Académique Documents

Professionnel Documents

Culture Documents

RODAC - CFW-ENG-FST - Conductive Material

Transféré par

Rodrigo Jechéla BarriosTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

RODAC - CFW-ENG-FST - Conductive Material

Transféré par

Rodrigo Jechéla BarriosDroits d'auteur :

Formats disponibles

Simmerring® with Electrically Conductive Nonwoven Material

Simmerring® with

Electrically Conductive

NonWoven Material

Many traditional radial shaft seals are used in hybrid and purely Values for the customer

electric vehicles. However, in the transmission or E-drive unit of an

electrically powered vehicle, the input shaft may become electri- The Simmerring shaft seal with integrated electro conductive

cally charged resulting in a positive charge travelling through bridge:

various components in the gear box damaging the gears and other

moving components. yy Provides a cost-efficient alternative compared to traditional

solutions

The Simmerring shaft seal with electrically conductive nonwoven

fabric eliminates this risk through a fleece ring glued onto the air yy Is a more compact solution, saving space and weight

side of the seal. Because the carbon fiber-PTFE nonwoven material

contacts both the shaft and the housing, the design forms a yy Delivers extended service life due to the mechanical properties

conductive bridge which grounds the gear box preventing of the electrically conductive fleece

mechanical system damage.

yy Offers additional contamination protection

By adding this function to the Simmerring it is possible to eliminate

additional components used to ground the unit, saving costs.

In addition to the conductive bridge, the fleece ring also excludes Installation situations

contamination from the primary sealing lip. Conductive carbon fiber-PTFE

ADVANTAGES OF THE ELECTRICALLY CONDUCTIVE

NONWOVEN MATERIAL

yy Special mechanical properties

yy Excellent electrical conductivity (resistance value <10 Ohm)

yy Very wide temperature range (–40 °C to +250 °C)

In the gearing mechanism (series) In the electric motor

yy Nearly temperature-independent electrical conductivity

yy Good air permeability prevents vacuum build up under sealing

lip at high speed

Simmerring® with Electrically Conductive Nonwoven Material

Features and Benefits

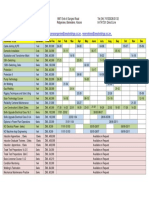

Compare these important features between traditional solutions versus Simmerring with electrically conductive nonwoven material

Simmerring® with Electrically

Benefits Carbon Brush Jumper Ring

Conductive Nonwoven Material

Costs + – –

Space-saving in the unit ++ –– –

Service life + – –

Conductivity + ++ ++

Contamination due to abrasion of the component

++ – –

and the opposing surface

Friction ++ – –

Temperature coefficient of the electrically conductive nonwoven material: Constant resistance values over a wide temperature range

100 12

Temperature (°C)

80 Resistance value (Ohm) 11

Resistance Value (Ohm)

60 10

Temperature (°C)

40 9

20 8

0 7

–20 6

–40 5

–60 4

0 100 200 300 400 500 600 700

Time (minutes)

Comparison of friction torque: Simmerring® with and without electrically conductive nonwoven material

0.070

1 minute at 20 °C

0.060 10 hours at 80 °C

4 hours at 20 °C

Friction Torque (Nm)

0.050

0.040

0.030

0.020

0.010 Simmerring with electrical conductive nonwoven material (shaft Ø 28 mm)

Simmerring without electrical conductive nonwoven material (shaft Ø 28 mm)

0.000

90 °C 110 °C 130 °C 150 °C

100

2000

100

500

1000

1500

2000

2500

6000

8000

500

1000

1500

2000

2500

6000

8000

500

1000

1500

2000

2500

6000

8000

8000

Shaft Speed (rpm)

The information contained herein is believed to be reliable, but no representation, guarantees or warranties of any kind are made to its accuracy or

suitability for any purpose. The information presented herein is based on laboratory testing and does not necessarily indicate end product performance.

