Académique Documents

Professionnel Documents

Culture Documents

Jis

Transféré par

Andre YosiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Jis

Transféré par

Andre YosiDroits d'auteur :

Formats disponibles

JIS Standard VCON

JIS The four types of product conforming to the JIS

Standard can be provided according to the needs

of our customers.

Chemical composition of Vcon

Chemical constituents %

Type code Mn

C Si Mn P S C+ 6

SD295A _ _ _ _

0.050 or below 0.050 or below

SD345 0.27or below 0.55 or below 1.60 or below 0.040 or below 0.040 or below 0.50 or below

SD390 0.29 or below 0.55 or below 1.80 or below 0.040 or below 0.040 or below 0.55 or below

SD490 0.32 or below 0.55 or below 1.80 or below 0.040 or below 0.040 or below 0.60 or below

Mechanical property of Vcon

Yield point or Tensile Elongation Bending Bendability

Type code 0.2% proof stress strength Tension test specimen

(2) % angle Inner radius

N / mm3 N / mm3

Equivalent to No.2 test piece 16 or above D16 and below 1.5 times larger

than the nominal

(specified in JIS Z2201) diameter

SD295A 295 or above 440∼600 180

Equivalent to No. 14A test Above D16 2 times larger

17 or above than the nominal

piece(specified in JIS Z2201) diameter

Equivalent to No.2 test piece 18 or above D16 and below 1.5 times larger

than the nominal

(specified in JIS Z2201) diameter

345-440 490 or above 180

SD345 2 times larger

Equivalent to No. 14A test Above D16,

19 or above and at or than the nominal

piece(specified in JIS Z2201) diameter

below D38

Equivalent to No.2 test piece 2.5 times larger

16 or above than the nominal

560 or above (specified in JIS Z2201) diameter

SD390 390-510 180

Equivalent to No. 14A test

piece(specified in JIS Z2201) 17 or above

Equivalent to No.2 test piece 12 or above D25 and below 2.5 times larger

(specified in JIS Z2201) than the nominal

diameter

SD490 490-625 620 or above 90

Equivalent to No. 14A test Above D25 3 times larger

piece(specified in JIS Z2201) 13 or above than the nominal

diameter

If the bar designation is over D32: for every increase of the bar designation by 3, 2% should be subtracted from

each elongation value in the list. However, the value of subtraction should not exceed 4%.

Standard dimensions & mass of Vcon products and tolerance limits of knots

Nominal Nominal Nominal cross mass Maximum average Knot height Maximum value of

Bar diameter perimeter -sectional area Unit

kg/m

spacing of knots sum of knot gaps

designation (d) mm (I) cm (S) cm3 Minimum Maximum

mm

mm mm mm

D 10 9.53 3.0 0.7133 0.560 6.7 0.4 0.8 7.5

D 13 12.7 4.0 1.267 0.995 8.9 0.5 1.0 10.0

D 16 15.9 5.0 1.986 1.56 11.1 0.7 1.4 12.5

D 19 19.1 6.0 2.865 2.25 13.4 1.0 2.0 15.0

D 22 22.2 7.0 3.871 3.04 15.5 1.1 2.2 17.5

D 25 25.4 8.0 5.067 3.98 17.8 1.3 2.6 20.0

D 29 28.6 9.0 6.424 5.04 20.0 1.4 2.8 22.5

D 32 31.8 10.0 7.942 6.23 22.3 1.6 3.2 25.0

D 35 34.9 11.0 9.566 7.51 24.4 1.7 3.4 27.5

D 38 38.1 12.0 11.40 8.95 26.7 1.9 3.8 30.0

Mass tolerance of Vcon-

per piece/set Length tolerance of Vcon Markings on each Vcon

Size Tolerance Tolerance Length Tolerance

per piece per set SD295A

D10 or above, 7m or +40mm

and below D16 6% 5% below 0

(bar designation)

For every increase of SD345

D16 or above, length by 1m (or a fraction

and below D29 5% 4% less than 1m), 5mm should

(bar designation) Over 7m be added to the upper

tolerance value. However,

D29 or above the value should not SD390

4% 3.5%

(bar designation) exceed 120 mm.

