Académique Documents

Professionnel Documents

Culture Documents

74SmithKlineTransitoryStall PDF

Transféré par

myskyshepherdTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

74SmithKlineTransitoryStall PDF

Transféré par

myskyshepherdDroits d'auteur :

Formats disponibles

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/282157535

An Experimental Investigation of the Transitory Stall Regime in Two-

Dimensional Diffusers

Article in Journal of Fluids Engineering · March 1974

DOI: 10.1115/1.3447086

CITATIONS READS

24 165

1 author:

Charles R. Smith

Lehigh University

92 PUBLICATIONS 3,958 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Electronic Text Book: Introduction to Graduate Fluid Mechanics View project

All content following this page was uploaded by Charles R. Smith on 25 September 2015.

The user has requested enhancement of the downloaded file.

I n Experimental investigation of the

C. R. SMITH, JR.

Transitory Stall Regime in Two-Dimensional

Assistant Professor,

School of Mechanical Engineering,

Purdue University,

Diffusers

Lafayette, Ind.

Assoc, Mem. ASME

A study of flow behavior of transitory stall in two-dimensional diffusers at low Mach

numbers is reported. The changes in flow patterns from stall inception to full-stall

S. J . KLINE are described; the geometries for maximum fluctuations are located. The mean times

Professor, and distribution of stall build-up and wash-out periods are given for a series of units

Department of Mechanical of varying total angle. The mean times are found to scale on total stall volume, and a

Engineering, Stanford University, nondimensional correlation of stall period is given. The distribution of stall periods,

Stanford, Calif. Fellow ASME

for random inlet fluctuations, is found to be broad and strongly skewed toward lower

periods. Comparable results are found in water for R^IO* and in air at R~105. A

further series of tests with periodic inlet disturbances indicates that the stall behavior

is modified strongly when the pulsing period is 0.5 to 1.0 times the natuarl mean

period, but not otherwise. Details of flow patterns and blockage are summarized.

Introduction chosen somewhat arbitrarily from an infinite variety which could

be created, but is believed to give results which indicate the

T* I HE need to obtain high recovery in diffusers primary response characteristics of the oscillator system.

often forces the designer to employ geometries at or near the

limit of first appreciable stall. In such a condition, or just Experimental Apparatus

beyond it, the diffuser passes into the flow regime called large

The major portion of the investigation reported, employed a

transitory stall. In this flow regime the diffuser acts as a self-

two-dimensional, plexiglas diffuser test section positioned in a

excited oscillator, with large stalls building up and washing out

closed circuit, open-surface water table, as shown in Fig. 2.

in a quasi-periodic fashion. Although the existence of this regime

Three different length diffuser wall sections were used in con-

has been known for over a decade, no detailed studies of the actual

nection with a 1 in. wide, variable angle inlet to allow the ex-

periods or magnitudes of the characteristic fluctuations have been

amination of a wide range of geometries. The throat Reynolds

reported in the literature. These data are of importance to the

number was low (ffi„.i = 0.8 X 104), but boundary layer trips

designer in anticipating the effects on downstream components

insured turbulent boundary layers at the throat. Aspect ratio

and in attempts to either minimize or maximize the oscillations.

(b/wi) was held constant at 10 + 1 / a , and inlet turbulence with-

The present paper is a summary of a detailed study of the

out the disturbance device was of the order of 1 percent to 2

flow characteristics in the transitory stall region (Smith and

percent. All tests were run with a downstream plenum.

Kline [7]).1 The extent of the geometries studied is indicated

The inlet disturbance device was built form a 7 /s in. stainless

by the region enclosed by dashed lines on the flow-regime chart

steel piano hinge and was activated by a solenoid driven by a

of Fox and Kline [4], Fig. 1. The apparatus employed is similar

variable frequency signal generator system.

to that of Fox and Kline, with the exception of provision for

Flow behavior was visualized using both dye injection and

creating pulses of various frequencies in the inlet flow. The de-

hydrogen-bubble wires. Mean-flow data were obtained using a

tails are shown in Fig. 2. Note that the hinge extends from

specially designed probe (Fig. 3), consisting of two back-to-

above the open surface of the water unit to the floor, so that a

back cylindrical total pressure probes referenced to opposing

pulse is created across the entire inlet. This form of pulse was

ports of differential pressure transducer ( ± 1 in. of water maxi-

mum).

A brief, additional experimental study was done using a two-

dimensional air diffuser, previously described by Chui and Kline

•Numbera In brackets designate References »t and of papor. [1]. Mean-flow data and periodic flow behavior were examined

Contriubted by the Fluids Engineering Division and presented at the via a specially developed directional hot-wire probe (Fig. 3).

Winter Annual Meeting, Detroit, Mich., November 11-15, 1973, of Tsa More extensive descriptions of the experimental apparatus and

AMERICAN SOCIETY OF MECHANICAL EHGINEEBS. Manuscript received at

ASME Headquarters, July 26, 1073. Paper No. 73-WA/FE-U. instrumentation can be found in reference [1].

Journal of Ffyids Engineering Copyright © 1974 by ASME MARCH 1 9 7 4 / 11

Downloaded From: http://fluidsengineering.asmedigitalcollection.asme.org/ on 09/24/2015 Terms of Use: http://www.asme.org/about-asme/terms-of-use

TO PRESSOR!

