Académique Documents

Professionnel Documents

Culture Documents

Corrosion

Transféré par

S_Venkat0 évaluation0% ont trouvé ce document utile (0 vote)

156 vues4 pagesThis article deals with methods for solving cold, or back end corrosion as it is called. In municipal solid waste fired plants, in addition to sulfuric acid, one has to deal with hydrochloric and hydrobromic acid formation. To compute the sulfuric acid dew point, one should know the amount of S03 in the flue gases.

Description originale:

Titre original

corrosion

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis article deals with methods for solving cold, or back end corrosion as it is called. In municipal solid waste fired plants, in addition to sulfuric acid, one has to deal with hydrochloric and hydrobromic acid formation. To compute the sulfuric acid dew point, one should know the amount of S03 in the flue gases.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

156 vues4 pagesCorrosion

Transféré par

S_VenkatThis article deals with methods for solving cold, or back end corrosion as it is called. In municipal solid waste fired plants, in addition to sulfuric acid, one has to deal with hydrochloric and hydrobromic acid formation. To compute the sulfuric acid dew point, one should know the amount of S03 in the flue gases.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

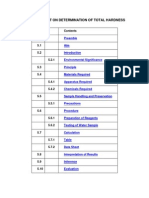

MAINTENANCE: HEAT TRANSFER

Cold end corrosion:

causes and cures

Calculating dew points of various

acid gases and options for reducing

cold end corrosion of heat

recovery exchangers are

presented

V Ganapathy , ABCO Industries, Abilene, Texas

WHENEVER FOSSIL FUELS containing sulfur are fired

in heaters or boilers, sulfur dioxide, and to a small extent

sulfur trioxide, are formed in addition to C02 and water

vapor. The S03 combines with water vapor in the flue g as to

form sulfuric acid and condenses on heat transfer surfaces,

which could lead to corrosion and destruction of the

surfaces. This condensation occurs on surfaces that are at or

below the dew point of the acid gas. Also, when cooled

below the water vapor dew point, C02 can combine with

water vapor to form carbonic acid, which though weak, can

attack mild steel.

While thermal efficiency of the equipment is increased with

reduction in exit gas temperature (or enthalpy), lower

temperatures than the acid gas dew point are not advisable

for metallic surfaces in contact with the gas.

In municipal solid waste fired plants, in addition to sulfuric

acid, one has to deal with hydrochloric and hydro bromic

acid formation.

This article deals with methods for solving cold, or back

end corrosion as it is called, with the most commonly used

heat recovery equipment, namely economizers or water

heaters. These are used to preheat feed water entering the

system (Fig. 1) and operate at low metal temperatures,

thereby increasing their susceptibility to corrosion by sul-

furic, hydrochloric, hydrobromic and carbonic acid.

Estimating the dew point of these acid gases is the starting

point in understanding the problem of back end corrosion.

Appendix 1 gives the dew points of the various acid gases

as a function of their partial pressures in the flue gas.' Fig. 2

gives the dew point for sulfuric acid.2

C0 2 + = 87%, H2 0 = 12%, N2 = 73%, S02 = 0.02%, substitution in the equations in Appendix 1, we have: dew

HCL = 0.015%, 02 = 6 % , HBR = 0.01%, all by volume. point of sulfuric acid = 267° F, dew point of hydrochloric

To compute the sulfuric acid dew point, one should know acid = 128° F, dew point of hydrobromic acid = 134° F and

the amount of S03 in the flue gases. The formation of S0 3 dew point of water vapor = 121°F.

is primarily derived from two sources. Hence, it is apparent the limiting dew point is that due to

sulfuric acid and any heat transfer surface should be above

1. Reaction of S02 with atomic oxygen in the flame this temperature (267°F) if condensation is to be avoided.

zone. It depends on the excess air used and the sulfur There is a misconception even among experienced engi-

content. neers that the gas temperature dictates the metal tempera-

2. Catalytic o xidation of S02 with the oxides of vanadium ture of surfaces such as economizers. It is not so. To

and iron, which are formed from the vanadium in the fuel explain this, an example will be worked to show the metal

oil. tempera ture of an economizer with two different gas

It is widely agreed that 1 to 5 % of S02 converts to S03 .

temperatures . Appendix 2 shows this calculation.

