Académique Documents

Professionnel Documents

Culture Documents

Arc Blow

Transféré par

Apostolie Iulian0 évaluation0% ont trouvé ce document utile (0 vote)

242 vues3 pagesArc blow occurs when the arc stream does not follow the shortest path between the electrode and the workpiece. Back blow occurs when welding toward the workpiece connection, the end of a joint or into a corner. Arc blow can cause excessive spatter, incomplete fusion and porosity.

Description originale:

Titre original

Arc blow

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentArc blow occurs when the arc stream does not follow the shortest path between the electrode and the workpiece. Back blow occurs when welding toward the workpiece connection, the end of a joint or into a corner. Arc blow can cause excessive spatter, incomplete fusion and porosity.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

242 vues3 pagesArc Blow

Transféré par

Apostolie IulianArc blow occurs when the arc stream does not follow the shortest path between the electrode and the workpiece. Back blow occurs when welding toward the workpiece connection, the end of a joint or into a corner. Arc blow can cause excessive spatter, incomplete fusion and porosity.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

Prevent Arc Blow

Electrode

Travel

When Welding Forward

blow

Back

blow

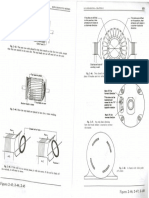

Fig. 2—Flux concentration behind the welding arc at the start

of joint forces the arc forward while flux concentration ahead

of the arc at the end of the joint forces the arc backward.

Arc blow can cause a number

of welding problems including Arc

Direction

excessive spatter, incomplete rection to relieve Work

of arc blow

fusion and porosity. What is squeezing and re-

store the magnet-

arc blow and how can it be ic-field balance,

Fig. 3—Here, arc blow is caused by the welding current

veering away from

prevented? the side of flux returning to the workpiece connection. The resulting

magnetic flux combines with the flux around the elec-

concentration.

This veering is ob- trode, causing a high-flux concentration at (x) that blows

served as arc blow. the arc away from the workpiece connection.

A rc blow, also called arc wan-

der, occurs in DC arc weld-

ing when the arc stream does

not follow the shortest path between

the electrode and the workpiece and

Arc-Blow Direction

and Joint Location

Fig. 2 illustrates flux squeezing

and distortion at the start and finish

Arc movement due to this effect

combines with movement resulting

from the flux concentration previ-

ously described to give the observed

deflects forward or backward from of a weld joint. At the start, flux lines arc blow. The effect of the returning

the direction of travel or, less fre- concentrate behind the electrode. current may diminish or increase the

quently, to one side. The arc tries to compensate for this arc blow caused by the arc flux. In

Back blow occurs when welding imbalance by moving forward, cre- fact, controlling the direction of re-

toward the workpiece connection, ating forward arc blow. As the elec- turning current is one way to control

the end of a joint or into a corner. trode approaches the end of the arc blow.

Forward blow occurs when welding joint, the lines squeeze ahead of the In Fig. 4a, the workpiece cable

away from the workpiece connec- arc. Again, the arc moves in a direc- connects to the starting end of the

tion, or at the starting end of the tion to relieve squeezing, in this case joint, and the flux created by the re-

joint. It is especially troublesome backward and observed as back turning welding current in the work

when shielded-metal-arc (SMA) blow. At the middle of a joint in two forms behind the arc. The resulting

welding with electrodes that tend to plates of the same width, the mag- arc movement is forward. Near the

produce large slag coverings. In netic field is symmetrical, so no arc end of the joint, however, forward

these cases, forward blow drags the blow occurs. But, if one plate is arc movement diminishes the total

slag or the crater forward and under Arc blow can be one of two types: Fig. 1 shows a the direction of the current. These wider than the other, side blow arc blow by canceling some back

the arc, disrupting the weld. magnetic or thermal. DC current pass- lines of force diminish in intensity in could occur at the midpoint of the blow created by flux concentration

