Académique Documents

Professionnel Documents

Culture Documents

Steamview Radiator Brochure

Transféré par

e-ComfortUSACopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Steamview Radiator Brochure

Transféré par

e-ComfortUSADroits d'auteur :

Formats disponibles

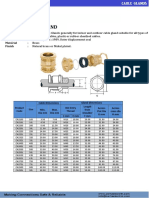

S T E A M V I E W S E R I E S

The

stylish

alternative

to bulky

cast iron!

Style: Sleek 2 1⁄2” profile. Available in two heights (16”

and 24”) and five lengths (24”, 36”, 48”, 60”, and 72”)

Immediate Delivery: Available for immediate delivery

in white. Hundreds of colors are available by special order.

Quick and Easy Installation: The Steamview is made

P.O. Box 8287 for both one pipe and two pipe steam systems. Single piece

Ward Hill, MA 01835 construction, continuous mounting, individual wrapping and

Tel: 978-373-1942

tagging, and uniform fittings (which allow the radiators to

Fax: 978-372-1466

Toll-Free: 800-966-0587 be piped six ways) make Steamview easy to specify and install.

www.steamradiators.com

Durability: The Steamview’s all-welded steel construction

E-Mail: sales@steamradiators.com

ensures a long service life. Proprietary internal construction

guards against steam corrosion. All Steamview Radiators

have a five-year limited warranty.

16”

S T E A M V I E W C A P A C I T I E S

Nominal Length 24” 36” 48” 60” 72”

B T U / H O U T P U T S

24” 16” HEIGHT 2,564 3,763 5,104 6,306 7,646

24” HEIGHT 3,553 5,225 7,106 8,778 10,659

S T E A M V I E W S E R I E S

STEAM RADIATOR INSTALLATION TIPS

ROUGHING-IN

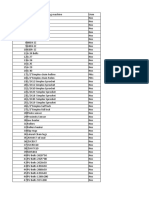

16” MODEL SV16-24 SV16-36 SV16-48 SV16-60 SV16-72

Nominal Length 24” 36” 48” 60” 72”

LENGTH (IN.) 23.34” 34.68” 47.44” 58.78” 71.53”

15.75” WEIGHT (LBS) 10 lbs 15 lbs 22 lbs 27 lbs 33 lbs

(SV16 series)

23.6”

(SV24 series) 22.44”

24” MODEL SV24-24 SV24-36 SV24-48 SV24-60 SV24-72

14.6”

Nominal Length 24” 36” 48” 60” 72”

LENGTH (IN.) 23.34” 34.68” 47.44” 58.78” 71.53”

WEIGHT (LBS) 14 lbs 21 lbs 30 lbs 37 lbs 46 lbs

MOUNTING

Mounting Tips:

1. Lay out the desired position of the radiator on the wall. Determine the locations of solid wall

members (wall studs, bracing, etc.). Mark the positions for the mounting brackets, noting that each

bracket should fit in the center of the space between adjacent radiator tubes. Note: All of the

brackets supplied with the radiator should be used, half as top supports and half as bottom supports.

2. Attach all of the bracket sleeves (A) to solid wall members, using the appropriate mounting fastener (B)

(by others).

3. Position mounting bracket cylinders (C) between adjacent radiator(D) tubes, so that the cylinders (C) will

line up with the bracket sleeves (A), mounted on the wall.

4. Rotate cylinder (C) to tighten and clamp the cylinder’s end piece between the radiator’s tubes.

E 5. Slide the cylinders (C) into the mounting sleeves (A), making final adjustments by loosening

cylinder (C), sliding it into final alignment, and re-tightening it. Secure cylinder (C) to sleeve (A)

by tightening up allen head screw (E). Note: The radiator should tilt towards the condensate

return at a rate of 1/16” per foot of radiator length.