Hence the % volume in our case would be 4 ppm, assuming

a 2 % conversion. Continued

Using these numbers and after proper conversion and Hydrocarbon Processing, January 1989

57

It can be seen that the water side coefficient is so high that the

tube wall temperature runs very close to the water tem-

perature in spite of a large difference in the gas temperatures.

Thus, the tube wall temperature will be close to the water

temperature and the water temperature fixes the wall

temperature and hence, the dew point. Some engineers think

that by increasing the flue gas temperature the economizer At 5 psig the saturation is 228°F and at 10 psig it is 240°F

corrosion can be solved; not so. 2. In case the deaerator pressure cannot be raised, a heat

It should be noted also that the maximum corrosion rate exchanger may be used ahead of the economizer (Fig. 4) to

occurs at a temperature much below the dew point (Fig. 3). increase the feed water temperature. It may be steam or wa -

Methods of dealing with cold end corrosion. Basi- ter heated.

cally there are two approaches used by engineers to combat 3. Fig. 5 shows a method for using an exchanger to pre heat

the problem of cold end corrosion: the water. The same amount of water from the economizer

A. Avoid it by using protective measures such as main - exit preheats the incoming water. By controlling the flow of

taining a high cold end temperature so that condensation of the hotter water, one can adjust the water te mperature to the

any vapor does not occur. economizer so that a balance between corrosion criterion

B. Permit condensation of acid vapor or both acid and and efficiency of operation can be maintained.

water vapor, thereby increasing the duty of the heat transfer 4. Hot water from either the economizer exit or the steam

surface, and use corrosion resistant materials such as glass, drum (Fig. 6), can be recirculated and mixed with the

teflon, etc. incoming water. The economizer has to handle a higher

Methods of avoiding cold end corrosion: flow, but the exchanger is eliminated and a pump is added.

1. Maintain a reasonably high feed water inlet tempera ture. Note that some engineers have the misconception that by-

If the computed dew point is say 250°F, a feed water of passing a portion of the economizer (Fig. 7) would solve the

250°F should keep the minimum tube wall temperature problem; not so. While bypassing, the heat transfer surface

above the dew point. With finned heat transfer surfaces, reduces the duty on the economizer and increases the exit

the wall temperature will be slightly higher than with bare gas temperature; it does not help to increase the wall

tubes. temperature of the tubes, which is the most important

The simplest way would be to operate the deaerator at a variable. A higher exit gas temperature probably helps the

slightly higher pressure, if the feed water enters the downstream ductwork and equipment, but not the

economizer from a deaerator (Fig.1). economizer. One benefit, however, from bypassing is

58 Hydrocarbon Processing, January 1989

The author APPENDIX 1-Dew points of acid gases'

V. Ganapathy is a heat transfer specialist HCI, HBr, HN03 and S0 2 correlations were derived from vapor-

liquid equilibrium data .4 The H2 SO4 correlation is from reference 5.

with ABCO Industries Inc., Abilene, Texas. He

is engaged in the engineering of heat recovery Hydrobromic acid:

1,000/TDP = 3.5639 - 0.1350 In (PH20 )

boilers for process, incineration and 0.0398 1 n (PHBr) + 0.00235 In (PH20 ) l n (PHBr)

cogeneration applications. He also develops

software for engineering of heat recovery Hydrochloric acid:

systems and components. He holds a B Tech 1,000/T DP = 3.7368 - 0.1591 In (PH2 0) –

degree in mechanical engineering from Indian 0.0326 In (PHCI) + 0.00269 In (PH2o) In (PHCI)

Institute of Technology, Madras, India, and

nology from MadrasanUniversity.

