Académique Documents

Professionnel Documents

Culture Documents

Modbus & BACNet Communication Information For Centrifugal

Transféré par

Savy PhanethDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Modbus & BACNet Communication Information For Centrifugal

Transféré par

Savy PhanethDroits d'auteur :

Formats disponibles

Centrifugal Installation Operation and Maintenance Manual

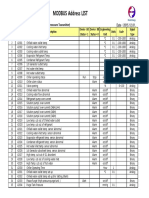

Modbus Communication Information

Modbus Standard Objects

Read

Network Control

/ Data Type Index Description

Property

Write

Cool Setpoint(9) R/W Holding Register 40002 3~21

Ice Setpoint R/W Holding Register 40051 -9.4~3.4

Heat Setpoint R/W Holding Register 40006 35~55

Capacity Limit Setpoint(10) W Holding Register 40004 0~100%

Chiller Mode Setpoint(2) W Holding Register 40146 1=Ice,2=Cool,3=Heat

Chiller Enable Input(4) R/W Coil 2 0=Off,1=On

0=Off,

Run Enabled R Coil 3

1=Run Allowed

Chiller Local/Remote R Coil 6 0=Remote,1=Local

0=Not Limited,

Chiller Limited R Coil 7

1=Limited

Chiller Mode Output R Holding Register 40148 1=Ice,2=Cool,3=Heat

0=Off,1=Start,

2=Run,

Chiller Status(1) R Holding Register 40147

3=Pre-Shutdown,

4=Service

Active Setpoint R Holding Register 40003 -9.4~55

Actual Capacity(3) R Holding Register 40011 0~125%

Capacity Limit Output R Holding Register 40043 0~100%

Evaporator Entering

R Holding Register 40005 -25~100

Water Temperature(5)

Evaporator Leaving

R Holding Register 40007 -25~100

Water Temperature(6)

Condenser Entering

R Holding Register 40008 -25~100

Water Temperature(7)

Condenser Leaving

R Holding Register 40009 -25~100

Water Temperature(8)

Heat Recovery Entering

R Holding Register 40023 -25~100

Water Temperature

Heat Recovery Leaving

R Holding Register 40024 -25~100

Water Temperature

0=No Flow,

Evaporator Flow Switch Status R Coil 8

1=Flow

0=No Flow,

Condenser Flow Switch Status R Coil 9

1=Flow

0=Pump Off,

Evaporator Pump Status R Coil 30

1=Pump On

0=Pump Off,

Condenser Pump Status R Coil 32

1=Pump On

0=Pump No.1

Pump Select R/W Coil 20

1=Pump No.2

Evaporator Pump Run Hours

Pump Select R Holding Register 40176 0~65,535

Pump#2 Holding Register 40232 0~65,535

Condenser Pump Run Hours R

66 Engineered for Flexibility and performance

Centrifugal Installation Operation and Maintenance Manual

Pump Select Holding Register 40177 0~65,535

Pump#2 Holding Register 40233 0~65,535

Comp Select R/W Holding Register 40161 0~65,535

Condenser Refrigerant Pressure

Compressor Select R Holding Register 40022 0~2800kPa

Compressor #2 Holding Register 40094 0~2800kPa

Condenser Saturated

Temperature

R

Compressor Select Holding Register 40021 -25~62

Compressor #2 Holding Register 40093 -25~62

Evaporator Refrigerant Pressure

Compressor Select R Holding Register 40018 0~910kPa

Compressor #2 Holding Register 40091 0~910kPa

Evaporator Saturated

Temperature

R

Compressor Select Holding Register 40017 -25~40

Compressor #2 Holding Register 40090 -25~40

Liquid Line Temperature

Compressor Select R Holding Register 40037 -25~100

Compressor #2 Holding Register 40105 -25~100

Compressor Current(Benshow

Starter)

R

Compressor Select Holding Register 40027 0~65,535Amps

Compressor #2 Holding Register 40096 0~65,535Amps

Compressor Voltage(Benshow

Starter)

R

Compressor Select Holding Register 40030 0~65,535Volts

Compressor #2 Holding Register 40099 0~65,535Volts

Compressor Power(Benshow

Starter)

R

Compressor Select Holding Register 40028 0~65,535kiloWatts

Compressor #2 Holding Register 40097 0~65,535kiloWatts

Compressor Percent RLA

Compressor Select R Holding Register 40026 0~125%

Compressor #2 Holding Register 40095 0~125%

Discharge Temperature

Compressor Select R Holding Register 40020 -25~100

Compressor #2 Holding Register 40092 -25~100

Suction Temperature

Compressor Select R Holding Register 40016 -25~100

Compressor #2 Holding Register 40089 -25~100

Oil Feed Pressure

Compressor Select R Holding Register 40033 0~2800kPa

Compressor #2 Holding Register 40101 0~2800kPa

Oil Sump Pressure

Compressor Select R Holding Register 40034 0~910kPa

Compressor #2 Holding Register 40102 0~910kPa

Oil Feed Temperature

Compressor Select R Holding Register 40035 -25~100

Compressor #2 Holding Register 40103 -25~100

Oil Sump Temperature

R

Compressor Select Holding Register 40036 -25~100

Engineered for Flexibility and performance 67

Centrifugal Installation Operation and Maintenance Manual

Compressor #2 Holding Register 40104 -25~100

Compressor Run Hours

Compressor Select R Holding Register 40175 0~65,535

Compressor #2 Holding Register 40236 0~65,535

Compressor Starts

Compressor Select R Holding Register 40174 0~65,535

Compressor #2 Holding Register 40235 0~65,535

Modbus Alarms Messages

WSC

WDC

Holding

# Description WCC Bit

Register

HSC

TSC

Warnings

Entering Condenser Water Temperature Sensor

1 X 40130 1

Fault

Entering Condenser Water Temperature Sensor

2 X 40130 2

Fault

3 Liquid Line Refrigerant Temperature Sensor Fault X 40130 3

Leaving Condenser Water Temperature Sensor

4 X 40130 4

Fault

Problems

5 NA 40131 0

6 NA 40131 1

7 NA 40131 2

8 NA 40131 3

9 Condenser Water Freeze Protect Comp1 X 40131 4

10 Condenser Water Freeze Protect Comp2 X 40131 5

11 NA 40131 6

12 NA 40131 7

13 Condenser Pump#1 Fault X 40131 8

14 Condenser Pump#2 Fault X 40131 9

15 NA X 40131 10

16 NA X 40131 11

17 NA 40131 12

18 NA 40131 13

Entering Evaporator Temperature Sensor

19 X 40131 14

Fault(EWT reset active)