HYSTERESIS ZONE f TRANSDUCER

D

FULL' DEVELOPED

TWO-DIMENSIONAL STALL

,'CT WIRE

PROBE -

0,060 DIA

1/16"

~1

i/8" —I t- T

,5 2 3 4 6 8 10 15 20 30 TO 60

0.10"-

e —

sti:sir;c

ELEMC.T

N/W,

;A) WATER PROSE 'FULL SCALE, ;B; AIR PROBE ;3X SCALE.

Fig. 1 Diffuser Flow Regime Chart of Fox and Kline [3] for Two-Di- Fig. 3 Water and Air Probes

monsional Diffusers Showing the Line of Maximum Unsteadiness.

Experimental Results: Undisturbed Inlet

Conditions

Visual Results

Initial results for the water channel apparatus gave agree-

ment with the patterns and the locations of lines a-a and b-b

reported by Fox and Kline [4], Fig. 1. Additional visual results

were obtained, augmenting and extending previous informa-

tion of Fox and Kline and of Reneau, Johnston, and Kline [6]

with respect to stall development and behavior.

The whole transition from unstalled flow to full-stalled flow

FLOW STRAIGHTEHER is a continuum of states, as previously reported by Reneau,

. S SETTLING SCREENS Johnston, and Kline [6]; however, stall wash-out characteristics

(A) FLOW CHANNEL AND DIFFUSER for this region can be categorized as either complete or partial

wash-outs. Near line a-a in the transitory regime, stalls build-up

and wash-out completely. Nearer line b-b, however, the stalled

fluid only partially washes o u t ; the partial wash-outs never

FLOOR

eliminate all the stalled fluid. The amount of the stalled fluid

remaining after a partial wash-out increases as the geometry of a

FLOW !

^> I diffuser approaches line b-b. More detailed information on the

behavior of transitory stalls, particularly the effect of increasing

TO SOLENOID -

length ratio, is given in [7].

In the present study, the concept of the stall period was em-

ployed to allow quantification of transitory stall behavior. The

"BLADE" SECTIONS stall period was defined as the time required for completion of

IMMERSED IN WATER

a stall wash-out cycle; where a wash-out is defined in turn as a

(OPEN POSITION)

rapid entrainment and expulsion of stalled fluid sufficient to

(B) INLET DISTURBANCE DEVICE cause a major change in the exit plane velocity profile. The major

Fig. 2 Water Channel Apparatus with Detail of Inlet Disturbance quantitative results which follow are generally expressed in

Device. terms of the stall period.

.Diffuser Geometry and

Nomenclature

AR = diffuser area ratio, W2/W1 e

= half angle of the diffuser

PLANE: b = width of diffuser between parallel V = kinematic viscosity

walls P = fluid density

L = diffuser diverging wall length cr = standard deviation of stall period

N = diffuser centerline length about the mean

P = inlet disturbance period Subscripts

R = Reynolds number, Ui/Wi/v 1 = diffuser entrance or throat

F1.0W- T = stall (wash-out) period ' 2 = diffuser exit

T = mean stall period Hi = includes only stall periods greater

V = area averaged velocity than the mean stall period

W = width of diffuser between diverg- Lo = includes only stall periods less

ing walls than or equal to the mean stall

X = axial and flow directions measured period

from the throat N = undisturbed inlet conditions

12 / M A R C H 1974 Transactions of the ASME

Downloaded From: http://fluidsengineering.asmedigitalcollection.asme.org/ on 09/24/2015 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Mean Stall Period. Mean natural stall periods (TN), are large data falling below TN (low deviation). Values for the high

sample ( > 100) time averages evaluated from flow visualization deviation are typically 40 percent to 60 percent of TN; values

of consecutively occurring stall periods. The mean natural stall for the low deviation are typically 30 percent to 40 percent

periods, so called because they occur with "natural" or undis- of TN. Several typical values are indicated on Figs. 5 and 6.

turbed inlet conditions, appear to depend primarily on three

system parameters: diffuser length (L), total included angle Mean Flow Characteristics

(2d), and averaged throat velocity (Ui). Scaling TN on a stall

U Measurement of mean flow data was done in the water channel

volume-time parameter, , collapses all data for the with the previously described probe-transducer system run on-

L sin 2a line with an integrated digital data acquisition system. The

water channel apparatus as shown in Fig. 4. As a check of the probe, its response characteristics, methods of data collection,

water channel data, additional stall period data were collected and the data acquisition system are detailed in [7J.

using the air diffuser and hot-wire probe described previously.

The normalized data from this check are also presented in Fig. Mean Velocity Profiles. All velocity profiles were taken at

4, and agree well with the water channel data. These results the exit plane of the diff users; the results are available in [7].

cover approximately the lower two-thirds of the transitory stall

regime above line a-a in Fig. 1. Near line b-b, wash-out behavior MEAN STALL PERIOD - 15.72 SEC

became too indistinct for rational designation of a single wash- STORBED INLET CONDITION

173 STALL PERIODS

out and data collection was terminated. IE,9 SEC LA1! = 11,25

Several previous diffuser studies have made crude estimates = 25,1) SEC AR = n.o

of the mean stall periods of transitory stalls. In most cases, only Ui = 1,01 FPS

simple order of magnitude estimates were made from limited

visualization studies. When normalized, most of these estimates

fall in the same general range as the results of this study. Of 20 10 60

\h

80 100

JLfl.

