Académique Documents

Professionnel Documents

Culture Documents

American Woodworker 100 200305

Transféré par

Adrian Cocis100%(1)100% ont trouvé ce document utile (1 vote)

867 vues65 pagesContents # I 00, May 2003 Drum Sander 40 Sand faster with this surprisingly simple and low-cost machine. Country-Style Grandfather Clock 64 complete step-by-step instructions for this charming heirloom timepiece. TOOL TEST Benchtop Planers 77 We chose the best of todays advanced machines.

Description originale:

Titre original

2988305-American-Woodworker-100-200305

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentContents # I 00, May 2003 Drum Sander 40 Sand faster with this surprisingly simple and low-cost machine. Country-Style Grandfather Clock 64 complete step-by-step instructions for this charming heirloom timepiece. TOOL TEST Benchtop Planers 77 We chose the best of todays advanced machines.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

867 vues65 pagesAmerican Woodworker 100 200305

Transféré par

Adrian CocisContents # I 00, May 2003 Drum Sander 40 Sand faster with this surprisingly simple and low-cost machine. Country-Style Grandfather Clock 64 complete step-by-step instructions for this charming heirloom timepiece. TOOL TEST Benchtop Planers 77 We chose the best of todays advanced machines.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 65

ao a)

Dust Collectio

The ultimate small-shop-system=

Inut Bookshelf

asics aot po) ULM ICL Clo

Contents

#100, May 2003

Shop-Made

Drum Sander 4

Sand faster with this surprisingly

simple and low-cost machine,

Walnut Wall Shelves

Build this stylish home for your

favorite books and personal treasures

Central

Dust Collection

Banish dust with an easy-to-build

system tailored for the small shop.

Country-Style

Grandfather Clock

Complete step-by-step instructions

for this charming heirloom timepiece.

Benchtop Planers

We chose the best of today’s

advanced machines.

Contents

DEPARTMENTS

Question & Answer

Workshop Tips

Small Shop Tips

The Well-Equipped Shop

Great Wood!

Curly Soft Maple

Sources

Oops!

page 18

Subscriptions:

American Woodworker 5

email: AWWeustserv@et

Article Index: A complete index is available online at wwwamericanwoodworker.com

Copies of Past Articles: Photocopies are available for $3 each, Write or call American Woodworker Reprint Center, PO Box 83605,

Slater, MN 55083-0095, (715) 246-4344, 8 AM to 5 PM CST, Mon. through Fri. Visa, MasterCard and Discover accepted.

Back Issues: Some are available for $5 each. Order from the Reprint Center at the address above.

Comments & Suggestion: American Woodworker, 2915 Commers Dr, Suite 700, Egan, MN 35121

Phone: (651) 4549200 Tax: tes soe3230 ‘emul: aweditor@readersdigest.com

ber Service Dept., PO Box 8148, Red Oak, 1A 51591-1148, (800) 660-3111

llment.com.

American Woodworker myzon 5

coy Jan Carr

uestion&

Answer

How Do | Get Rust Off My Saw? «

Qj By accident left a pressurectreated 2x4 on my

spotless tablesaw for a couple of days. Big mistake!

‘What can | do to remove the rust it left behind?

Here isa fast and simple technique for removing

light rust. Pull out your random-orbit sander and

a square about the size of your disc from a non-

woven abrasive pad. A green or dark-red 1/4-in-

thick Scotch-Brite pad is the right coarseness, The

dark-red pads willlast longer than the green one.

If your sander uses hook-and-loop discs,

remove the sandpaper and press right down on

the pad. If yoursander hasa smooth bottom for

pressure-sensitive paper, put on a piece of

coarse (60 to 80 grit) sandpaper firs.

Before you begin sanding, unplug your saw

and apply alubricant to the rusty area with a

paper towel. Mineral spirits or WD-40 work

‘well but put on no more than a very light coat

Now, put on some eye protection. Turn on

the sander and exert just enough pressure

to keep the pad in place. The rust should be

‘gone ina matter of seconds.