20 NA 40131 15

21 NA X 40132 0

22 NA X 40132 1

23 NA 40132 2

24 NA 40132 3

25 NA 40132 4

26 NA X 40132 5

27 NA X 40132 6

28 NA 40132 7

29 NA 40132 8

30 NA X 40132 9

31 NA X 40132 10

32 NA 40132 11

68 Engineered for Flexibility and performance

Centrifugal Installation Operation and Maintenance Manual

33 NA 40132 12

34 Evaporator Water Freeze Protect Comp 1 X 40132 13

35 Evaporator Water Freeze Protect Comp 2 X 40132 14

36 NA 40132 15

37 NA 40133 0

38 Evaporator Pump 1 Fault X 40133 1

39 Evaporator Pump 2 Fault X 40133 2

40 NA 40133 3

41 NA 40133 4

42 Compressor Current Overload Trip 1 X 40133 5

43 Compressor Current Overload Trip 2 X 40133 6

44 NA 40133 7

45 NA 40133 8

46 Motor Current Imbalance On Compressor 1 X 40133 9

47 Motor Current Imbalance On Compressor 2 X 40133 10

48 NA 40133 11

49 NA 40133 12

50 Low Motor Current Comp 1 X 40133 13

51 Low Motor Current Comp 2 X 40133 14

52 NA 40133 15

53 NA 40134 0

54 NA 40134 1

55 NA 40134 2

56 NA 40134 3

57 High Motor Temperature Comp 1 X 40134 4

58 High Motor Temperature Comp2 X 40134 5

59 NA 40134 6

60 NA 40134 7

61 Phase Loss At Compressor 1 X 40134 8

62 Phase Loss At Compressor 2 X 40134 9

63 NA 40134 10

64 NA 40134 11

65 Phase Reversal At Compressor# 1 X 40134 12

66 Phase Reversal At Compressor# 2 X 40134 13

67 NA 40134 14

68 NA 40134 15

69 Overvoltage On Compressor# 1 X 40135 0

70 Overvoltage On Compressor# 2 X 40135 1

71 NA 40135 2

72 NA 40135 3

73 Under voltage On Compressor# 1 X 40135 4

74 Under voltage On Compressor# 2 X 40135 5

75 NA 40135 6

76 NA 40135 7

77 NA 40135 8

78 Condenser Pressure Sensor Fault Circuit 1 X 40135 9

79 Condenser Pressure Sensor Fault Circuit 2 X 40135 10

80 NA 40135 11

81 NA 40135 12

82 No Condenser Water Flow X 40135 13

83 NA 40135 14

Engineered for Flexibility and performance 69

Centrifugal Installation Operation and Maintenance Manual

84 High Condenser Pressure Circuit 1 X 40135 15

85 High Condenser Pressure Circuit 2 X 40136 0

86 NA 40136 1

87 NA 40136 2

88 No Compressor Stop Comp #1 X 40136 3

89 No Compressor Stop Comp #2 X 40136 4

90 NA 40136 5

91 NA 40136 6

92 Discharge Temperature Sensor Fault Circuit 1 X 40136 7

93 Discharge Temperature Sensor Fault Circuit 2 X 40136 8

94 NA 40136 9

95 NA 40136 10

96 High Discharge Temperature Circuit 1 X 40136 11

97 High Discharge Temperature Circuit 2 X 40136 12

98 NA 40136 13

99 NA 40136 14

100 NA 40136 15

101 No Evaporator Water Flow X 40137 0

102 NA 40137 1

103 NA 40137 2

104 Low Evaporator Pressure Circuit 1 X 40137 3

105 Low Evaporator Pressure Circuit 2 X 40137 4

106 NA 40137 5

107 NA 40137 6

108 NA 40137 7

109 Evaporator Pressure Sensor Fault Circuit 1 X 40137 8

110 Evaporator Pressure Sensor Fault Circuit 2 X 40137 9

111 NA 40137 10

112 NA 40137 11

113 Ground Fault Protection 1 X 40137 12

114 Ground Fault Protection 2 X 40137 13

115 NA 40137 14

116 NA 40137 15

117 Economizer Pressure Sensor Fault 40138 0

118 NA 40138 1

119 IGV Position Sensor Fault 40138 2

120 NA 40138 3

121 DDC Position Sensor Fault 40138 4

122 NA 40138 5

123 Low Discharge Superheat 40138 6

124 NA 40138 7

125 Low Lift Pressure 40138 8

126 NA 40138 9

127 Hot Gas Bypass Position Sensor Fault 40138 10

128 NA 40138 11

129 NA 40138 12

130 NA 40138 13

131 NA 40138 14

132 NA 40138 15

133 NA 40139 0

134 NA 40139 1

135 Leaving Evaporator Water Temperature Sensor X 40139 2

70 Engineered for Flexibility and performance

Centrifugal Installation Operation and Maintenance Manual

Fault Comp 1

Leaving Evaporator Water Temperature Sensor 40139

136 X 3

Fault Comp 2

137 NA 40139 4

138 NA 40139 5

139 NA 40139 6

140 Mechanical High Pressure Circuit 1 X 40139 7

141 Mechanical High Pressure Circuit 2 X 40139 8

142 NA 40139 9

143 NA 40139 10

144 Low Oil Net Pressure Comp 1 X 40139 11

145 Low Oil Net Pressure Comp 2 X 40139 12

146 NA 40139 13

147 NA 40139 14

148 High Oil Feed Temperature Comp 1 X 40139 15

149 High Oil Feed Temperature Comp 2 X 40140 0

150 NA 40140 1

151 NA 40140 2

152 Low Oil Feed Temperature Comp 1 X 40140 3

153 Low Oil Feed Temperature Comp 2 X 40140 4

154 NA 40140 5

155 NA 40140 6

156 Oil Feed Temperature Sensor Fault Comp 1 X 40140 7

157 Oil Feed Temperature Sensor Fault Comp 2 X 40140 8

158 NA 40140 9

159 NA 40140 10

160 NA 40140 11

161 NA 40140 12

162 NA 40140 13

163 NA 40140 14

164 NA 40140 15

165 NA 40141 0

166 NA 40141 1

167 NA 40141 2

168 Oil Feed Pressure Sensor Fault Comp 1 X 40141 3

169 Oil Feed Pressure Sensor Fault Comp 2 X 40141 4

170 NA 40141 5

171 NA 40141 6

172 Oil Sump Pressure Sensor Fault Comp 1 X 40141 7

173 Oil Sump Pressure Sensor Fault Comp 2 X 40141 8

174 NA 40141 9

175 NA 40141 10

176 Oil Sump Temperature Sensor Fault Comp 1 X 40141 11

177 Oil Sump Temperature Sensor Fault Comp 2 X 40141 12

178 NA 40141 13

179 NA 40141 14

180 NA 40141 15

181 Starter Fault Compressor 1 X 40142 0

182 Starter Fault Compressor 2 X 40142 1

183 NA 40142 2

184 NA 40142 3

185 No Starter Transition Compressor 1 X 40142 4

Engineered for Flexibility and performance 71

Centrifugal Installation Operation and Maintenance Manual

186 No Starter Transition Compressor 2 X 40142 5

187 NA 40142 6

188 NA 40142 7

189 No Oil Pressure Start Comp 1 X 40142 8

190 No Oil Pressure Start Comp2 X 40142 9

191 NA 40142 10

192 NA 40142 11

193 NA 40142 12

194 NA 40142 13

195 NA 40142 14

196 NA 40142 15

197 Surge High Suct SH-Running Comp 1 X 40143 0

198 Surge High Suct SH-Running Comp 2 X 40143 1

199 NA 40143 2

200 NA 40143 3

201 Surge High Suct SH-Starting Comp 1 X 40143 4

202 Surge High Suct SH-Starting Comp 2 X 40143 5

203 NA 40143 6

204 NA 40143 7

205 Suction Temperature Sensor Fault Comp 1 X 40143 8

206 Suction Temperature Sensor Fault Comp 2 X 40143 9

207 NA 40143 10

208 NA 40143 11

209 Vanes Open No Start Comp 1 X 40143 12

210 Vanes Open No Start Comp 2 X 40143 13

211 NA 40143 14

212 NA 40143 15

72 Engineered for Flexibility and performance

Centrifugal Installation Operation and Maintenance Manual

BACnet Communication Information(M350147406)

BACnet Standard Objects

Network Control Property Units Object Name Description

Object Instance

Keypad attributes available as

Object Type

BACnet Standard Objects for

W = Write

R = Read

network control of the unit

Active Setpoint R AI 7 °F ActiveLvgWaterTarg -40° 199°F

et

*Actual Capacity (3) R AI 9 NA ChillerCapacity 0 160%

Actual RPM R 0-32678

AI 56 RPM Comp1ActualRPM

AI 60 RPM Comp2ActualRPM

*Capacity Limit (Output) (10) R AI 8 NA ActiveCapacityLimit 0 160%

*Capacity Limit Setpoint (10) W AO 32 NA NetworkCapacityLimi 0 to 160%; Default=100%

*Chiller Enable (Input) (4) W BV 41 NA ChillerEnable 0=Request Chiller Off,

1=Request Chiller On,

Chiller Limited R BI 39 NA ChillerLimited 0=Not Limited, 1=Limited

Chiller Local/Remote R BI 38 NA ChillerLocalRemote 0=Remote, 1=Local

Chiller Mode Output R MSI 44 NA ActiveMode 1=Ice, 2=Cool, 3=Heat,

Chiller Mode Setpoint W MSO 45 NA ChillerOperationMod 1=Ice, 2=Cool, 3=Heat,

Chiller On Off R BI 33 NA UnitOFF 0=Chiller Off, 1=Chiller On

Chiller Power R AI 67 NA TotalChillerKW Totalized compressor

*Chiller Status BACnet (1) R MSI 43 NA UnitStatus 1=Off, 2=Start,3=Run,

4=Pre Shutdown,

Chiller Type R MSI 48 NA DAIKIN ChillerType 1=AGZS, 2=AGZD,

3=WGZD/TGZD,

4=WSC/WDC/HTS/HTD,

5=AGSU, 6=ACZS,

7=ACZD, 8=HTM/HTMXE,

9=WGSD,

10=AGSD, 11=AGZS,

12=AGZDU, 13=WGZU,

Compressor 2 Active Capacity R AI 88 Percent Comp2ActiveCapLimi

Compressor 2 VFD Speed R AI 80 Percent Comp2Speed

Compressor Current R Amperes 0 65,535

AI 51 Current

AI 76 Comp2Current

AI 95 Comp3Current

AI 103 Comp4Current

AI 111 Comp5Current

AI 117 Comp6Current

Compressor Discharge R °F

Temperature AI 18 DischargeTemp -460° 621°F

AI 72 Comp2DischargeTm -460° 621°F

Compressor Percent RLA R Percent -3276.8 3276.7

AI 24 CompMotorCurrentP

AI 75 Comp2CurrentPercen

AI 94 Comp3CurrentPercen

AI 102 Comp4CurrentPercen

AI 110 Comp5CurrentPercen

AI 116 Comp6CurrentPercen

Compressor Power R kiloWatts 0 65,535

AI 54 Kilowatts

AI 77 Comp2Kilowatts

AI 96 Comp3Kilowatts

AI 104 Comp4Kilowatts

AI 112 Comp5Kilowatts

AI 118 Comp6Kilowatts

Compressor Run Hours R Hours

Engineered for Flexibility and performance 73

Centrifugal Installation Operation and Maintenance Manual

Network Control Property Units Object Name Description

Object Instance

Keypad attributes available as

Object Type

BACnet Standard Objects for

W = Write

R = Read

network control of the unit

Compressor Select AI 26 NA CompHours

AI 93 Comp2Hours

AI 101 Comp3Hours

AI 109 Comp4Hours

Compressor Select W MSO 46 NA CompSelect 1=Comp1, 2=Comp2,

3=Comp3, 4=Comp4,

Compressor Starts R NA

Compressor Select AI 25 CompStarts 0 65,535

AI 92 Comp2Starts

AI 100 Comp3Starts

AI 108 Comp4Starts

Compressor Status R NA Bitwise logic:

Compressor Select AI 123 CompressorStatus Bit 0=Off

AI 91 Comp2Status Bit 1=Start Oil Pump,

AI 99 Comp3Status Bit

AI 107 2=Interlock/Prelube,

Comp4Status

Bit 3=Run

AI 115 Comp5Status Bit 4=Shutdown

AI 121 Comp6Status Bit 5=Postlube

Suction Line Temperature R °F -40° 244°F

Compressor Select AI 15 SuctionTemp

AI 69 Comp2SuctTemp

Compressor Voltage R VAC 0 65,535

Compressor Select AI 52 Voltage

AI 79 Comp2Voltage

AI 98 Comp3Voltage

AI 106 Comp4Voltage

AI 114 Comp5Voltage

AI 120 Comp6Voltage

*Condenser Entering Water R AI 3 °F EntCondWaterTemp -40° 244°F

Temperature (7)

Condenser Flow Switch Status R BI 35 NA CondWaterFlowStatus 0=No Flow, 1=Flow

*Condenser Leaving Water R AI 4 °F LvgCondWaterTemp -40° 244°F

Condenser Pump Run Hours R NA

AI 28 CondPumpOperHours 0 65,535

AI 90 CondPmp2Hrs 0 65,535.