120

particular interest is data taken from studies by McDonald and STALL PERIOD LENGTH, SEC

Fox [5] of conical diffusers using water. Their estimates of stall

periods, obtained using dye visualization, are normalized and

included in Fig. 4. The comparison with the present results is MEAN STALL PERIOD - 11,1 SEC

quite good. PULSED INLET PERIOD = 15 SE

20

Stall Period Distribution. Distributions of stall periods about

the mean value were obtained for several cases. Two typical n 179 STALL PERIODS

o-Lo = 7.5 SEC

distributions," which clearly illustrate the quasi-periodic nature 16 o-Hl = 10,3 SEC

of the wash-outs, are presented in Fig. 5. In all cases examined,

the stall period distributions were strongly skewed toward the 12 L/H, -11,25

low side of the mean. Mean stall periods are repeatable, but AR = 1,0

individual stall periods may vary from V 3 TN to 2 TN or more. 8 U, =1.01 FPS

Further data are given in [7].

J

4

Stall Period Standard Deviation. In order to accurately rep-

resent the high skewness in the stall period distributions, an TJlfL

n

unorthodox method of calculating what we term the high devia- 20 10 60 80 100

tion and the low deviation was employed. The standard method

STAl L PERIOD LENGTH, SEC

of calculating a standard deviation was applied first to the data

Fig. 5 Example of Stall Period Distributions Showing the Effect

falling above TN (high deviation), and then separately to the

of Periodically Disturbing the Inlet Conditions

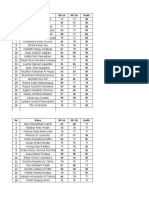

SYrffiOL MEDIUM L/Nj Uj FPS REH

l,6r

320 HATER 5,25 1.01 0,87xl0 If

o 11,25 1,01 O.S/xlO1'

B 11.25 1,70 1.30X1011

280 A 23,25 1,01 0.87x10^

0 AIR 8,0 105 1.67x10=

o * 8,0 56 0,87xl0 5

210

OT

200 a

D 0

160 •

A o

120

MCDONALD'S "TIRE CONSTANT"

ESTIMATES

20

Fig. 4 Nondimensional Mean Natural Stall Period (Mixing-Inertia PULSE PERIOD/MEAN NATURAL STALL PERIOD

Parameter) versus Total Included, Angle with Comparative Data of

McDonald and Fox [5]. b/W, =10, U1 = 1.01 fps. Fig. 6 Mean StallJ'eriod versus Pulse Period for Various Area Ratios.

fa/W, = 10, U,=l,01 fps, Pulse Amplitude~8 percent (_/,.

Journal of Flyids Engineering MARCH 1 9 7 4 / 13

Downloaded From: http://fluidsengineering.asmedigitalcollection.asme.org/ on 09/24/2015 Terms of Use: http://www.asme.org/about-asme/terms-of-use

A characteristic of all the velocity profiles measured for diffusers separation and/or build-up of the stalled fluid to a point where

with transitory stalls present was a definite affinity of the it becomes unstable; and (2) the triggering of a wash-out of the

through flow for one diverging wall over the other. The degree stall by an upstream disturbance. The portion of a wash-out

of flow attachment grew stronger as diffuser geometry approached cycle t h a t each of the these phenomena occupied varied in length

line b-b. Apparently, even near line a-a, transitory stalls will although the separation and stall build-up phase appeared to

occur more frequently on one wall than the other; an effect be more uniform. A wash-out triggering disturbance could be

borne out also by flow visualization. either a large turbulent eddy, a fluctuation in flowrate, or an

artificially induced disturbance, as in the case of this study.

Fluctuation Intensity. The fluctuation intensity is defined

Following a stall wash-out, a certain minimum time period

identically to turbulence intensity except that it is normalized

is required for a stall to redevelop before it can subsequently

on the average inlet velocity. Due to the poor high frequency

wash-out. Fig. 6 indicates that if the period between disturb-

( > 2 Hz) response characteristics of the probe-transducer sys-

ances, P , is greater than about 0.5 TN, there is sufficient time

tem, fluctuation intensities are only a rough measure of the

for a stall to develop before it can be "triggered" by an up-

larger scale unsteadiness and fluctuations observed in the

stream disturbance. Additionally, if 0.5 TN < P < TN each

transitory stall regime. If a measure of average unsteadiness of

disturbance will cause a wash-out, forcing the stall period to

different diffusers is taken to be an exit area average of the fluctu- follow the disturbance period, P . For P > fN there is a time

ation intensities, several important characteristics are observed. for naturally triggered wash-outs to occur also, thus diminishing

First, average fluctuation intensity increases sharply from a the forcing effect of the artificial disturbances. If P < 0.5 TN,

minimum near line a-a to a maximum near the center of the a stall has insufficient time to "recover" after a wash-out has

transitory stall regime, followed by a gradual decrease in un- occurred, and each disturbance will not "trigger" a wash-out;

steadiness for geometries approaching line b-b. This peak in the stall period thus responds less to the disturbance period.

average fluctuation intensity is found to occur at approximately For P < < 0.5 TN, stalls do not respond to the disturbances per

26 — 20 to 24 deg; the same region of maximum unsteadiness se, but appear to behave as if the inlet turbulence level has

noted for two-dimensional air diffusers by Cochran and Kline simply been raised.

