Académique Documents

Professionnel Documents

Culture Documents

Control Philosophy

Transféré par

tsplinstDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Control Philosophy

Transféré par

tsplinstDroits d'auteur :

Formats disponibles

Date:16.5.

09

CONTROL & INTERLOCK

PHILOSOPHY for RECOVERY BOILER

Sheet 2 of 13

INDEX

Sl. Nr. Content Page Nrs. Remarks

1 Introduction & Control Summary 3-4

2 Operation Procedure 4-5

3 Description of Closed Loop Controls 5-9

4 Safety Interlocks 9-11

5 Description of Open Loop Controls 11-12

6 Reference Drawings & Documents 13-13

PDF created with pdfFactory trial version www.pdffactory.com

Date:16.5.09

CONTROL & INTERLOCK

PHILOSOPHY for RECOVERY BOILER

Sheet 3 of 13

1). Introduction & control summary :

The Recovery Boiler recovers heat from the exhaust gases of Rotary

Kiln with dust particles of Zinc carbonate ore and produces 15 tons of steam at

a pressure of 12 bar, g and Satuarted temperature of 192°C at the MSSV

outlet. Waste heat is available from the Rotary Kiln at a temperature of 350°C.

The hot gas pass through the Recovery Boiler with evaporator bundles. The

heat is transfered to the boiler water by the heating surfaces. All heating

surfaces are connected to the steam drum by downcomer and riser pipes.

Common down comer is connected to evaporator bundles and membrane

walls. The seperation of saturated steam takes place in the steam drum at a

pressure of approx. 12 bar, g & Temperature of 192°C

Boiler Feed Water is fed into the steam drum through BFW Pump from

Feed water tank. This boiler feed water of tempearture 105°C and a pressure of

20.5 bar, g. The Recovery Boiler is provided with the necessary instruments

and controls to ensure safe operation of the system. All the controls and

indications are implemented in the DCS system provided by Client. All the

requisite field instrumentation as per scope is supplied by TSPL.

For controlling boiler water quality, Dosing systems are used. Each

system consists of mixing cum storage tank with agitator, dosing pumps (one

running & one standby) along with necessary valves, instruments and local

starter panel for operation. Tri-sodium phosphate is injected into the boiler

steam drum to correct conductivity & pH of boiler water and Sodium Sulphate is

injected into the feed water tank to correct the boiler water alkalinity.

The feed water storage tank along with deaerator is used for removal of

oxygen in feed water and used as storage tank from where BFW pump delivers

water to the boiler. The water level in feed water storage tank is controlled by

controlling the DM water flow through a control valve in DM water line. In case

PDF created with pdfFactory trial version www.pdffactory.com

Vous aimerez peut-être aussi

- Process Control NarrativeDocument28 pagesProcess Control NarrativeGeetha_jagadish30100% (3)

- Process Operation and Control PhilosophyDocument13 pagesProcess Operation and Control PhilosophyKarem Jeanette Saenz Bernal100% (4)

- 02 0186 06 PB 005 A Control Philosophy Rev 0 FaridhDocument40 pages02 0186 06 PB 005 A Control Philosophy Rev 0 FaridhVijay Rajaindran100% (1)

- 3103 - Level TransmitterDocument10 pages3103 - Level Transmittersudhiryadav99Pas encore d'évaluation

- Control Philosophy - Rev 5Document113 pagesControl Philosophy - Rev 5Anish Kumar Dhiraj100% (2)

- Control Philosophy REVBDocument73 pagesControl Philosophy REVBrlowe55100% (3)

- CH2MHILL - Process Control Philosohpy - Pinon Ridge ProjectDocument23 pagesCH2MHILL - Process Control Philosohpy - Pinon Ridge ProjectyyuliusPas encore d'évaluation

- C Ot 25 001 - Rev B - Process Description Control PhilosophyDocument50 pagesC Ot 25 001 - Rev B - Process Description Control PhilosophyAngel CuyaPas encore d'évaluation

- Control Philosophy - UpdatedDocument13 pagesControl Philosophy - UpdatedAlvin SmithPas encore d'évaluation

- Process Control PhilosophyDocument91 pagesProcess Control PhilosophyFR75% (4)

- Control Philosophy - Rev 5Document113 pagesControl Philosophy - Rev 5Rakesh Karan SinghPas encore d'évaluation

- Spare Part ListDocument23 pagesSpare Part ListCarloAugentiPas encore d'évaluation