IF this doesnt do the trick,

youive got two more

options. First, try a

light-duty rust

remover asan alter-

native lubricant (see

Sources, page 100). If

that doesnt work, switch

toaamoreabrasive pad ora

sandpaper disc (220 grit or

higher). Again, apply a thin coat

of lubricant. Take it easy with

‘ABRASIVE PAD

sandpaper, because you will be

removing a small amount of metal

along with the rust.

When the rust is gone, apply a coat of

furniture paste wax to your saw right away

to prevent it from rusting,

10 American Woodworker wav=u

Question & Answer

Which is the “

Right Air Fitting?

Q. | bought a new coupler for my

air hose, but it doesn't fit my tools.All the

couplers looked the same.Arentt these things

standardized?

UNIVERSAL

ye cou

A. No,thereare actualy five different styesin the

1/4-in, size. But you can easily solve your problem by buy-

ing a“universa” quick connect for your hose. At around

Aa

$550, itis a bit more

expensive than a regular cou-

per (see Sources, page 100), but it

fits the three most popular styles of fittings:

industrial, automotive and ARO. Most woodworking

tools use the industrial style.

There are no functional dfferencesamong the styles. Years

ago, each manufacturer devised their own special shape.

Every store that carries fittings will have the industrial and

automotive styles. Some stores will have all five.

Ifyou dont buy the universal couplerzbe sure to take the fit-

InousTmiAL AUTOMOTIVE on ting you are trying to match with you to the store, and try the

fitting in a coupler before you buy it.

2 American Woodworker moa

JDS AIR-TECH and Dust-Force =

When only the Best will Do!

Put the Force tawaork in your shop... °%=**ere

Our new 1.5 HP Dust-Force is

$289 the perfect addition to our award

Model750-ER _ winning line of air filtration units, -

Powerful, portable, and ready to

JDS, the leader in quality air filtration work for you, the Dust-Force will

products, introduces the ultimate air cleaner make/your shop a cleaner,

for your shop (Model 750-ER). This remote healthier, more productive

controlled unit will clean the air in a 30x30x8" environment.

shop once every ten minutes, or larger areas

the models 8-12, 10-16, and 2400 are available.

To remove odors, fumes and smoke, order our _ Specifications

optional charcoal filter.

Model750-ER

When only the Best will Do!

€@ LcD Remote Contratwith speed end timer function

@ Highest Maximum Air Flow in its Class 1,050 CFM

(750 CFM Fitered Air) ie

(© 95% ASHREA Tested main fiter SwitchPrewired for 10¥

(@1%4Efficiency at | micron ~99% at 5 microns)

© Washable Electrostatic PreFiter Another quality productfrom = > MAP AY

‘With ten year manufacturer's warranty ‘ ses

Toplacean order or for the dealer nearest youcallustolifiee. 1-800-480-7269. wanw:theasconpany.com

Question & Answer

TRANS:

— Outfeed Table:

me Melamine or Laminate?

> — Q Iimbuiding an ourfeed table for lar layer of paper, but under that isa

coLon

i olf my tablesaw. Should | use melamine decor shect (which carries the color

rh or plastic laminate? ‘or pattern) and three to five layers of

Laven kraft paper fused tothe first two lay-

OF RAPER A. Plasticlaminate is more durable _exs with tough phenolic resins.

than melamine, but it will cost you Before choosing laminate, how.