[2] and by Waitman, et al. [8]. The location of geometries of

In general, for P > 0.5 TN, artificially induced wash-outs re-

maximum exit plane unsteadiness are indicated by the line of

sulted in greater expulsion of stalled fluid, longer lull times prior

maximum unsteadiness in Fig. 1.

to subsequent stall build-up, and deeper upstream penetration

Another significant result was that increasing a diffuser's

of new stalled fluid than was observed for naturally occurring

length decreases the average fluctuation intensity or exit un-

wash-outs. However, for P < 0.5 TN, these effects rapidly

steadiness, contrary to previous speculation (although this ef-

diminished.

fect had been observed qualitatively by Waitman [8]). This

An additional observation was that the pulse level used in this

effect was also confirmed using visualization techniques.

study ( + 6 percent of Ui) could be replaced by a smaller inlet

Reversed Flow Lines. Lines of constant percent reversed flow, disturbance and still have relatively the same triggering effect.

indicating reversed flow of stalled fluid, were constructed for Visual investigations substantiate that relatively small disturb-

the diffuser exit plane using probe-transducer measurements. ances are sufficient to cause a wash-out. However, insufficient

The reversed flow lines served to illustrate the inception and information was gathered in this study to allow prediction of the

growth of mean stall patterns, comparing favorably with previous minimum necessary size or the effectiveness of various types of

descriptions by Fox and Kline [3]. disturbances.

Detailed information and results for the above mean flow

Stall Period Distribution. Fig. 5 compares typical stall period

characteristics, plus additional mean flow data obtained with

distributions for a diffuser with an undisturbed inlet flow and

the air diffuser apparatus, are presented in [7],

the same diffuser with P = TN- The effect of the disturbance

Experimental Results: Periodically Disturbed is basically to create stall periods of quite uniform length, and

Inlet Conditions hence a far more narrow, peaked histogram.

The inlet disturbance device described previously was used Stall Period Standard Deviation. The typical effect of an inlet

to investigate the effect of a periodic inlet disturbance on dif- disturbance on high and low stall period deviation is included

fusers operating in the transitory stall regime. The device in Figs. 5 and 6. From a deviation of 40 to 50 percent of TN for

generated a wake followed by a jet superimposed on the inlet the undisturbed case, the deviation decreases with decreasing

velocity profile. The device caused a disturbance for only 10 to P, becoming narrower (15 percent of TN) as the inlet disturbance

20 percent of the disturbance period; the maximum amplitude begins to drive the stall periods. As the disturbance period de-

of the disturbance was + 6 percent of Ui. The disturbance creases to the point of diminishing effect on the stall period (P

form is similar to that frequently observed downstream of an < 0.5 TN), the stall period standard deviation begins to in-

axial compressor or fan. crease.

Visual Results Mean Flow Results

Mean Stall Period. Visual studies of the effect of the inlet Mean velocity profiles, average fluctuation intensities, and

disturbance were made for L/Wi = 5.25 and 11.25, and for reversed flow lines were obtained for several diffuser geometries

disturbance periods (P) varying from 2 to 3 times TN to about lying within the transitory stall regime and subject to periodic

V< TN- A plot of normalized mean stall period versus normalized inlet disturbances.

disturbance period is presented in Fig. 6 for several different Periodically disturbing the inlet flow increased the uniformity

geometries. Both f and P were normalized with respect to of time averaged exit velocity profiles in both a spanwise and

TN for each respective geometrical setting. The data for the depthwise direction. Area averaged fluctuation intensities were

two length ratios shown in Fig. 6 indicate t h a t the reaction of found to generally increase when a periodic disturbance was in-

transitory stalls to periodic inlet disturbances may be inde- troduced. Some unusual behavior was experienced for geometries

pendent of geometry. A summary of visual observations and lying near the center of the transitory stall regime, and is dis-

physical interpretations of inlet disturbances follows. cussed in detail in [7].

The wash-out or stall period cycle, as observed in this study, Exit plane reversed flow lines showed t h a t periodic inlet dis-

seems to be composed of two distinct phenomena: (1) the turbances both decrease exit area blockage and cause a shift in

14 / M A R C H 1974 Transactions ©f the ASHE

Downloaded From: http://fluidsengineering.asmedigitalcollection.asme.org/ on 09/24/2015 Terms of Use: http://www.asme.org/about-asme/terms-of-use

the position of stalled fluid. Normally, an inlet disturbance iformity in stall period lengths. Disturbance periods lying out-

caused stalled fluid to shift from a diverging wall to either a side the above range have rapidly diminishing effects on wash-

parallel wall or a corner juncture of the walls. The criterion Fox out behavior.

and Kline [3] used for determining line a-a was that stalled fluid 2 Periodic disturbances flatten exit velocity profiles, cause

must be present at some time on 20 percent or more of a diverging a substanital shift in position and size of stall exit blockage, and

wall. If one applies this guideline to the reversed flow line and induce moderate changes in exit unsteadiness.

visual information of this study, line a-a is raised about 1 deg

(of 26) for P = TV and 3 deg (of 26) for P = 0.5 TV. References

1 Chui, G., and Kline, S. J., "Investigation of a Two-Di-

Conclusions mensional Fully Stalled Turbulent Flow Field," Report MD-19,

Department of Mechanical Engineering, Stanford University,

The mean flow and periodic behavior characteristics of the Aug. 1967.

transitory stall flow regime in two-dimensional diffusers has been 2 Cochran, D. L., and Kline, S. J., "The Use of Short Flat

investigated, for both undisturbed and periodically disturbed Vanes for Producing Efficient Wide-Angle Two-Dimensional

inlet conditions. The following conclusions can be reached: Subsonic Diffusers," NACA T N 4309, Sept. 1958.