MSc(eng) inMr

boiler tech

Ganapathy is the author of Nitric acid:

over 150 articles on boilers, heat transfer and steam plant 1,000/TDP = 3.6614 - 0.1446 In (P H )

systems and has written four books: Applied Heat Transfer,

Steam Plant Calculations Manual, Nomograms for Steam Sulfurous acid:

1,000/T DP = 3.9526 - 0.1863 In (P H30) +

Generation and Utilization and Basic Programs for Steam Plant 0.000867 In (PS0 2) - 0.000913 in (PH20) In (PS02)

Engineers (book and diskette), copies of which are available

from him. He also has contributed several chapters to the Sulfuric acid:

that steaming possibilities in the economizer are minimized. 1,000/T DP = 2.276 - 0.0294 In (P H20) –

0.0858 In (PH3 SO4 ) + 0.0062 In (PH20) In (PH2 SO4 )

Permitting condensation on surfaces. By using proper

materials one can protect the heating surfaces from corrosion Where: T DP is dew point temperature (K) and P is partial pressure

attack, if condensation is likely. This concept has now been (mmHg).

Compared with published data, the predicted dew points are within

extended to recovering the sensible and latent heat from the flue about 6K of actual values except for H2 SO4 which is within about 9K.

gases, thereby increasing the thermal efficiency of the system by REFERENCES

several percentage points in what are called condensing heat

3

exchangers. If flue gases contain say 10% by volume water Pierce, R. R., "Estimating acid dewpoints in stack gases," Chem.

Eng., Apt. 11, 1973.

vapor, by condensing even half of it, approxi mately 30 Btu/lb of 4

Perry, R. H., and Chilton C. H., ed., "Chemical Engineers'

flue gas can be recovered. This is nearly equivalent to a 120°F Handbook," 5th ed., McGraw-Hill, New York, 1973.

5

drop in gas temperature if sensible heat alone is transferred. Verhoff, F H., and Banchero, J. T, "Predicting Dew Points of Flue

A large amount of sensible and latent heat in the flue gas can Gases," Chem. Eng. Prog., August, 1974.

be recovered if the gas is cooled below the water dew point. This

implies that sulfuric acid, if present in the gas stream, will APPENDIX 2-Determining tube wall

condense on the heat transfer surfaces as its dew point is much temperatures of economizers

higher than that of water vapor.

The average wall temperature of a bare tube economizer is given by

Borosilicate glass and teflon coated tubes have been widely the simple equation:

used as heat transfer surfaces for this service. Glass is suitable

t w = 0.5[t; + t g - U(tg - t;) (1/h a - 1/h,)]

for low pressures and temperatures (less than 450°F and 20 to

Where:

100 psig). However, presence of fluorides and alkalis is harmful h; = heat transfer coefficient inside tubes, Btu/ ft 2 h °F

to the glass tubes. It. = heat transfer coefficient outside tubes, Btu/ ft 2 h °F

One manufacturer of condensing heat exchangers uses teflon t; = temperature of water inside tubes, °F tg =

coated tubes. A thin film (about 0.015 in.) is extruded onto temperature of gas outside tubes, °F

t w = average tube wall temperature, °F

carbon or alloy steel tubes, and the surface is resistant to U = overall heat transfer coefficient, Btu/ft 2h °F 11U = 1

corrosion of sulfuric acid. Finned tubes cannot be used as teflon /h i + 11h., neglecting fouling and metal resistance,

cannot be extruded onto these surfaces. Hence, these exchangers which are much smaller.

will be larger than those with extended surfaces, however, the

higher heat transfer rates with condensation process improves

the overall heat transfer coefficients and partly compensates for Typically h; = 1,000, h a = 15 and hence U = 4.77

the lower surface area per linear foot of bare tubes. Case 1: Determine t w when t g = 750°F and t i =50°F tw = 0.5

The high initial investment associated with condensing heat [250 + 750 - 14.77 (750 - 250) (0.066 - 0.001)] =

260°F

exchangers has to be carefully reviewed along with the energy Case 2: t g = 350°F, t; = 250°F

recovered, fuel costs, etc. If the fuel cost is not high, then the t w = 0.5 [250 + 350 - 14.77 (350 - 250)

payback period for this type of equipment may be long. (0.066 - 0.001)] = 252°F

Materials such as cast iron and stainless steels probably have

better corrosion resistance than carbon steel, but still they are not Thus, for a variation of 400°F gas temperature, the tube wall

Conclusion The article outlined the importance of the dew temperature hardly changes by 8°F Thus, the water temperature fixes the

tube wall temperature.

point of acid gas and methods for dealing with the problem of

condensation on heating surfaces such as economi zers. Similar LITERATURE CITED

methods could be used for air heaters. The basic difference lies 1

Kiang, Yen-Hsiung, "Predicting dewpoints of acid gases," Chemical

in the fact that the back end temperature is a function of both 2

Engineering, Feb. 9, 1981, p. 127.