PIPING

2-PIPE STEAM SYSTEM

PREFERRED ALTERNATE 1-PIPE STEAM SYSTEM

Left Hand Steam Supply Left Hand Steam Supply Left Hand Steam Supply

Right Hand Steam Supply Right Hand Steam Supply Right Hand Steam Supply

GENERAL INSTALLATION TIPS

2- Pipe Steam System 1- Pipe Steam System

1. A 1” NPT tapping is included on each corner of the radiator. Two 1” 1. A 1” NPT tapping is included on each corner of the radiator. Two

plugs are provided to plug the two unused radiator tappings. 1” plugs are provided to plug the two unused radiator tappings. Use a

Use a 5/8” allen wrench to tighten these plugs. A third plug with a 1/8” 5/8” allen wrench to tighten these plugs. A third plug with a 1/8” vent

vent tapping is also included. Pipe dope should be applied to the plugs. tapping is also included. Pipe dope should be applied to the plugs.

2. The installer should supply and install the proper size reducing 2. The installer should supply and install the proper one pipe steam air

bushing for the steam trap to be used. vent or control valve in the 1/8” vent tapping.

3. The mounting brackets must be secured to a load-bearing wall 3. The mounting brackets must be secured to a load-bearing wall member

member (like a wall stud or solid backing) capable of handling the (like a wall stud or solid backing) capable of handling the radiator’s weight.

radiator’s weight. 4. The radiator should be tilted a minimum of 1/16” per foot toward the

4. The radiator should be tilted a minimum of 1/16” per foot toward condensate return.

the condensate return.

Vous aimerez peut-être aussi

- Steel Tables by R Agor, Birla Publications PDFDocument97 pagesSteel Tables by R Agor, Birla Publications PDFankitPas encore d'évaluation

- Geodesic Dome InfoDocument29 pagesGeodesic Dome InfoMariusProtopopescu100% (2)

- 03 Wire Rope Strand TerminationsDocument20 pages03 Wire Rope Strand Terminationsoluomo1Pas encore d'évaluation

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderD'EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderPas encore d'évaluation

- Knit Hats with Woolly Wormhead: Styles for the Whole FamilyD'EverandKnit Hats with Woolly Wormhead: Styles for the Whole FamilyÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Parts of ShipDocument6 pagesParts of ShipJaime RodriguesPas encore d'évaluation

- Flanders Commercial Replacement Air Filter CatalogDocument121 pagesFlanders Commercial Replacement Air Filter Cataloge-ComfortUSAPas encore d'évaluation

- Project On Stones & TilesDocument41 pagesProject On Stones & TilesMegha GolaPas encore d'évaluation

- Multiaqua Products CatalogDocument418 pagesMultiaqua Products Cataloge-ComfortUSAPas encore d'évaluation

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationD'EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Swagelok Hand Tube Bender ManualDocument32 pagesSwagelok Hand Tube Bender Manualharrywj100% (1)

- Clean Milk ProductionDocument19 pagesClean Milk ProductionMohammad Ashraf Paul100% (3)

- Lyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticDocument13 pagesLyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticJayr Mercado0% (1)

- Interactive Architecture Adaptive WorldDocument177 pagesInteractive Architecture Adaptive Worldhoma massihaPas encore d'évaluation

- Cutting 1897Document102 pagesCutting 1897Ema Avarvarii100% (1)

- API 650 Manhole Torque Values PDFDocument2 pagesAPI 650 Manhole Torque Values PDFVanaa MohanPas encore d'évaluation

- API 650 bolt torque values manholesDocument2 pagesAPI 650 bolt torque values manholesMunir KadernaniPas encore d'évaluation

- Charleston Steam Radiator BrochureDocument2 pagesCharleston Steam Radiator Brochuree-ComfortUSAPas encore d'évaluation

- API 650 Manhole Torque ValuesDocument2 pagesAPI 650 Manhole Torque ValuesJadon TheophilusPas encore d'évaluation

- API 650 Manhole Torque ValuesDocument2 pagesAPI 650 Manhole Torque Valuesivan rocoPas encore d'évaluation

- API 650 Manhole Torque Values PDFDocument2 pagesAPI 650 Manhole Torque Values PDFreynaldoPas encore d'évaluation

- API 650 Manhole Torque Values PDFDocument2 pagesAPI 650 Manhole Torque Values PDFRashidul Islam MasumPas encore d'évaluation