Condenser Refrigerant Pressure R psi

Compressor Select AI 16 CondPressure -3276.8 3276.7

AI 74 Comp2CondPress -3276.8 3276.7

Condenser Saturated Refrigerant R °F

Temperature AI 17 CondSatTemp -40° 244°F

AI 73 Comp2CondSatTemp -40° 244°F

Condenser Water Flow Rate R AI 50 GP CondWaterFlowRat Flow Rate in GPM

M e Centrifugals Only

Condenser Water Pump Status R BI 37 NA CondPumpState 0=No Flow, 1=Flow

*Cool Setpoint (9) W AO 29 °F NetworkCoolTempSetp 10 120°F;

Design RPM R RPM 0-32678

AI 63 Comp1DesignRPM

AI 64 Comp2DesignRPM

*Evaporator Entering Water R AI 1 °F EntEvapWaterTem -

Temperature (5) p 4

Evaporator Flow Switch Status R BI 34 NA EvapWaterFlowSta 0=No Flow, 1=Flow

*Evaporator Leaving Water R AI 2 °F LvgEvapWaterTem -

Temperature for Unit (6) pUnit 4

Evaporator Leaving Water R °F

Temperature for AI 23 LvgEvapWaterTem -40° 244°F

74 Engineered for Flexibility and performance

Centrifugal Installation Operation and Maintenance Manual

Compressor AI 68 Comp2EvapLvgWT -40° 244°

Engineered for Flexibility and performance 75

Centrifugal Installation Operation and Maintenance Manual

Network Control Property Units Object Name Description

Object Instance

Keypad attributes available

Object Type

W = Write

R = Read

as BACnet Standard Objects

for network control of the unit

Evaporator Pump Run Hours R NA

AI 27 EvapPumpOperHours 0 65,535

AI 89 EvapPmp2Hrs 0 65,535.

Evaporator Refrigerant R psi

Pressure AI 13 EvapPressure -3276.8 3276.7

AI 71 Comp2EvapPress -3276.8 3276.7

Evaporator Saturated R °F

Refrigerant Temperature AI 14 EvapSatTemp -40° 244°F

AI 70 Comp2EvapSatRTmp -40° 244°F

Evaporator Water Flow Rate R AI 49 GPM EvapWaterFlowRate Flow Rate in GPM

Evaporator Water Pump R BI 36 NA EvapPumpState 0=No Flow, 1=Flow

Heat Recovery Entering R AI 5 °F HeatRecEntWaterTemp -40° 244°F

Heat Recovery Leaving R AI 6 °F HeatRecLvgWaterTemp -40° 244°F

Heat Setpoint W AO 31 °F NetworkHeatTempSetpoint 50 150°F,

Ice Setpoint W AO 30 °F NetworkIceTempSetpoint 15 35°F,

IGV Percentage Open R % 0-110%

AI 58 Comp1IGVPercentOpen

AI 62 Comp2IGVPercentOpen

Inverter Temperature R °F

AI 66 Comp1InverterTmp

AI 87 Comp2InverterTmp

Liquid Line Refrigerant R AI 12 psi LiquidLinePress -22592 22591 psi

Liquid Line Refrigerant R °F

Temperature AI 11 LiquidLineTemp -40° 244°F

AI 85 Comp2LiqLineTemp -40° 244°F

Maximum RPM R RPM 0-32678

AI 55 Comp1MaxRPM

AI 59 Comp2MaxRPM

Minimum RPM R RPM 0-32678

AI Comp1MinRPM

AI Comp2MinRPM

Motor Cavity Temperature R °F

AI 65 Comp1MotorCavityTmp

AI 86 Comp1MotorCavityTmp

Oil Feed Pressure R psi

AI 19 OilFeedPressure -22592 22591 psi

AI 81 Comp2OilFeedPress -22592 22591 psi

Oil Feed Temperature R °F

AI 21 OilFeedTemp -40° 244°F

AI 83 Comp2OilFeedTemp -40° 244°F

Oil Sump Pressure R psi

AI 20 OilSumpPressure -22592 22591 psi

AI 82 Comp2OilSumpPress -22592 22591 psi

Oil Sump Temperature R °F

AI 22 OilSumpTemp -40° 244°F

AI 84 Comp2OilSumpTemp -40° 244°F

Outdoor Air Temperature R AI 10 °F OutdoorAirTemp -40° 244°F

Power Factor R Power -99 - +100

AI 53 PowerFactor

AI 78 Comp2PowerFactor

AI 97 Comp3PowerFactor

AI 105 Comp4PowerFactor

AI 113 Comp5PowerFactor

AI 119 Comp6PowerFactor

Pump Select W MSO 47 NA PumpSelect 1=Pump No. 1,

2=Pump No. 2;

Default=1

76 Engineered for Flexibility and performance

Centrifugal Installation Operation and Maintenance Manual

Network Control Property Units Object Name Description

Object Instance

Keypad attributes

Object Type

available as BACnet

W = Write

R = Read

Standard Objects for

network control of the unit

Run Enabled R BI 33 NA UnitOFF 0=OFF, 1=Run Allowed

*Boldface denotes data points for typical minimum integration.

Chiller Alarm Objects

Network Control Property Object Name Description

Object Instance

Object Type

Keypad attributes available as

W = Write

R = Read

BACnet Standard Objects for network

control of the unit

Warning Alarms, Analog Input Object R AI 902 AIWarningAlarm Alarm Index

Problem Alarms, Analog Input Object R AI 900 AIProblemAlarm Alarm Index

Fault Alarms, Analog Input Object (11) R AI 901 AIFaultAlarm Alarm Index

Warning Alarms, Multi-state Input R MSI 902 MSIWarningAlarm Alarm Index and Alarm Text

Problem Alarms, Multi-state Input R MSI 900 MSIProblemAlarm Alarm Index and Alarm Text

Fault Alarms, Multi-state Input Object R MSI 901 MSIFaultAlarm Alarm Index and Alarm Text

Alarm Digital Output (11) R BI 40 AlarmDigitalOutput 0-No Alarm, 1=Alarm

BACnet Clear Alarm (12) W BV 42 ClearAlarm 0= Normal, 1=Clear Alarm

BACnet Alarm Messages

The following table identifies each alarm, class, whether an acknowledgement

is required, the alarm text, and indicates system parameters at the time of the

alarm.

