivietPas encore d'évaluation

- Tap Drill Sizes For Forming Taps Tap Drill Sizes For Forming TapsDocument1 pageTap Drill Sizes For Forming Taps Tap Drill Sizes For Forming Tapsamir.suljic23-1Pas encore d'évaluation

- Master CatalogDocument114 pagesMaster CatalogFINNING CATPas encore d'évaluation

- JIS ChannelsDocument5 pagesJIS ChannelsRuri IswadiPas encore d'évaluation

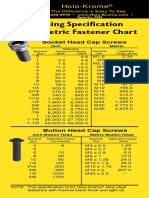

- Torquing Specification Inch & Metric Fastener Chart: Socket Head Cap ScrewsDocument2 pagesTorquing Specification Inch & Metric Fastener Chart: Socket Head Cap ScrewsgielPas encore d'évaluation

- PVC and CPVC Pressure Pipes: PVC Astm D1785 Schedule 80Document33 pagesPVC and CPVC Pressure Pipes: PVC Astm D1785 Schedule 80Muhammad AfzaalPas encore d'évaluation

- Compression StrengthDocument7 pagesCompression StrengthkrunalPas encore d'évaluation

- Model 7041-A Flange-Ansi Class 125/150Document2 pagesModel 7041-A Flange-Ansi Class 125/150Zaira LorenaPas encore d'évaluation

- Heat Exchanger Tube - Principal BWG Sizes: Outside Diameter Birmingham Wire Gauge (BWG)Document1 pageHeat Exchanger Tube - Principal BWG Sizes: Outside Diameter Birmingham Wire Gauge (BWG)amr kouranyPas encore d'évaluation

- Schedule ChartDocument1 pageSchedule ChartSubash Gold KingPas encore d'évaluation

- Nominal Wall Thickness For Schedule Sizes.: 5 10 20 30 40 60 STD 80 XS 100 120 140 160 XXSDocument2 pagesNominal Wall Thickness For Schedule Sizes.: 5 10 20 30 40 60 STD 80 XS 100 120 140 160 XXSChano HanokPas encore d'évaluation

- USP Mechanical Joint Fittings C153 Submittal DigitalDocument20 pagesUSP Mechanical Joint Fittings C153 Submittal DigitalAbdel Mongy AhmedPas encore d'évaluation

- Thread TableDocument2 pagesThread TableDon RecardoPas encore d'évaluation

- 2 Resorte Anchor Lamina Pulgadas PDFDocument16 pages2 Resorte Anchor Lamina Pulgadas PDFJhon Jairo VásquezPas encore d'évaluation

- Imperial Drill SizeDocument1 pageImperial Drill SizeJulian MPas encore d'évaluation

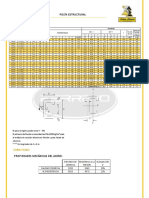

- Polin Monten, PTRDocument2 pagesPolin Monten, PTROmar NavarroPas encore d'évaluation

- Galvanized Steel Wire Strands (GSW) JIS G 3537: 1994Document1 pageGalvanized Steel Wire Strands (GSW) JIS G 3537: 1994boedak korporatPas encore d'évaluation

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesD'EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesÉvaluation : 5 sur 5 étoiles5/5 (3)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesD'EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Handbook Best Practice Dropped Object Management - Engelsk - GodkjentDocument108 pagesHandbook Best Practice Dropped Object Management - Engelsk - Godkjentmiguel angelPas encore d'évaluation

- Lecture6 - Losses in Electric MachinesDocument24 pagesLecture6 - Losses in Electric Machinesthulasi_krishnaPas encore d'évaluation

- Avt 200 #1 Aircarft StructureDocument99 pagesAvt 200 #1 Aircarft StructureStrause Vince Jansen RetuyaPas encore d'évaluation

- ASCO Series 307 Solenoid Valves No Voltage ReleaseDocument6 pagesASCO Series 307 Solenoid Valves No Voltage Releasehacene omarPas encore d'évaluation

- Note On Mac 1 Casting Process 1. Draw Block Diagram of Foundry Layout. Discuss Objectives of Good Plant LayoutDocument28 pagesNote On Mac 1 Casting Process 1. Draw Block Diagram of Foundry Layout. Discuss Objectives of Good Plant LayoutBVoc AutomobilePas encore d'évaluation