- Control Philosophy PDFDocument39 pagesControl Philosophy PDFverzehre100% (3)

- Technical Bid Evaluation Sheet For Fuel Gas ScrubberDocument3 pagesTechnical Bid Evaluation Sheet For Fuel Gas ScrubberSiva baalanPas encore d'évaluation

- Process Control Narrative SampleDocument12 pagesProcess Control Narrative Samplefri_13th100% (2)

- Process Control PhilosophyDocument36 pagesProcess Control PhilosophyCarlos Plasencia Pozo0% (1)

- HP Fuel Gas SystemDocument8 pagesHP Fuel Gas SystemAnonymous QSfDsVxjZPas encore d'évaluation

- Process Control PhilosophyDocument30 pagesProcess Control Philosophyahmad santoso100% (2)

- Safeguarding PhilosophyDocument47 pagesSafeguarding PhilosophyAnonymous QSfDsVxjZ100% (8)

- Control Philosophy of Pumps.Document5 pagesControl Philosophy of Pumps.Dashrath SinghPas encore d'évaluation

- Process Engineering StandardsDocument8 pagesProcess Engineering Standardssal143100% (1)

- List of Instrumentation Project Engineering DocumentsDocument19 pagesList of Instrumentation Project Engineering DocumentsVraja KisoriPas encore d'évaluation

- 6.19 Process Isolation System Design Philosophy PDFDocument6 pages6.19 Process Isolation System Design Philosophy PDFdamanpb3633Pas encore d'évaluation

- Pressure Safety Valve DatasheetDocument1 pagePressure Safety Valve DatasheetAlvin Smith100% (5)

- Operation Control PhilosophyDocument71 pagesOperation Control PhilosophySiva Sankari67% (3)

- Data SheetDocument12 pagesData SheetHimawan Sigit NugrohoPas encore d'évaluation

- IO / Interlock List FormatDocument6 pagesIO / Interlock List FormatMahesh Chaudhari0% (1)

- Line Sizing With Api RP 14E Sizing For Liquid LinesDocument5 pagesLine Sizing With Api RP 14E Sizing For Liquid LinesArief Rahman DhuhriPas encore d'évaluation

- Control PhilosophyDocument132 pagesControl PhilosophyTudor Taranu100% (1)

- Control Philosophy Rev 5 PDFDocument113 pagesControl Philosophy Rev 5 PDFpawerxlPas encore d'évaluation

- Process Description &: Control PhilosophyDocument12 pagesProcess Description &: Control PhilosophyHendiko PanggabeanPas encore d'évaluation

- RotameterDocument9 pagesRotameterSimbu Arasan100% (1)

- Instrument Level Sketches PDFDocument8 pagesInstrument Level Sketches PDFcherif yahyaoui67% (3)

- Data Sheet For PSVDocument9 pagesData Sheet For PSVashams492Pas encore d'évaluation

- Pug MillDocument4 pagesPug Millprashant mishraPas encore d'évaluation

- P&IDDocument3 pagesP&IDSurendra Kumar Suman100% (1)

- Hyoffwind Power To Gas End ReportDocument68 pagesHyoffwind Power To Gas End Reportapi-267204600Pas encore d'évaluation

- HAZOP ON Sulfuric Acid Transfer To Storage TankDocument6 pagesHAZOP ON Sulfuric Acid Transfer To Storage Tankram0% (1)

- Operating & Control PhilosophyDocument16 pagesOperating & Control PhilosophyPrasadPas encore d'évaluation

- Intrument Air ConsumptionDocument4 pagesIntrument Air ConsumptionyogacruisePas encore d'évaluation

- Instrumentation GoodDocument28 pagesInstrumentation GoodAyman SaberPas encore d'évaluation

- DatasheetDocument17 pagesDatasheetHimawan Sigit NugrohoPas encore d'évaluation

- PP Aaa PP1 148Document14 pagesPP Aaa PP1 148Rabah AmidiPas encore d'évaluation

- Process Control Philosophy Rev A PDFDocument48 pagesProcess Control Philosophy Rev A PDFsswahyudi100% (2)

- Control NarrativeDocument19 pagesControl NarrativeVilla VallejosPas encore d'évaluation

- 몽중1 P&ID 131227-제본파일 (링크) -MARK UP (수정3) PDFDocument303 pages몽중1 P&ID 131227-제본파일 (링크) -MARK UP (수정3) PDFLê Thành Chung100% (1)