3 Fox, R. W., and Kline, S. J., "Flow Regime D a t a and De-

sign Methods for Curved Subsonic Diffusers," Report PD-6,

Undisturbed Inlet Conditions Department of Mechanical Engineering, Stanford University,

Aug. 1960.

1 Stall wash-out periods are quasi-periodic with broad 4 Fox, R. W., and Kline, S. J., "Flow Regime D a t a and De-

probability distributions (a ^ + 0.5 TV) and are skewed sign Methods for Curved Subsonic Diffusers," Journal of Basic

Engineering, TRANS. ASME, Series D, Vol. 84, Sept. 1962, p p .

strongly to the low side of the mean. 303-312.

2 Mean natural stall periods (TV) are generally measureable 5 McDonald, A. T., and Fox, R. W., "Incompressible Flow

for the first Va to 2/;s of the transitory stall regime. A parameter, in Conical Diffusers," Purdue Research Foundation Tech.

TVf/i/L sin 2d, roughly correlates all the mean natural stall Report 1, Sept. 1964.

6 Reneau, L. It., Johnston, J. P., and Kline, S. J., "Perform-

period data of this stud}', as well as data from other studies. ance and Design of Straight Two-Dimensional Diffusers," Re-

3 In the transitory stall regime, exit flow unsteadiness in- port PD-8, Department of Mechanical Engineering, Stanford

creases rapidly with increased included angle; maximum un- University, Sept. 1964.

7 Smith, C. It., and Kline, S. J., "An Experimental Investi-

steadiness occurs at approximately 26 = 20 to 24 deg. gation of the Transitory Stall Regime in Two-Dimensional Dif-

fusers Including the Effects of Periodically Disturbed Inlet Con-

Periodically Disturbed Inlet Conditions ditions," Report PD-15, Thermosciences Div., Mechanical En-

gineering Department, Stanford University, Aug. 1971.

1 Disturbance periods in the range 0.5 TV to TV show the 8 Waitman, B. A., Reneau, L. It., and Kline, S. J., "Effects

of Inlet Conditions on Performance of Two-Dimensional Dif-

most effect on transitory stalls, forcing the mean stall period fusers," Report PD-5, Department of Mechanical Engineering

to follow the disturbance period and creating increased un- Stanford University, Aug. 1960.

Journal of Fluids Engineering MARCH 1 9 7 4 / 11

DownloadedViewFrom:

publicationhttp://fluidsengineering.asmedigitalcollection.asme.org/

stats on 09/24/2015 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Vous aimerez peut-être aussi

- Cross-Flow Vibrations of A Pipe Close To A Rigid Boundary: V.JacobsenDocument7 pagesCross-Flow Vibrations of A Pipe Close To A Rigid Boundary: V.Jacobsen李智Pas encore d'évaluation

- 27 Hagedorn 1965 PDFDocument10 pages27 Hagedorn 1965 PDFDexter CastilloPas encore d'évaluation

- Tandfonline5876b513 17eb 20190516114057Document14 pagesTandfonline5876b513 17eb 20190516114057rezaPas encore d'évaluation

- The Unsteady Wake of An Oscillating Cylinder at Low Reynolds NumberDocument10 pagesThe Unsteady Wake of An Oscillating Cylinder at Low Reynolds NumberManu K VasudevanPas encore d'évaluation

- Positive Streamer Propagation in Large Oil: Experimental Characterization of Propagation ModesDocument11 pagesPositive Streamer Propagation in Large Oil: Experimental Characterization of Propagation ModesAlberto OrtizPas encore d'évaluation

- Walter2003 UnlockedDocument13 pagesWalter2003 UnlockedLorena CamposPas encore d'évaluation

- 3D Numerical Modelling of Open Channel Flow With Submerged VegetationDocument9 pages3D Numerical Modelling of Open Channel Flow With Submerged VegetationIhtesham KhanPas encore d'évaluation

- Lecture Note Ch-1 IntroductionDocument7 pagesLecture Note Ch-1 IntroductionHd MuluPas encore d'évaluation

- Hagedorn and Brown 1965Document10 pagesHagedorn and Brown 1965LIDIA PUGLIESSAPas encore d'évaluation

- Experimental and Theoretical Scaling Laws For TranDocument4 pagesExperimental and Theoretical Scaling Laws For TranMora TrisPas encore d'évaluation

- Hydraulic Energy Dissipaters A ReviewDocument3 pagesHydraulic Energy Dissipaters A ReviewPinjis PliersPas encore d'évaluation

- Suppression of Von Karman Vortex Streets Past PoDocument31 pagesSuppression of Von Karman Vortex Streets Past PoLuis PressoPas encore d'évaluation

- Vertical Drain Consolidation With Overlapping Smear Zones: Géotechnique January 2007Document6 pagesVertical Drain Consolidation With Overlapping Smear Zones: Géotechnique January 2007DanilmunthePas encore d'évaluation

- Ramanan1994 PDFDocument13 pagesRamanan1994 PDFSahar NasrallahPas encore d'évaluation

- 1008 2294 PDFDocument17 pages1008 2294 PDFالاسمر الجنوبيPas encore d'évaluation

- Liquid-Liquid Mass Transfer in An Agitated Vessel With A Flat InterfaceDocument7 pagesLiquid-Liquid Mass Transfer in An Agitated Vessel With A Flat InterfaceSagar MishraPas encore d'évaluation

- Numerical Research On Water Hammer Phenomenon of Parallel Pump-Valve System by Coupling FLUENT With RELAP5Document10 pagesNumerical Research On Water Hammer Phenomenon of Parallel Pump-Valve System by Coupling FLUENT With RELAP5skyPas encore d'évaluation