HTS/

Alarm Class Description Event Values

HTD/HTC

1 W NO ACTION - Condenser Entering Water Temperature Sensor 1,2,3,4,9 X

Failure

2 W NO ACTION - Evaporator Entering Water Temperature Sensor 1,2,3,4,9,10 X

Failure

3 W NO ACTION - Liquid Line Refrigerant Temperature Sensor Failure 1,2,3,4,9 X

NO ACTION (STOP if Heat) - Condenser Leaving Water

4 W 1,2,3,4,9 X

Temperature Sensor Failure

5 P RESTART DELAYED - Power Loss While Running #1 1,2,9,10

6 P RESTART DELAYED - Power Loss While Running #2 1,2,9,10

7 P RESTART DELAYED - Power Loss While Running #3 1,2,9,10

9 W Expansion Alarm Warning 1,2,9,10

10 P START INHIBITED - Ambient Temperature Low 1,2,3,4,9,10

11 P INHIBIT LOAD - Condenser Pressure High #1 1,2,9,10

Engineered for Flexibility and performance 77

Centrifugal Installation Operation and Maintenance Manual

HTS/

Alarm Class Description Event Values

HTD/HTC

12 P INHIBIT LOAD - Condenser Pressure High #2 1,2,9,10

13 P INHIBIT LOAD - Condenser Pressure High #3 1,2,9,10

15 P UNLOAD - Condenser Pressure High 1,2,9,10

16 P UNLOAD - Condenser Pressure High #1 1,2,3,4,9,10

17 P UNLOAD - Condenser Pressure High #2 1,2,3,4,9,10

18 P UNLOAD - Condenser Pressure High #3 1,2,9,10

20 P CONDENSER PUMP ON - Condenser Water Freeze Protection #1 1,2,3,4,9 X

21 P CONDENSER PUMP ON - Condenser Water Freeze Protection #2 1,2,3,4,9 X

24 P PUMP #2 START ATTEMPTED - Condenser Pump #1 Failure 1,2,3,4,9 X

25 P PUMP #1 START ATTEMPTED - Condenser Pump #2 Failure 1,2,3,4,9 X

26 P LOAD - Discharge Temperature High #1 1,2,3,4,9 X

27 P LOAD - Discharge Temperature High #2 1,2,3,4,9 X

30 P NO EWT RESET - Entering Evaporator Temperature Sensor 1,2,3,4,9 X

Failure

31 P INHIBIT LOAD - Evaporator Pressure Low 1,2,3,4,9,10

32 P INHIBIT LOAD - Evaporator Pressure Low #1 1,2,3,4,9,10 X

33 P INHIBIT LOAD - Evaporator Pressure Low #2 1,2,3,4,9,10 X

34 P INHIBIT LOAD - Evaporator Pressure Low #3 1,2,9,10

36 P UNLOAD - Evaporator Pressure Low 1,2,3,4,9,10

37 P UNLOAD - Evaporator Pressure Low #1 1,2,3,4,9,10 X

38 P UNLOAD - Evaporator Pressure Low #2 1,2,3,4,9,10 X

39 P UNLOAD - Evaporator Pressure Low #3 1,2,9,10

41 P UNLOAD - Compressor Motor Current High #1 1,2,3,4,9,10 X

42 P UNLOAD - Compressor Motor Current High #2 1,2,3,4,9,10 X

43 P UNLOAD - Compressor Motor Current High #3 1,2,9,10

45 P EVAPORATOR PUMP ON - Evaporator Water Freeze Protection 1,2,3,4,9 X

Comp #1

46 P EVAPORATOR PUMP ON - Evaporator Water Freeze Protection 1,2,3,4,9 X

Comp #2

49 P PUMP #2 START ATTEMPTED - Evaporator Pump #1 Failure 1,2,3,4,9 X

50 P PUMP #1 START ATTEMPTED - Evaporator Pump #2 Failure 1,2,3,4,9 X

52 F COMPRESSOR SHUTDOWN - Outside Air Temperature Sensor 1,2,3,4,9,10

Fault

53 F COMPRESSOR SHUTDOWN - Current Overload Trip #1 1,2,3,4,9,10 X

54 F COMPRESSOR SHUTDOWN Current Overload Trip #2 1,2,3,4,9,10 X

55 F COMPRESSOR SHUTDOWN Current Overload Trip #3 1,2,9,10

57 F COMPRESSOR SHUTDOWN Motor Current Imbalance #1 1,2,9,10 X

58 F COMPRESSOR SHUTDOWN Motor Current Imbalance #2 1,2,9,10 X

61 F COMPRESSOR SHUTDOWN Low Motor Current #1 1,2,9,10 X

62 F COMPRESSOR SHUTDOWN Low Motor Current #2 1,2,9,10 X

HTS/

Alarm Class Description Event Values HTD/

HTC

78 Engineered for Flexibility and performance

Centrifugal Installation Operation and Maintenance Manual

65 F UNIT SHUTDOWN - Motor Protector Trip 1,2,3,4,9,10

66 F COMPRESSOR SHUTDOWN - Motor Protector Trip #1 1,2,3,4,9,10

67 F COMPRESSOR SHUTDOWN - Motor Protector Trip #2 1,2,3,4,9,10

68 F COMPRESSOR SHUTDOWN - Motor Temperature High #1 1,2,3,4,9,10 X

69 F COMPRESSOR SHUTDOWN - Motor Temperature High #2 1,2,3,4,9,10 X

70 F COMPRESSOR SHUTDOWN - Motor Temperature High #3 1,2,9,10

72 F COMPRESSOR SHUTDOWN - Phase Loss #1 1,2,3,4,9,10

73 F COMPRESSOR SHUTDOWN - Phase Loss #2 1,2,3,4,9,10

74 F COMPRESSOR SHUTDOWN - Phase Loss #3 1,2,9,10

76 F COMPRESSOR SHUTDOWN - Phase Reversal #1 1,2,3,4,9,10

77 F COMPRESSOR SHUTDOWN - Phase Reversal #2 1,2,3,4,9,10

78 F COMPRESSOR SHUTDOWN - Phase Reversal #3 1,2,9,10

80 F COMPRESSOR SHUTDOWN - Overvoltage #1 1,2,3,4,9,10

81 F COMPRESSOR SHUTDOWN - Overvoltage #2 1,2,3,4,9,10

82 F COMPRESSOR SHUTDOWN - Overvoltage #3 1,2,9,10

84 F COMPRESSOR SHUTDOWN - Undervoltage #1 1,2,3,4,9,10

85 F COMPRESSOR SHUTDOWN - Undervoltage #2 1,2,3,4,9,10

86 F COMPRESSOR SHUTDOWN - Undervoltage #3 1,2,9,10

88 F COMPRESSOR SHUTDOWN - Condenser Pressure Sensor Fault 1,2,3,4,9,10

89 F COMPRESSOR SHUTDOWN - Condenser Pressure Sensor Fault 1,2,3,4,9,10 X

#1

90 F COMPRESSOR SHUTDOWN - Condenser Pressure Sensor Fault 1,2,3,4,9,10 X

#2

91 F COMPRESSOR SHUTDOWN - Condenser Pressure Sensor Fault 1,2,9,10

#3

93 F COMPRESSOR SHUTDOWN - Condenser Water Flow Loss 1,2,3,4,9 X

94 F COMPRESSOR SHUTDOWN - Condenser Pressure High 1,2,3,4,9,10 X

95 F COMPRESSOR SHUTDOWN - Condenser Pressure High #1 1,2,3,4,9,10 X

96 F COMPRESSOR SHUTDOWN - Condenser Pressure High #2 1,2,3,4,9,10 X

97 F COMPRESSOR SHUTDOWN - Condenser Pressure High #3 1,2,9,10

99 F COMPRESSOR OFF - Current High with Compressor OFF #1 1,2,3,4,9 X

100 F COMPRESSOR OFF - Current High with Compressor OFF #2 1,2,3,4,9 X

103 F COMPRESSOR SHUTDOWN Discharge Temperature Sensor 1,2,3,4,9,10 X

Fault #1

104 F COMPRESSOR SHUTDOWN Discharge Temperature Sensor 1,2,3,4,9,10 X

Fault #2

105 F COMPRESSOR SHUTDOWN Discharge Temperature Sensor 1,2,9,10

Fault #3

107 F COMPRESSOR SHUTDOWN Discharge Temperature High #1 1,2,3,4,9,10 X

108 F COMPRESSOR SHUTDOWN Discharge Temperature High #2 1,2,3,4,9,10 X

HTS/

Alarm Class Description Event Values

HTD/HTC

109 F COMPRESSOR SHUTDOWN - Discharge 1,2,9,10

Temperature High #3

Engineered for Flexibility and performance 79

Centrifugal Installation Operation and Maintenance Manual

111 F COMPRESSOR SHUTDOWN - Condenser Entering Water 1,2,3,4,9,10

Temperature Sensor Fault

112 F COMPRESSOR SHUTDOWN - Evaporator Water Flow Loss 1,2,3,4,9,10 X

113 F COMPRESSOR SHUTDOWN - Evaporator Leaving Water Temperature 1,2,3,4,9,10

Low (Freeze)

