Académique Documents

Professionnel Documents

Culture Documents

National Steel Bridge Alliance Prize Bridge Competition Winner

Transféré par

Marcelo AlbeTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

National Steel Bridge Alliance Prize Bridge Competition Winner

Transféré par

Marcelo AlbeDroits d'auteur :

Formats disponibles

NATIONAL STEEL BRIDGE ALLIANCE PRIZE BRIDGE COMPETITION

NATIONAL AWARD MEDIUM SPAN

US 59–Houston Gateway

HOUSTON

OWNER/STRUCTURAL ENGINEER he Southwest Freeway (US 59) is locat- post-tensioned longitudinally and overlaid with

Texas Department of Transportation

ARCHITECT

Rey de la Reza Architects, Inc., Houston

ENGINEERING SOFTWARE

ANSYS, STAAD, StruCAD*3D

T ed near downtown Houston. In 1998,

construction began for the addition of

two high-occupancy vehicle lanes and

two travel lanes as part of an effort to

increase capacity throughout the corridor. Four

continuous post-tensioned concrete bridges

spanning the freeway first needed to be replaced

composite concrete.

The bridge is founded on soldier-pile retaining

walls on each side of the depressed section.

Forty-eight-inch-diameter drilled shafts spaced at

5’ were used for the retaining wall. Each bridge

crosses the freeway at a small but slightly differ-

ent skew angle. TxDOT engineers avoided com-

to provide space for a cross section, and to plicated detailing of skewed bridges by increas-

GENERAL CONTRACTOR accommodate construction traffic control for the ing the bridge length slightly and recessing the

Williams Brothers Construction 250,000 vehicles per day that use the freeway. square ends of the bridges into the embankment

Company, Inc., Houston Increasing vertical clearance also was key: Due to at each end. All four superstructures are exact

deficient clearance under the bridge, high loads duplicates, resulting in economies in design, fab-

STEEL DETAILER frequently struck the existing Hazard Street rication, and construction.

Tensor Engineering Co., underpass, and its outside lane and sidewalk had

Indian Harbor Beach, FL been closed to traffic for more than a year as a DESIGN CHALLENGES

(AISC member, NISD member) result. The structural solution was constrained by

several primary design challenges. The surface

BRIDGE DESCRIPTION profile of the streets above the freeway had to be

The new steel tied-arch bridges clear span maintained due to residential driveways immedi-

224’ over the freeway. They carry two lanes of traf- ately adjacent to the bridge ends. The existing

fic, two bicycle lanes, a utility parapet in each freeway surface could not be lowered because of

direction, and sidewalks outside of each arch. the storm-drainage system just under the pave-

Their total widths are 60’ each. The arches, 45’ ment. It was not possible to replace the drainage

apart, are fabricated from steel plate and braced system because exceptionally high road-user

with rectangular HSS. The deck is composed of costs dictated that four lanes of traffic in each

full-width precast and prestressed panels that are direction had to be maintained throughout the

November 2003 • Modern Steel Construction

the junction with the arch rib. Designers labeled

this detail a “knee joint” and conducted extensive

finite-element analysis and detailing of it. They

evaluated many configurations and plate arrange-

ments to control high local stresses and ensure a

smooth flow of stress to the bearings. The final

configuration required large partial-penetration

welds at the intersection of the bottom plate of the

arch rib with the top plate of the tie. This weld was

modified and reduced in size at the fabricator’s

request due to difficulties in attaining a quality

weld of such size.

COST SAVINGS

project during peak hours. Additionally, traffic The arch-tie beam was encased in concrete The bridge cost of $150.00 per square foot is

control and lane configurations did not allow with reinforcing steel embedded in the precast higher than conventional bridge construction in

columns within the freeway limits. In order to segments, lapped with reinforcing steel sur- the Houston area, but the structural system

provide increased clearance below the new rounding the tie beams. The bridge deck is employed in these bridges saved many times the

bridges, minimize roadway user costs, and avoid crowned at centerline of roadway, enabling the cost of the bridges in roadway-user costs. Steel

skewed ends, a structural system was needed that precast segments to be thickened where the dead- framing and the precast segmental deck enabled

could clear an 218’ span with an apparent struc- load moment is largest. The precast deck seg- all four bridges to be built in sequence within 14

ture depth of 1’, about the thickness of typical ments were post-tensioned longitudinally to months.

concrete pavement on Houston freeways. eliminate tension in the concrete.