Full scale testing and end product performance are the responsibility of the user.

www.fst.com

Vous aimerez peut-être aussi

- Linear IC Applications: A Designer's HandbookD'EverandLinear IC Applications: A Designer's HandbookÉvaluation : 4 sur 5 étoiles4/5 (1)

- John Deere Diesel GensetDocument2 pagesJohn Deere Diesel Gensetnanocycle0% (1)

- B767 200-300 BOOK 24 101 - Electrical PowerDocument34 pagesB767 200-300 BOOK 24 101 - Electrical PowerTarik Benzineb100% (1)

- Tiger LM 60HC: 355-375 WattDocument2 pagesTiger LM 60HC: 355-375 WattmoonridergPas encore d'évaluation

- Jinko245w T JKMS245P 60 Poly Vico Export Solar EnergyDocument2 pagesJinko245w T JKMS245P 60 Poly Vico Export Solar EnergySamuel JACOBBOPas encore d'évaluation

- JKM355 375M 60HLM (V) F1 enDocument2 pagesJKM355 375M 60HLM (V) F1 enEn BunthongPas encore d'évaluation

- Specification of Branch Connector (Y)Document5 pagesSpecification of Branch Connector (Y)Kalyanaraman RamakrishnanPas encore d'évaluation

- Type SBT Load Cell: Product Description Key FeaturesDocument2 pagesType SBT Load Cell: Product Description Key FeaturesKelly FosterPas encore d'évaluation

- DATA SHEET 182-M772BH530-550WWWB-2274x1134Document2 pagesDATA SHEET 182-M772BH530-550WWWB-2274x1134D SBPas encore d'évaluation

- MV Cable TerminationDocument16 pagesMV Cable TerminationsulemankhalidPas encore d'évaluation

- Hengtong Cable AustraliaDocument20 pagesHengtong Cable Australianarinder kumarPas encore d'évaluation

- Rennergy LLC solar module sales and specificationsDocument2 pagesRennergy LLC solar module sales and specificationsHêrnæn TæpîäPas encore d'évaluation

- 642C PDFDocument2 pages642C PDFGustavo CelyPas encore d'évaluation

- Jinko 400Document2 pagesJinko 400kamlesh pardeshiPas encore d'évaluation

- 182-M760BH435-455WWWBDocument2 pages182-M760BH435-455WWWBRuben ValenciaPas encore d'évaluation

- ABS-/ESP-Sensor Cables: LEONI - Your Way To Be ConnectedDocument6 pagesABS-/ESP-Sensor Cables: LEONI - Your Way To Be ConnectedmichrohPas encore d'évaluation

- Cladding Web v21Document7 pagesCladding Web v21foo-hoat LimPas encore d'évaluation

- SRP (400 415) BMD Full Black HV - 182 - ENDocument2 pagesSRP (400 415) BMD Full Black HV - 182 - ENGem RPas encore d'évaluation

- Hyundai TDS 385-400 VG BFR ENDocument2 pagesHyundai TDS 385-400 VG BFR ENe_vendrellPas encore d'évaluation

- Made in Europe: Pid Free El Tested + 5WDocument2 pagesMade in Europe: Pid Free El Tested + 5WStefan TintilaPas encore d'évaluation

- jkm355 375n 6tl3 B f2.1 en Iec 2016Document2 pagesjkm355 375n 6tl3 B f2.1 en Iec 2016LucaPas encore d'évaluation

- Ficha Tecnica Panel Solar Jinko280WpDocument2 pagesFicha Tecnica Panel Solar Jinko280WpJair SaavedraPas encore d'évaluation

- Eaton 107186 BBA TP3 CU BAND en - 800ADocument2 pagesEaton 107186 BBA TP3 CU BAND en - 800AAleksandar SekuloskiPas encore d'évaluation

- Pc12 Datasheet enDocument3 pagesPc12 Datasheet enGabriel RodríguezPas encore d'évaluation

- BS 400-410 M10HB Eng 031121Document2 pagesBS 400-410 M10HB Eng 031121Gigi Laurentiu MocanuPas encore d'évaluation

- MB4B/MF/MF/3F-65 product specsDocument3 pagesMB4B/MF/MF/3F-65 product specsselvam kksPas encore d'évaluation

- TeroMatec Brochure enDocument12 pagesTeroMatec Brochure enjay_rajeshirkePas encore d'évaluation

- sb8 Datasheet enDocument3 pagessb8 Datasheet ensrinivas raghavanPas encore d'évaluation

- Tension Compression Load Cell Tension Compression Load Cell: Model 614Document3 pagesTension Compression Load Cell Tension Compression Load Cell: Model 614Juan Carlos BallinariPas encore d'évaluation

- Specification of DC Connector - MC4 TypeDocument4 pagesSpecification of DC Connector - MC4 TypeKalyanaraman RamakrishnanPas encore d'évaluation

- ZALUX Datasheet ACQUEX 030323Document2 pagesZALUX Datasheet ACQUEX 030323hamza.zouikriiPas encore d'évaluation

