Académique Documents

Professionnel Documents

Culture Documents

Microcomputer Thermostat Serial 《EW-801AH 》 Directions: Brief on Controlling Procedure

Transféré par

predragstojicicDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Microcomputer Thermostat Serial 《EW-801AH 》 Directions: Brief on Controlling Procedure

Transféré par

predragstojicicDroits d'auteur :

Formats disponibles

Code:M801AH.15.08.

18

Brief on Controlling Procedure

Microcomputer Thermostat Serial

1. Low temperature zone temperature settings: Press displays the

《EW-801AH Directions》 temperature of low temperature zone, press or to change the

This product is mainly used in solar water heater equipment, the use of controlling temperature. Without pressing any key when finished operating,it

the temperature difference and temperature to control the output. This will automatic save memory setting parameters after six seconds.

2.Parameter setting: Holding and after six seconds to enter Setup,

product has two-ways output control, one way to control the temperature

the corresponding indicator flashes, more than once every press to run the

difference between the two temperature zones, when the temperature

next function indicators, then press or to change the parameters for

difference reaches the set value, automatically run the pump cycle, the each function. Without pressing any key when finish operation, it will

temperature of the two temperature zones to reach equilibrium, another automatic save memory setting parameters after six seconds.

way to control electric heating; when solar heating fails reached (low

Temperature difference between the started

temperature) set temperature, the electric heating system is heated

When two temperature sensor detects a

to a set temperature automatically start and automatic temperature control Ewelly

temperature of two zones, the difference is greater

range values w ithin a temperature difference. than the value of thetemperature difference

between the set start value, the circulation pump

relay ON, temperature difference setting range:

Technical Specifications EW-80 1 temperature of the pump stopped+1 ℃ ~ 50 ℃.

Temperature difference of the pump stopped

1、Operating voltage:AC220V ±10% 50HZ/60HZ

When the temperature difference between the two

2、Output Load:5A/220V/AC Ewelly sensors is less than this value, the circulation pump

stops, Range 1 ℃ ~ started temperature difference-1 ℃。

3、Power Consumption: ≤3W Note: When difference of the pump stops setting “0”,

once the circulation pump relay ON, circulation

4、Working environment:-10℃ ~50℃ RH≤90% E W- 801

pump not stopped.

5、Control of heating:2℃~99℃ Heating temperature difference

6、Control of thermal start-up:3℃~50℃ High temperature zone must be

higher than the setting temperature

7、Resolution:1℃ Accuracy:±1℃ difference. Equal or less than this

8、nput signal:two-ways sensors,20KX1.5mX2 value automatically start heating

E W-801 control. Heating temperature

9、Overall Dimension:76(L)×35(H)×76(D)mm range:0℃~20℃。

Temperature hysteresis

10、Hole Size:71(L)×29(H)mm

Ewelly After reaches the set point and stop

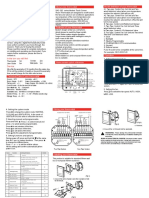

Panel Diagram heating, temperature down, and then

Display the current temperature of restart the difference between electric

the low temperature zone heating, temperature hysteresis setting

EW-80 1

range: 1 ℃ ~ 20 ℃.

Ewelly

High temperature zone temperature correction

When the thermostat detects the

Ewelly

temperature of the high temperature

EW-801 zone and the actual value error, this

feature can be amended. Correction

E W- 80 1 range: -10 ℃ ~ 10 ℃.

Running lights

Low temperature zone temperature correction

Ewelly When the thermostat detects the

temperature of the low temperature

E W- 80 1 zone and the actual value error, this

EW- 80 1 feature can be amended. Correction

In the non setting state, press can see the current range: -10 ℃ ~ 10 ℃.

temperature of the high temperature zone.

Sensor error self-test function

Demand of install Ewelly

When the high temperature zone

sensor circuit or open circuit

1.The voltage must accord with controller's demand. will show "EH" symbol.

EW-801

The voltage's deviation is no more than ±10%.

2.The loop of sensor is possible to keep away from the

loop of power. Ewelly When the low temperature zone

sensor circuit or open circuit will

3.The sequence of line's must have been connected show "EL" symbol.