Essentially, a system was needed to suspend the Designers solved the issue of differential cam- AESTHETICS

pavement from above without floor beams. ber in prestressed concrete elements placed side- TxDOT engineers engaged an architect to help

by-side by placing a 4” composite overlay over ensure that the project would enhance the com-

DESIGN SOLUTION the segments. Volumetric change in the deck and munity. Brick-paved sidewalks and an ornamental

Tied arches were chosen as the structural sys- its effect on the steel structure was resolved by fence add to the attractive tied arches. Red con-

tem for aesthetic reasons, and steel was cost- stipulating completion of all deck concrete work crete differentiates bicycle lanes from traffic lanes,

effective, quick and simple to erect. and steel post-tensioning before encasing the and exposed aggregate finish was specified for

Only one weekend closure was required for arch tie in concrete. The deck was allowed to the tie-beam encasement. The shape of the arch

each bridge. There were no other traffic impacts move relative to the arch tie by slotting the bolt was reinforced by adding a continuous cap with

during construction. To maintain freeway traffic holes in the arch tie and using neoprene washers integral fiber-optic lighting, and red finials were

under the bridges during all phases of construc- under steel-plate washers. This allowed the 3’- added at the ends of each arch.

tion, the arches were located to fit within the exist- long panel bolts to rotate with minimal bending. The original freeway split the community in

ing bridge width so that the existing bridges The arches and tie beams are box sections two parts when it was built in 1961. The previous

could serve as work platforms. Even though one with thin webs. Lateral bracing was required bridges were inadequate for pedestrian traffic and

existing bridge was damaged due to multiple along the arch for stability. Bracing could have led to a sense of separation. The new landmark

impacts over the years, the lightweight steel arch- been avoided with thicker webs but at the expense bridges beckon pedestrian traffic and have

es still could be shored from the bridge deck. The of increased steel weight. The bridges were origi- restored the feeling of one community. ★

length of the new bridges enabled construction of nally detailed with X-bracing. A Vierendeel sys-

the abutments without affecting the existing tem was substituted for aesthetic reasons. Further

bridges or impacting traffic. Once the steel arches analysis during construction revealed that the

were in place, straddling the existing bridges, the Vierendeel system was inadequate under wind

contractor used explosives to drop the old loading, and X-bracing was added to the already

bridges down to freeway pavement level. Workers erected Vierendeel braces. The X-brace nodes are

broke up the concrete using conventional meth- cylindrical sections. The circular or semicircular

ods. The speed of steel erection also enabled top and bottom plates are welded to the arch rib.

TxDOT engineers to minimize the duration of The HSS braces are welded to the top and bottom

street closures. plates, similar to a gusset-plate connection.

The full-width precast segments that form the Finally, the circumference is enclosed and seal-

deck are incarnations of precast slab beams com- welded all around. This fully field-welded detail

monly used in Texas coastal areas for their shal- enabled all braces to be cut square, and allowed

low structure depth. Instead of resting on bear- for axial and rotational fabrication error along

ings at abutments, designers suspended them three axes.

from the arch-tie beams using bolts. The precast Detailing the structural steel at the junction of

deck segments were installed over active traffic the arch with the arch tie was a challenge. Post-

lanes during the same-weekend freeway closure tensioning of the arch tie provided redundancy

that was used for demolition of the existing and virtually eliminated tension in the tie. This

bridges. allayed concerns of tie-beam problems, but

necessitated passing the arch-tie flanges through

Modern Steel Construction • November 2003

Vous aimerez peut-être aussi

- AASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Document8 pagesAASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Mike2322Pas encore d'évaluation

- Transverse Post-Tensioning Design and Detailing of Precast Prestressed Concrete Adjacent-Box-Girder Bridges PDFDocument15 pagesTransverse Post-Tensioning Design and Detailing of Precast Prestressed Concrete Adjacent-Box-Girder Bridges PDFSanti CheewabantherngPas encore d'évaluation

- 1997v01 High StrengthDocument5 pages1997v01 High StrengthIgnacio Hiram M RoquePas encore d'évaluation