- Tsahal Is 1982Document10 pagesTsahal Is 1982cmkohPas encore d'évaluation

- Frequency-Domain Analysis of Otec CW Pipe and Platform DynamicsDocument12 pagesFrequency-Domain Analysis of Otec CW Pipe and Platform DynamicsYoyok SetyoPas encore d'évaluation

- A Priori and A Posteriori Tests of Inflow ConditioDocument18 pagesA Priori and A Posteriori Tests of Inflow ConditioTestPas encore d'évaluation

- Hydraulic: Official FileDocument44 pagesHydraulic: Official Filechu42Pas encore d'évaluation

- Hajajs HSJD FDocument11 pagesHajajs HSJD FRohan PrajapatiPas encore d'évaluation

- Numerical Simulation of Multiphase Flow Inside Hydrocyclone Based On CFDDocument6 pagesNumerical Simulation of Multiphase Flow Inside Hydrocyclone Based On CFD89prasantaPas encore d'évaluation

- Disorder Distal To Modeled Stenoses in Steady and Pulsatile FL - OW TDocument13 pagesDisorder Distal To Modeled Stenoses in Steady and Pulsatile FL - OW TAmanullah KabirPas encore d'évaluation

- Malamataris NA Balakotaiah AIChE 2008Document16 pagesMalamataris NA Balakotaiah AIChE 2008Behnam CheraghiPas encore d'évaluation

- Duan Etal2019 AAMDocument25 pagesDuan Etal2019 AAMaminardakaniPas encore d'évaluation

- River Crossing Pipeline - PaperDocument6 pagesRiver Crossing Pipeline - PaperJoko NugrohoPas encore d'évaluation

- Flow Through Venturi Flume DONEDocument10 pagesFlow Through Venturi Flume DONEAdel MoflhiPas encore d'évaluation

- Miau 1990Document7 pagesMiau 1990amirPas encore d'évaluation

- Active Control of A Backward Facing Step Flow With Plasma ActuatorsDocument9 pagesActive Control of A Backward Facing Step Flow With Plasma ActuatorsGopi KrishnaPas encore d'évaluation

- Dead Zone Area at The Downstream Flow of Barrages: Ain Shams Engineering JournalDocument8 pagesDead Zone Area at The Downstream Flow of Barrages: Ain Shams Engineering JournalAnonymous oVmxT9KzrbPas encore d'évaluation

- Effect of Thermal Buoyancy On A Fluid Flowing Past A Pair of Side-By-Side Square Bluff-Bodies in A Low-Reynolds Number Flow RegimeDocument1 pageEffect of Thermal Buoyancy On A Fluid Flowing Past A Pair of Side-By-Side Square Bluff-Bodies in A Low-Reynolds Number Flow Regimeঅনিরুদ্ধ সান্যালPas encore d'évaluation

- Fluid Flow in Perforated Pipes - BaileyDocument10 pagesFluid Flow in Perforated Pipes - BaileyapitbhuPas encore d'évaluation

- Dean Vortices in Pipe FlowDocument5 pagesDean Vortices in Pipe Flowgaurav agarwalPas encore d'évaluation

- 1966- (简单解析解) Pulse-Testing A New Method for Describing Reservoir Flow Properties Between WellsDocument6 pages1966- (简单解析解) Pulse-Testing A New Method for Describing Reservoir Flow Properties Between WellsddqylxgPas encore d'évaluation

- Cavitation Tests On Hydrofoils in Cascade: (A) ExperimentDocument12 pagesCavitation Tests On Hydrofoils in Cascade: (A) Experimentpallav sahuPas encore d'évaluation

- Scoffoni 2001Document5 pagesScoffoni 2001Nasim KazemiPas encore d'évaluation

- Spe 96587 PDFDocument6 pagesSpe 96587 PDFMohamed YousryPas encore d'évaluation

- SPE 71582 Theory and Analysis of Injectivity Tests On Horizontal WellsDocument16 pagesSPE 71582 Theory and Analysis of Injectivity Tests On Horizontal Wellsmohammad karimiPas encore d'évaluation

- Wind Around CylinderDocument10 pagesWind Around CylinderAnonymous ARMtmNKLPas encore d'évaluation

- Over Flow FSIDocument19 pagesOver Flow FSIEswaran MuthaiahPas encore d'évaluation

- Large-Eddy Simulation of Turbulent Natural-Bed FlowDocument12 pagesLarge-Eddy Simulation of Turbulent Natural-Bed FlowSourabh KumarPas encore d'évaluation

- Determination of Discharge Coefficient and Head-Discharge Relationships of Different Hydraulic StructuresDocument13 pagesDetermination of Discharge Coefficient and Head-Discharge Relationships of Different Hydraulic StructuresShruti BiradarPas encore d'évaluation

- Effects of Reservoir Heterogeneity On Performance: S F IETYDocument11 pagesEffects of Reservoir Heterogeneity On Performance: S F IETYmartin ferrerPas encore d'évaluation

- SPE 77951 Multirate Test in Horizontal Wells: SurcolombianaDocument12 pagesSPE 77951 Multirate Test in Horizontal Wells: SurcolombianaJorge RochaPas encore d'évaluation

- Continuous Thickening in A Pilot PlantDocument8 pagesContinuous Thickening in A Pilot PlantsaverrPas encore d'évaluation