114 F COMPRESSOR SHUTDOWN - Evaporator Pressure Low 1,2,3,4,9,10

115 F COMPRESSOR SHUTDOWN - Evaporator Pressure Low #1 1,2,3,4,9,10 X

116 F COMPRESSOR SHUTDOWN - Evaporator Pressure Low #2 1,2,3,4,9,10 X

117 F COMPRESSOR SHUTDOWN - Evaporator Pressure Low #3 1,2,9,10

119 F COMPRESSOR SHUTDOWN - Evaporator Pressure Sensor Fault 1,2,3,4,9,10

120 F COMPRESSOR SHUTDOWN - Evaporator Pressure Sensor Fault #1 1,2,3,4,9,10 X

121 F COMPRESSOR SHUTDOWN - Evaporator Pressure Sensor Fault #2 1,2,3,4,9,10 X

122 F COMPRESSOR SHUTDOWN - Evaporator Pressure Sensor Fault #3 1,2,9,10

124 F COMPRESSOR SHUTDOWN - Ground Fault Trip #1 1,2,3,4,9,10

125 F COMPRESSOR SHUTDOWN - Ground Fault Trip #2 1,2,3,4,9,10

126 F COMPRESSOR SHUTDOWN - Ground Fault Trip #3 1,2,9,10

128 F COMPRESSOR SHUTDOWN - Lift Pressure Low #1 1,2,9,10

129 F COMPRESSOR SHUTDOWN - Lift Pressure Low #2 1,2,9,10

130 F COMPRESSOR SHUTDOWN - Lift Pressure Low #3 1,2,9,10

132 F COMPRESSOR SHUTDOWN - Liquid Line Pressure Sensor Fault #1 1,2,9,10

133 F COMPRESSOR SHUTDOWN - Liquid Line Pressure Sensor Fault #2 1,2,9,10

134 F COMPRESSOR SHUTDOWN - Liquid Line Pressure Sensor Fault #3 1,2,9,10

136 F COMPRESSOR SHUTDOWN - Liquid Line Temperature Sensor Fault #1 1,2,9,10

137 F COMPRESSOR SHUTDOWN - Liquid Line Temperature Sensor Fault #2 1,2,9,10

138 F COMPRESSOR SHUTDOWN - Liquid Line Temperature Sensor Fault #3 1,2,9,10

140 F UNIT LOCKOUT - Number of Allowed Re-Starts Exceeded 1,2,9,10

141 F COMPRESSOR LOCKOUT - Number of Allowed Re- Starts Exceeded #1 1,2,3,4,9,10

142 F COMPRESSOR LOCKOUT - Number of Allowed Re- Starts Exceeded #2 1,2,3,4,9,10

143 F COMPRESSOR LOCKOUT - Number of Allowed Re- Starts Exceeded #3 1,2,9,10

145 F COMPRESSOR SHUTDOWN - Evaporator Leaving Water Temperature 1,2,3,4,9,10

Sensor Fault

146 F COMPRESSOR SHUTDOWN - Evaporator Leaving Water Temperature 1,2,3,4,9 X

Sensor Fault #1

147 F COMPRESSOR SHUTDOWN - Evaporator Leaving Water Temperature 1,2,3,4,9 X

Sensor Fault #2

150 F UNIT STOP - Mechanical High Pressure Trip 1,2,9,10

HTS/

Alarm Class Description Event Values

HTD/HTC

151 F COMPRESSOR SHUTDOWN - Mechanical High Pressure Trip #1 1,2,3,4,9,10 X

80 Engineered for Flexibility and performance

Centrifugal Installation Operation and Maintenance Manual

152 F COMPRESSOR SHUTDOWN - Mechanical High Pressure Trip #2 1,2,3,4,9,10 X

153 F COMPRESSOR SHUTDOWN - Mechanical High Pressure Trip #3 1,2,9,10

155 F COMPRESSOR SHUTDOWN - Oil Net Pressure Low #1 1,2,3,4,9 X

156 F COMPRESSOR SHUTDOWN - Oil Net Pressure Low #2 1,2,3,4,9 X

159 F COMPRESSOR SHUTDOWN - Oil Feed Temperature High #1 1,2,3,4,9 X

160 F COMPRESSOR SHUTDOWN - Oil Feed Temperature High #2 1,2,3,4,9 X

163 F COMPRESSOR SHUTDOWN - Oil Feed Temperature Low #1 1,2,3,4,9 X

164 F COMPRESSOR SHUTDOWN - Oil Feed Temperature Low #2 1,2,3,4,9 X

167 F COMPRESSOR SHUTDOWN - Oil Feed Temperature Sensor Fault #1 1,2,3,4,9 X

168 F COMPRESSOR SHUTDOWN - Oil Feed Temperature Sensor Fault #2 1,2,3,4,9 X

171 F COMPRESSOR SHUTDOWN - Oil Level Low #1 1,2,9,10

172 F COMPRESSOR SHUTDOWN - Oil Level Low #2 1,2,9,10

173 F COMPRESSOR SHUTDOWN - Oil Level Low #3 1,2,9,10

175 F COMPRESSOR SHUTDOWN - Oil Filter Delta Pressure High #1 1,2,9,10

176 F COMPRESSOR SHUTDOWN - Oil Filter Delta Pressure High #2 1,2,9,10

177 F COMPRESSOR SHUTDOWN - Oil Filter Delta Pressure High #3 1,2,9,10

179 F COMPRESSOR SHUTDOWN - Oil Feed Pressure Sensor Fault #1 1,2,3,4,9 X

180 F COMPRESSOR SHUTDOWN - Oil Feed Pressure Sensor Fault #2 1,2,3,4,9 X

183 F COMPRESSOR SHUTDOWN - Oil Sump Pressure Sensor Fault #1 1,2,3,4,9 X

184 F COMPRESSOR SHUTDOWN - Oil Sump Pressure Sensor Fault #2 1,2,3,4,9 X

187 F COMPRESSOR SHUTDOWN - Oil Sump Temperature Sensor Fault #1 1,2,3,4,9 X

188 F COMPRESSOR SHUTDOWN - Oil Sump Temperature Sensor Fault #2 1,2,3,4,9 X

191 F SHUTDOWN Phase Voltage Protection 1,2,3,4,9

192 F COMPRESSOR SHUTDOWN - Starter Fault Compressor #1 1,2,3,4,9,10 X

193 F COMPRESSOR SHUTDOWN - Starter Fault Compressor #2 1,2,3,4,9,10 X

194 F COMPRESSOR SHUTDOWN - Starter Fault Compressor #3 1,2,9,10

196 F COMPRESSOR SHUTDOWN - No Starter Transition #1 1,2,3,4,9 X

197 F COMPRESSOR SHUTDOWN - No Starter Transition #2 1,2,3,4,9 X

200 F COMPRESSOR START ABORT - Oil Pressure Low #1 1,2,3,4,9 X

201 F COMPRESSOR START ABORT - Oil Pressure Low #2 1,2,3,4,9 X

204 F COMPRESSOR SHUTDOWN - Subcooling Low #1 1,2,9,10

HTS/

Alarm Class Description Event Values

HTD/HTC

205 F COMPRESSOR SHUTDOWN - Subcooling Low #2 1,2,9,10

Engineered for Flexibility and performance 81

Centrifugal Installation Operation and Maintenance Manual

206 F COMPRESSOR SHUTDOWN - Subcooling Low #3 1,2,9,10

COMPRESSOR SHUTDOWN - Surge Suction Superheat High-Running

208 F 1,2,3,4,9 X

#1

COMPRESSOR SHUTDOWN - Surge Suction Superheat High-Running

209 F 1,2,3,4,9 X

#2

212 F COMPRESSOR SHUTDOWN - Surge Suction Superheat High-Starting #1 1,2,3,4,9 X

213 F COMPRESSOR SHUTDOWN - Surge Suction Superheat High-Starting #2 1,2,3,4,9 X

216 F COMPRESSOR SHUTDOWN - Suction Temperature Sensor Fault #1 1,2,3,4,9,10 X

217 F COMPRESSOR SHUTDOWN - Suction Temperature Sensor Fault #2 1,2,3,4,9,10 X

218 F COMPRESSOR SHUTDOWN - Suction Temperature Sensor Fault #3 1,2,9,10

COMPRESSOR START ABORT - Vanes Open OR No Start Interlock

220 F 1,2,3,4,9 X

Switch #1

COMPRESSOR START ABORT - Vanes Open OR No Start Interlock

221 F 1,2,3,4,9 X

Switch #2

224 F COMPRESSOR SHUTDOWN - (Check Chiller Display for Cause) 1,2,3,4,9,10 X

225 F C-Stop - General Comp Fault#1 1,2,3,4,9,10 X

226 F C-Stop - General Comp Fault#2 1,2,3,4,9,10 X

227 F C-Stop - Communication Fault #1 1,2,3,4,9,10 X

228 F C-Stop - Communication Fault #2 1,2,3,4,9,10 X

229 F C-Stop - Interlock Fault #1 1,2,3,4,9,10 X

230 F C-Stop - Interlock Fault #2 1,2,3,4,9,10 X

231 F C-Stop - Bearing Fault #1 1,2,3,4,9,10 X

232 F C-Stop - Bearing Fault #2 1,2,3,4,9,10 X

233 F C-Stop - Motor Fault #1 1,2,3,4,9,10 X

234 F C-Stop - Motor Fault #2 1,2,3,4,9,10 X

235 F C-Stop - Drive Fault #1 1,2,3,4,9,10 X

236 F C-Stop - Drive Fault #2 1,2,3,4,9,10 X

237 F C-Stop - Internal Control Err#1 1,2,3,4,9,10 X

238 F C-Stop - Internal Control Err#2 1,2,3,4,9,10 X

239 W Warn-Chiller Capacity Limited 1,2,3,4,9,10 X

240 F U-Stop - Check Valve Fault #1 1,2,3,4,9,10 X

241 F U-Stop - Check Valve Fault #2 1,2,3,4,9,10 X

242 F U-Stop - LB Valve Fault #1 1,2,3,4,9,10 X

243 F U-Stop - LB Valve Fault #2 1,2,3,4,9,10 X

82 Engineered for Flexibility and performance

Centrifugal Installation Operation and Maintenance Manual

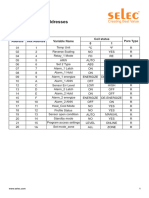

BACnet Communication Information(E8211212/3)

BACnet Data Points

Chiller Variables

Network Control Read/

Data Type Index Description

Property Write

Cool Setpoint(9) R/W AV 1 3~21

Ice Setpoint R/W AV 50 -9.4~3.4

Heat Setpoint R/W AV 5 35~55

Capacity Limit AV

W 3 0~100%

Setpoint(10)

Chiller Mode AV

W 1017 1=Ice,2=Cool,3=Heat

Setpoint(2)

Chiller Enable

R/W BV 1 0=Off,1=On

Input(4)

BV 0=Off,

Run Enabled R 2

1=Run Allowed

Chiller Local/Remote R BV 5 0=Remote,1=Local

BV 0=Not Limited,

Chiller Limited R 6

1=Limited

Chiller Mode AV

R 1019 1=Ice,2=Cool,3=Heat

Output

AV 1=Off,2=Start,

3=Run,

Chiller Status(1) R 1018

4=Pre-Shutdown,

5=Service

Active Setpoint R AV 2 -9.4~55

Actual Capacity(3) R AV 10 0~125%

Capacity Limit AV

R 42 0~100%

Output

Evaporator Entering AV

R 4 -25~100

Water Temperature(5)

Evaporator Leaving AV

R 6 -25~100

Water Temperature(6)

Condenser Entering AV

R 7 -25~100

Water Temperature(7)

Condenser Leaving AV

R 8 -25~100

Water Temperature(8)