The direction of arc blow can be ing through a direct proportion to their distances weld due to flux squeezing. from the arc at the end of the work-

observed during open-arc welding, Magnetic Arc Blow conductor—ei- Direction from the electrical conductor. Another squeezing phenomenon piece (Fig. 5a).

but not during submerged-arc weld- Magnetic arc blow, responsible ther the welding of flux The lines of force remain circular results from the welding current re- In Fig. 4b, the work cable con-

ing. In this case, direction is deter- for more welding problems than electrode or the in a medium large enough to con- turning back toward the workpiece nects to the finish end of the seam,

mined by the type of weld defect thermal arc blow, results from an plasma stream tain them until they diminish to es- connection within the workpiece. As resulting in back blow, increasing in

produced. unbalanced condition in the mag- between an elec- sentially nothing. But if the medium shown in Fig. 3, electrical current intensity at the finish of the weld.

Back blow is indicated by spatter; netic field surrounding the arc. This trode and a weld changes, from steel plate to air, for passing through the workpiece to Fig. 5b illustrates the combination of

undercut, either continuous or inter- unbalanced condition usually occurs joint. A magnetic Direction example, the circular lines become the workpiece lead may create a squeezed fluxes. A workpiece con-

mittent; a narrow, high bead, usually because the arc is located farther field surrounds of current distorted and tend to concentrate in flux. The heavy line represents the nection at the finish of the weld,

with undercut; an increase in pene- from one end of the weld joint than the conductor; Fig. 1—Current the steel where they encounter less path of the welding current while however, may be needed to reduce

tration; or surface porosity at the fin- the other end and at varying dis- its lines of mag- passing through a resistance. At a boundary between the light lines represent the flux cre- excessive forward blow at the start

ish end of welds on sheetmetal. tances from the workpiece connec- netic force, or conductor sets up a the edges of a steel plate and air, the ated by the current. As the current of the weld. But workpiece-connec-

Forward blow is indicated by a tion. Imbalance also exists due to flux, are repre- magnetic field, rep- lines squeeze and deform. This re- changes direction or turns the corner tion positioning is only moderately

wide bead, irregular in width; a the change in direction of weld cur- sented by con- resented by planes sults in a heavy flux concentration from the arc to the work, a flux con- effective in controlling arc blow.

wavy bead; undercut, usually inter- rent as it flows through the arc and centric circles at of concentric circles behind or ahead of the welding arc. centrates at x, causing arc blow away Other measures should be used to re-

mittent; or a decrease in penetration. into and through the workpiece. right angles to known as flux lines. The arc then tends to move in a di- from the workpiece connection. duce arc blow when welding.

42 www.metalforming.com MetalForming/May 2001 May 2001/MetalForming www.metalforming.com 43

Prevent Arc Blow When Welding

Fixtures

Contribute Travel

to Arc Blow (a) (b)

Fig. 4—Flux due to the welding current returning to the workpiece

e aware of the relationship of

B arc blow to weldment fixtur-

ing. Steel fixtures may effect the

connection is behind the arc in (a) and ahead of the arc in (b).

magnetic field around the arc,

and may become magnetized

over time. Usually, fixturing

won’t cause problems when

SMA-welding if weld current Travel

(a) (b)

does not exceed 250 amps. Fix-

tures used with higher currents Fig. 5—In (a), magnetic blow at the finished end of a joint is reduced

and mechanized welding should because the two flux fields tend to offset each other. In (b), the two

be designed to minimize arc- fields combine to cause a strong back blow.

blow-promoting situations.