- 01 - Utility Consumption PDFDocument6 pages01 - Utility Consumption PDFVinod Varadan SPas encore d'évaluation

- Sov - 1Document1 pageSov - 1biswasdipankar05Pas encore d'évaluation

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Document24 pagesSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801Pas encore d'évaluation

- PSV Blocked Fire Relief Valve CasesDocument21 pagesPSV Blocked Fire Relief Valve CasesTun Naing WinPas encore d'évaluation

- To-HQ-02-024-00 Philosophy Emergency Process Shutdown Systems OnshoreDocument23 pagesTo-HQ-02-024-00 Philosophy Emergency Process Shutdown Systems Onshoregiskardrev100% (5)

- IO List Document EngineeringDocument3 pagesIO List Document EngineeringEphraem KalisPas encore d'évaluation

- Operation and Control of Crude Oil Refining Process Using Atmospheric Distillation Column With PLCDocument5 pagesOperation and Control of Crude Oil Refining Process Using Atmospheric Distillation Column With PLCMule HådgúPas encore d'évaluation

- Operation and Control of Crude Oil Refining Process Using Atmospheric Distillation Column With PLCDocument5 pagesOperation and Control of Crude Oil Refining Process Using Atmospheric Distillation Column With PLCBihina HamanPas encore d'évaluation

- 10.4 Other Features of Steam and Power Conversion System: 10.4.1 Main CondenserDocument46 pages10.4 Other Features of Steam and Power Conversion System: 10.4.1 Main Condenserpok75thPas encore d'évaluation

- Thermax BoilerDocument10 pagesThermax Boileramitrawal0100% (1)

- Chevron Industrial ReportDocument46 pagesChevron Industrial ReportIrtiaz RahmanPas encore d'évaluation

- General Description of Afbc BoilerDocument8 pagesGeneral Description of Afbc BoilerSaurabh Barange100% (1)

- Best Practices For Energy Efficient Cleanrooms: Control of Chilled Water SystemDocument6 pagesBest Practices For Energy Efficient Cleanrooms: Control of Chilled Water SystemSing Yew LamPas encore d'évaluation

- Assignment 1 (Review Problems) 2018-2019Document7 pagesAssignment 1 (Review Problems) 2018-2019helmyPas encore d'évaluation

- Nfpa 72Document6 pagesNfpa 72vijimurugan2003100% (3)

- KF GateGlobeCheckNeedle ForgedSteelDocument40 pagesKF GateGlobeCheckNeedle ForgedSteelsenioor2004Pas encore d'évaluation

- Dell 5537Document7 pagesDell 5537tsplinstPas encore d'évaluation

- CONTROL VALVESt748Document17 pagesCONTROL VALVESt748tsplinstPas encore d'évaluation

- Process Piping DraftingDocument3 pagesProcess Piping DraftingtsplinstPas encore d'évaluation

- Technical Forum TFCDocument2 pagesTechnical Forum TFCtsplinstPas encore d'évaluation

- Data Sheet: PDF Created With Pdffactory Trial VersionDocument3 pagesData Sheet: PDF Created With Pdffactory Trial VersiontsplinstPas encore d'évaluation

- 3.5 Fans & BlowersDocument8 pages3.5 Fans & BlowersPrasad GangavathuPas encore d'évaluation

- (Notes On Numerical Fluid Mechanics and Multidisciplinary Design 127) Rudibert King (Eds.) - Active Flow and Combustion Control 2014-Springer International Publishing (2015) PDFDocument405 pages(Notes On Numerical Fluid Mechanics and Multidisciplinary Design 127) Rudibert King (Eds.) - Active Flow and Combustion Control 2014-Springer International Publishing (2015) PDFerney03Pas encore d'évaluation

- Coal GasificationDocument37 pagesCoal GasificationSadam BalochPas encore d'évaluation

- Chapter-13.1 Nature of GasesDocument2 pagesChapter-13.1 Nature of GasesJill Taylor67% (3)

- Pressure and Pressure Measuring Devices: Brownian Motion", Due To WhichDocument23 pagesPressure and Pressure Measuring Devices: Brownian Motion", Due To WhichSamuel GaétanPas encore d'évaluation

- Rashtriya Chemicals and Fertilizers Limited Mini Ratna CompanyDocument20 pagesRashtriya Chemicals and Fertilizers Limited Mini Ratna CompanyRana KeyurPas encore d'évaluation

