Académique Documents

Professionnel Documents

Culture Documents

03 Design Example Case 1

Transféré par

Ricardo RodrigoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

03 Design Example Case 1

Transféré par

Ricardo RodrigoDroits d'auteur :

Formats disponibles

Puraflo ®

PEAT FIBRE BIOFILTER for Wastewater Treatment

PURAFLO® PEAT BIOFILTER –CASE 1

DESIGN EXAMPLE (GENERAL)

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 http://www.bnm-us.com/

CASE 1

PURAFLO® PEAT BIOFILTER - DESIGN EXAMPLE (GENERAL)

Site Conditions:

• 3 bedroom dwelling (360 gpd design flow; this will vary from state to state)

• Group II soil (Sandy Loam) with a 0.5 LTAR for conventional drainfield

• Soil wetness condition at 18 inch below natural grade in limited area close to

water-front

• Water-front property with 50 ft set-back - best soil at or inside the 50 ft.

setback

• Level site (0-1% slope)

System Design:

1. Size Treatment System

One module required per bedroom; therefore, 3 modules are required

2. Select Disposal System

Area of suitable Group II soil is limited; therefore, select a Type A

(Pad/Bed) Puraflo® disposal system

3. Size and Locate Disposal System

Use a loading rate of 1.0 gpd per sq. ft. for pre-treated effluent in a Sandy

Loam, Group II soil. In general, we can use a higher loading rate for pre-

treated effluent (how much higher will vary). The better soil is at or within

the 50 ft. setback. Based on the high quality of the effluent, reduce the

horizontal setback to 35 ft. This allows us to install the system in the most

suitable soil without polluting near by surface waters. (Some reduction in

horizontal setback is usually permitted with high quality effluent.)

Therefore, use the 1.0 gpd per sq. ft. and reduce the 50 ft. water-front set-

back to 35 ft.

Pad Size = 360 gpd at 1.0 gpd per sq. ft. = 360 sq. ft.

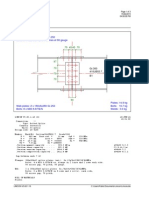

4. Disposal Field Layout/Configuration

Longer narrower pads are preferred in most cases. Available area, soil

and topographic limitations will also influence the pad layout. Pad should

follow contour to insure required vertical separation distances are

satisfied, pad bottom must be level

Select a 10 ft. by 36 ft. pad to provide the required 360 sq. ft.

(with adjacent reserve area of equal size)

[SHOW ACCURATE POSITION OF DRAINFIELD ON PLAT]

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

5. Determine Module and Manifold Configuration

Modules with weep holes are placed in a row (end to end), leveled and

centered along the long axes of the pad disposal area (preferred layout).

They can also be placed side by side and in some cases in a cluster

arrangement. Modules can be centered on equal portions of the pad or

placed adjacent to each other.

Place modules in a row on 10’ by 12’ sections of the pad

Run manifold along side modules. Manifold connects into each module

via a Tee piece with short flexible connection pipe [SEE MODULE GRID

DETAIL].

6. Determine Installation Depth

due to the quality of the effluent, the vertical stand-off distance from trench

bottom to wetness condition, rock or other restrictions can be reduced

(reductions will vary). A typical system requires a 12 inch vertical

separation distance (VSD) between the pad bottom and the seasonal

wetness condition (which is the limiting factor in this case). Assume the

10 ft. by 36 ft. pad was staked out on contour in the most suitable area

and spot elevations on the four corners indicated a negligible difference in

elevation over the selected area. Therefore, maximum installation depth

at the low point on the pad is:

(Depth of suitable soil) minus (VSD);

or in this case, 18 - 12 = 6 inches below grade

The pad will be installed 6 inches below grade

[SHOW ACCURATE CROSS-SECTION OF DRAINFIELD PAD]

7. Determine Pump Requirements

2 inch PVC Sch.40 force main line is standard

Establish total equivalent length as usual between pump and manifold

Example:

Horizontal pumping distance .......................................... 60 ft.

7 elbows at 9 equivalent ft. per elbow ............................ 63 ft.

1 diversion Tee at 11 equivalent ft. per Tee ................... 11 ft.

1 disconnect at 2 equivalent ft. per disconnect................. 2 ft.

1 check value at 17 equivalent ft. per check valve ......... 17 ft.

1 ball value at 54 equivalent ft. per ball valve................. 54 ft.

Total Equivalent Length................................................ 207 ft.