Rib Knot SD490

Width of rib

Contact us

Spacing between knots Knot height

Vous aimerez peut-être aussi

- Standard Test Tensile DimensiDocument5 pagesStandard Test Tensile DimensiQA LAB ISMPas encore d'évaluation

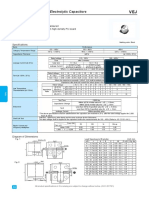

- Aluminum Electrolytic Capacitors: SpecificationsDocument3 pagesAluminum Electrolytic Capacitors: Specificationsویرا محاسب پاسارگادPas encore d'évaluation

- LGN 2C102Document4 pagesLGN 2C102Milton SobrevillaPas encore d'évaluation

- Gs01f06a00 50eDocument8 pagesGs01f06a00 50eDaniloPas encore d'évaluation

- E GG PDFDocument3 pagesE GG PDFqwePas encore d'évaluation

- SMD Aluminum Electrolytic Capacitors VEJ SeriesDocument2 pagesSMD Aluminum Electrolytic Capacitors VEJ SeriesJános JuhászPas encore d'évaluation

- Cummins G12 Diesel Fuel Oil Use in Aggreko EnginesDocument2 pagesCummins G12 Diesel Fuel Oil Use in Aggreko EnginesAhmed AbdullahPas encore d'évaluation

- Rebar SpecificationsDocument5 pagesRebar SpecificationsJeffrey James AvenidoPas encore d'évaluation

- Rebar SpecificationsDocument5 pagesRebar SpecificationsJeffrey James AvenidoPas encore d'évaluation

- PNS Rebars PDFDocument4 pagesPNS Rebars PDFAnthony AngelesPas encore d'évaluation

- Fig - 34 TI P064 01 ENDocument4 pagesFig - 34 TI P064 01 ENVincenzo SenatorePas encore d'évaluation

- Surface Mount Type TPB: Conductive Polymer Tantalum Solid CapacitorsDocument1 pageSurface Mount Type TPB: Conductive Polymer Tantalum Solid CapacitorsTestronicpartsPas encore d'évaluation

- Dep7 SG Iron Excess Pressure Valve: DescriptionDocument11 pagesDep7 SG Iron Excess Pressure Valve: Descriptiontony smithPas encore d'évaluation

- Applications: DCS200 SeriesDocument3 pagesApplications: DCS200 SeriesAgus YulfizarPas encore d'évaluation

- HCGF5ASERIESDocument3 pagesHCGF5ASERIESPalmPas encore d'évaluation

- "ZNR" Transient/Surge Absorbers: Recommended Applications FeaturesDocument20 pages"ZNR" Transient/Surge Absorbers: Recommended Applications FeaturesKodok NgorekPas encore d'évaluation

- Tolerances and Fits: Min MaxDocument24 pagesTolerances and Fits: Min MaxIrfan MuhammadPas encore d'évaluation

- "ZNR" Transient/Surge Absorbers (Type D)Document4 pages"ZNR" Transient/Surge Absorbers (Type D)VeronicaGonzalezPas encore d'évaluation

- 5 Pipe Specification Api5lDocument1 page5 Pipe Specification Api5lMuneeb YounisPas encore d'évaluation

- Capxon (Radial) 2011 FL SeriesDocument2 pagesCapxon (Radial) 2011 FL Serieshes545Pas encore d'évaluation

- Safety Shut-Off Valve RMG 720Document8 pagesSafety Shut-Off Valve RMG 720dianudin safarudinPas encore d'évaluation

- Gfps System Specification Sygef Standard PVDF enDocument27 pagesGfps System Specification Sygef Standard PVDF enGerardo Leon RoblesPas encore d'évaluation

- Iso 65 PDFDocument1 pageIso 65 PDFJustin ReyesPas encore d'évaluation

- Z95X I5 R0 EnglishDocument1 pageZ95X I5 R0 English阿康Pas encore d'évaluation

- G150 09 2010 PDFDocument4 pagesG150 09 2010 PDFСергей КолесниковPas encore d'évaluation

- Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 en PDFDocument4 pagesData Sheet 2136 Docol 420LA 2016-11-25 317 371857150 en PDFchristos032Pas encore d'évaluation

- SSAB Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 enDocument4 pagesSSAB Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 enchristos032Pas encore d'évaluation