Here are some fixture-design

Problem Areas produced by magnetic fields in the

tips:

Arc blow is especially problemat- material. Hand-held Gauss meters

• Design fixtures for welding ic in the corners of fillet welds and in easily detect and measure these fields.

the longitudinal seam of cylinders weld joints that use deep weld Fields higher than 20 Gauss can

with a minimum of 1-in. clearance preparations. Here, the cause of arc cause arc blow in these nickel steels.

between the supporting beam blow is the same as when welding a

and the work. Use nonmagnetic straight seam—flux concentration Thermal Arc Blow

clamping fingers or workholding and the movement of the arc to re- Thermal arc blow occurs because

bars. Do not attach the workpiece lieve it. Figs. 6 and 7 illustrate where an electric arc requires hot zones on

cable to the copper backup bar— arc blow, when using DC current, is the electrode and workpiece plate to

make the work connection direct- problematic. maintain a continuous flow of cur-

ly to the workpiece. Using low welding current pro- rent in the arc stream. As the elec-

• Fabricate the fixture from duces less arc blow than using high trode advances along the work, the

low-carbon steel to prevent current because a higher current arc tends to lag behind, caused by

buildup of permanent magnet- causes a more intense magnetic reluctance of the arc to move to the

ism in the fixture. field. Usually, serious arc-blow colder plate. The ionized space be-

• Weld toward the closed end problems do not occur when SMA- tween the end of the electrode and

of horn-type fixtures to reduce welding with DC under 250 amps, the hot surface of the molten crater

back blow. although joint fitup and geometry creates a more conductive path than

• Design the fixture long enough play a role. from the electrode to the colder

so that end tabs can be used. The use of AC current markedly

• Do not use a copper strip in-

reduces the likelihood of arc

blow. The rapid reversal of Fig. 6—Arc-

serted in a steel bar for a backing. blow difficul-

The steel part of the backup bar

the AC current induces

eddy currents in the ties abound

will increase arc blow. when high-amp

base metal, and the

• Provide for continuous or fields created by the DC welding in

close clamping of parts to be eddy currents greatly deep-groove joints.

seam welded. Wide, intermittent reduce the strength of Switching to AC current

clamping may cause seams to the magnetic fields that cause can alleviate this.

gap between clamping points, arc blow.

causing arc blow over the gaps. Some materials, such as Fig. 7—Expect consid-

• Do not build into the fixture nine-percent nickel steels, are erable arc blow when

large masses of steel on one side easily magnetized by external placing the inside

of the seam only; counterbalance magnetic fields, such as those fillet using DC

with a similar mass on the oppo- from power lines. These current. Again,

site side of the fixture. materials are difficult to switching to AC

weld due to arc blow current can help.

44 www.metalforming.com MetalForming/May 2001

Prevent Arc Blow When Welding

ity, can cause arc-blow problems,

especially when two arcs are locat-

(a) (b)

ed close together.

If these two arcs have opposite

polarities (Fig. 8a), magnetic fields

between the arcs cause the arcs to

Arc blow Blow reduced

deflect away from each other. If po-

a

larity is identical (Fig. 8b), magnetic

Fig. 9—Arc blow (a) may be corrected

fields between

by angling the electrode (b).

the arcs oppose

each other, re-

sulting in a Bead sequence

weaker field be-

tween the arcs

and causing the

arcs to deflect Direction of welding

toward each Weld

b other. both sides

When using Fig. 10—The direction of welding and the sequence of

two arcs, one beads is illustrated for the back-step technique. Note the

may be DC, the tabs on each end of the seam—they should be of the

other AC (Fig. same thickness as the workpiece.

8c). Here, the

AC-arc flux field

completely reverses for each cycle, • Reduce the welding current.

which barely affects the DC field and This may require an arc-speed

results in very little arc blow. reduction.

c When using two AC arcs, a com- • Angle the electrode with the

mon arrangement, arc-blow interfer- work opposite to the direction of arc

Fig. 8—Multiple-arc welding, ence is avoided mainly by phase- blow (Fig. 9).

when the two arcs are located shifting the current of one arc 80 to • Make a heavy tack weld on

close together, may cause mag- 90 deg. from the other arc. With a both ends of the seam; apply fre-

netic arc blow. When the arcs are phase shift, the current and magnet- quent tack welds along the seam, es-

of different polarity (a), the mag- ic fields of one arc reach a maximum pecially if fitup is loose.

netic fields combine to blow arcs when the current and magnetic • Weld toward a heavy tack weld

outward. If the arcs are of the fields of the other arc are at or near or toward a previously made weld.