Properly. E W- 801

Wiring Diagram

Parameters for Procedure

Model: EW-M801AH Ex-factory Unit

Lights NO. Function Setting range Value

Output load:

220V/AC

Temperature difference Temp.difference ℃

NO.1Indicator of stopped pump+1~50 5

5A 5A start-up

Stop the pump 1~temp.difference

NO.1.2 Indicator temperature started-1 2 ℃

Heating temperature

NO.3.4 Indicator 0~20 5 ℃

difference

Temperature

NO.2 Indicator difference 1~20 5 ℃

1 2 3 4 5 6 7 8 9 10 11

High temperature

NO.3 Indicator correction -10~10 0 ℃

Controlled Water pump

Heating circulation Low temperature

NO.4 Indicator correction -10~10 0 ℃

Low-temp. High-temp. Note: When the temperature difference is set at 0, the electric power is entered

220V/AC Sensor Sensor

into the heating state.

At the same time, press the set key and key 6 seconds will restore

the factory settings

Trouble shooting

Failure Causes Precautions

Check if the power is broken or the Check power supply and change fuse.

No display when power

thermostat failture. 。 Check if the input voltage is right or

is on.

change the thermostat with our distributor.

The setting temperature is lower than the

Reset the necessary controlling temperature.

Displaying but machine present temperature.

Check the reasons for overload and overheating.

doesn't work The heat protector is open circuit because the

pressure is over loads. After the trouble is solved, restart to work.

Displayed temperature is The sensor is interfered; or poor wiring; Separate sensor wiring with power cables

unstable or there exists or Together with other power cord bundle; or change shielded lines or check if the contact

misplay. or line damage. is tight or not.

All sensors should be corrected at their locations.

The installation position of the sensor is not

Measurement error between correct; or the sensor's wiring is too long and Enlarge the cross section of the expanded wires.

current temperature and its resistance is over; or the wiring connected Make sure the wires sealed is good. or Change the

displayed. poor; or the sensor is damaged sensor.

Machine does not stop The sensor is not correctly installed and cannot Check if the sensor has accurately measured

when the temperature measure the correct temperature. Compressor the temperature or not. Change compressor

reaches. contactor fails. contactor.

Return difference value is too small or the Reset and enlarge return difference value. Adjust

Relay work with overload

setting for pressure protection is not correct. setting for pressure protection.

Check to see if the sensor wiring has good contact

“EH” or “EL” is displayed The sensor is opened or shorted circuit.

with coupling end or not.

Warnings

1. Please read this product instruction carefully and connect If the products including but not limited to, the following is

input/output plugs of power & sensor to the corresponding sockets not the product itself quality problem caused by the damage,

strictly by following connection diagram, otherwise the usage & Install and use under the do not conform to the safe environment;

operations will be affected. Check again to make sure there is no That the load capacity is beyond the scope of product is allowed;

mistake. Tighten all the screw of connection plugs again, and then Products by users to disassemble and change, change the internal

connect it to the power for running. components, etc.,We will not be so and damaged products

provide a replacement and maintenance services, regardless of

2. Keep away this product from moist or corrosive air and high

whether its in the quality assurance period; Meanwhile, we will

magnetic field. Otherwise the normal operation of this product will

not assume so direct or indirect losses caused by the liability to

be affected.

pay compensation.

.

Product warranty date on the case is important basis of

3. All our products have passed strict quality inspections before

product quality assurance. Appeared including but not limited to

leaving factory. We provide one-year quality guarantee (which is

full filling without permission, to change, to replace lost,

limited to product itself ,and is not responsible for any other joint

damaged, scratched, dirty, and so on, we will not provide a

and several liability) period for this product.

replacement and maintenance services for these products.

If you have any doubt or problem concerning the electronic

Guangzhou Eliweli Autocontrol Tech. Co., Ltd. temperature or humidity controller made by us, please contact

http://www.eliweli.com our distributors and we will provide you high-quality after-

sale services. Thanks!