- Bolt Torque Values For API 650: Roof Manholes and Shell ManholesDocument2 pagesBolt Torque Values For API 650: Roof Manholes and Shell ManholesvaliullahPas encore d'évaluation

- API 650 Manhole Torque ValuesDocument2 pagesAPI 650 Manhole Torque ValuesreynaldoPas encore d'évaluation

- API 650 Manhole Torque ValuesDocument2 pagesAPI 650 Manhole Torque ValuestamelvisPas encore d'évaluation

- PIPE BENDING MACHINES FOR 32-60 INCH PIPESDocument4 pagesPIPE BENDING MACHINES FOR 32-60 INCH PIPESgoomishPas encore d'évaluation

- ROUND HVAC DUCT FITTINGS AND ACCESSORIESDocument12 pagesROUND HVAC DUCT FITTINGS AND ACCESSORIESMoses_JakkalaPas encore d'évaluation

- Sumitec CatalogDocument90 pagesSumitec CatalogIfan JSEPas encore d'évaluation

- Style Ss3: Widest Range 1.20"Document1 pageStyle Ss3: Widest Range 1.20"Al JameelPas encore d'évaluation

- KODE500ESS Dimension Guide enDocument2 pagesKODE500ESS Dimension Guide enChristoper GloePas encore d'évaluation

- A1/A2 Brass Cable Gland SpecsDocument1 pageA1/A2 Brass Cable Gland SpecskrishnalalPas encore d'évaluation

- TPB Radson OTDocument146 pagesTPB Radson OTOnno ClaassensPas encore d'évaluation

- What Are Miter Elbows - China Steel Pipes, Flanges, Pipe Fittings ManufacturerDocument1 pageWhat Are Miter Elbows - China Steel Pipes, Flanges, Pipe Fittings ManufacturerJai Sam DanielPas encore d'évaluation

- Cutoutdimensionsforovens InstalledundercooktopDocument4 pagesCutoutdimensionsforovens InstalledundercooktopHewa PCPas encore d'évaluation

- Flat Oval Spiral Pipe & Fittings: Sheet Metal Connectors, Inc. (SMC)Document4 pagesFlat Oval Spiral Pipe & Fittings: Sheet Metal Connectors, Inc. (SMC)Shaun SullivanPas encore d'évaluation

- Gas Built-In Cooktop: KGCC506R KGCC566R KGCK306V KGCK366VDocument1 pageGas Built-In Cooktop: KGCC506R KGCC566R KGCK306V KGCK366VMaría Elena Gómez VerdugaPas encore d'évaluation

- Vertical PumpsDocument4 pagesVertical PumpsGaurav NarulaPas encore d'évaluation

- 3d.E1W GlandsDocument1 page3d.E1W GlandskrishnalalPas encore d'évaluation

- Public Pool Specifications: 8', 10', 12', 14', & 16' DIVING BOARDSDocument1 pagePublic Pool Specifications: 8', 10', 12', 14', & 16' DIVING BOARDSchanks498Pas encore d'évaluation

- Quasar: Architectural UmbrellasDocument2 pagesQuasar: Architectural UmbrellasSalvador RamosPas encore d'évaluation

- Closet Organizer Installation InstructionsDocument6 pagesCloset Organizer Installation InstructionsElizabeth Acevedo AcevedoPas encore d'évaluation

- 4 de 5) VÁLVULA MARIPOSA Marca NIBCO (Inglés)Document12 pages4 de 5) VÁLVULA MARIPOSA Marca NIBCO (Inglés)Maximiliano StaitiPas encore d'évaluation

- Spares List MachinesDocument6 pagesSpares List MachinesVishal MehtrePas encore d'évaluation

- NRF 206 Pemex 2008 FDocument17 pagesNRF 206 Pemex 2008 FJavier GarcíaPas encore d'évaluation

- Installation and Maintenance Guidelines For Nibco Butterfly Valves With Rubber SeatsDocument16 pagesInstallation and Maintenance Guidelines For Nibco Butterfly Valves With Rubber SeatsJosé marinPas encore d'évaluation