- 1999 Harry H. Edwards Industry Advancement Award Winners Projects HighlightDocument22 pages1999 Harry H. Edwards Industry Advancement Award Winners Projects HighlightAnderson UrreaPas encore d'évaluation

- Dot 28771 DS1Document2 pagesDot 28771 DS1Marco BourdonPas encore d'évaluation

- Evaluation of A High Performance Concrete Box Girder BridgeDocument12 pagesEvaluation of A High Performance Concrete Box Girder Bridgeyitakel assfawPas encore d'évaluation

- Medway Bridge DesignDocument10 pagesMedway Bridge DesignTamaduianu IoanPas encore d'évaluation

- Pages From Smith & Hendy 2009 2Document1 pagePages From Smith & Hendy 2009 2Napong SubanpongPas encore d'évaluation

- Chenab Bridge Construction Project Group ReportDocument6 pagesChenab Bridge Construction Project Group Reportaniruddha nikamPas encore d'évaluation

- 73-Article Text-329-1-10-20190904Document5 pages73-Article Text-329-1-10-20190904Ghiyas UddinPas encore d'évaluation

- Steel and Concrete Composite Design For Long-Span BridgesDocument6 pagesSteel and Concrete Composite Design For Long-Span BridgesamigotPas encore d'évaluation

- Precast Prestressed Concrete Short Span BridgesDocument41 pagesPrecast Prestressed Concrete Short Span Bridgescdestudos100% (1)

- Recuperação Estrutural ViadutoDocument4 pagesRecuperação Estrutural ViadutojclessioPas encore d'évaluation

- Shin Karato Bridge in Kobe JapanDocument3 pagesShin Karato Bridge in Kobe JapanZakee MohamedPas encore d'évaluation

- KURILPA BRIDGE TENSEGRITY DESIGNDocument4 pagesKURILPA BRIDGE TENSEGRITY DESIGNkamomartPas encore d'évaluation

- Simple-Made - Continuous Design Benefits Unbalanced Two-Span Steel BridgeDocument10 pagesSimple-Made - Continuous Design Benefits Unbalanced Two-Span Steel BridgeGinoPas encore d'évaluation

- Buitengragt BridgeDocument4 pagesBuitengragt BridgeJohn AndersonPas encore d'évaluation

- Planning and Designing of Bridge Over Solani RiverDocument5 pagesPlanning and Designing of Bridge Over Solani RiverCurious RajPas encore d'évaluation

- DOUBLE LANE LEAFLET 8 PGDocument8 pagesDOUBLE LANE LEAFLET 8 PGAshish SharmaPas encore d'évaluation

- NN7fP: Antiseismic Bridge Highway-Railway FramedDocument2 pagesNN7fP: Antiseismic Bridge Highway-Railway FramedTeo Peng KeatPas encore d'évaluation

- 20-0005 Alawneh MA22Document21 pages20-0005 Alawneh MA22Nicholas FeatherstonPas encore d'évaluation

- Hao - I35W - NoteDocument7 pagesHao - I35W - NoteJobs feelPas encore d'évaluation

- Imp Design of Rail Over BridgeDocument5 pagesImp Design of Rail Over BridgeShivangi MishraPas encore d'évaluation

- Design and Testing of Two Bridge Railings For Transverse Nail-Laminated Timber Deck BridgesDocument12 pagesDesign and Testing of Two Bridge Railings For Transverse Nail-Laminated Timber Deck BridgesCarlla Camilly Verneque Cordeiro de Moura JorgePas encore d'évaluation

- Land Transportation Implementation Cross (Bridge) Using Box Pushing TechnologyDocument5 pagesLand Transportation Implementation Cross (Bridge) Using Box Pushing TechnologyNaresh KumarPas encore d'évaluation

- Design and Construction of Single Lane Road BridgesDocument10 pagesDesign and Construction of Single Lane Road BridgesIsacjohnkurishinkalPas encore d'évaluation

- C CI Segmental Concrete Bridges Oct 051Document4 pagesC CI Segmental Concrete Bridges Oct 051Varun VermaPas encore d'évaluation

- July10 Bagley ST Bridge WebDocument6 pagesJuly10 Bagley ST Bridge Websiva_civil4051Pas encore d'évaluation