- Capsun (Radial Thru-Hole) SL4 SeriesDocument2 pagesCapsun (Radial Thru-Hole) SL4 Serieshes545Pas encore d'évaluation

- Aluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsDocument3 pagesAluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsTadilakshmikiranPas encore d'évaluation

- Actaris Gas Regulators SERusDocument2 pagesActaris Gas Regulators SERushendrik muellerPas encore d'évaluation

- Capsun (Radial Thru-Hole) SWR SeriesDocument3 pagesCapsun (Radial Thru-Hole) SWR Serieshes545Pas encore d'évaluation

- Varistores PDFDocument20 pagesVaristores PDFDaniel SantosPas encore d'évaluation

- Pressure Switch CQ21Document7 pagesPressure Switch CQ21محمد امين التشغيل الآليPas encore d'évaluation

- General ToleranceDocument13 pagesGeneral TolerancekeozturkPas encore d'évaluation

- Capxon (Radial) 2011 GL SeriesDocument3 pagesCapxon (Radial) 2011 GL Serieshes545Pas encore d'évaluation

- Vishay Siliconix: Product SummaryDocument5 pagesVishay Siliconix: Product SummaryytnatePas encore d'évaluation

- Screw Terminal Type, 105°C Standard: LNR LNUDocument6 pagesScrew Terminal Type, 105°C Standard: LNR LNUpo truongPas encore d'évaluation

- Fig - 33 TI S60 03 ENDocument5 pagesFig - 33 TI S60 03 ENAditomo PutrantoPas encore d'évaluation

- GP 11127Document5 pagesGP 11127SHivaprasad APITPas encore d'évaluation

- POSCO HighStrength Rebar PDFDocument19 pagesPOSCO HighStrength Rebar PDFLe Phan TaPas encore d'évaluation

- Japan Standard - 1320141511Document1 pageJapan Standard - 1320141511virtual drumPas encore d'évaluation

- 6TPF330M9LDocument2 pages6TPF330M9Lnguyen thuanPas encore d'évaluation

- Marco Material Datasheet V1000Document2 pagesMarco Material Datasheet V1000FinPas encore d'évaluation

- Silicone Rubber Sheet (General Purpose, Solid)Document2 pagesSilicone Rubber Sheet (General Purpose, Solid)MohamedPas encore d'évaluation

- 12 Samss 018Document4 pages12 Samss 018Dhaval PatelPas encore d'évaluation

- Walter Perform Line 2016 en 1Document44 pagesWalter Perform Line 2016 en 1Taner AkkaşPas encore d'évaluation

- CFM Instrument - Liquid Turbine Flowmeter User ManualDocument11 pagesCFM Instrument - Liquid Turbine Flowmeter User ManualRubens MarquesPas encore d'évaluation

- NIC Components NSTLW SeriesDocument2 pagesNIC Components NSTLW SeriesNICCompPas encore d'évaluation

- Process Measurement and Control: Enraf Small Volume Prover Specifications Worksheet Rev VDocument6 pagesProcess Measurement and Control: Enraf Small Volume Prover Specifications Worksheet Rev VadjiPas encore d'évaluation

- Shin Nan Catalogue PDFDocument38 pagesShin Nan Catalogue PDFElan ChezhiyanPas encore d'évaluation

- "ZNR" Transient/Surge Absorbers (Type D)Document4 pages"ZNR" Transient/Surge Absorbers (Type D)Eduard BusePas encore d'évaluation

- Capsun (Radial Thru-Hole) SWT SeriesDocument2 pagesCapsun (Radial Thru-Hole) SWT Serieshes545Pas encore d'évaluation

- KMHN E-2509057Document4 pagesKMHN E-2509057Rodrigo BenitezPas encore d'évaluation

- DatasheetDocument2 pagesDatasheetLima LogictelPas encore d'évaluation

- Virgin PTFE Datasheet: Property Method Units ValuesDocument2 pagesVirgin PTFE Datasheet: Property Method Units ValuesMuhammad Ejaz QureshiPas encore d'évaluation

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazPas encore d'évaluation

- AluminizedDocument4 pagesAluminizedmarkengineerPas encore d'évaluation

- Seamless Circular Tubes of Non-Alloy Steels With Special Quality RequirementsDocument2 pagesSeamless Circular Tubes of Non-Alloy Steels With Special Quality RequirementsWiryanto DewobrotoPas encore d'évaluation