From Friction and Pressure Head Tables, select the closest corresponding

equivalent length for a three bedroom application (the 200 ft. column in

this case) to determine the friction and pressure heads for a range of flows

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

Flow gpm 200 ft.

0 0.00

10 1.60

20 6.39

30 14.37

40 25.54

50 39.91

Determine the static head for given site conditions

Ground elevation at proposed pump tank location is 9 ft.

Assume the “OFF” float switch will be set at 5 ft. below grade (el. 4 ft.)

Ground elevation at module location = 10 ft.

Module height (grid height) above ground elevation = 2 ft.

Module grid elevation = 12 ft.

Therefore, total static head = 12 - 4 = 8 ft. (constant)

Add static head to friction and pressure heads from table to yield TDH

(Total Dynamic Head)

Flow gpm 200 ft. Static Head TDH

0 0.00 8.0 8.00

10 1.60 8.0 9.60

20 6.39 8.0 14.39

30 14.37 8.0 22.37

40 25.54 8.0 33.54

50 39.91 8.0 47.91

Plot TDH system curve over the selected pump curve

The pump will operate where the two curves intersect

Drop a vertical line from the intersection point and read off the anticipated

flow in gpm - approximately 27 gpm in this case for the Zoeller “98” 1/2 HP

effluent pump (or 9 gpm per module)

The pump delivery rate should be between 7 to 12 gpm per module (below

7 gpm the distribution to each module may begin to suffer and above 12

gpm indicates an unnecessarily powerful pump is being considered)

Therefore, the above selected 1/2 HP pump is suitable for this

application

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

8. Determine Panel Requirements and Settings

A simplex control panel with programmable timer is the standard

method for controlling dosing to the treatment modules. Panel and pump

electrical requirements must be compatible with each other and with the

proposed power supply.

Calculate the timer settings as follows:

Dose volume should be between 7 to 12 gallons per module

Assume 12 doses per day (typical); therefore, a daily design flow of 360

gallons will require 12 doses of (360/12) 30 gallons which is 10 gallons per

module per dose (within range). From above pump calculations, a 27 gpm

pump delivery rate is expected; therefore, the timer “ON” cycle should be

set for;

30 (gal.) / 27 (gpm) = 1.11 minutes or 67 seconds (realistically say 1

minute)

The timer “OFF” cycle should be set for;

24 (hrs. per day) / 12 (doses per day) = 2 hours per dose

Timer Settings: 1 Min. “ON” and 2 Hrs. “OFF”

9. Determine Septic Tank Size

Size per current regulations (2 times daily design flow or greater)

Specify a 1,000 gallon septic tank for this 3 bedroom application

Specify a Zabel filter, Model A300 for installation in septic tank

[SEE SEPTIC TANK DETAIL]

10. Determine Pump Tank Size

Generally recommend a 1,000 gallon pump tank for 4 bedrooms or less

Specify a 1,000 gallon pump tank

[SEE PUMP TANK DETAIL]

11. Specify Sampling Option

For Type A pad systems, samples are taken via the pre-molded sampling

chamber [SEE SAMPLE CHAMBER DETAIL]. (For Type B systems, a

drop box can be used.)

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

NOTES

General

1 All construction materials and methods must conform to applicable Local and State Sewage

Handling and Disposal Regulations

2 All pressure joints shall be primed and chemically fused

3 Pumps shall be a Zoeller, 1/2 HP effluent pump with a capacity of 25 gpm at 20' of TDH or its

equivalent

4 Any deviation from this design must be approved by the designer prior to installation

5 The contractor shall contact the Bord na Mona prior to construction for a pre-construction

conference

6 Electrical wiring to be installed under the direct supervision of a licensed electrical contractor,

according to NEC, State and Local Electrical Codes, as applicable

7 Contractor is to install concrete tanks on uniformly firm and stable compacted ground, crushed

stone is recommended to provide uniform support to tank bottom

8 Septic and pump tanks should be water-tight and conform to applicable Local and State Sewage

Handling and Disposal Regulations

9 Contractor must contact the appropriate UTILITY AUTHORITY prior to any digging on site

Biofibrous Peat Specifications

1 Peat fiber is residue of Eriophorum (cotton grass) plants, carefully extracted from raised bog

peats (other natural residues and peat fines are present in small quantities)