- 01 4 132Document5 pages01 4 132cmkohPas encore d'évaluation

- Bridge RetroDocument13 pagesBridge RetroKiller BeePas encore d'évaluation

- UntitledDocument102 pagesUntitledASSEFAGETNETPas encore d'évaluation

- Chapter 1 FBDDocument6 pagesChapter 1 FBDephrem100% (1)

- Concrete Segmental Bridges: Design and Construction ofDocument8 pagesConcrete Segmental Bridges: Design and Construction ofMinh LinhTinhPas encore d'évaluation

- 111 46 - Seamless Pavements - 0913RB 10.47.24 AMDocument4 pages111 46 - Seamless Pavements - 0913RB 10.47.24 AMsky moonPas encore d'évaluation

- Construction of Large Span Shallow Tunnels: A Case Study From The New M5 - PublishedDocument6 pagesConstruction of Large Span Shallow Tunnels: A Case Study From The New M5 - Publisheddafo407Pas encore d'évaluation

- RH Girder Method for Road Under BridgesDocument4 pagesRH Girder Method for Road Under BridgesAmarpreet SinghPas encore d'évaluation

- 21 M.V. Jatkar and G.P. Joshi (May 2005)Document4 pages21 M.V. Jatkar and G.P. Joshi (May 2005)Mayank SinghPas encore d'évaluation

- June 2017 CI Franklin Avenue Bridge ArticleDocument10 pagesJune 2017 CI Franklin Avenue Bridge ArticleFernando Castillo HerreraPas encore d'évaluation

- Steel Bridge Erection MethodsDocument9 pagesSteel Bridge Erection MethodsMiguel PerezPas encore d'évaluation

- 1995 - Immersed Steel Tube Tunnels An American Experience PDFDocument15 pages1995 - Immersed Steel Tube Tunnels An American Experience PDFIvonne CalderaPas encore d'évaluation

- Detailed Design of The Main Bridge - Viaduct Spans in Padma Multipurpose Bridge Project, BangladeshDocument10 pagesDetailed Design of The Main Bridge - Viaduct Spans in Padma Multipurpose Bridge Project, BangladeshS S Reddy SomuPas encore d'évaluation

- Post-tensioned prestressed concrete girder bridge studyDocument78 pagesPost-tensioned prestressed concrete girder bridge studyBharath Chakravarthy100% (3)

- Incremental Launching of Composite Bridge Deck Ch198Document6 pagesIncremental Launching of Composite Bridge Deck Ch198Miguel PerezPas encore d'évaluation

- Bren 2006 159 1 35Document8 pagesBren 2006 159 1 35rohanZorbaPas encore d'évaluation

- BBR CMI Tendon Brochure - OptimizeDocument3 pagesBBR CMI Tendon Brochure - OptimizeWenix008 OniPas encore d'évaluation

- Bridge at BhagalpurDocument9 pagesBridge at BhagalpurDhruv GuptaPas encore d'évaluation

- RDSO Substructure Code PDFDocument71 pagesRDSO Substructure Code PDFTarun Sai100% (1)

- CE 416 Prestressed Concrete Lab ManualDocument47 pagesCE 416 Prestressed Concrete Lab Manualkorosh75Pas encore d'évaluation

- MN_crosstown_spr09Document27 pagesMN_crosstown_spr09baalorkakaPas encore d'évaluation

- Transverse Post-Tensioning Design and Detailing of Precast, Prestressed Concrete Adjacent-Box-Girder BridgesDocument16 pagesTransverse Post-Tensioning Design and Detailing of Precast, Prestressed Concrete Adjacent-Box-Girder BridgesLorenzo LeardiniPas encore d'évaluation

- Gatwick Air BridgeDocument7 pagesGatwick Air BridgemrasdanPas encore d'évaluation

- 2008 GeoEdmonton Tunnel BridgeunderpinningDocument8 pages2008 GeoEdmonton Tunnel BridgeunderpinningPrashantPas encore d'évaluation

- Schlick ReportDocument5 pagesSchlick ReportAg PatriaPas encore d'évaluation

- Full Depth Precast Concrete Bridge Deck System for Rapid ConstructionDocument17 pagesFull Depth Precast Concrete Bridge Deck System for Rapid ConstructionAfdhal LazuardiansyahPas encore d'évaluation

- Design of Long Span Concrete Box Girder Bridges: Challenges and SolutionsDocument11 pagesDesign of Long Span Concrete Box Girder Bridges: Challenges and SolutionsRajkamal AroraPas encore d'évaluation