- KompositDocument2 pagesKompositAndre YosiPas encore d'évaluation

- Linkbelt 348 HYLAB 5 Lattice Crawler Cranes BrochureDocument46 pagesLinkbelt 348 HYLAB 5 Lattice Crawler Cranes BrochureAndre YosiPas encore d'évaluation

- Complexometric Reactions and TitrationDocument6 pagesComplexometric Reactions and TitrationAndre YosiPas encore d'évaluation

- MATLAB Command Window A - YDocument1 pageMATLAB Command Window A - YAndre YosiPas encore d'évaluation

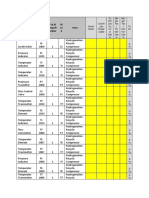

- Instrument List ChackDocument30 pagesInstrument List ChackAndre YosiPas encore d'évaluation

- Welding Metallurgy of Nickel Steel Andre Yosi 1606842814: Wu Et Al. (2015) Used CODocument5 pagesWelding Metallurgy of Nickel Steel Andre Yosi 1606842814: Wu Et Al. (2015) Used COAndre YosiPas encore d'évaluation

- Aluminum Matrix CompositesDocument16 pagesAluminum Matrix Compositesntsdharma100% (1)

- Statik H2O2 Yang Dibuka Rev 1Document2 pagesStatik H2O2 Yang Dibuka Rev 1Andre YosiPas encore d'évaluation

- Pipe Schedule PDFDocument1 pagePipe Schedule PDFSrinivasan SeenuPas encore d'évaluation

- Kurva PolarisasiDocument1 pageKurva PolarisasiAndre YosiPas encore d'évaluation

- SAP Advanced MaterialsDocument4 pagesSAP Advanced MaterialsAndre YosiPas encore d'évaluation

- Journal of Alloys and CompoundsDocument6 pagesJournal of Alloys and CompoundsAndre YosiPas encore d'évaluation

- Pengujian Mekanik PDFDocument47 pagesPengujian Mekanik PDFAndre YosiPas encore d'évaluation

- Installation & Operation Manual TurbineDocument30 pagesInstallation & Operation Manual TurbineAndre YosiPas encore d'évaluation

- Hot Explosive Pressing: of High Strength and Superhard MaterialsDocument21 pagesHot Explosive Pressing: of High Strength and Superhard MaterialsAndre YosiPas encore d'évaluation

- CPE SAUNDERSIDV60PG BU EN A4 2015 - 09 - 09 Web PDFDocument60 pagesCPE SAUNDERSIDV60PG BU EN A4 2015 - 09 - 09 Web PDFSafePas encore d'évaluation

- Propylene PolymersDocument72 pagesPropylene PolymersAndre Yosi100% (1)

- Reliability Centered Maintenance White PaperDocument7 pagesReliability Centered Maintenance White PaperRoman AhmadPas encore d'évaluation

- Installation & Operation Manual TurbineDocument30 pagesInstallation & Operation Manual TurbineAndre YosiPas encore d'évaluation

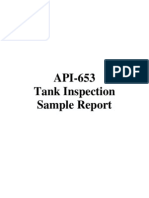

- API-653 Tank Inspection Sample ReportDocument19 pagesAPI-653 Tank Inspection Sample Reportツ ツ93% (15)

- Super AlloysDocument17 pagesSuper AlloysMohamed WahidPas encore d'évaluation

- Far Leghe Al CromoDocument1 pageFar Leghe Al CromoAndre YosiPas encore d'évaluation

- Ni Base SuperalloysDocument21 pagesNi Base SuperalloysGelos SpicoPas encore d'évaluation

- Plano Electrico PC130-8Document9 pagesPlano Electrico PC130-8jon fredyPas encore d'évaluation

- TM - Chapter 1 Exercises PDFDocument6 pagesTM - Chapter 1 Exercises PDFVõ Văn VũPas encore d'évaluation

- Non-returns-DampersDocument1 pageNon-returns-DampersProject enghvacPas encore d'évaluation

- Introduction To Offshore Petroleum Production SystemDocument55 pagesIntroduction To Offshore Petroleum Production SystemJoaoCOS100% (1)