Ganapathy, V., "Nomograms for steam generation and utilization,"

the gas and air temperatures. Steam air heating or air Fairmont Press, 1986, p. 15.

bypassing have been used to combat the problem of corrosion.

Replaceable matrices and corrosion resistant materials such as Hydrocarbon Processing, January 1989 59

enamels have been used at the cold end of regenrative air

beaters.

Vous aimerez peut-être aussi

- Dew Point Od Acid GasDocument4 pagesDew Point Od Acid GassrshahPas encore d'évaluation

- ENVIRONMENT/HEAT TRANSFER - Waste Heat RecoveryDocument4 pagesENVIRONMENT/HEAT TRANSFER - Waste Heat Recoverycvolkan1100% (1)

- Application of Energy-Saving Technology On Furnaces of Oil Refining UnitsDocument7 pagesApplication of Energy-Saving Technology On Furnaces of Oil Refining UnitsRupam MukherjeePas encore d'évaluation

- Economizers: Colin FrenchDocument6 pagesEconomizers: Colin Frenchsathesh100% (1)

- Designing Steam Reformers For Hydrogen Production: Keep These Important Factors in Mind When Designing, Revamping or TroubleshootingDocument7 pagesDesigning Steam Reformers For Hydrogen Production: Keep These Important Factors in Mind When Designing, Revamping or TroubleshootingdjinxdPas encore d'évaluation

- Design Co2 EvaporatorsDocument7 pagesDesign Co2 EvaporatorsYutt Watt100% (1)

- Ammonia Process InformationDocument4 pagesAmmonia Process InformationRishikesh AwalePas encore d'évaluation

- Comb CycleDocument13 pagesComb Cyclerain55555Pas encore d'évaluation

- Soot & ScaleDocument12 pagesSoot & ScaleLow Shen WeiPas encore d'évaluation

- Latent Heat Recovery from Flue GasDocument24 pagesLatent Heat Recovery from Flue GasSiraj AL sharifPas encore d'évaluation

- Understand Boiler Performance CharacteristicsDocument5 pagesUnderstand Boiler Performance CharacteristicsdeerajksPas encore d'évaluation

- Cleaning Primary Reformer's Convection Section and Combustion Chamber's Firebrick CoatingDocument7 pagesCleaning Primary Reformer's Convection Section and Combustion Chamber's Firebrick CoatingakjayaPas encore d'évaluation

- Effect of Reaction Furnace and Converter Temperatures On Performance of Sulfur Recovery Units (SRUs)Document3 pagesEffect of Reaction Furnace and Converter Temperatures On Performance of Sulfur Recovery Units (SRUs)SEP-PublisherPas encore d'évaluation

- 2nd Part of CalculationDocument26 pages2nd Part of CalculationLohith NatarajPas encore d'évaluation

- Heating With Coils and JacketsDocument14 pagesHeating With Coils and Jacketsibal_machine100% (1)

- Energy Consumption of Tanks & VatsDocument12 pagesEnergy Consumption of Tanks & Vatsamechmar5935Pas encore d'évaluation

- Heat Recovery Systems Using Ceramic Heat PipesDocument11 pagesHeat Recovery Systems Using Ceramic Heat PipesChander Prakash KamraPas encore d'évaluation

- Condensing Economizer ArticleDocument4 pagesCondensing Economizer ArticleErhan KayabaşıPas encore d'évaluation

- Failure of Heat Exchanger in Sulphur Recovery Unit PDFDocument8 pagesFailure of Heat Exchanger in Sulphur Recovery Unit PDFticaram rPas encore d'évaluation