- The Design of The Ruck-A-Chucky BridgeDocument7 pagesThe Design of The Ruck-A-Chucky BridgeAbdelaziz AbdelazizPas encore d'évaluation

- Bridge D & E Almonte PDFDocument3 pagesBridge D & E Almonte PDFShamaPas encore d'évaluation

- A Guide to Some of the Equations used in Constructing a Suspension BridgeD'EverandA Guide to Some of the Equations used in Constructing a Suspension BridgePas encore d'évaluation

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsD'EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsPas encore d'évaluation

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionD'EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionPas encore d'évaluation

- Metal Building Crane Detailsby Nucor Building SystemsDocument22 pagesMetal Building Crane Detailsby Nucor Building SystemsMarcelo AlbePas encore d'évaluation

- VSL ThreadbarDocument8 pagesVSL ThreadbarMarcelo AlbePas encore d'évaluation

- VSL SSI 2000 Stay Cable SystemDocument13 pagesVSL SSI 2000 Stay Cable SystemMarcelo AlbePas encore d'évaluation

- Bar Grating ManualDocument36 pagesBar Grating ManualSiPp.T100% (1)

- (Apostila) TreliçasDocument85 pages(Apostila) TreliçasEduardo BandeiraPas encore d'évaluation

- Hilti Hit Hy 150-5193Document10 pagesHilti Hit Hy 150-5193Marcelo AlbePas encore d'évaluation

- S3LDocument1 pageS3LkcarmachPas encore d'évaluation

- Mac Alloy Tension StructuresDocument16 pagesMac Alloy Tension StructuresFrancisco LebrePas encore d'évaluation

- DIN 18914 - Silos Metálicos PDFDocument6 pagesDIN 18914 - Silos Metálicos PDFMarcelo AlbePas encore d'évaluation

- CTT Elastomeric BearingsDocument20 pagesCTT Elastomeric Bearingsjajaytt100% (1)

- Cranes Today 2009-01Document60 pagesCranes Today 2009-01Marcelo AlbePas encore d'évaluation

- CP1998 - 37 - Welding Inspection PDFDocument9 pagesCP1998 - 37 - Welding Inspection PDFMarcelo AlbePas encore d'évaluation

- ANSI-ASAE EP433 - Loads Exerted by Free Flowing Grain On BinsDocument4 pagesANSI-ASAE EP433 - Loads Exerted by Free Flowing Grain On BinsMarcelo AlbePas encore d'évaluation

- CTT Elastomeric BearingsDocument20 pagesCTT Elastomeric Bearingsjajaytt100% (1)

- JDK Procedures (July 2017)Document12 pagesJDK Procedures (July 2017)Ethan PoonPas encore d'évaluation

- VTBS 21-7Document1 pageVTBS 21-7wong keen faivPas encore d'évaluation

- Iot Based Smart Pedestrian Crossing SystemDocument3 pagesIot Based Smart Pedestrian Crossing Systemabdul kareemPas encore d'évaluation

- Detailed road inventory and traffic analysis of an intersection in Bantay, Ilocos SurDocument4 pagesDetailed road inventory and traffic analysis of an intersection in Bantay, Ilocos SurVinz GonzagaPas encore d'évaluation

- Lell PDFDocument10 pagesLell PDFMiguel Angel MartinPas encore d'évaluation

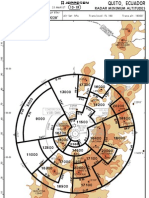

- Sequ/Uio Quito, Ecuador: 10-1R Mariscal Sucre Intl Radar Minimum Altitudes 119.7 121.2 9228'Document21 pagesSequ/Uio Quito, Ecuador: 10-1R Mariscal Sucre Intl Radar Minimum Altitudes 119.7 121.2 9228'Gerardo Rol100% (2)

- Pedestrian Subways For East Tsim Sha Tsui StationDocument7 pagesPedestrian Subways For East Tsim Sha Tsui StationSomesh SiddharthPas encore d'évaluation

- 121 West 27 Street, Suite 705 New York, NY 10001 (212) 242-2490 FAX: (212) 242-2549Document18 pages121 West 27 Street, Suite 705 New York, NY 10001 (212) 242-2490 FAX: (212) 242-2549M-NCPPCPas encore d'évaluation