Vous aimerez peut-être aussi

- Manual de Uso Camara Bioclimaticabjpx-A450Document11 pagesManual de Uso Camara Bioclimaticabjpx-A450Lucecita NoeliaPas encore d'évaluation

- 20151210201922RC-112E User Manual220v10Document2 pages20151210201922RC-112E User Manual220v10Anonymous ZLmk6mPPnPas encore d'évaluation

- Manual ControlDocument4 pagesManual ControljuanPas encore d'évaluation

- SP1 ManualDocument13 pagesSP1 ManualAnonymous RCPxaonfvPas encore d'évaluation

- STC-1000 Temperature Controller Operating Manual: or or orDocument1 pageSTC-1000 Temperature Controller Operating Manual: or or orziandPas encore d'évaluation

- TOL47WIFI Heating Thermostat ManualDocument3 pagesTOL47WIFI Heating Thermostat ManualJorge Juan MANRIQUEPas encore d'évaluation

- SP 24 ManualDocument7 pagesSP 24 ManualOrlando Meza MachadoPas encore d'évaluation

- Termostato UMA CasablancaDocument3 pagesTermostato UMA CasablancaCris YañezPas encore d'évaluation

- Manual Termostato Digitall t6812 FancoilDocument4 pagesManual Termostato Digitall t6812 FancoilaarroyofPas encore d'évaluation

- 《EW-981 Directions》 Microcomputer Thermostat Serial: Technical SpecificationsDocument2 pages《EW-981 Directions》 Microcomputer Thermostat Serial: Technical SpecificationsVu Quang TrungPas encore d'évaluation

- ManualDocument1 pageManualJuan Francisco BallestasPas encore d'évaluation

- DIGITAL DIMMING THERMOSTAT DAY & NIGHT + TIMER DTC-120 User ManualDocument2 pagesDIGITAL DIMMING THERMOSTAT DAY & NIGHT + TIMER DTC-120 User Manualthommcsi2013Pas encore d'évaluation

- Digital Dimming Thermostat Day & Night + Timer DTC-120: User ManualDocument2 pagesDigital Dimming Thermostat Day & Night + Timer DTC-120: User Manualthommcsi2013Pas encore d'évaluation

- Dometic SMXHT ManualDocument2 pagesDometic SMXHT ManualAndri MorenoPas encore d'évaluation

- Vacuum Drying Oven BOV-90V'215V Series User ManualDocument13 pagesVacuum Drying Oven BOV-90V'215V Series User ManualJs Caballero0% (1)

- Thermostat MH1210A Datasheet PDFDocument3 pagesThermostat MH1210A Datasheet PDFFreddy ValeraPas encore d'évaluation

- 4.1 Proteccion Por TemperaturaDocument6 pages4.1 Proteccion Por TemperaturaJorge Luis Morales GonzalezPas encore d'évaluation

- 450 RR 1Document18 pages450 RR 1aliPas encore d'évaluation

- BAC-002 ModbusDocument2 pagesBAC-002 ModbusAlfredo Ferrari Jr.Pas encore d'évaluation

- Danfoss EKC201CDocument16 pagesDanfoss EKC201CGabriel PiticasPas encore d'évaluation

- Thermostat Tms810Document7 pagesThermostat Tms810Katherin PazPas encore d'évaluation

- XMTG818 (T) Temperaturecontrollerwithtimer 14315713197 PDFDocument6 pagesXMTG818 (T) Temperaturecontrollerwithtimer 14315713197 PDFyesdanPas encore d'évaluation

- MP803FCT-2W: Fan Coil Unit On/Off Digital ThermostatDocument1 pageMP803FCT-2W: Fan Coil Unit On/Off Digital ThermostatChhomPas encore d'évaluation

- Smart Series SSM SSMX ManualDocument7 pagesSmart Series SSM SSMX ManualDinh Thi TruongPas encore d'évaluation

- Auber Instruments SYL-1614 ManualDocument4 pagesAuber Instruments SYL-1614 ManualDPas encore d'évaluation

- MP908FCT-2: Fan Coil Unit On/Off Digital ThermostatDocument1 pageMP908FCT-2: Fan Coil Unit On/Off Digital ThermostatChhomPas encore d'évaluation