2 Moisture content on wet basis is 50-70%

3 Min. organic content on anhydrous basis is 95%

4 Water adsorption capacity, 72 hr. test, is 400-700%

5 Average air filled porosity(AFP) is 51%

Site Preparation Work:

1 Hand clear wooded sites

2 Machinery should not traverse the percolation area

3 Machinery must never traverse excavated/exposed percolation area

4 Contractor must provide adequate access for correct installation

5 Avoid installation under wet site conditions

Design:

1 Design LTAR/PERC = 50 MPI

2 Design flow = 600 gpd

3 Depth to SHWT = 30+ inches (see soil report)

4 Percolation area provided = Six 45' L trenches 3' W (18" max. install'n depth)

5 Number of treatment modules = 5

Percolation Area:

1 Install trenches level and along contour where applicable

3 Cover stone in trench/pad with filter fabric

4 Min. distance between trenches = 3 times trench width (approx.)

5 Do not smear trench/pad base or sides during excavation

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

Site Restoration:

1 Min. cover of fill over stone is 4" (6" in NC)

2 Backfill with suitable loose material free of large or damaging objects

3 Straw and seed backfilled areas (or sod when required)

4 Provide erosion protection for backfill material in accordance with Local and County standards

and maintain until permanent protection is established

5 Backfill should be graded to prevent the infiltration of surface water and divert storm water run-off

away from the system

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

Friction Pressure Head Table for 2'' Diameter Pipe

PRESSURE AND FRICTION LOSSES FOR 1 MODULE SYSTEM

Q (gpm) hf + hp (ft) for Various Values of Equivalent Length in Feet

1 50 100 150 200 250 300 350 400 450 500 550 600

0 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

10 10.63 10.74 10.84 10.95 11.06 11.16 11.27 11.38 11.48 11.59 11.70 11.81

20 42.52 42.95 43.38 43.80 44.23 44.66 45.09 45.51 45.94 46.37 46.79 47.22

30 95.68 96.64 97.60 98.56 99.52 100.48 101.44 102.40 103.36 104.33 105.29 106.25

40 170.09 171.80 173.51 175.22 176.93 178.63 180.34 182.05 183.76 185.47 187.18 188.88

50 265.77 268.44 271.11 273.78 276.45 279.12 281.79 284.46 287.12 289.79 292.46 295.13

60 382.71 386.55 390.40 394.24 398.08 401.93 405.77 409.62 413.46 417.30 421.15 424.99

70 520.91 526.14 531.37 536.60 541.84 547.07 552.30 557.53 562.76 568.00 573.23 578.46

80 680.37 687.20 694.04 700.87 707.70 714.54 721.37 728.20 735.04 741.87 748.71 755.54

PRESSURE AND FRICTION LOSSES FOR 2 MODULE SYSTEM

Q (gpm) hf + hp (ft) for Various Values of Equivalent Length in Feet

2 50 100 150 200 250 300 350 400 450 500 550 600

0 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

10 2.74 2.84 2.95 3.06 3.16 3.27 3.38 3.49 3.59 3.70 3.81 3.91

20 10.95 11.38 11.81 12.23 12.66 13.09 13.51 13.94 14.37 14.80 15.22 15.65

30 24.64 25.60 26.56 27.52 28.48 29.44 30.41 31.37 32.33 33.29 34.25 35.21

40 43.80 45.51 47.22 48.93 50.64 52.35 54.05 55.76 57.47 59.18 60.89 62.60

50 68.44 71.11 73.78 76.45 79.12 81.79 84.46 87.13 89.80 92.47 95.14 97.81

60 98.56 102.40 106.25 110.09 113.94 117.78 121.62 125.47 129.31 133.16 137.00 140.84

70 134.15 139.38 144.61 149.85 155.08 160.31 165.54 170.77 176.01 181.24 186.47 191.70

80 175.22 182.05 188.88 195.72 202.55 209.39 216.22 223.05 229.89 236.72 243.55 250.39