- Q A BoilerDocument19 pagesQ A Boilerlavpandey8719Pas encore d'évaluation

- Optimization of Wsa TechnologyDocument5 pagesOptimization of Wsa TechnologyAhmed Ali100% (1)

- A New Method For Co2 CaptureDocument6 pagesA New Method For Co2 CaptureAbul HassanPas encore d'évaluation

- Economize RsDocument2 pagesEconomize RsRyan PerezPas encore d'évaluation

- Good Heater Specifications Pay OffDocument6 pagesGood Heater Specifications Pay Offrvkumar61100% (1)

- High Temperature Corrosion Problems in Waste Heat BoilersDocument2 pagesHigh Temperature Corrosion Problems in Waste Heat BoilersEdenrafaPas encore d'évaluation

- V. Ganapathy. Simplify Heat Recovery Steam Generator Evaluation PDFDocument7 pagesV. Ganapathy. Simplify Heat Recovery Steam Generator Evaluation PDFgonzalezpcjPas encore d'évaluation

- The Heating of Liquids in TanksDocument25 pagesThe Heating of Liquids in Tanksaleksandar_djordjic100% (1)

- Topsoe Wsa Meet Industry DemandsDocument6 pagesTopsoe Wsa Meet Industry DemandsBobie C. KurniawanPas encore d'évaluation

- Packaged steam generators: Custom designs have advantages over standard onesDocument90 pagesPackaged steam generators: Custom designs have advantages over standard onespinenamuPas encore d'évaluation

- Rethink Specifications For Fired HeatersDocument7 pagesRethink Specifications For Fired HeatersAhmed SeliemPas encore d'évaluation

- Air Cooler Design SheikoDocument22 pagesAir Cooler Design Sheikojayhuacat7743100% (1)

- Super HeaterDocument5 pagesSuper HeaterSurya VankayalaPas encore d'évaluation

- Heating With Coils and Jackets - Spirax SarcoDocument14 pagesHeating With Coils and Jackets - Spirax SarcoWEN GIE KONGPas encore d'évaluation

- Effectively Design ACHE'sDocument22 pagesEffectively Design ACHE'sSeshu BulusuPas encore d'évaluation

- Energy Consumption of Tanks VatsDocument12 pagesEnergy Consumption of Tanks VatsPouria SabbaghPas encore d'évaluation

- Mini Project On The Design of Heat ExchangerDocument48 pagesMini Project On The Design of Heat ExchangerSuraya AfriyaniPas encore d'évaluation

- Deaerating Boiler FeedwaterDocument4 pagesDeaerating Boiler Feedwaterritesh sharmaPas encore d'évaluation

- Understanding Thermal Oxidiser Design for Waste DestructionDocument6 pagesUnderstanding Thermal Oxidiser Design for Waste DestructionMohammed AlShammasiPas encore d'évaluation

- Design of Heat Exchanger Mini ProjectDocument45 pagesDesign of Heat Exchanger Mini ProjectSuraya Afriyani100% (1)

- O 040894100Document7 pagesO 040894100IJERDPas encore d'évaluation

- Acid Gas Dew PointDocument8 pagesAcid Gas Dew Pointzubair195Pas encore d'évaluation

- Thermal power plant economiser guideDocument7 pagesThermal power plant economiser guideSteve M D'souzaPas encore d'évaluation

- Steam Generator PerformanceDocument7 pagesSteam Generator Performancervkumar61Pas encore d'évaluation

- Boiler Heat Transfer Theory-02Document18 pagesBoiler Heat Transfer Theory-02Sai SwaroopPas encore d'évaluation

- Individual waste heat boiler design projectDocument22 pagesIndividual waste heat boiler design projectIsaac Mohanadasan100% (1)

- The Soot and Scale Problems: IssueDocument12 pagesThe Soot and Scale Problems: IssuebjaabdouPas encore d'évaluation

- Boilers, Boiler Fuel andDocument7 pagesBoilers, Boiler Fuel andVivek RamnohurPas encore d'évaluation