- All in One - 10th Class em - Fa-2Document35 pagesAll in One - 10th Class em - Fa-2sai ramxeroxPas encore d'évaluation

- Diamond Trainee Manual 901190 2 PDF FreeDocument242 pagesDiamond Trainee Manual 901190 2 PDF Freeswaters98Pas encore d'évaluation

- Intermolecular Forces and Its Applications: For General Chemistry 2/grade 12 (STEM) Quarter 3/week 1.a-DDocument19 pagesIntermolecular Forces and Its Applications: For General Chemistry 2/grade 12 (STEM) Quarter 3/week 1.a-DSherwin Jay PalaspasPas encore d'évaluation

- C12200Document3 pagesC12200xgiorg100% (1)

- Binary Phase DiagramsDocument60 pagesBinary Phase DiagramsmaryzeenPas encore d'évaluation

- Alternative To Practical Ig1Document10 pagesAlternative To Practical Ig1Sandeep NehraPas encore d'évaluation

- 1-Pentene: Cautionary Response InformationDocument2 pages1-Pentene: Cautionary Response InformationMumahmmad Rizwan RPas encore d'évaluation

- E985F8E88F069BF1BB6F005056AC67B7Document1 pageE985F8E88F069BF1BB6F005056AC67B7Jose ReynosoPas encore d'évaluation

- Chap 14 PDFDocument22 pagesChap 14 PDFnelson escuderoPas encore d'évaluation

- Lanco Antifloat D-14, TDSDocument2 pagesLanco Antifloat D-14, TDSZein HayekPas encore d'évaluation

- Mechanics of Deformable Bodies Module 1Document14 pagesMechanics of Deformable Bodies Module 1jhuascute06Pas encore d'évaluation

- Worldwide Engineering Standards: Aluminized Sheet SteelDocument7 pagesWorldwide Engineering Standards: Aluminized Sheet SteelJose ValenciaPas encore d'évaluation

- 7.14.2 - Composite and Non-Metallic NCDocument17 pages7.14.2 - Composite and Non-Metallic NCAhmed Aman IbrahimPas encore d'évaluation

- Scraper Wiper LimpiadorDocument100 pagesScraper Wiper LimpiadorRPINILLA (EICO S.A.)Pas encore d'évaluation

- High Performance SeriesDocument8 pagesHigh Performance SeriesRonCarPas encore d'évaluation

- Light Rails: National Standard of The People's Republic of ChinaDocument13 pagesLight Rails: National Standard of The People's Republic of ChinaBaoPas encore d'évaluation

- List of Contractors and Status of Work of Sports Villa 25 To 48A & B Civil Work Plumbing Work Finishing WorkDocument4 pagesList of Contractors and Status of Work of Sports Villa 25 To 48A & B Civil Work Plumbing Work Finishing WorkManasPas encore d'évaluation

- Chemsheets GCSE 1032 More Group 7Document2 pagesChemsheets GCSE 1032 More Group 7Cheuk Him Ngai0% (1)

- 175 026510Document2 pages175 026510Abu Anas M.SalaheldinPas encore d'évaluation

- For EntingDocument5 pagesFor EntingVicente TanPas encore d'évaluation

- IGCSE Prep - 4Document17 pagesIGCSE Prep - 4Yoel Friady HutabaratPas encore d'évaluation

- BS en 682-2002 Elastomeric Seals-Materials Requirements For Seals Used in PipesDocument22 pagesBS en 682-2002 Elastomeric Seals-Materials Requirements For Seals Used in PipesM Alim Ur RahmanPas encore d'évaluation

- Buckling of Spherical Shells Subjected To External PressureDocument7 pagesBuckling of Spherical Shells Subjected To External PressureSUBHASH100% (1)

- Solutions For Heat Transfer Quiz-II: D. Height of The CylinderDocument2 pagesSolutions For Heat Transfer Quiz-II: D. Height of The CylindermkvemulaPas encore d'évaluation

- Design For RC Flat SlabsDocument70 pagesDesign For RC Flat SlabsAil AafaaqPas encore d'évaluation