same polarity (b), magnetic fields minimum, resulting in very little, if • Use a backstep welding tech-

oppose each other and the arcs any, arc blow. nique (Fig. 10).

blow inward. With one arc pow- • Weld away from the workpiece

ered by DC current and the other How to Reduce Arc Blow connection to reduce back blow,

by AC current (c), little or no arc Not all arc blow is detrimental. In and weld toward the workpiece

blow occurs. fact, a small amount helps form the connection to reduce forward blow.

bead shape, control molten slag and • If welding produces heavy slag,

control penetration. But arc blow a small amount of back blow is de-

plate. During manual welding, a must be controlled when it con- sirable, and is attained by welding

small amount of thermal back blow tributes to defects such as undercut, toward the workpiece connection.

due to arc lag is not detrimental, but inconsistent penetration, crooked • Wrap the work cable around

becomes problematic at higher beads, beads of irregular width, the workpiece so that the current re-

welding speeds, as occurring in au- porosity, wavy beads and excessive turning to the power supply passes

tomatic welding. Thermal arc blow spatter. Possible corrective measures through it in such a direction that

sometimes may combine with mag- include the following: the magnetic field setup neutralizes

netic back blow, leading to quality • If DC current is being used with the magnetic field causing the arc

problems. the SMAW process—especially at blow. MF

welding current greater than 250

Arc Blow with amps—change to AC current. Information for this article was

Multiple-Arc Welding • Hold as short an arc as possible supplied by The Lincoln Electric Co.,

Welding with multiple arcs, for to help arc force counteract arc Cleveland, OH; tel. 216/481-8100;

high speed and increased productiv- blow. www.lincolnelectric.com.

46 www.metalforming.com MetalForming/May 2001

Vous aimerez peut-être aussi

- Corriente Continua PDFDocument44 pagesCorriente Continua PDFGeraldynne SierraPas encore d'évaluation

- Waves Program Feb 2023Document56 pagesWaves Program Feb 2023mohgana ponnampalamPas encore d'évaluation

- Cover Concrete: Effectively Confined Section B-B Cover Concrete (Spalls Off) - Q-Ra Ineffectively Confined Core S/sDocument1 pageCover Concrete: Effectively Confined Section B-B Cover Concrete (Spalls Off) - Q-Ra Ineffectively Confined Core S/sRonal J Clavijo RPas encore d'évaluation

- Notes-Api Exams-Prathap DhasDocument7 pagesNotes-Api Exams-Prathap DhasAnonymous 4e7GNjzGWPas encore d'évaluation

- Figure 9Document1 pageFigure 9suryansh guptaPas encore d'évaluation

- Iso 9600Document19 pagesIso 9600Chinh PhamPas encore d'évaluation

- How To Prevent Arc BlowDocument12 pagesHow To Prevent Arc BlowFelix GomintongPas encore d'évaluation

- Arc BlowDocument8 pagesArc BlowAnonymous 4e7GNjzGWPas encore d'évaluation

- Polarity of Power Inductor An-E 0 ROHMDocument11 pagesPolarity of Power Inductor An-E 0 ROHMcyo3fffPas encore d'évaluation

- V-8120 DWG CommentsDocument1 pageV-8120 DWG CommentsSulist N WahyudiePas encore d'évaluation

- Deflection of Beams and Shafts: The Elastic CurveDocument13 pagesDeflection of Beams and Shafts: The Elastic CurveNoermansyar SikandePas encore d'évaluation

- Switch Nozzle Position As Per Latest Dwg. (Mirrored), See Below CaptureDocument1 pageSwitch Nozzle Position As Per Latest Dwg. (Mirrored), See Below CaptureSulist N WahyudiePas encore d'évaluation

- Seminar - Active Magnetic BearingsDocument14 pagesSeminar - Active Magnetic BearingskichupadiyathPas encore d'évaluation