- Eaton Temporary Strainers LUBRICARTEDocument1 pageEaton Temporary Strainers LUBRICARTEsrangel77Pas encore d'évaluation

- 3c.CW GlandsDocument1 page3c.CW GlandskrishnalalPas encore d'évaluation

- Kidde Mounting Straps and Wall Brackets For Clean Agent and Nitrogen Pilot and Driver Cylinders K-85-1230Document6 pagesKidde Mounting Straps and Wall Brackets For Clean Agent and Nitrogen Pilot and Driver Cylinders K-85-1230Isa KumPas encore d'évaluation

- ConnectorsizeDocument1 pageConnectorsizeilachezhiyanPas encore d'évaluation

- Hytrol Conveyor Gravity Skatewheel CurvesDocument1 pageHytrol Conveyor Gravity Skatewheel CurvesJorge H. GuerreroPas encore d'évaluation

- Bridas s/norma ASME B16.47 y BS 32 93 FlangesDocument54 pagesBridas s/norma ASME B16.47 y BS 32 93 FlangesvalentinPas encore d'évaluation

- 10506-Hayfield SoftTwistDK (Free)Document4 pages10506-Hayfield SoftTwistDK (Free)Kyae ThawPas encore d'évaluation

- BUT29991 FLY Canada Duplex 2017 RZ WEB 02Document6 pagesBUT29991 FLY Canada Duplex 2017 RZ WEB 02Benny PoPas encore d'évaluation

- Caja de 4 Salidas System OneDocument1 pageCaja de 4 Salidas System OneivanbautistataPas encore d'évaluation

- Lined Split ClampDocument0 pageLined Split ClampSundar RamasamyPas encore d'évaluation

- American Comfort - E-Catalogue - Updated - 31-12-2019 - FinalDocument19 pagesAmerican Comfort - E-Catalogue - Updated - 31-12-2019 - FinalAnushaPas encore d'évaluation

- V Belt Technical Specification POLYESTER CORD Neoprene Jacketed HIC Manufactured UNIVERSAL BrandDocument5 pagesV Belt Technical Specification POLYESTER CORD Neoprene Jacketed HIC Manufactured UNIVERSAL Brandmonahend100% (1)

- V Belts PDFDocument5 pagesV Belts PDFAsela BandaraPas encore d'évaluation

- ASTM PIPES CATALOGUEDocument12 pagesASTM PIPES CATALOGUESanjeev GoelPas encore d'évaluation

- TwistdrillcatalogueDocument64 pagesTwistdrillcatalogueSubam ProjectsPas encore d'évaluation

- 6V Geodesic Dome Calculator DomeramaDocument5 pages6V Geodesic Dome Calculator DomeramaSHAH SHITALPas encore d'évaluation

- Kafes Üretim ÇeşitleriDocument1 pageKafes Üretim ÇeşitleriJose RosePas encore d'évaluation

- Manual For PEINER HV-Structural Bolt Sets" According To DIN EN 14399 DIN EN 1090-2 DIN EN 1993-1-8/NADocument14 pagesManual For PEINER HV-Structural Bolt Sets" According To DIN EN 14399 DIN EN 1090-2 DIN EN 1993-1-8/NAAbd Alkarim MohamedPas encore d'évaluation

- Electric Cooktop Installation InstructionsDocument24 pagesElectric Cooktop Installation InstructionsMarioPas encore d'évaluation

- Pipe BD VARDocument3 pagesPipe BD VARBrian Alex MagnoPas encore d'évaluation

- Pipe Supports: Adjustable Pipe Saddle Support With U-BoltDocument1 pagePipe Supports: Adjustable Pipe Saddle Support With U-BoltJimmy Alexander AvilaPas encore d'évaluation

- PAW Heating Components and Solar Systems BrochureDocument56 pagesPAW Heating Components and Solar Systems Brochuree-ComfortUSAPas encore d'évaluation

- Biomass Boilers BrochireDocument2 pagesBiomass Boilers Brochiree-ComfortUSAPas encore d'évaluation