- Dr. Ayan Mukherjee WebinarDocument51 pagesDr. Ayan Mukherjee WebinarAYAN MUKHERJEEPas encore d'évaluation

- Nkt-06086 Katalog HochspannungsgarniturenDocument20 pagesNkt-06086 Katalog Hochspannungsgarniturenrjk941-1Pas encore d'évaluation

- WIDE SPAN STRUCTURE RELIABILITY ISSUESDocument19 pagesWIDE SPAN STRUCTURE RELIABILITY ISSUES20-062 Asep Didin SimamoraPas encore d'évaluation

- HYUNDAI M6 SHINGLED VI (72 SIZE) - EU and AustraliaDocument2 pagesHYUNDAI M6 SHINGLED VI (72 SIZE) - EU and AustraliaEL RINCON DEL CHISPAPas encore d'évaluation

- Memodo Zubehoer Enwitec Bat Breaker Big 250a DatasheetDocument4 pagesMemodo Zubehoer Enwitec Bat Breaker Big 250a DatasheetHapa MONtAGEPas encore d'évaluation

- AWCCA-48R32 Series: Moisture Sensitivity Level (MSL) - MSL 1Document2 pagesAWCCA-48R32 Series: Moisture Sensitivity Level (MSL) - MSL 1cbdk71Pas encore d'évaluation

- Somera Grand Ultima: 10% Higher Power OutputDocument2 pagesSomera Grand Ultima: 10% Higher Power OutputShimmy AntonyPas encore d'évaluation

- SM300W-30V Mono Crystalline Solar PanelDocument2 pagesSM300W-30V Mono Crystalline Solar PanelElkQuyquePas encore d'évaluation

- Tiger Pro 60HC: 440-460 WattDocument2 pagesTiger Pro 60HC: 440-460 WattCristian IancuPas encore d'évaluation

- Jinko 345Document2 pagesJinko 345nelson_grandePas encore d'évaluation

- Hyundai M6 Shingled VGBF - 25y 210901Document2 pagesHyundai M6 Shingled VGBF - 25y 210901subtirelu lucianPas encore d'évaluation

- M B3 BH /3F - 6 5/PSA4 - 1 5/19 DE Tri-Band Antenna Dual Polarization HPBWDocument3 pagesM B3 BH /3F - 6 5/PSA4 - 1 5/19 DE Tri-Band Antenna Dual Polarization HPBWselvam kksPas encore d'évaluation

- 2005 Structural Architecture of Wide Span Enclosures Uncertainties in Reliability Assesment PDFDocument17 pages2005 Structural Architecture of Wide Span Enclosures Uncertainties in Reliability Assesment PDFdamandadinoPas encore d'évaluation

- Nexans_Anti-Theft-Power-Cable-PVC-in...Document5 pagesNexans_Anti-Theft-Power-Cable-PVC-in...abdulkawi alasharyPas encore d'évaluation

- IBC MonoSol 315 VL5 - Data Sheet Global - EN PDFDocument2 pagesIBC MonoSol 315 VL5 - Data Sheet Global - EN PDFmilosgmilanovicPas encore d'évaluation

- Data Rack BusbarDocument32 pagesData Rack Busbarivano rovidaPas encore d'évaluation

- Cci ADocument2 pagesCci AGodfried SimonPas encore d'évaluation

- Materials Today: Proceedings: Divya Marelli, Singh S.K., Sateesh Nagari, Ram SubbiahDocument7 pagesMaterials Today: Proceedings: Divya Marelli, Singh S.K., Sateesh Nagari, Ram SubbiahGopinath GangadhariPas encore d'évaluation

- Documentation Technique Module BP3220T PDFDocument2 pagesDocumentation Technique Module BP3220T PDFTaoufik BaztaouiPas encore d'évaluation

- Aluminum Single-Point Load Cell Aluminum Single-Point Load CellDocument3 pagesAluminum Single-Point Load Cell Aluminum Single-Point Load CellMakhis RifaiPas encore d'évaluation

- Dielectric Properties of Materials: Basics of Measuring TheDocument34 pagesDielectric Properties of Materials: Basics of Measuring TheTapabrataPas encore d'évaluation

- AERIAL BUNCHED CABLESDocument1 pageAERIAL BUNCHED CABLESrobinknit2009Pas encore d'évaluation

- TP660P: 275W Solar Panel with 10-Year WarrantyDocument2 pagesTP660P: 275W Solar Panel with 10-Year WarrantyJose MarioPas encore d'évaluation

- Schunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFDocument2 pagesSchunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFMUHAMMAD ASYRAAF BIN ANUARPas encore d'évaluation

- Application of Metal Matrix Composite & Ceramic Matrix CompositeDocument5 pagesApplication of Metal Matrix Composite & Ceramic Matrix CompositeDzulkarnaen Mohd KamalPas encore d'évaluation

- Tiger Pro 60HC: 440-460 WattDocument2 pagesTiger Pro 60HC: 440-460 WattmoonridergPas encore d'évaluation

- Flintec_SB8Document2 pagesFlintec_SB8josuePas encore d'évaluation

- Model 355: Tedea-HuntleighDocument2 pagesModel 355: Tedea-HuntleighJuan Carlos BallinariPas encore d'évaluation

- Hyundai HiE S395 415 Modulo Fotovoltaico SchedaDocument2 pagesHyundai HiE S395 415 Modulo Fotovoltaico SchedaFederico De FranceschiPas encore d'évaluation

- Spherical Roller Bearings for Vibrating EquipmentDocument2 pagesSpherical Roller Bearings for Vibrating EquipmentRodrigo Jechéla Barrios100% (1)

- The Perfect Cylinder Program For Hydraulic SealsDocument2 pagesThe Perfect Cylinder Program For Hydraulic SealsRodrigo Jechéla BarriosPas encore d'évaluation

- Cat5952 PDFDocument12 pagesCat5952 PDFRodrigo Jechéla BarriosPas encore d'évaluation

- RFN 7012-In: Ringfeder Locking AssembliesDocument6 pagesRFN 7012-In: Ringfeder Locking AssembliesRodrigo Jechéla BarriosPas encore d'évaluation

- AddinolDocument18 pagesAddinolRodrigo Jechéla BarriosPas encore d'évaluation

- 15 TollokDocument4 pages15 TollokRodrigo Jechéla BarriosPas encore d'évaluation

- NSK Cat E728g 1Document6 pagesNSK Cat E728g 1shukhanPas encore d'évaluation

- PDFDocument1 pagePDFRodrigo Jechéla BarriosPas encore d'évaluation

- Lubricant Application - Grease Volumes and Frequencies - TLT Article - April09Document76 pagesLubricant Application - Grease Volumes and Frequencies - TLT Article - April09Rodrigo Jechéla BarriosPas encore d'évaluation

- Beka LubricadoresDocument2 pagesBeka LubricadoresRodrigo Jechéla BarriosPas encore d'évaluation

- Optibelt TT - Frequency Tension TesterDocument2 pagesOptibelt TT - Frequency Tension TesterRodrigo Jechéla BarriosPas encore d'évaluation

- KUKKODocument1 pageKUKKORodrigo Jechéla BarriosPas encore d'évaluation

- FYH ZlockDocument2 pagesFYH ZlockRodrigo Jechéla BarriosPas encore d'évaluation

- Tabla Compatibilidad Quimica RetenedoresDocument36 pagesTabla Compatibilidad Quimica RetenedoresadolfoadolfoavilaPas encore d'évaluation

- Bearing Load CalculationDocument9 pagesBearing Load CalculationwahyoesoemantriPas encore d'évaluation

- PARKERDocument141 pagesPARKERRodrigo Jechéla BarriosPas encore d'évaluation

- PBB de enDocument8 pagesPBB de enRodrigo Jechéla BarriosPas encore d'évaluation

- KUKKODocument1 pageKUKKORodrigo Jechéla BarriosPas encore d'évaluation

- Beka LubricadoresDocument2 pagesBeka LubricadoresRodrigo Jechéla BarriosPas encore d'évaluation

- Sensors: Low-Cost Oil Quality Sensor Based On Changes in Complex PermittivityDocument16 pagesSensors: Low-Cost Oil Quality Sensor Based On Changes in Complex PermittivityRodrigo Jechéla BarriosPas encore d'évaluation

- Bolas NSKDocument16 pagesBolas NSKRodrigo Jechéla BarriosPas encore d'évaluation

- GLXXMobil SHC Gear SeriesDocument8 pagesGLXXMobil SHC Gear SeriesMarcelo GuarachiPas encore d'évaluation

- Flyer - Rodac Descase Eng Drum TopperDocument5 pagesFlyer - Rodac Descase Eng Drum TopperRodrigo Jechéla BarriosPas encore d'évaluation

- Bearing Load CalculationDocument9 pagesBearing Load CalculationwahyoesoemantriPas encore d'évaluation