- Bending of BeamDocument4 pagesBending of BeamsvpPas encore d'évaluation

- CE Board Nov 2020 - RCD - Set 8 and 9Document6 pagesCE Board Nov 2020 - RCD - Set 8 and 9Dale MalazzabPas encore d'évaluation

- Electromagnetic Waves 2022Document12 pagesElectromagnetic Waves 2022ADITYA MAHECHAPas encore d'évaluation

- VBNJLKJHGDocument1 pageVBNJLKJHGAli MahamedPas encore d'évaluation

- IMG - 0032 PSME Code 2008 21Document1 pageIMG - 0032 PSME Code 2008 21Arwyn BermasPas encore d'évaluation

- Dae Hep Poster2Document2 pagesDae Hep Poster2Random PersonPas encore d'évaluation

- Sample Exam 2Document3 pagesSample Exam 2DiexPas encore d'évaluation

- Electrical Machines IIDocument6 pagesElectrical Machines IIsuryaprakash001Pas encore d'évaluation

- Preparing To Weld: Unit 11Document3 pagesPreparing To Weld: Unit 11ahmedPas encore d'évaluation

- Electrostatics + Magnetostatic + CurrentDocument1 pageElectrostatics + Magnetostatic + Currentrudraveer2805Pas encore d'évaluation

- PH34 7.0 Physics Exam Cheat Sheet BorderDocument2 pagesPH34 7.0 Physics Exam Cheat Sheet BorderBatza BatsakisPas encore d'évaluation

- DeepLay-eks-2022-183 - Distributed Buoyancy Module For Lazy WaveDocument13 pagesDeepLay-eks-2022-183 - Distributed Buoyancy Module For Lazy WaveGunawan SuwarnoPas encore d'évaluation

- Scan0055 PDFDocument1 pageScan0055 PDFJayson Jonson AraojoPas encore d'évaluation

- RRTC Sept.05 G Caronno Fired Heaters PresentationJH Final 1 AnimatedDocument21 pagesRRTC Sept.05 G Caronno Fired Heaters PresentationJH Final 1 AnimatedAhmed J Al-Terkait0% (1)

- Fire Resistant Cables CatalogueDocument7 pagesFire Resistant Cables CatalogueSathis Kumar Naidu Thasnamoothy100% (2)

- Short Circuit Design 9.8.22Document51 pagesShort Circuit Design 9.8.22jackthonetPas encore d'évaluation

- Wave Optics Class - 1 (Notes)Document21 pagesWave Optics Class - 1 (Notes)Krishna GuptaPas encore d'évaluation

- 15.3 Open Coiled Helical Springs: To and MeanDocument19 pages15.3 Open Coiled Helical Springs: To and MeanBiswadeep Roy ChoudhuryPas encore d'évaluation

- Numerical Investigation of Oblique Shock Wave/vortex Interaction.Document14 pagesNumerical Investigation of Oblique Shock Wave/vortex Interaction.alvaro737max10Pas encore d'évaluation

- Unit 9 PDFDocument20 pagesUnit 9 PDFpoojaPas encore d'évaluation

- Def Fen Baugh 1946Document4 pagesDef Fen Baugh 1946Kevin Fachrul Razi LubisPas encore d'évaluation

- Relativistic Pendulum and The Weak Equivalence PriDocument11 pagesRelativistic Pendulum and The Weak Equivalence PriVatsalPas encore d'évaluation

- A Study of The Initial Surge Distribution inDocument17 pagesA Study of The Initial Surge Distribution inibrahimPas encore d'évaluation

- Linear Theory With Snell'S: Wave Transformation ACES Technical ReferenceDocument18 pagesLinear Theory With Snell'S: Wave Transformation ACES Technical ReferenceSamirPas encore d'évaluation

- TwoStep Linkage SSP9028 v10Document1 pageTwoStep Linkage SSP9028 v10David BriggsPas encore d'évaluation

- Light Lenses EM SpectrumDocument25 pagesLight Lenses EM SpectrumSYED MUHAMMAD UZAIRPas encore d'évaluation