- An00008642930101 000201Document4 pagesAn00008642930101 000201alecandro_90Pas encore d'évaluation

- Termômetro Digital 12 VoltzDocument2 pagesTermômetro Digital 12 VoltzguilhermewrPas encore d'évaluation

- Laboratory No. 8 ThermometersDocument3 pagesLaboratory No. 8 ThermometersNicol Nogales NuñezPas encore d'évaluation

- Programmable Touchscreen Thermostat: Ideal For Light Commercial ApplicationsDocument2 pagesProgrammable Touchscreen Thermostat: Ideal For Light Commercial ApplicationsnasierrasPas encore d'évaluation

- BIODOM ROKO ManualDocument7 pagesBIODOM ROKO ManualDavid DyvvPas encore d'évaluation

- Xy Wt01 Thermostat DigitalDocument10 pagesXy Wt01 Thermostat Digitaltanee boonmalertPas encore d'évaluation

- Faqe7073ka0 Secadora FrigidaireDocument8 pagesFaqe7073ka0 Secadora FrigidaireVasti Diaz AguilarPas encore d'évaluation

- MP803PIT-V2-S1-F3: Modulating Digital ThermostatDocument1 pageMP803PIT-V2-S1-F3: Modulating Digital ThermostatChhomPas encore d'évaluation

- Danfoss EKC 366Document8 pagesDanfoss EKC 366RonnyPas encore d'évaluation

- TGR86WIFI Heating Thermostat ManualDocument17 pagesTGR86WIFI Heating Thermostat ManualJoana Lier SanchezPas encore d'évaluation

- WKHDDocument2 pagesWKHDWakhid PrabowoPas encore d'évaluation

- Aermec WMT 10 Installation Manual EngDocument7 pagesAermec WMT 10 Installation Manual Engdacky75Pas encore d'évaluation

- 9400 Thermostat Manual - 110-1039Document11 pages9400 Thermostat Manual - 110-1039andrewh3Pas encore d'évaluation

- MP810FCT-2: Fan Coil Unit On/Off Digital ThermostatDocument1 pageMP810FCT-2: Fan Coil Unit On/Off Digital ThermostatChhomPas encore d'évaluation

- EXT RC.. 24 Datasheet en APDocument3 pagesEXT RC.. 24 Datasheet en APCuajinike1Pas encore d'évaluation

- Pid Temperature Controller ManualDocument12 pagesPid Temperature Controller ManualraffaelePas encore d'évaluation

- q7rf Manual enDocument48 pagesq7rf Manual enSanthia MoralesPas encore d'évaluation

- EKC 315A Danfoss Rs8cS302Document16 pagesEKC 315A Danfoss Rs8cS302davebigelow42Pas encore d'évaluation

- Im Ec 50154 20180813Document28 pagesIm Ec 50154 20180813Jeff BaumanPas encore d'évaluation

- MP3000FCT-2A: Fan Coil Unit On/Off Digital Touch Screen ThermostatDocument1 pageMP3000FCT-2A: Fan Coil Unit On/Off Digital Touch Screen ThermostatChhomPas encore d'évaluation

- MP803FCT-2: Fan Coil Unit On/Off Digital ThermostatDocument1 pageMP803FCT-2: Fan Coil Unit On/Off Digital ThermostatChhomPas encore d'évaluation

- Manual KJ A1200Document15 pagesManual KJ A1200Manuel GeorgePas encore d'évaluation

- EWPC 901/A: Temperature Controller With Alarm OutputDocument5 pagesEWPC 901/A: Temperature Controller With Alarm OutputOswaldo Rengifo MuozPas encore d'évaluation

- ASTM D86 Petroleum Product Distillation TesterDocument11 pagesASTM D86 Petroleum Product Distillation TesterFraz AhmadPas encore d'évaluation

- Energy: Smart Thermostat and Smart Radiator Valves User ManualDocument56 pagesEnergy: Smart Thermostat and Smart Radiator Valves User ManualLuis SilvaPas encore d'évaluation

- M Odel: SF-102 Digital Temperature Controller: Features of FunctionDocument2 pagesM Odel: SF-102 Digital Temperature Controller: Features of FunctionVictor AAPas encore d'évaluation