- Justification Document For The Chilled Water Piping InstallationDocument7 pagesJustification Document For The Chilled Water Piping InstallationFrancis Mayowa EzekielPas encore d'évaluation

- 8.3 Factors Affecting RXN RateDocument36 pages8.3 Factors Affecting RXN RateNur AleyaPas encore d'évaluation

- General Biology Laboratory ModuleDocument6 pagesGeneral Biology Laboratory ModuleEunice Moureen MaravillaPas encore d'évaluation

- Bronze c54400 SpecificationsDocument3 pagesBronze c54400 SpecificationsRam Parimalam100% (1)

- ActuatorsDocument9 pagesActuatorsAvinash BaldiPas encore d'évaluation

- SP 1211Document87 pagesSP 1211Anoop gokhalePas encore d'évaluation

- Kinetics 3.2. Surfaces and InterfacesDocument43 pagesKinetics 3.2. Surfaces and InterfacesCường Nguyễn ĐứcPas encore d'évaluation

- Environmental Science 7 3 QuarterDocument5 pagesEnvironmental Science 7 3 QuarterMichael Angelo ConuiPas encore d'évaluation

- Wave Phenomena in A Double Plasma Experiment: Fortgeschrittenen-Praktikum Der TUMDocument11 pagesWave Phenomena in A Double Plasma Experiment: Fortgeschrittenen-Praktikum Der TUMsaurabhidPas encore d'évaluation

- chapter 4 (updated materials for final exam) -محولDocument17 pageschapter 4 (updated materials for final exam) -محولمروان الشباليPas encore d'évaluation

- Airflow Measuring With Piezometer RingDocument4 pagesAirflow Measuring With Piezometer RingcassindromePas encore d'évaluation

- 3-15-6 Pressure Vessels Austenitic SteelDocument24 pages3-15-6 Pressure Vessels Austenitic SteelJaime CastilloPas encore d'évaluation

- Torsion in Beams and How To Eliminate Torsion in EtabsDocument2 pagesTorsion in Beams and How To Eliminate Torsion in Etabsabdul khaderPas encore d'évaluation

- CD Optical Block AssembliesDocument2 pagesCD Optical Block AssembliesRayner MihailovPas encore d'évaluation

- OceanographyDocument8 pagesOceanographyAyush PandeyPas encore d'évaluation

- Content RCC Fanella PDFDocument4 pagesContent RCC Fanella PDFJulio Cesar ValdiviesoPas encore d'évaluation

- Grade 10 March 2024 Term 1 Physical Sciences TestDocument11 pagesGrade 10 March 2024 Term 1 Physical Sciences TestTererai Lalelani Masikati HovePas encore d'évaluation

- Blowing AgentDocument12 pagesBlowing AgentHimanshu PainulyPas encore d'évaluation

- EPRI TR 1004019 Guide For Develping and Managing An IRT Program PDFDocument108 pagesEPRI TR 1004019 Guide For Develping and Managing An IRT Program PDFLuis GonzalezPas encore d'évaluation

- Module 1 Quiz AaDocument8 pagesModule 1 Quiz AaGUILLER BELENPas encore d'évaluation

- Cooling Tower Data Sheet REV-00Document12 pagesCooling Tower Data Sheet REV-00Anonymous ZnuMEWN1Pas encore d'évaluation

- Design A Safe, In-Compliance Relief ValveDocument5 pagesDesign A Safe, In-Compliance Relief Valvehans nijmeijerPas encore d'évaluation

- Astm D 2171-2018Document10 pagesAstm D 2171-2018Mohammed AliPas encore d'évaluation

- The Modelling and Design of Scale Inhibitor Squeeze Treatments PDFDocument14 pagesThe Modelling and Design of Scale Inhibitor Squeeze Treatments PDFLaura Natalia SalcedoPas encore d'évaluation

- CENG 197 - CE Competency Appraisal II Problem Set 3b Fluid Statics 2 - Hydrostatic Forces On Plane and Curved SurfacesDocument13 pagesCENG 197 - CE Competency Appraisal II Problem Set 3b Fluid Statics 2 - Hydrostatic Forces On Plane and Curved SurfacesApple AterradoPas encore d'évaluation