Heat Recovery Entering AV

R 22 -25~100

Water Temperature

Heat Recovery Leaving AV

R 23 -25~100

Water Temperature

Evaporator Flow Switch 0=No Flow,

R BV 7

Status 1=Flow

Condenser Flow Switch 0=No Flow,

R BV 8

Status 1=Flow

0=Pump Off,

Evaporator Pump Status R BV 29

1=Pump On

0=Pump Off,

Condenser Pump Status R BV 31

1=Pump On

Pump Select R/W BV 19 0=Pump No.1

Engineered for Flexibility and performance 83

Centrifugal Installation Operation and Maintenance Manual

1=Pump No.2

Evaporator Pump

Run Hours

R

Pump Select AV 1047 0~65,535

Pump#2 AV 1103 0~65,535

Condenser Pump Run Hours

Pump Select R AV 1048 0~65,535

Pump#2 AV 1104 0~65,535

Comp Select R/W AV 1032 0~65,535

Condenser Refrigerant

Pressure

AV 0~2800kP

Compressor Select R 21

a

AV 0~2800kP

Compressor #2 93

a

Condenser Saturated

Temperature

R

Compressor Select AV 20 -25~62

Compressor #2 AV 92 -25~62

Evaporator Refrigerant

Pressure

R

Compressor Select AV 17 0~910kPa

Compressor #2 AV 90 0~910kPa

Evaporator Saturated

Temperature

R

Compressor Select AV 16 -25~40

Compressor #2 AV 89 -25~40

Liquid Line

Refrigerant Temperature

AV -

Compressor Select R 36

25~100

AV -

Compressor #2 104

25~100

Compressor

Current(Benshow Starter)

AV 0~65,535

Compressor Select R 26

Amps

AV 0~65,535

Compressor #2 95

Amps

Compressor

Voltage(Benshow Starter)

AV 0~65,535

Compressor Select R 29

Volts

AV 0~65,535

Compressor #2 98

Volts

Compressor Power(Benshow

Starter)

AV 0~65,535k

Compressor Select R 27

iloWatts

AV 0~65,535k

Compressor #2 96

iloWatts

Compressor

R

Percent RLA

84 Engineered for Flexibility and performance

Centrifugal Installation Operation and Maintenance Manual

Compressor Select AV 25 0~125%

Compressor #2 AV 94 0~125%

Discharge Temperature

AV -

Compressor Select 19

R 25~100

AV -

Compressor #2 91

25~100

Suction Temperature

AV -

Compressor Select 15

R 25~100

AV -

Compressor #2 88

25~100

Oil Feed Pressure

AV 0~2800kP

Compressor Select 32

R a

AV 0~2800kP

Compressor #2 100

a

Oil Sump Pressure

Compressor Select R AV 33 0~910kPa

Compressor #2 AV 101 0~910kPa

Oil Feed Temperature

AV -

Compressor Select 34

R 25~100

AV -

Compressor #2 102

25~100

Oil Sump Temperature

AV -

Compressor Select 35

R 25~100

AV -

Compressor #2 103

25~100

Compressor Run Hours

Compressor Select R AV 1046 0~65,535

Compressor #2 AV 1107 0~65,535

Compressor Starts

Compressor Select R AV 1045 0~65,535

Compressor #2 AV 1106 0~65,535

Chiller Alarm Variables

Network Control Read/

Data Type Index Description

Property Write

0=No Alarm,

Alarm Digital Output(11) R BV 3

1=Alarm

0=Normal,

Clear Alarm(12) R/W BV 24

1=Clear Alarm

1001~ 16Holding Registers:

Active Alarms(13) R AV 1014(MV/ Each bit representing

AV) an alarm condition

Modbus Alarms

WSC

WDC

Holding

# Description WCC WMC WT C Bit

Register

HSC

TSC

Engineered for Flexibility and performance 85

Centrifugal Installation Operation and Maintenance Manual

Warnings

1 Entering Condenser Water Temperature Sensor Fault X X X 1001 1

2 Entering Condenser Water Temperature Sensor Fault X X X 1001 2

3 Liquid Line Refrigerant Temperature Sensor Fault X X X 1001 3

4 Leaving Condenser Water Temperature Sensor Fault X X X 1001 4

Problems

5 NA 1002 0

6 NA 1002 1

7 NA 1002 2

8 NA 1002 3

9 Condenser Water Freeze Protect Comp1 X X X 1002 4

10 Condenser Water Freeze Protect Comp2 X X X 1002 5

11 NA 1002 6

12 NA 1002 7

13 Condenser Pump#1 Fault X X X 1002 8

14 Condenser Pump#2 Fault X X X 1002 9

15 NA X X X 1002 10

16 NA X X 1002 11

17 NA 1002 12

18 NA 1002 13

19 Entering Evaporator Temperature Sensor Fault(EWT reset active) X X X 1002 14

20 NA 1002 15

21 NA X X X 1003 0

22 NA X X 1003 1

23 NA 1003 2

24 NA 1003 3

25 NA 1003 4

26 NA X X X 1003 5

27 NA X X 1003 6

28 NA 1003 7

29 NA 1003 8

30 NA X X X 1003 9

31 NA X X 1003 10

32 NA 1003 11

33 NA 1003 12

34 Evaporator Water Freeze Protect Comp 1 X X X 1003 13

35 Evaporator Water Freeze Protect Comp 2 X X 1003 14

36 NA 1003 15

37 NA 1004 0

38 Evaporator Pump 1 Fault X X X 1004 1

39 Evaporator Pump 2 Fault X X 1004 2

40 NA 1004 3

41 NA 1004 4

Faults

42 Compressor Current Overload Trip 1 X X X 1004 5

43 Compressor Current Overload Trip 2 X X 1004 6

44 NA 1004 7

45 NA 1004 8

46 Motor Current Imbalance On Compressor 1 X X X 1004 9

47 Motor Current Imbalance On Compressor 2 X X 1004 10

48 NA 1004 11

49 NA 1004 12

86 Engineered for Flexibility and performance

Centrifugal Installation Operation and Maintenance Manual

50 Low Motor Current Comp 1 X X X 1004 13

51 Low Motor Current Comp 2 X X 1004 14

52 NA 1004 15

53 NA 1005 0

54 NA 1005 1

55 NA 1005 2

56 NA 1005 3

57 High Motor Temperature Comp 1 X X X 1005 4

58 High Motor Temperature Comp2 X X 1005 5

59 NA 1005 6

60 NA 1005 7

61 Phase Loss At Compressor 1 X1 1005 8

62 Phase Loss At Compressor 2 X1 1005 9

63 NA 1005 10

64 NA 1005 11

65 Phase Reversal At Compressor# 1 X1 1005 12

66 Phase Reversal At Compressor# 2 X1 1005 13

67 NA 1005 14

68 NA 1005 15

69 Overvoltage On Compressor# 1 X1 1006 0

70 Overvoltage On Compressor# 2 X1 1006 1

71 NA 1006 2

72 NA 1006 3

73 Under voltage On Compressor# 1 X1 1006 4

74 Under voltage On Compressor# 2 X1 1006 5

75 NA 1006 6

76 NA 1006 7

77 NA 1006 8

78 Condenser Pressure Sensor Fault Circuit 1 X X X 1006 9

79 Condenser Pressure Sensor Fault Circuit 2 X X 1006 10

80 NA 1006 11

81 NA 1006 12

82 No Condenser Water Flow X X X 1006 13

83 NA 1006 14

84 High Condenser Pressure Circuit 1 X X X 1006 15

85 High Condenser Pressure Circuit 2 X X 1007 0

86 NA 1007 1

87 NA 1007 2

88 No Compressor Stop Comp #1 X X X 1007 3

89 No Compressor Stop Comp #2 X X 1007 4

90 NA 1007 5

91 NA 1007 6

92 Discharge Temperature Sensor Fault Circuit 1 X X X 1007 7

93 Discharge Temperature Sensor Fault Circuit 2 X X 1007 8

94 NA 1007 9

95 NA 1007 10

96 High Discharge Temperature Circuit 1 X X X 1007 11

97 High Discharge Temperature Circuit 2 X X 1007 12

98 NA 1007 13

99 NA 1007 14

100 NA 1007 15

101 No Evaporator Water Flow X X X 1008 0

Engineered for Flexibility and performance 87

Centrifugal Installation Operation and Maintenance Manual

102 NA 1008 1

103 NA 1008 2

104 Low Evaporator Pressure Circuit 1 X X X 1008 3

105 Low Evaporator Pressure Circuit 2 X X 1008 4

106 NA 1008 5

107 NA 1008 6

108 NA 1008 7

109 Evaporator Pressure Sensor Fault Circuit 1 X X X 1008 8

110 Evaporator Pressure Sensor Fault Circuit 2 X X 1008 9

111 NA 1008 10

112 NA 1008 11

113 Ground Fault Protection 1 X1 1008 12

114 Ground Fault Protection 2 X1 1008 13

115 NA 1008 14

116 NA 1008 15

117 Economizer Pressure Sensor Fault X 1009 0

118 NA 1009 1

119 IGV Position Sensor Fault X 1009 2

120 NA 1009 3

121 DDC Position Sensor Fault X 1009 4

122 NA 1009 5

123 Low Discharge Superheat X 1009 6

124 NA 1009 7

125 Low Lift Pressure X 1009 8

126 NA 1009 9

127 Hot Gas Bypass Position Sensor Fault X 1009 10

128 NA 1009 11

129 NA 1009 12

130 NA 1009 13

131 NA 1009 14

132 NA 1009 15

133 NA 1010 0

134 NA 1010 1

135 Leaving Evaporator Water Temperature Sensor Fault Comp 1 X X X 1010 2

136 Leaving Evaporator Water Temperature Sensor Fault Comp 2 X X 1010 3

137 NA 1010 4

138 NA 1010 5

139 NA 1010 6

140 Mechanical High Pressure Circuit 1 X X X 1010 7

141 Mechanical High Pressure Circuit 2 X X 1010 8

142 NA 1010 9

143 NA 1010 10

144 Low Oil Net Pressure Comp 1 X X 1010 11

145 Low Oil Net Pressure Comp 2 X 1010 12

146 NA 1010 13

147 NA 1010 14

148 High Oil Feed Temperature Comp 1 X X 1010 15

149 High Oil Feed Temperature Comp 2 X 1011 0

150 NA 1011 1

151 NA 1011 2

152 Low Oil Feed Temperature Comp 1 X X 1011 3

153 Low Oil Feed Temperature Comp 2 X 1011 4

88 Engineered for Flexibility and performance

Centrifugal Installation Operation and Maintenance Manual

154 NA 1011 5

155 NA 1011 6

156 Oil Feed Temperature Sensor Fault Comp 1 X X 1011 7

157 Oil Feed Temperature Sensor Fault Comp 2 X 1011 8

158 NA 1011 9

159 NA 1011 10

160 NA 1011 11

161 NA 1011 12

162 NA 1011 13

163 NA 1011 14

164 NA 1011 15

165 NA 1012 0

166 NA 1012 1

167 NA 1012 2

168 Oil Feed Pressure Sensor Fault Comp 1 X X 1012 3

169 Oil Feed Pressure Sensor Fault Comp 2 X 1012 4

170 NA 1012 5

171 NA 1012 6

172 Oil Sump Pressure Sensor Fault Comp 1 X X 1012 7

173 Oil Sump Pressure Sensor Fault Comp 2 X 1012 8

174 NA 1012 9

175 NA 1012 10

176 Oil Sump Temperature Sensor Fault Comp 1 X X 1012 11

177 Oil Sump Temperature Sensor Fault Comp 2 X 1012 12

178 NA 1012 13

179 NA 1012 14

180 NA 1012 15

181 Starter Fault Compressor 1 X X X 1013 0

182 Starter Fault Compressor 2 X X 1013 1

183 NA 1013 2

184 NA 1013 3

185 No Starter Transition Compressor 1 X X 1013 4

186 No Starter Transition Compressor 2 X 1013 5

187 NA 1013 6

188 NA 1013 7

189 No Oil Pressure Start Comp 1 X X 1013 8

190 No Oil Pressure Start Comp2 X 1013 9

191 NA 1013 10

192 NA 1013 11

193 NA 1013 12

194 NA 1013 13

195 NA 1013 14

196 NA 1013 15

197 Surge High Suct SH-Running Comp 1 X X X 1014 0

198 Surge High Suct SH-Running Comp 2 X X 1014 1

199 NA 1014 2

200 NA 1014 3

201 Surge High Suct SH-Starting Comp 1 X X X 1014 4

202 Surge High Suct SH-Starting Comp 2 X X 1014 5

203 NA 1014 6

204 NA 1014 7

205 Suction Temperature Sensor Fault Comp 1 X X X 1014 8

Engineered for Flexibility and performance 89

Centrifugal Installation Operation and Maintenance Manual

206 Suction Temperature Sensor Fault Comp 2 X X 1014 9

207 NA 1014 10

208 NA 1014 11

209 Vanes Open No Start Comp 1 X X2 X 1014 12

210 Vanes Open No Start Comp 2 X X2 1014 13

211 NA 1014 14

212 NA 1014 15

1

_Solid State Starter Option required. Not available on WMC.

2

_Should be No Start- Interlock Switch on WMC chiller.

90 Engineered for Flexibility and performance

Vous aimerez peut-être aussi

- Pac ZamilDocument41 pagesPac ZamilasindonPas encore d'évaluation

- VRV4 Service Course SV06 - 5-Troubleshooting - Service Training - EnglishDocument40 pagesVRV4 Service Course SV06 - 5-Troubleshooting - Service Training - Englishjmdc100% (1)

- ELGI OM Manual AirCompressorDocument173 pagesELGI OM Manual AirCompressorBIRUK DAWIT100% (1)

- Practical Thermal Design of Shell-And-Tube Heat ExchangersDocument243 pagesPractical Thermal Design of Shell-And-Tube Heat Exchangerswasp14989100% (11)

- Fire Alarm Commissioning ChecklistDocument2 pagesFire Alarm Commissioning ChecklistSavy PhanethPas encore d'évaluation

- 50TC-A07 Spare PartsDocument17 pages50TC-A07 Spare PartsKumar sssssPas encore d'évaluation

- Fire Alarm Sequence of Operations 2Document1 pageFire Alarm Sequence of Operations 2Savy PhanethPas encore d'évaluation

- Input/Output List: ChillersDocument13 pagesInput/Output List: ChillersKrishna PATEL50% (2)

- Variable Displacement Pump A11VO: For Open CircuitsDocument48 pagesVariable Displacement Pump A11VO: For Open Circuitsjose salvadorPas encore d'évaluation

- Chiller Plant Manager - IO Summary-200219 PDFDocument1 pageChiller Plant Manager - IO Summary-200219 PDFShruti NandPas encore d'évaluation

- T 362Document184 pagesT 362aislandesouza23Pas encore d'évaluation

- Kobelco SK330 Excavator Mitsubishi Engine Workshop ManualDocument2 pagesKobelco SK330 Excavator Mitsubishi Engine Workshop ManualErdenekhuu Unurjargal0% (2)

- Company Profile 2019 - Graha Inti KreasindoDocument10 pagesCompany Profile 2019 - Graha Inti Kreasindowika mepPas encore d'évaluation

- AAD03040D Elevator Door Controller User Manual: 4SW Induction ModeDocument10 pagesAAD03040D Elevator Door Controller User Manual: 4SW Induction ModeAnk100% (2)

- Heat Recovery - EfficiencyDocument58 pagesHeat Recovery - EfficiencyEshref AlemdarPas encore d'évaluation

- Xe Sierra SG Modbus PDFDocument4 pagesXe Sierra SG Modbus PDFLi TANGPas encore d'évaluation

- Xe Sierra SG Modbus PDFDocument4 pagesXe Sierra SG Modbus PDFLi TANGPas encore d'évaluation

- Programa de Mantenimiento Preventivo ACS880Document2 pagesPrograma de Mantenimiento Preventivo ACS880JaimePas encore d'évaluation

- Xe-90-145M Modbus and Airbus Manual 3rd EdDocument27 pagesXe-90-145M Modbus and Airbus Manual 3rd EdMiguel NavarretePas encore d'évaluation

- Xe-90M and Xe-145M Modbus Tables: R55 - R160 Fixed Speed Modbus TableDocument1 pageXe-90M and Xe-145M Modbus Tables: R55 - R160 Fixed Speed Modbus TableHygor MaiorkiPas encore d'évaluation

- Xe-90M and Xe-145M Modbus Tables: R55 - R160 Fixed Speed Modbus TableDocument13 pagesXe-90M and Xe-145M Modbus Tables: R55 - R160 Fixed Speed Modbus TableAkun BaruPas encore d'évaluation

- Siemens Modbus CommunicationDocument1 pageSiemens Modbus CommunicationBoss OvitchPas encore d'évaluation

- Relay Box, Specifications: Service InformationDocument1 pageRelay Box, Specifications: Service InformationBeniamin KowollPas encore d'évaluation

- R - 00 SeriesDocument16 pagesR - 00 SeriesAdrian SetyadharmaPas encore d'évaluation

- Water ChillerDocument74 pagesWater ChillerDimitri LyssiPas encore d'évaluation

- Practical-Electronics-1973-09 Phase UnitDocument4 pagesPractical-Electronics-1973-09 Phase UnitJohan TaalanderwijsPas encore d'évaluation

- BMS Communication Table (PCO3)Document2 pagesBMS Communication Table (PCO3)pabloabelgilsotoPas encore d'évaluation

- 62te GDDocument4 pages62te GDluiz fernando leal vernePas encore d'évaluation

- Modbus Address List: Model: SIEMENS Controller - 2ABH&LHH (Preessure Transmitter)Document2 pagesModbus Address List: Model: SIEMENS Controller - 2ABH&LHH (Preessure Transmitter)Orlando Gamboa HuertasPas encore d'évaluation

- Chapter 11 M5 ControllerDocument10 pagesChapter 11 M5 ControllerCủ Lạc Giòn TanPas encore d'évaluation

- Rev. Status: Customer Drawing ListDocument9 pagesRev. Status: Customer Drawing ListDebesh ChaudharyPas encore d'évaluation

- Actuvator ModelDocument21 pagesActuvator ModelammeenaqualiamacePas encore d'évaluation

- Belimo R3..-S.. Datasheet En-GbDocument3 pagesBelimo R3..-S.. Datasheet En-GbLaurentiu LapusescuPas encore d'évaluation

- Ingenio Chaparrastiqu 19-0699 ECM1 - Control-Instrumentation DataDocument6 pagesIngenio Chaparrastiqu 19-0699 ECM1 - Control-Instrumentation DataOmar turco curiPas encore d'évaluation

- PLC Programming Ladder LogicDocument18 pagesPLC Programming Ladder LogicPackiyaraj BMSPas encore d'évaluation

- Reed-Switch-lb 8200 Int RD 003Document2 pagesReed-Switch-lb 8200 Int RD 003AbhijitPas encore d'évaluation

- Experiment No - UGPE01: TitleDocument6 pagesExperiment No - UGPE01: TitleRudraraju ChaitanyaPas encore d'évaluation

- Datasheet Rev. 010218: Qty Value Parts DescriptionDocument2 pagesDatasheet Rev. 010218: Qty Value Parts DescriptionJefrei OrtizPas encore d'évaluation

- WRP22G Oea5 - 400 P 121121 e 00Document4 pagesWRP22G Oea5 - 400 P 121121 e 00Eng-Mohammed SalemPas encore d'évaluation