- G.R. Engineering Pvt. LTD.: Hydrotest Pressure Test Stress CalculationDocument2 pagesG.R. Engineering Pvt. LTD.: Hydrotest Pressure Test Stress CalculationTushar Mangrati100% (2)

- Salient Features of UFFLDocument92 pagesSalient Features of UFFLMd. Abu NayeemPas encore d'évaluation

- Ex Problem 10 - Countercurrent Packed Tower For Absorption of Ammonia Gas (Pilat)Document5 pagesEx Problem 10 - Countercurrent Packed Tower For Absorption of Ammonia Gas (Pilat)joesuhrePas encore d'évaluation

- Gilles Gabolde and Jean-Paul NguyenDocument14 pagesGilles Gabolde and Jean-Paul Nguyenshuvo134Pas encore d'évaluation

- Falling Film Evaporator PDFDocument28 pagesFalling Film Evaporator PDF^o100% (2)

- Deliverable Report IngasDocument54 pagesDeliverable Report Ingaseko handoyoPas encore d'évaluation

- Tugas Propulsi 2Document37 pagesTugas Propulsi 2yandaPas encore d'évaluation

- Data Sheet of High Pressure PumpDocument2 pagesData Sheet of High Pressure Pumpsajeesh5113699Pas encore d'évaluation

- Fluid Mechanics ProjectDocument5 pagesFluid Mechanics ProjectHAmza AliPas encore d'évaluation

- Menred Central Vacuum Cleaner&Ventilation ProductsDocument16 pagesMenred Central Vacuum Cleaner&Ventilation ProductsbjainnPas encore d'évaluation

- Water Distribution Manual PDFDocument96 pagesWater Distribution Manual PDFgalca_stefanPas encore d'évaluation

- Gast Test AnalysisDocument10 pagesGast Test Analysismariem.soueidiPas encore d'évaluation

- Rev.2 Calculation Tag# HAA10AA201Document4 pagesRev.2 Calculation Tag# HAA10AA201psaayoPas encore d'évaluation

- Gas Absorption: Operating Calibrated Operating CalibratedDocument4 pagesGas Absorption: Operating Calibrated Operating CalibratedAuzaPas encore d'évaluation

- LRCS NGAS SSM - 1st - 3 18Document2 pagesLRCS NGAS SSM - 1st - 3 18Worldwide Equipment SolutionsPas encore d'évaluation

- Valve Technical DataDocument14 pagesValve Technical DataDhimas IriantoPas encore d'évaluation

- Modification of Pump Curves by Installing Restrictive Orifices at Pump Discharge (Part 2) - LinkedInDocument3 pagesModification of Pump Curves by Installing Restrictive Orifices at Pump Discharge (Part 2) - LinkedInABRAHAM ESTRADAPas encore d'évaluation

- SPP Pumps - Mod. TD15F - Información TécnicaDocument7 pagesSPP Pumps - Mod. TD15F - Información TécnicaGabriel LopezPas encore d'évaluation

- Enhanced Oil RecoveryDocument43 pagesEnhanced Oil RecoveryDigvijay DasPas encore d'évaluation

- BK117C2 B1 ED2REV4 06 Power Plant 14.06.2016 eDocument163 pagesBK117C2 B1 ED2REV4 06 Power Plant 14.06.2016 eЕвгений Касьянов100% (2)

- NR-220301 - Mechanics of FluidsDocument8 pagesNR-220301 - Mechanics of FluidsSrinivasa Rao GPas encore d'évaluation

- Understanding Details of Cavitation:, IncludingDocument10 pagesUnderstanding Details of Cavitation:, IncludingKriz Hor Jiunn ShyangPas encore d'évaluation

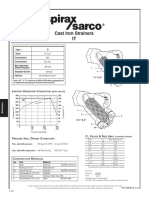

- Filtro It Spirax Sarco PDFDocument2 pagesFiltro It Spirax Sarco PDFLina GarciaPas encore d'évaluation

- ME-458 Turbomachinery: Muhammad Shaban Lecturer Department of Mechanical EngineeringDocument113 pagesME-458 Turbomachinery: Muhammad Shaban Lecturer Department of Mechanical EngineeringAneeq Raheem0% (1)

- The Pivotrol Pump PTC & PTF Pressure Powered Pump: Accessories DescriptionDocument2 pagesThe Pivotrol Pump PTC & PTF Pressure Powered Pump: Accessories DescriptionCarlos MtzPas encore d'évaluation