- Comfort Star NS50-B2 BrochureDocument2 pagesComfort Star NS50-B2 Brochuree-ComfortUSAPas encore d'évaluation

- ComfortStar Diamond Series MiniSplit Systems BrochureDocument4 pagesComfortStar Diamond Series MiniSplit Systems Brochuree-ComfortUSAPas encore d'évaluation

- Icm326 BrochureDocument15 pagesIcm326 Brochuree-ComfortUSAPas encore d'évaluation

- Tekmar Controls BrochureDocument16 pagesTekmar Controls Brochuree-ComfortUSAPas encore d'évaluation

- Comfort Star 88AC07-230 BrochureDocument4 pagesComfort Star 88AC07-230 Brochuree-ComfortUSAPas encore d'évaluation

- Venmar IAQ Products BrochureDocument12 pagesVenmar IAQ Products Brochuree-ComfortUSAPas encore d'évaluation

- Schluter Kerdi Line Data SheetDocument8 pagesSchluter Kerdi Line Data Sheete-ComfortUSAPas encore d'évaluation

- Comfort Star EAC-900R BrochureDocument2 pagesComfort Star EAC-900R Brochuree-ComfortUSAPas encore d'évaluation

- Profab Empyre Elite Boiler BrochureDocument4 pagesProfab Empyre Elite Boiler Brochuree-ComfortUSAPas encore d'évaluation

- Comfort Star MPK12-410 BrochureDocument2 pagesComfort Star MPK12-410 Brochuree-ComfortUSAPas encore d'évaluation

- Haier Air Conditioners Owners ManualDocument24 pagesHaier Air Conditioners Owners Manuale-ComfortUSAPas encore d'évaluation

- ComfortStar CCH/CHH Series MiniSplit Air Conditioners BrochureDocument16 pagesComfortStar CCH/CHH Series MiniSplit Air Conditioners Brochuree-ComfortUSA50% (2)

- Daikin Split Systems BrochureDocument32 pagesDaikin Split Systems Brochuree-ComfortUSA100% (1)

- Aspen Pumps Operation ManualDocument4 pagesAspen Pumps Operation Manuale-ComfortUSA100% (1)

- Tile Redi Products BrochureDocument6 pagesTile Redi Products Brochuree-ComfortUSAPas encore d'évaluation

- Lennox Germicidal LampsDocument4 pagesLennox Germicidal Lampse-ComfortUSAPas encore d'évaluation

- Navien CH Combi Heater BrochureDocument4 pagesNavien CH Combi Heater Brochuree-ComfortUSAPas encore d'évaluation

- Clear Water BrochureDocument28 pagesClear Water Brochuree-ComfortUSAPas encore d'évaluation

- Branch Box Installation ManualDocument4 pagesBranch Box Installation Manuale-ComfortUSAPas encore d'évaluation

- LG 2011 Accessories CatalogDocument32 pagesLG 2011 Accessories Cataloge-ComfortUSAPas encore d'évaluation

- Mitsubishi System CatalogDocument76 pagesMitsubishi System Cataloge-ComfortUSAPas encore d'évaluation

- SpacePak PurePak Air Cleaners BrochureDocument4 pagesSpacePak PurePak Air Cleaners Brochuree-ComfortUSAPas encore d'évaluation

- LG HVAC 2011 Full CatalogDocument72 pagesLG HVAC 2011 Full Cataloge-ComfortUSAPas encore d'évaluation

- Separation Tube Installation ManualDocument2 pagesSeparation Tube Installation Manuale-ComfortUSAPas encore d'évaluation

- Fujitsu AOU48RLXFZ Design and Technical ManualDocument312 pagesFujitsu AOU48RLXFZ Design and Technical Manuale-ComfortUSA100% (2)

- Fujitsu AOU24RLXFZ Indoor Design and Technical ManualDocument209 pagesFujitsu AOU24RLXFZ Indoor Design and Technical Manuale-ComfortUSAPas encore d'évaluation

- PDFViewer - JSP 3Document46 pagesPDFViewer - JSP 3Kartik ChaudharyPas encore d'évaluation