- SET-002ALNE (2 Pipe) - ELNE (4 Pipe) - (3speed OnOffValve)Document2 pagesSET-002ALNE (2 Pipe) - ELNE (4 Pipe) - (3speed OnOffValve)jimmylo3224Pas encore d'évaluation

- STC 9000 CombistatoDocument1 pageSTC 9000 CombistatoHernan de rein100% (1)

- ZL-7901A Intelligent Temperature and Humidity Controller: FeatureDocument8 pagesZL-7901A Intelligent Temperature and Humidity Controller: FeatureBasemPas encore d'évaluation

- Kezelesi Utmutato Q3 RF 2010 AngolDocument12 pagesKezelesi Utmutato Q3 RF 2010 AngolClaudiu AdamPas encore d'évaluation

- Instruction Manual: Microcomputer Based Temperature Indicating ControllerDocument12 pagesInstruction Manual: Microcomputer Based Temperature Indicating ControllerChrist Rodney MAKANAPas encore d'évaluation

- Inctrykcija Po Zkcplyatacii YLCSDocument90 pagesInctrykcija Po Zkcplyatacii YLCSpredragstojicicPas encore d'évaluation

- Gree After-Sale Service Manual - HRDocument39 pagesGree After-Sale Service Manual - HRpredragstojicic100% (2)

- SortimoDocument149 pagesSortimopredragstojicicPas encore d'évaluation

- HILTI 07 - Direct - FasteningDocument50 pagesHILTI 07 - Direct - FasteningpredragstojicicPas encore d'évaluation

- Komplet Katalog Conmetal-NoviDocument404 pagesKomplet Katalog Conmetal-NovipredragstojicicPas encore d'évaluation

- THOMSON Linear GuidesDocument266 pagesTHOMSON Linear Guidespredragstojicic100% (1)

- EXTECH Kalibrator PRC30 - DS-en PDFDocument2 pagesEXTECH Kalibrator PRC30 - DS-en PDFpredragstojicicPas encore d'évaluation

- DEMMELER Katalog Proizvoda 2016Document190 pagesDEMMELER Katalog Proizvoda 2016predragstojicicPas encore d'évaluation

- Cp1l Povezivanje Servo MotoraDocument10 pagesCp1l Povezivanje Servo MotorapredragstojicicPas encore d'évaluation

- Parker Motori PDFDocument32 pagesParker Motori PDFpredragstojicicPas encore d'évaluation

- Brother PT E300vpDocument2 pagesBrother PT E300vppredragstojicicPas encore d'évaluation

- 1587 Cmeng0200 Uputstvo Za KalibracijuDocument46 pages1587 Cmeng0200 Uputstvo Za KalibracijupredragstojicicPas encore d'évaluation

- Therma V 2p Leaft - FinalDocument2 pagesTherma V 2p Leaft - FinalpredragstojicicPas encore d'évaluation

- VHR Installation Operation & Maintenance Instruction GuideDocument26 pagesVHR Installation Operation & Maintenance Instruction GuidepredragstojicicPas encore d'évaluation

- Tl260-Tl265 Installation Manual Eng Fre Spa Braz-Port 29007618r002Document68 pagesTl260-Tl265 Installation Manual Eng Fre Spa Braz-Port 29007618r002predragstojicicPas encore d'évaluation

- Baseline - Access Control Terminal (IVMS-4200 Operation) - User Manual - 20160303Document203 pagesBaseline - Access Control Terminal (IVMS-4200 Operation) - User Manual - 20160303predragstojicic100% (1)

- BF-870 User ManualDocument26 pagesBF-870 User ManualpredragstojicicPas encore d'évaluation

- Is 3073Document34 pagesIs 3073rohan sharmaPas encore d'évaluation

- P102 Lesson 4Document24 pagesP102 Lesson 4Tracy Blair Napa-egPas encore d'évaluation

- Maintenance Repair Overhaul: Safely To New Horizons Ensuring Your Aircraft Is Ready Whenever Duty CallsDocument10 pagesMaintenance Repair Overhaul: Safely To New Horizons Ensuring Your Aircraft Is Ready Whenever Duty CallsSuryaPas encore d'évaluation