- RNP W RWY 33 (AR) Approach Chart for Campinas / Viracopos Int'l Airport (SBKPDocument1 pageRNP W RWY 33 (AR) Approach Chart for Campinas / Viracopos Int'l Airport (SBKPLuciano PedroPas encore d'évaluation

- CAIS - Complete Manual - Rev 3 - 2023-03-30Document1 340 pagesCAIS - Complete Manual - Rev 3 - 2023-03-30Muhammad UmarPas encore d'évaluation

- Revised Schedules - Jalgaon City RoadDocument59 pagesRevised Schedules - Jalgaon City RoadHemant GhotkarPas encore d'évaluation

- Jeppview For Windows: General Information General InformationDocument55 pagesJeppview For Windows: General Information General InformationLuis SaldañaPas encore d'évaluation

- Benefit-Cost Analysis of Potential Safety Improvements in Conjunction With 3R ProjectsDocument13 pagesBenefit-Cost Analysis of Potential Safety Improvements in Conjunction With 3R ProjectsRonaldo B VillaromanPas encore d'évaluation

- Bridge Technical Note 2022 - 011 Approach Slabs v20 May 2022Document5 pagesBridge Technical Note 2022 - 011 Approach Slabs v20 May 2022AlbertoPas encore d'évaluation

- HCM 2016 Vol 1 PDFDocument330 pagesHCM 2016 Vol 1 PDFAngie Suescún100% (7)

- 3.4 Capacity-Level-of-ServiceDocument21 pages3.4 Capacity-Level-of-ServiceMikealla DavidPas encore d'évaluation

- Traffic Speed StudyDocument19 pagesTraffic Speed StudyMd. Abdullah Al ArafatPas encore d'évaluation

- Brian's Guide To Getting Around Germany - German Traffic Signs & Signals (Page 2 of 2)Document19 pagesBrian's Guide To Getting Around Germany - German Traffic Signs & Signals (Page 2 of 2)Mentewab EthiopiaPas encore d'évaluation

- HojunLee - Black Ice Detection Using CNN For The Prevention of Accidents in Automated VehicleDocument4 pagesHojunLee - Black Ice Detection Using CNN For The Prevention of Accidents in Automated Vehicleseokheehan06Pas encore d'évaluation

- Measuring Non-Motorized Accessibility and Connectivity in A Robust Pedestrian NetworkDocument27 pagesMeasuring Non-Motorized Accessibility and Connectivity in A Robust Pedestrian NetworkAhmad HafizPas encore d'évaluation

- Calls Back. Indian RTR-Radio Telephoney Restricted (A), For Part-1 (Doc-B)Document137 pagesCalls Back. Indian RTR-Radio Telephoney Restricted (A), For Part-1 (Doc-B)Gaurav Sawaai100% (8)

- DPWH History Background ExistenceDocument50 pagesDPWH History Background ExistenceFor StuffsPas encore d'évaluation

- Collision Report Details Deadly Tanker and Bulk Carrier CrashDocument42 pagesCollision Report Details Deadly Tanker and Bulk Carrier CrashLyubomir IvanovPas encore d'évaluation

- ARB 350/03 NOV/OVD-LCG: - Not For Real World NavigationDocument37 pagesARB 350/03 NOV/OVD-LCG: - Not For Real World NavigationjosePas encore d'évaluation

- History of Indian RailwaysDocument12 pagesHistory of Indian Railwaysaaquib ansariPas encore d'évaluation

- Modern Communication Methods Bring People TogetherDocument5 pagesModern Communication Methods Bring People TogetherHuong TranPas encore d'évaluation

- SP09 Australian 10 Years GregDocument30 pagesSP09 Australian 10 Years GregMasuda AkterPas encore d'évaluation

- WPDL (Dil) - Pres Nicolau Lobato IntlDocument12 pagesWPDL (Dil) - Pres Nicolau Lobato IntlAbang FayyadPas encore d'évaluation

- A320 - Type Rating Student Guide - V1.0Document55 pagesA320 - Type Rating Student Guide - V1.0langkawiPas encore d'évaluation

- Expressways Irc SP 99 2013Document4 pagesExpressways Irc SP 99 2013Suyog GorePas encore d'évaluation