- 15 TollokDocument4 pages15 TollokRodrigo Jechéla BarriosPas encore d'évaluation

- Tpi 252 de en Lubricators PDFDocument94 pagesTpi 252 de en Lubricators PDFRodrigo Jechéla BarriosPas encore d'évaluation

- PT5 007 FaqDocument26 pagesPT5 007 FaqRodrigo Jechéla BarriosPas encore d'évaluation

- 15 TollokDocument4 pages15 TollokRodrigo Jechéla BarriosPas encore d'évaluation

- Lithium Ion CellDocument34 pagesLithium Ion Cell24RAYANPas encore d'évaluation

- Conversor DualDocument22 pagesConversor DualAndré CarlosPas encore d'évaluation

- Frenic-Ehvac (F2e) User - S ManualDocument631 pagesFrenic-Ehvac (F2e) User - S ManualkarunPas encore d'évaluation

- Mp-In001 - En-P Servomoteur ReférenceDocument26 pagesMp-In001 - En-P Servomoteur ReférenceAbdou DEPas encore d'évaluation

- System Diagram: Body Electrical - Air Conditioner BE-31Document1 pageSystem Diagram: Body Electrical - Air Conditioner BE-31Fix Gps GarminPas encore d'évaluation

- 100 AgmDocument6 pages100 AgmDragos StoianPas encore d'évaluation

- WindingsDocument2 pagesWindingsCarlo Jay VizcarraPas encore d'évaluation

- Voltage Dividers and Current DividersDocument24 pagesVoltage Dividers and Current DividersRon RexPas encore d'évaluation

- Datasheet M 2000ia 2300Document1 pageDatasheet M 2000ia 2300carlosdr.05.09.1993Pas encore d'évaluation

- 2016/01/13 Service Tools: The Following Service Tools Should Be Used To Aid in Troubleshooting The Electrical SystemDocument3 pages2016/01/13 Service Tools: The Following Service Tools Should Be Used To Aid in Troubleshooting The Electrical SystemLuis Lossio GuayamaPas encore d'évaluation

- System OverviewDocument28 pagesSystem Overviewdylan_dearing@hotmail.comPas encore d'évaluation

- Clap Sensor Project ReportDocument5 pagesClap Sensor Project Reportnrqm50% (2)

- Pspice TutorialDocument25 pagesPspice Tutorialamar7716dumPas encore d'évaluation

- Charging System PDFDocument19 pagesCharging System PDFSSEVERAiTJUGAPas encore d'évaluation

- DSX PDFDocument76 pagesDSX PDFkat1014Pas encore d'évaluation

- Republic Act R.A 7832Document7 pagesRepublic Act R.A 7832rhealuceromPas encore d'évaluation

- Reviewer in Tle 8 For 2nd Quarter ExaminationDocument19 pagesReviewer in Tle 8 For 2nd Quarter ExaminationJaeda EuclidPas encore d'évaluation

- 7483 - 4 Bit Adder PDFDocument5 pages7483 - 4 Bit Adder PDFSurapaneni Varun KarthikPas encore d'évaluation

- Smart Security SystemDocument8 pagesSmart Security SystemNeeraj Chowdary BinnuPas encore d'évaluation

- R6013e MVTRDocument6 pagesR6013e MVTRlucnhamdaidon8426Pas encore d'évaluation

- Arsenic For High Capacity Lithium and Sodium-Ion BatteriesDocument11 pagesArsenic For High Capacity Lithium and Sodium-Ion BatteriesLIZANA QUISPE ELMER ARSENIOPas encore d'évaluation

- Tesla Hairpin Circuit Radiant Energy DiscoveryDocument3 pagesTesla Hairpin Circuit Radiant Energy DiscoveryShane Halaska0% (1)

- Technical Training Calendar 20220122Document1 pageTechnical Training Calendar 20220122Lawson Shumirai Sango100% (1)

- Wps Register Last Updated May 12Document1 pageWps Register Last Updated May 12Abdullah Al JubayerPas encore d'évaluation

- DC DC ConverterDocument5 pagesDC DC Converterckean_ngPas encore d'évaluation

- Activity Sheet No. 3 - Current Resistance EMFDocument5 pagesActivity Sheet No. 3 - Current Resistance EMFJoena EmejasPas encore d'évaluation

- Solar FenceDocument31 pagesSolar FenceSARIKAPas encore d'évaluation

- Training ReportDocument114 pagesTraining ReportMuhammad JahenzebPas encore d'évaluation