- ModbusConfig V1 01Document1 pageModbusConfig V1 01pedro pabloPas encore d'évaluation

- SRKhannaDocument12 pagesSRKhanna20gradoshoy hvacPas encore d'évaluation

- Adress IP SGNeDocument6 pagesAdress IP SGNexaviPas encore d'évaluation

- WSP22G Ona3 - 400 P 120801 e 01Document4 pagesWSP22G Ona3 - 400 P 120801 e 01Eng-Mohammed SalemPas encore d'évaluation

- WT60 Modbus Protocol Manual ENDocument24 pagesWT60 Modbus Protocol Manual ENvuong buiPas encore d'évaluation

- Technical Data Sheet R3..-S..: Type OverviewDocument3 pagesTechnical Data Sheet R3..-S..: Type OverviewMohammed AttounPas encore d'évaluation

- LM Modbus User InstructionsDocument2 pagesLM Modbus User InstructionsMarcos Luiz AlvesPas encore d'évaluation

- AAD03040DOL Elevator Door Controller User Manual: 4SW Induction ModeDocument11 pagesAAD03040DOL Elevator Door Controller User Manual: 4SW Induction ModeЕржан АмановPas encore d'évaluation

- ChillerDocument2 pagesChillersiruslara6491100% (1)

- Page 050Document1 pagePage 050docpot2008Pas encore d'évaluation

- Aoh Check - List - EmdDocument187 pagesAoh Check - List - EmdElectrical Team100% (1)

- Ocd Datasheet 010817Document5 pagesOcd Datasheet 010817Sebastiano MuratorePas encore d'évaluation

- TME27091-ACRC3xx BACnet Application MapDocument12 pagesTME27091-ACRC3xx BACnet Application MapprasadPas encore d'évaluation

- PID500 U MODBUS AddressDocument13 pagesPID500 U MODBUS Addressdilraj.spePas encore d'évaluation

- Name Minimum Maximum para Type Coil No: Selec Controls PVT LTDDocument16 pagesName Minimum Maximum para Type Coil No: Selec Controls PVT LTDJeyadheepan KaPas encore d'évaluation

- Maintenance Schedule ACS600 RevKDocument1 pageMaintenance Schedule ACS600 RevKDev KumarPas encore d'évaluation

- Van Nap LT06Document3 pagesVan Nap LT06hoiPas encore d'évaluation

- Electronics Ch14Document22 pagesElectronics Ch14Boudi ChouPas encore d'évaluation

- Chiller Technical Datasheet - Aircooled Screw Chiller Tech Data - DC IIIDocument3 pagesChiller Technical Datasheet - Aircooled Screw Chiller Tech Data - DC IIIVenu GopalPas encore d'évaluation

- CA1524, CA2524 CA3524: Regulating Pulse Width ModulatorDocument15 pagesCA1524, CA2524 CA3524: Regulating Pulse Width ModulatorPaul Abi najemPas encore d'évaluation

- Verification of Maximum Power Transfer TheoremDocument4 pagesVerification of Maximum Power Transfer TheoremsivaiahjettiPas encore d'évaluation

- RHRP8120 D PDFDocument5 pagesRHRP8120 D PDFgameel alabsiPas encore d'évaluation

- Technical Data Sheet R7..R-B..: Type OverviewDocument3 pagesTechnical Data Sheet R7..R-B..: Type OverviewHamdi Al-sarooryPas encore d'évaluation

- Operating Manual: RobinairDocument21 pagesOperating Manual: RobinairGeorge Anderzon Victoriano RengifoPas encore d'évaluation

- LHGH EvaporadoresDocument12 pagesLHGH EvaporadoresluismozoPas encore d'évaluation

- M-7000 Address Mapping (Base 1)Document54 pagesM-7000 Address Mapping (Base 1)GabiBaciuPas encore d'évaluation

- Standard Patch Cable A EIA - TIA 568A Colour Scheme Standard Patch Cable B EIA - TIA 568B ... (PDFDrive)Document402 pagesStandard Patch Cable A EIA - TIA 568A Colour Scheme Standard Patch Cable B EIA - TIA 568B ... (PDFDrive)Savy PhanethPas encore d'évaluation

- 223 PM RepDocument5 pages223 PM RepSavy PhanethPas encore d'évaluation

- Vertx Evo: Installation GuideDocument19 pagesVertx Evo: Installation GuideSavy PhanethPas encore d'évaluation

- Cable Tray & Conduit SizingDocument2 pagesCable Tray & Conduit SizingSavy PhanethPas encore d'évaluation

- Qbic Engineers & Architects Co.,Ltd.: RetailDocument1 pageQbic Engineers & Architects Co.,Ltd.: RetailSavy PhanethPas encore d'évaluation

- Technical Requirements, Specifications and Bidding Documents: Dated: 11-14-2016Document20 pagesTechnical Requirements, Specifications and Bidding Documents: Dated: 11-14-2016Savy PhanethPas encore d'évaluation

- MI02D202 ManualDocument2 pagesMI02D202 ManualSavy PhanethPas encore d'évaluation

- Product Listing Data Sheet: (Active Fire Protection Equipment)Document8 pagesProduct Listing Data Sheet: (Active Fire Protection Equipment)Savy PhanethPas encore d'évaluation

- Product Data Sheet: Circuit Breaker Compact Nsx160F, 36 Ka at 415 Vac, TMD Trip Unit 160 A, 3 Poles 3DDocument3 pagesProduct Data Sheet: Circuit Breaker Compact Nsx160F, 36 Ka at 415 Vac, TMD Trip Unit 160 A, 3 Poles 3DSavy PhanethPas encore d'évaluation

- VISIO - Fire Alarm - 201207130855008633Document1 pageVISIO - Fire Alarm - 201207130855008633Savy PhanethPas encore d'évaluation

- PR300T 4.2.0 Modbus RED Variable ListDocument19 pagesPR300T 4.2.0 Modbus RED Variable ListNikitaPas encore d'évaluation

- Specifications Tropical Split Type Technical ManualDocument1 pageSpecifications Tropical Split Type Technical ManualgrwgPas encore d'évaluation

- Hvacr Designer Tips: Design Review and Startup ChecklistDocument1 pageHvacr Designer Tips: Design Review and Startup ChecklistsajuherePas encore d'évaluation

- Electronic Room Thermostat SRE06: Description FeaturesDocument3 pagesElectronic Room Thermostat SRE06: Description FeaturesDaniel NogueiraPas encore d'évaluation

- Avionic VentilationDocument2 pagesAvionic Ventilationffelipe123Pas encore d'évaluation

- WP-2 - Locker Rooms and Humidity ProblemsDocument2 pagesWP-2 - Locker Rooms and Humidity ProblemskprasannanPas encore d'évaluation

- Ahu DetailDocument1 pageAhu DetailAhmad FauziPas encore d'évaluation

- Edoc - Pub ManualDocument4 pagesEdoc - Pub ManualVictoria CoronaPas encore d'évaluation

- Bq240 50 HZ TechDocument28 pagesBq240 50 HZ Techmauricio.vidalyork6735Pas encore d'évaluation

- Air-Cooled-Condensers y Un50 00Document12 pagesAir-Cooled-Condensers y Un50 00gustavsilverPas encore d'évaluation

- Training Provider Directory Issue 9 July 2019Document110 pagesTraining Provider Directory Issue 9 July 2019Sonia GonzalezPas encore d'évaluation

- Basic Heat Pump ComponentsDocument6 pagesBasic Heat Pump Componentsdrabc123Pas encore d'évaluation

- Gce, Dharmapuri Project5Document22 pagesGce, Dharmapuri Project5mani manisPas encore d'évaluation

- Compressors: Select Criterion For ServiceDocument34 pagesCompressors: Select Criterion For ServiceZoran TrajkovicPas encore d'évaluation

- MULTI V 5 Catalog - CompressedDocument148 pagesMULTI V 5 Catalog - CompressedTechnical OfficePas encore d'évaluation

- Climatic 2 LF20.EDocument8 pagesClimatic 2 LF20.EOnurCinarPas encore d'évaluation

- 06 ASLI Floor Diffusers Set PDFDocument13 pages06 ASLI Floor Diffusers Set PDFLâmHoàngDuyPas encore d'évaluation

- 2100-692 - Bard SystemsDocument44 pages2100-692 - Bard Systemstqbpc5hmfnPas encore d'évaluation

- Service Manual CSCU-RE12GKE PDFDocument16 pagesService Manual CSCU-RE12GKE PDFJose Vicente Ausina100% (1)

- Temperature Readings in Heating The Soil and WaterDocument1 pageTemperature Readings in Heating The Soil and WaterAlex Sildon100% (1)

- Marvair CommStat-10 PDS-Manual 04.04.23 Rev.3Document12 pagesMarvair CommStat-10 PDS-Manual 04.04.23 Rev.3Henry Iván Alejandro AyalaPas encore d'évaluation

- Chapter 04Document5 pagesChapter 04stephen jamesPas encore d'évaluation

- ShuttleAIRE Brochure 2015Document8 pagesShuttleAIRE Brochure 2015Cristobal CamposPas encore d'évaluation

- Chiller, Cooling Tower, System, Make Up Water Pump: Aeon Mall Tan Phu Celadon ExtensionDocument18 pagesChiller, Cooling Tower, System, Make Up Water Pump: Aeon Mall Tan Phu Celadon ExtensionVinh Bùi QuangPas encore d'évaluation

- Brochure Uniflair Chiller TRA - 60Hz PDFDocument7 pagesBrochure Uniflair Chiller TRA - 60Hz PDFGerardo BáezPas encore d'évaluation