- SDS enDocument6 pagesSDS enAnup BajracharyaPas encore d'évaluation

- Autodesk Inventor Practice Part DrawingsDocument25 pagesAutodesk Inventor Practice Part DrawingsCiprian Fratila100% (1)

- Session 2 - 01 (Energy Efficiency Potential Assessment of Chandrapura TPS, DVC)Document52 pagesSession 2 - 01 (Energy Efficiency Potential Assessment of Chandrapura TPS, DVC)pkumarPas encore d'évaluation

- Pulido VsDocument14 pagesPulido Vsroyel arabejoPas encore d'évaluation

- Harmony Radio, R2.8: Order Codes ReferenceDocument51 pagesHarmony Radio, R2.8: Order Codes ReferenceRalaivao Solofohery Dieu-donnéPas encore d'évaluation

- HP Training Diagnostics 75 Usage and AdministrationDocument2 pagesHP Training Diagnostics 75 Usage and AdministrationraviskskskPas encore d'évaluation

- Sony Ericsson Secret MenuDocument2 pagesSony Ericsson Secret MenuZeljana MaksicPas encore d'évaluation

- Pas 38 Pas 41 Pas 40Document12 pagesPas 38 Pas 41 Pas 40Leddie Bergs Villanueva VelascoPas encore d'évaluation

- 150 67-Eg1Document104 pages150 67-Eg1rikoPas encore d'évaluation

- HYD CCU: TICKET - ConfirmedDocument2 pagesHYD CCU: TICKET - ConfirmedRahul ValapadasuPas encore d'évaluation

- Brigada EskwelaDocument4 pagesBrigada EskwelaJas Dela Serna SerniculaPas encore d'évaluation

- Chapter 9 CompensationDocument24 pagesChapter 9 CompensationSophie CheungPas encore d'évaluation

- Contingent Liabilities For Philippines, by Tarun DasDocument62 pagesContingent Liabilities For Philippines, by Tarun DasProfessor Tarun DasPas encore d'évaluation

- Lean ManufacturingDocument61 pagesLean ManufacturingWasiYamanChoudhuryPas encore d'évaluation

- Defining The Audiovisual IndustryDocument20 pagesDefining The Audiovisual IndustryAyoub Ait MahmoudPas encore d'évaluation

- What Is Highway EngineeringDocument4 pagesWhat Is Highway EngineeringNagesh SinghPas encore d'évaluation

- Midterm Fin Oo4Document82 pagesMidterm Fin Oo4patricia gunio100% (1)

- 2 SpecificationDocument20 pages2 Specificationprithvi614710Pas encore d'évaluation

- Treatment of Dairy Waste Water Using Adsorbents From Solid WasteDocument7 pagesTreatment of Dairy Waste Water Using Adsorbents From Solid WasteIJRASETPublicationsPas encore d'évaluation

- Procter & Gamble Global Geothermal Screening Study FINAL 9 Feb 2023Document56 pagesProcter & Gamble Global Geothermal Screening Study FINAL 9 Feb 2023Mohammad Syahir JamaluddinPas encore d'évaluation

- Exp.1 (Screening) Group1Document16 pagesExp.1 (Screening) Group1itokki otoyaPas encore d'évaluation

- GB Programme Chart: A B C D J IDocument2 pagesGB Programme Chart: A B C D J IRyan MeltonPas encore d'évaluation

- PDF Applied Failure Analysis 1 NSW - CompressDocument2 pagesPDF Applied Failure Analysis 1 NSW - CompressAgungPas encore d'évaluation

- UN - Towards Sustainable DevelopmentDocument17 pagesUN - Towards Sustainable Developmentviva_33Pas encore d'évaluation

- National Knowledge Commision and Its Implication in Higher EducationDocument73 pagesNational Knowledge Commision and Its Implication in Higher Educationabhi301280100% (1)

- Principles of Care-Nursing For Children: Principle DescriptionDocument3 pagesPrinciples of Care-Nursing For Children: Principle DescriptionSanthosh.S.UPas encore d'évaluation