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

PRESSURE AND FRICTION LOSSES FOR 3 MODULE SYSTEM

Q (gpm) hf + hp (ft) for Various Values of Equivalent Length in Feet

3 50 100 150 200 250 300 350 400 450 500 550 600

0 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

10 1.28 1.38 1.49 1.60 1.70 1.81 1.92 2.02 2.13 2.24 2.34 2.45

20 5.10 5.53 5.96 6.39 6.81 7.24 7.67 8.09 8.52 8.95 9.38 9.80

30 11.48 12.45 13.41 14.37 15.33 16.29 17.25 18.21 19.17 20.13 21.09 22.06

40 20.42 22.13 23.83 25.54 27.25 28.96 30.67 32.38 34.08 35.79 37.50 39.21

50 31.90 34.57 37.24 39.91 42.58 45.25 47.92 50.59 53.26 55.93 58.60 61.27

60 45.94 49.78 53.63 57.47 61.32 65.16 69.00 72.85 76.69 80.54 84.38 88.22

70 62.53 67.76 72.99 78.23 83.46 88.69 93.92 99.15 104.39 109.62 114.85 120.08

80 81.67 88.50 95.34 102.17 109.01 115.84 122.67 129.51 136.34 143.17 150.01 156.84

PRESSURE AND FRICTION LOSSES FOR 4 MODULE SYSTEM

Q (gpm) hf + hp (ft) for Various Values of Equivalent Length in Feet

4 50 100 150 200 250 300 350 400 450 500 550 600

0 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

10 0.76 0.87 0.98 1.08 1.19 1.30 1.41 1.51 1.62 1.73 1.83 1.94

20 3.06 3.49 3.91 4.34 4.77 5.19 5.62 6.05 6.47 6.90 7.33 7.76

30 6.88 7.84 8.80 9.76 10.72 11.69 12.65 13.61 14.57 15.53 16.49 17.45

40 12.23 13.94 15.65 17.36 19.07 20.77 22.48 24.19 25.90 27.61 29.32 31.02

50 19.11 21.78 24.45 27.12 29.79 32.46 35.13 37.80 40.47 43.14 45.81 48.48

60 27.52 31.37 35.21 39.05 42.90 46.74 50.59 54.43 58.27 62.12 65.96 69.81

70 37.46 42.69 47.93 53.16 58.39 63.62 68.85 74.09 79.32 84.55 89.78 95.01

80 48.93 55.76 62.60 69.43 76.26 83.10 89.93 96.76 103.60 110.43 117.27 124.10

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

PRESSURE AND FRICTION LOSSES FOR 5 MODULE SYSTEM

Q (gpm) hf + hp (ft) for Various Values of Equivalent Length in Feet

5 50 100 150 200 250 300 350 400 450 500 550 600

0 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

10 0.53 0.63 0.74 0.85 0.95 1.06 1.17 1.28 1.38 1.49 1.60 1.70

20 2.11 2.54 2.97 3.39 3.82 4.25 4.67 5.10 5.53 5.95 6.38 6.81

30 4.75 5.71 6.67 7.63 8.59 9.55 10.52 11.48 12.44 13.40 14.36 15.32

40 8.44 10.15 11.86 13.57 15.28 16.99 18.69 20.40 22.11 23.82 25.53 27.24

50 13.19 15.86 18.53 21.20 23.87 26.54 29.21 31.88 34.55 37.22 39.89 42.56

60 19.00 22.84 26.69 30.53 34.37 38.22 42.06 45.91 49.75 53.59 57.44 61.28

70 25.86 31.09 36.32 41.55 46.79 52.02 57.25 62.48 67.71 72.95 78.18 83.41

80 33.78 40.61 47.44 54.28 61.11 67.94 74.78 81.61 88.44 95.28 102.11 108.94

PRESSURE AND FRICTION LOSSES FOR 6 MODULE SYSTEM

Q (gpm) hf + hp (ft) for Various Values of Equivalent Length in Feet

6 50 100 150 200 250 300 350 400 450 500 550 600

0 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

10 0.40 0.51 0.61 0.72 0.83 0.93 1.04 1.15 1.25 1.36 1.47 1.57

20 1.60 2.02 2.45 2.88 3.30 3.73 4.16 4.59 5.01 5.44 5.87 6.29

30 3.59 4.55 5.51 6.47 7.44 8.40 9.36 10.32 11.28 12.24 13.20 14.16

40 6.39 8.09 9.80 11.51 13.22 14.93 16.64 18.34 20.05 21.76 23.47 25.18

50 9.98 12.65 15.32 17.99 20.66 23.32 25.99 28.66 31.33 34.00 36.67 39.34

60 14.37 18.21 22.06 25.90 29.74 33.59 37.43 41.28 45.12 48.96 52.81 56.65

70 19.56 24.79 30.02 35.25 40.48 45.72 50.95 56.18 61.41 66.64 71.88 77.11

80 25.54 32.38 39.21 46.04 52.88 59.71 66.54 73.38 80.21 87.05 93.88 100.71

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

CASE 1

ENVIRONMENTAL PRODUCTS U.S. INC.