- Vortex Shedding and Lock-On in A Perturbed Flow: Mary S. HallDocument9 pagesVortex Shedding and Lock-On in A Perturbed Flow: Mary S. HallManu K VasudevanPas encore d'évaluation

- Rufer Et Kezios - 1966 - Analysis of Two-Phase, One-Component Stratified FLDocument8 pagesRufer Et Kezios - 1966 - Analysis of Two-Phase, One-Component Stratified FLMartinPas encore d'évaluation

- Spe 120022 PaDocument9 pagesSpe 120022 PatingggggagtPas encore d'évaluation

- 3536 6997 1 PBDocument10 pages3536 6997 1 PBRafael SalgadoPas encore d'évaluation

- Boom (1985) Dynamic Behaviour of Mooring LinesDocument14 pagesBoom (1985) Dynamic Behaviour of Mooring LineskometmayorPas encore d'évaluation

- Ignatenko 2021 J. Phys. Conf. Ser. 1867 012010Document7 pagesIgnatenko 2021 J. Phys. Conf. Ser. 1867 012010Atousa AtaieyanPas encore d'évaluation

- A Review of Effects of Initial and Boundary Conditions On Turbulent Jets, 2010 (H, Region)Document19 pagesA Review of Effects of Initial and Boundary Conditions On Turbulent Jets, 2010 (H, Region)Dong Hyun KimPas encore d'évaluation

- Renewable Energy: S.C. Tedds, I. Owen, R.J. PooleDocument14 pagesRenewable Energy: S.C. Tedds, I. Owen, R.J. PooleHasan AdelPas encore d'évaluation

- Flow Induced Vibration of A Radial Gate at Various Opening HeightsDocument18 pagesFlow Induced Vibration of A Radial Gate at Various Opening HeightskyogesswaranPas encore d'évaluation

- Mo2010 PDFDocument8 pagesMo2010 PDFGaurav KumarPas encore d'évaluation

- Design of An Experimental Arrangement To Study The Wind Loads On Transmission Towers Due To DownburstsDocument10 pagesDesign of An Experimental Arrangement To Study The Wind Loads On Transmission Towers Due To DownburstsFrancisco Javier Torres AlvaradoPas encore d'évaluation

- Hydrofoil Roughness Effects On Von Kármán Vortex Shedding: Philippe AUSONI Mohamed FARHATDocument4 pagesHydrofoil Roughness Effects On Von Kármán Vortex Shedding: Philippe AUSONI Mohamed FARHATFabio FolpiniPas encore d'évaluation

- Central Luzon State University: Module 4: Page 1 of 40Document40 pagesCentral Luzon State University: Module 4: Page 1 of 40LENARD DE LEONPas encore d'évaluation

- Overview of Numerical Codes Developed For Predicted Electrothermal Deicing of Aircraft BladesDocument16 pagesOverview of Numerical Codes Developed For Predicted Electrothermal Deicing of Aircraft BladesmyskyshepherdPas encore d'évaluation

- The Surface Roughness Effect On The Performance of Supersonic EjectorsDocument9 pagesThe Surface Roughness Effect On The Performance of Supersonic EjectorsmyskyshepherdPas encore d'évaluation

- An Overview of Scientific and Technical Literature On Coanda Effect Applied To NozzlesDocument14 pagesAn Overview of Scientific and Technical Literature On Coanda Effect Applied To NozzlesmyskyshepherdPas encore d'évaluation

- Computational Fluid Dynamics Applied To Jet Pumps: January 2015Document9 pagesComputational Fluid Dynamics Applied To Jet Pumps: January 2015myskyshepherdPas encore d'évaluation

- Verification of K-ω SST Turbulence Model for Supersonic Internal FlowsDocument5 pagesVerification of K-ω SST Turbulence Model for Supersonic Internal FlowsmyskyshepherdPas encore d'évaluation

- CFD Analysis of Ejector in A Combined Ejector Cooling SystemDocument10 pagesCFD Analysis of Ejector in A Combined Ejector Cooling SystemmyskyshepherdPas encore d'évaluation

- The Investigation of Gas Ejector Performance Using CFD ModellingDocument6 pagesThe Investigation of Gas Ejector Performance Using CFD ModellingmyskyshepherdPas encore d'évaluation

- Starting Transient Flows in A Chevron Ejector-Diffuser SystemDocument6 pagesStarting Transient Flows in A Chevron Ejector-Diffuser SystemmyskyshepherdPas encore d'évaluation

- Energy: Ali Jafarian, Mohammad Azizi, Pezhman ForghaniDocument9 pagesEnergy: Ali Jafarian, Mohammad Azizi, Pezhman ForghanimyskyshepherdPas encore d'évaluation

- An Ejector Transient Performance Model For Application in A Pulse Refrigeration SystemDocument14 pagesAn Ejector Transient Performance Model For Application in A Pulse Refrigeration SystemmyskyshepherdPas encore d'évaluation

- Visualization of Flow Instabilities in Supersonic Ejectors Using Large Eddy SimulationDocument3 pagesVisualization of Flow Instabilities in Supersonic Ejectors Using Large Eddy SimulationmyskyshepherdPas encore d'évaluation

- Hybrid Reynolds-Averaged/Large-Eddy Simulations of A Coaxial Supersonic Free-Jet ExperimentDocument36 pagesHybrid Reynolds-Averaged/Large-Eddy Simulations of A Coaxial Supersonic Free-Jet ExperimentmyskyshepherdPas encore d'évaluation