- Heating With Coils and Jackets - CompressDocument14 pagesHeating With Coils and Jackets - CompressIonut StavarachePas encore d'évaluation

- Papers - HighBeam ResearchDocument572 pagesPapers - HighBeam ResearchFrancisco Castro BenítezPas encore d'évaluation

- Design EquationsDocument7 pagesDesign EquationsThiagarajanPas encore d'évaluation

- Chee3004: Project 2Document43 pagesChee3004: Project 2faizzi100% (3)

- EPSRC Thermal Management Sheffield Progress Report July 2010Document76 pagesEPSRC Thermal Management Sheffield Progress Report July 2010Junaid MugholPas encore d'évaluation

- Firetube Heaters: FIG. 8-31 Convection HeaterDocument7 pagesFiretube Heaters: FIG. 8-31 Convection Heatery149487Pas encore d'évaluation

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesD'EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesPas encore d'évaluation

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersD'EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersPas encore d'évaluation

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementD'EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementPas encore d'évaluation

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersD'EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersÉvaluation : 4 sur 5 étoiles4/5 (13)

- Process Intensification for Sustainable Energy ConversionD'EverandProcess Intensification for Sustainable Energy ConversionPas encore d'évaluation

- Exp5 PDFDocument13 pagesExp5 PDFRahimi ShahimiPas encore d'évaluation

- Feed Water Pipe FailureDocument9 pagesFeed Water Pipe Failuredafteri11Pas encore d'évaluation

- Design of Scrubber PDFDocument33 pagesDesign of Scrubber PDFdafteri11Pas encore d'évaluation

- Tratamiento de Gua para CalderasDocument2 pagesTratamiento de Gua para CalderasMariel MinozPas encore d'évaluation

- Mathmatical Modeeling of SteamDocument9 pagesMathmatical Modeeling of Steamdafteri11Pas encore d'évaluation

- Oil & ExtractDocument4 pagesOil & Extractdafteri11Pas encore d'évaluation

- Total Quality Control: Lessons European Executives Can Learn From Japanese CompaniesDocument11 pagesTotal Quality Control: Lessons European Executives Can Learn From Japanese Companiesdafteri11Pas encore d'évaluation

- Mathmatical Modeeling of SteamDocument9 pagesMathmatical Modeeling of Steamdafteri11Pas encore d'évaluation

- Exp5 PDFDocument13 pagesExp5 PDFRahimi ShahimiPas encore d'évaluation

- Cationic Exchange ResinsDocument9 pagesCationic Exchange Resinsdafteri11Pas encore d'évaluation

- Cold End CorrosionDocument15 pagesCold End Corrosiondafteri11Pas encore d'évaluation

- PurityDocument37 pagesPuritydafteri11Pas encore d'évaluation

- Resin RegenerationDocument9 pagesResin Regenerationdafteri11Pas encore d'évaluation

- Phosphate Det.Document4 pagesPhosphate Det.dafteri11Pas encore d'évaluation

- TF 005Document4 pagesTF 005Abdul BokhariPas encore d'évaluation

- Silica Molybdate EqDocument11 pagesSilica Molybdate Eqdafteri11100% (1)

- DR500 CalibDocument846 pagesDR500 Calibdafteri11Pas encore d'évaluation

- Superheater FoulingDocument10 pagesSuperheater Foulingdafteri11Pas encore d'évaluation

- Spectrophotometric Determination of Hydrazine With para - (Dimethylamino) Benzaldehyde in Aqueous Streams of Purex ProcessDocument4 pagesSpectrophotometric Determination of Hydrazine With para - (Dimethylamino) Benzaldehyde in Aqueous Streams of Purex ProcessSEP-PublisherPas encore d'évaluation

- Spectrophotometric Determination of Hydrazine With para - (Dimethylamino) Benzaldehyde in Aqueous Streams of Purex ProcessDocument4 pagesSpectrophotometric Determination of Hydrazine With para - (Dimethylamino) Benzaldehyde in Aqueous Streams of Purex ProcessSEP-PublisherPas encore d'évaluation