(800) 787-2356 www.bnm.us.com

Vous aimerez peut-être aussi

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Ramfireco CableDocument1 pageRamfireco CableahsanPas encore d'évaluation

- Semiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007Document1 pageSemiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007civixxPas encore d'évaluation

- Unified SOR Inte RevisedDocument70 pagesUnified SOR Inte RevisedAncil AlexPas encore d'évaluation

- Adva XR 3057 - UaeDocument2 pagesAdva XR 3057 - UaektbaluPas encore d'évaluation

- Cable Extencion Marca TurckDocument2 pagesCable Extencion Marca Turckdevol999Pas encore d'évaluation

- Q Hardware Manual enDocument364 pagesQ Hardware Manual endevakumar1356Pas encore d'évaluation

- Atco 27 Rider ManualDocument34 pagesAtco 27 Rider ManualBestManuals4u100% (1)

- IC - pk.DIC.D5.22.NAM Danfoss General CatalogoDocument36 pagesIC - pk.DIC.D5.22.NAM Danfoss General Catalogoalstom100% (1)

- Top Drive PB169 - Blower - Motor - U-Bolt - SupportDocument6 pagesTop Drive PB169 - Blower - Motor - U-Bolt - SupportJoseMi Vacaflor Illanes100% (1)

- Catalogo Decortiles 2018Document276 pagesCatalogo Decortiles 2018luizPas encore d'évaluation

- 14354Document1 page14354Ioana SperleaPas encore d'évaluation

- Fatigue Analysis of Composite Material - White PaperDocument2 pagesFatigue Analysis of Composite Material - White PaperShino UlahannanPas encore d'évaluation

- Cofferdams Forces Analysis and Design CriteriaDocument4 pagesCofferdams Forces Analysis and Design CriteriaMarkPas encore d'évaluation

- Diagrama Flujo Toschi MarioDocument1 pageDiagrama Flujo Toschi MariomariofnmPas encore d'évaluation

- Transistor Catalog 2005Document24 pagesTransistor Catalog 2005Angelo PalamingPas encore d'évaluation

- June 2005 Geo-Heat Center Quarterly BulletinDocument36 pagesJune 2005 Geo-Heat Center Quarterly BulletinGeo-Heat Center Quarterly BulletinPas encore d'évaluation

- Flange SupportDocument1 pageFlange SupportvijayanmksPas encore d'évaluation

- Construction of Sucker Rod Pump: Presented By: Group No. 11Document13 pagesConstruction of Sucker Rod Pump: Presented By: Group No. 11Vishal RanaPas encore d'évaluation

- TUTORIAL 1 Drilling EngineerDocument4 pagesTUTORIAL 1 Drilling EngineerAnonymous AkV8maWxGNPas encore d'évaluation

- Astm A 884 PDFDocument5 pagesAstm A 884 PDFMuhammad NaumanPas encore d'évaluation

- Marine Engine IMO TierII ND TierIII Programme 2015 PDFDocument204 pagesMarine Engine IMO TierII ND TierIII Programme 2015 PDFmohamedIGCMOPas encore d'évaluation

- Angus Amp 95 Latexpaint TdsDocument5 pagesAngus Amp 95 Latexpaint TdsOng Kok TongPas encore d'évaluation

- Air Bag Launching SystemsDocument7 pagesAir Bag Launching SystemsJhon GreigPas encore d'évaluation

- Hydrogen Generation For Modern Refineries 2009Document7 pagesHydrogen Generation For Modern Refineries 2009Raudah RahimiPas encore d'évaluation

- Bose 301 Series V Service ManualDocument10 pagesBose 301 Series V Service ManualWenceslau Nunes Neto100% (1)

- Limcon SpliceDocument3 pagesLimcon SpliceconorkellysligoPas encore d'évaluation

- Brochure - Cat Marine Electronic ControlsDocument11 pagesBrochure - Cat Marine Electronic ControlsJose Manuel EscalantePas encore d'évaluation

- Fundamentals of Computer StudiesDocument60 pagesFundamentals of Computer StudiesADEBISI JELEEL ADEKUNLEPas encore d'évaluation

- Class X Foundation NTSEDocument294 pagesClass X Foundation NTSEPankaj Kumar Sahu0% (1)

- Module 1Document31 pagesModule 1Noor Aishah100% (1)