- A DNS Study of Entrainment in An Axisymmetric Turbulent Jet As An Episodic ProcessDocument25 pagesA DNS Study of Entrainment in An Axisymmetric Turbulent Jet As An Episodic ProcessmyskyshepherdPas encore d'évaluation

- Comparison of Control Strategies For Aircraft Bleed-Air SystemsDocument6 pagesComparison of Control Strategies For Aircraft Bleed-Air SystemsmyskyshepherdPas encore d'évaluation

- Jet Pumps For Thermoacoustic Applications: Design Guidelines Based On A Numerical Parameter StudyDocument29 pagesJet Pumps For Thermoacoustic Applications: Design Guidelines Based On A Numerical Parameter StudymyskyshepherdPas encore d'évaluation

- HG G5 Q1 Mod1 RTP PDFDocument11 pagesHG G5 Q1 Mod1 RTP PDFKimberly Abilon-Carlos100% (1)

- F3 Eng Mid-Term 2023Document5 pagesF3 Eng Mid-Term 2023Mwinyi BlogPas encore d'évaluation

- Organisation Restructuring 2023 MGMT TeamDocument9 pagesOrganisation Restructuring 2023 MGMT TeamArul AravindPas encore d'évaluation

- Ma HakalaDocument3 pagesMa HakalaDiana Marcela López CubillosPas encore d'évaluation

- 5HP500-590 4139 - 751 - 627dDocument273 pages5HP500-590 4139 - 751 - 627ddejanflojd100% (24)

- 2,3,5 Aqidah Dan QHDocument5 pages2,3,5 Aqidah Dan QHBang PaingPas encore d'évaluation

- Booklet - Frantic Assembly Beautiful BurnoutDocument10 pagesBooklet - Frantic Assembly Beautiful BurnoutMinnie'xoPas encore d'évaluation

- Anclas Placas Base para Columnas Thomas MurrayDocument89 pagesAnclas Placas Base para Columnas Thomas MurrayMariano DiazPas encore d'évaluation

- Teuku Tahlil Prosiding38491Document30 pagesTeuku Tahlil Prosiding38491unosa unounoPas encore d'évaluation

- Talent Development - FranceDocument6 pagesTalent Development - FranceAkram HamiciPas encore d'évaluation

- Approaches To Violence in IndiaDocument17 pagesApproaches To Violence in IndiaDeepa BhatiaPas encore d'évaluation

- Shkodër An Albanian CityDocument16 pagesShkodër An Albanian CityXINKIANGPas encore d'évaluation

- Physics - TRIAL S1, STPM 2022 - CoverDocument1 pagePhysics - TRIAL S1, STPM 2022 - CoverbenPas encore d'évaluation

- CogAT 7 PlanningImplemGd v4.1 PDFDocument112 pagesCogAT 7 PlanningImplemGd v4.1 PDFBahrouniPas encore d'évaluation

- 1027 12Document3 pages1027 12RuthAnayaPas encore d'évaluation

- Drapeau Resume May09Document5 pagesDrapeau Resume May09drmark212Pas encore d'évaluation

- Reported Speech Step by Step Step 7 Reported QuestionsDocument4 pagesReported Speech Step by Step Step 7 Reported QuestionsDaniela TorresPas encore d'évaluation

- Update UI Components With NavigationUIDocument21 pagesUpdate UI Components With NavigationUISanjay PatelPas encore d'évaluation

- Preliminaries Qualitative PDFDocument9 pagesPreliminaries Qualitative PDFMae NamocPas encore d'évaluation

- Bab 3 - Soal-Soal No. 4 SD 10Document4 pagesBab 3 - Soal-Soal No. 4 SD 10Vanni LimPas encore d'évaluation

- Iso 20816 8 2018 en PDFDocument11 pagesIso 20816 8 2018 en PDFEdwin Bermejo75% (4)

- Trigonometry Primer Problem Set Solns PDFDocument80 pagesTrigonometry Primer Problem Set Solns PDFderenz30Pas encore d'évaluation

- CV Michael Naughton 2019Document2 pagesCV Michael Naughton 2019api-380850234Pas encore d'évaluation

- Cruz-Arevalo v. Layosa DigestDocument2 pagesCruz-Arevalo v. Layosa DigestPatricia Ann RueloPas encore d'évaluation

- WaiverDocument1 pageWaiverWilliam GrundyPas encore d'évaluation

- Storage Emulated 0 Android Data Com - Cv.docscanner Cache How-China-Engages-South-Asia-Themes-Partners-and-ToolsDocument140 pagesStorage Emulated 0 Android Data Com - Cv.docscanner Cache How-China-Engages-South-Asia-Themes-Partners-and-Toolsrahul kumarPas encore d'évaluation

- Syllabus For B.A. (Philosophy) Semester-Wise Titles of The Papers in BA (Philosophy)Document26 pagesSyllabus For B.A. (Philosophy) Semester-Wise Titles of The Papers in BA (Philosophy)Ayan AhmadPas encore d'évaluation

- 2022 Drik Panchang Hindu FestivalsDocument11 pages2022 Drik Panchang Hindu FestivalsBikash KumarPas encore d'évaluation

- Public Service Media in The Networked Society Ripe 2017 PDFDocument270 pagesPublic Service Media in The Networked Society Ripe 2017 PDFTriszt Tviszt KapitányPas encore d'évaluation

- Spelling Master 1Document1 pageSpelling Master 1CristinaPas encore d'évaluation