- DENSO COMMON RAIL INJECTOR REPAIR GUIDEDocument22 pagesDENSO COMMON RAIL INJECTOR REPAIR GUIDEMarcoPas encore d'évaluation

- 11bg USB AdapterDocument30 pages11bg USB AdapterruddyhackerPas encore d'évaluation

- Ro-Buh-Qpl: Express WorldwideDocument3 pagesRo-Buh-Qpl: Express WorldwideverschelderPas encore d'évaluation

- Fundermax Exterior Technic 2011gb WebDocument88 pagesFundermax Exterior Technic 2011gb WebarchpavlovicPas encore d'évaluation

- Lathe - Trainer ScriptDocument20 pagesLathe - Trainer ScriptGulane, Patrick Eufran G.Pas encore d'évaluation

- BCP-8000 User's ManualDocument36 pagesBCP-8000 User's ManualAsad PatelPas encore d'évaluation

- Features Integration of Differential Binomial: DX BX A X P N MDocument4 pagesFeatures Integration of Differential Binomial: DX BX A X P N Mابو سامرPas encore d'évaluation

- Religion in Space Science FictionDocument23 pagesReligion in Space Science FictionjasonbattPas encore d'évaluation

- Datasheet PDFDocument6 pagesDatasheet PDFAhmed ElShoraPas encore d'évaluation

- Project Binder 2Document23 pagesProject Binder 2Singh DhirendraPas encore d'évaluation

- GLOBAL Hydro Turbine Folder enDocument4 pagesGLOBAL Hydro Turbine Folder enGogyPas encore d'évaluation

- Lesson Plan: Lesson: Projectiles Without Air ResistanceDocument4 pagesLesson Plan: Lesson: Projectiles Without Air ResistanceeltytanPas encore d'évaluation

- JY Series Single-Phase Capacitor Induction MotorsDocument1 pageJY Series Single-Phase Capacitor Induction MotorsAditya PrasetyoPas encore d'évaluation

- Sattvik Brochure - Web VersionDocument4 pagesSattvik Brochure - Web Versionudiptya_papai2007Pas encore d'évaluation

- 1010 PDS WLBP 170601-EN PDFDocument4 pages1010 PDS WLBP 170601-EN PDFIan WoodsPas encore d'évaluation

- Activities and Assessments:: ASSIGNMENT (SUBMIT Your Answers at EDMODO Assignment Section)Document5 pagesActivities and Assessments:: ASSIGNMENT (SUBMIT Your Answers at EDMODO Assignment Section)Quen CuestaPas encore d'évaluation

- 12 Week Heavy Slow Resistance Progression For Patellar TendinopathyDocument4 pages12 Week Heavy Slow Resistance Progression For Patellar TendinopathyHenrique Luís de CarvalhoPas encore d'évaluation

- Traffic Violation Monitoring with RFIDDocument59 pagesTraffic Violation Monitoring with RFIDShrëyãs NàtrájPas encore d'évaluation

- Magnetic Pick UpsDocument4 pagesMagnetic Pick UpslunikmirPas encore d'évaluation

- Proposal Anguria Pasta NewDocument24 pagesProposal Anguria Pasta NewNOOR IRDINA HAFIZAH BT TAUPISPas encore d'évaluation

- KAC-8102D/8152D KAC-9102D/9152D: Service ManualDocument18 pagesKAC-8102D/8152D KAC-9102D/9152D: Service ManualGamerAnddsPas encore d'évaluation

- Maintenance Handbook On Compressors (Of Under Slung AC Coaches) PDFDocument39 pagesMaintenance Handbook On Compressors (Of Under Slung AC Coaches) PDFSandeepPas encore d'évaluation

- CAE The Most Comprehensive and Easy-To-Use Ultrasound SimulatorDocument2 pagesCAE The Most Comprehensive and Easy-To-Use Ultrasound Simulatorjfrías_2Pas encore d'évaluation

- Oecumenius’ Exegetical Method in His Commentary on the RevelationDocument10 pagesOecumenius’ Exegetical Method in His Commentary on the RevelationMichał WojciechowskiPas encore d'évaluation