- Useof DescartesfoliumequationDocument13 pagesUseof Descartesfoliumequationموسى حسنPas encore d'évaluation

- Lecture 3 Sem 2 2020 PDFDocument8 pagesLecture 3 Sem 2 2020 PDFMohamadPas encore d'évaluation

- AP Physc em Electromagnetic Problem Solving Techniques 2020-03-20Document64 pagesAP Physc em Electromagnetic Problem Solving Techniques 2020-03-20Armored SumanPas encore d'évaluation

- HFBV Viaduct - IdeaDocument1 pageHFBV Viaduct - Ideastavros stergiopoulosPas encore d'évaluation

- 24 PDFDocument21 pages24 PDFJasdeepSinghPas encore d'évaluation

- Vogel PaperDocument7 pagesVogel PaperRanjith BhoopalPas encore d'évaluation

- Ae2 Comp Insta Guide Na enDocument2 pagesAe2 Comp Insta Guide Na enAnonymous rrD8UKYNXPas encore d'évaluation

- KMC EE 2022 JuneDocument10 pagesKMC EE 2022 JuneDIPPas encore d'évaluation

- Equipotential Surfaces For Uniformly Charged Symmetric Polyhedral ConductorsDocument7 pagesEquipotential Surfaces For Uniformly Charged Symmetric Polyhedral ConductorsNizwan AhammadPas encore d'évaluation

- Appendix IDocument5 pagesAppendix ISƠN NGUYỄN NGỌC TRƯỜNGPas encore d'évaluation

- Matirial ThingsDocument1 pageMatirial ThingshongPas encore d'évaluation

- De MagnetizationDocument9 pagesDe Magnetization322399mk7086Pas encore d'évaluation

- A Coneccion SD PastillasDocument1 pageA Coneccion SD PastillasCarlos NarvaezPas encore d'évaluation

- Pages From Smith & Hendy 2009 6Document1 pagePages From Smith & Hendy 2009 6Napong SubanpongPas encore d'évaluation

- The Macroscopic Electric Field Inside A DielectricDocument19 pagesThe Macroscopic Electric Field Inside A Dielectric馮維祥100% (1)

- Moving Charges and Magnetism NotesDocument10 pagesMoving Charges and Magnetism NotesAshwini SinghPas encore d'évaluation

- Dowding Ch03 1996Document22 pagesDowding Ch03 1996ola bou ghannamPas encore d'évaluation

- Lecture 6 Radiation-Matter Interactions - 2Document25 pagesLecture 6 Radiation-Matter Interactions - 2Yun WangPas encore d'évaluation

- Electron–Photon Shower Distribution Function: Tables for Lead, Copper and Air AbsorbersD'EverandElectron–Photon Shower Distribution Function: Tables for Lead, Copper and Air AbsorbersPas encore d'évaluation

- Harman Kardon Omni 50 PLDocument30 pagesHarman Kardon Omni 50 PLApostolie IulianPas encore d'évaluation

- Guidance On Bolted JointsDocument54 pagesGuidance On Bolted JointsGerman ToledoPas encore d'évaluation

- Cranes Inspection ChecklistDocument4 pagesCranes Inspection ChecklistApostolie IulianPas encore d'évaluation

- Laggan-Tormore Project: TOTAL E&P UK LimitedDocument2 pagesLaggan-Tormore Project: TOTAL E&P UK LimitedApostolie IulianPas encore d'évaluation

- Scientific Reasons Physics II HSCDocument37 pagesScientific Reasons Physics II HSCSIR USMAN KHANPas encore d'évaluation

- 2015 O-Level Physics Paper 2 Answer by Calvin Kong PhysicsDocument6 pages2015 O-Level Physics Paper 2 Answer by Calvin Kong PhysicsjesudassajPas encore d'évaluation

- Manual Sharkv3.94Document86 pagesManual Sharkv3.94Amarnath M DamodaranPas encore d'évaluation

- HVDC Transformer Volume 2Document85 pagesHVDC Transformer Volume 2sadeeskumar.dPas encore d'évaluation

- Physics 101 - Magnetic FieldsDocument37 pagesPhysics 101 - Magnetic FieldsCrazyBookWormPas encore d'évaluation

- Burner Control LGB21Document22 pagesBurner Control LGB21douglasPas encore d'évaluation

- Civil NDTDocument63 pagesCivil NDTArjuna De Silva100% (1)

- Transformer Short Circuit Current Calculation and SolutionsDocument37 pagesTransformer Short Circuit Current Calculation and Solutionsmano_bacsi100% (1)

- Sentron 7kg9661 UsDocument292 pagesSentron 7kg9661 UsSimpalean NicolaePas encore d'évaluation

- Electrical Handbook Formula Book SampleDocument73 pagesElectrical Handbook Formula Book Samplesnitin26100% (2)

- Ayantika Khanra UG23Document42 pagesAyantika Khanra UG23Anisha GoenkaPas encore d'évaluation

- Ee RelayDocument24 pagesEe RelayNeonPas encore d'évaluation

- Mig & MagDocument7 pagesMig & Magprap_1982Pas encore d'évaluation

- Earthing and Grounding PDFDocument29 pagesEarthing and Grounding PDFvikubhardwaj9224100% (1)

- 133 Preventive and Corrective Maintenance For Optical Cables On Overhead Power LinesDocument43 pages133 Preventive and Corrective Maintenance For Optical Cables On Overhead Power Linesmody100Pas encore d'évaluation

- Manual System Circuit Integrity e 0111Document112 pagesManual System Circuit Integrity e 0111ivoburiPas encore d'évaluation

- Underground Cables 2: Installation of 66Kv To 330Kv Xlpe Insulated CablesDocument33 pagesUnderground Cables 2: Installation of 66Kv To 330Kv Xlpe Insulated CablesYvonne TohPas encore d'évaluation

- Applications of The GPTRDocument7 pagesApplications of The GPTRjslrPas encore d'évaluation

- Electric CurrentDocument12 pagesElectric Currentstory manPas encore d'évaluation

- Semiconductor TransistorDocument526 pagesSemiconductor TransistorAkhmad Reza FathanPas encore d'évaluation

- Magnetic High Impact Cannon Coil Gun HTTPDocument27 pagesMagnetic High Impact Cannon Coil Gun HTTPjcarnley2005100% (1)

- Lec CH 17 Symmetric FaultsDocument16 pagesLec CH 17 Symmetric FaultsMajdi M. AbabnehPas encore d'évaluation

- Mcqs Preparation For Engineering Competitive ExamsDocument12 pagesMcqs Preparation For Engineering Competitive ExamsHussam GujjarPas encore d'évaluation

- Episode 406: Fields, Field Lines and EquipotentialsDocument15 pagesEpisode 406: Fields, Field Lines and EquipotentialswaelabunijemPas encore d'évaluation

- Basic Fundamentals of Solar Cell Semiconductor Physics For High School Level PhysicsDocument66 pagesBasic Fundamentals of Solar Cell Semiconductor Physics For High School Level PhysicsLibyan TripoliPas encore d'évaluation

- Power World Simulation Package pwr30c PDFDocument87 pagesPower World Simulation Package pwr30c PDFAhmed M H Al-YousifPas encore d'évaluation

- Devloper BoardDocument82 pagesDevloper Boardpukhraj titrePas encore d'évaluation

- Dictionary of Electronics and Communication Engineering - Engineering Bug PDFDocument870 pagesDictionary of Electronics and Communication Engineering - Engineering Bug PDFMirnesaPas encore d'évaluation

- Crystalline Silicon Solar CellsDocument252 pagesCrystalline Silicon Solar Cellsnawwar100% (4)

- Cse I Basic Electrical Engg. (10ele 15) NotesDocument200 pagesCse I Basic Electrical Engg. (10ele 15) NotesBala SubramanyamPas encore d'évaluation