Pree more timeand money to install, ever, consider cost and labor. A 4x8

Boar Laminate provides more abrasion sheet of thermofused melamine costs

and impactresistance than melamine. about $25.Cutitto the size you need,

You‘te les likely to wear through the and youre ready to go. For the sake of

top layer or dent and scar it. A top comparison, a 4x8 sheet of laminate

sno. with laminate on both sides will sag costs about $55, Add to that the cost

coLoReD far less than a melamine top. Ther- of the particleboard or medium-den-

PAPER mofused melamine, the kind most sity fiberboard (MDF) substrate ($20

manne ea Fe eee

RAD home centers, has a single layer of have to apply laminate toa substrate

cal paper adhered to the front and back — yourself and trim itwith a router. You

ACKER ofa particleboard substrate, heat- can wear out and replace several

sHeet fp fused with melamine resins. Lami- melamine outieed tables for the same

nate is much thicker. On top isa sim- cost as one laminate table

14 Amtriean Woodworker wan

www.amazon.com/dewalt The Leigh FMT

Sree Feast .

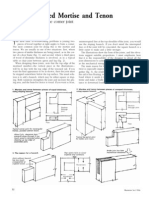

Mortise and Tenon Jig

Get an extra set of knives and dusthood with the Create mortises and tenons in one quick, easy setup!

DW733 DEWALT planer, an $84.99 value. Unique patented gue system + ont from a tiny Yan x co" x5" in took

nen er ener een ne mens

Pony ee bere eer

Prosar re eryireet nese eer eetae

poser oe et Ceo

TRIE Pb Tine ome

Fourcslumn hess ck secs cuterad to earinate snipe

Esta ng ine! and cuted ables provide 39 ies of malo

Support height eckin pestis

ong tora 100 pag cs

porn

Gran Tenn contr

Question & Answer

Must | Release the Tension?

Q. Do I really have to take the tension off my bandsaw, or

can | leave i tightened all the time?

TENSIONING

KNOB a

Ifyou want the longest life out of your saw and sawblades,

release the tension when your saw will sit idle for more than a

few days. You donit have to take off all the tension. Just rotate

the tensioning crank two or three complete turns,

Leaving the blade tensioned can create several problems.

First i can result in your blade breaking prematurely. The next

timeablade breaks, examine it carefully. fit didnt snap at the

weld, the break is likely the result of leaving the tension on,

Second, your ties will havea shorter life. Leaving the ten-

sion on will prematurely flatten their crowns and harden the

rubber, eventually causing tracking problems. Two new tires

fora 14-in, saw cost about $40, and they're no fun to replace

Third, you could prematurely compress the tension spring,

Ww

Jfyou havea question youd like answered, send it 10 us at)

Question & Answer, American Woodworker,

2915 Commers Drive, Suite 700, Eagan, MN 55121 or

e-mail to qanda@readersdigest.com. Sorry, bu the volume

‘of mail prevents us from ansvering each question individual

16 American Woodworker ua

‘The Leigh Dovetail Jig has it all. Hobbyist or proksiond, the Legh Dé Dene Jig wil ese you =

cree your be wk, Vai, pete and spe akc ak the Ligh Deel gee than se ee Rou ough and .

Tn bind dovetail up to 24° wide in Bods up to 11" sh, with infinitely varablespcing of pins and as —allon oe jg. Jing Tater Wath Te

1 Fig ins and mile moetise

Ph railing ard angled dona casy withthe DA, Ad cate dace ol

‘ctemonseffrileny with Leigh atachment and our exxpioal wir guide Make routing ener with Leigh Call ol fee now!

Call For Your FREE Leigh Catalog Today! 1-800-663-8932 isaisii

From Our Readers Futed by Randy Johnson

Anti-Slip

Dust-Collection Table

Here's a pair of sahcling helpers that work great

together. The rug pad provides a soft anti-slip

ard, combined with the holes

in the rug pad, allows dust to be sucked

down through the table. My shop vacuum

provides plenty of airflow

[bought the wood for my sanding table at

thelocal home center for about $20. found

the anti-slip rug pad atthe same store in

nt for $6. The

pad was bigger than my table,

surface. The P

the carpet d

but yasiéa

ly cut to size

witha

Way

Workshop Tips

ws

Rigid Routing Sled

A routing sled is a great help when coping the ends of rails and stiles. But

Thad a problem when I built my first sled. The pressure from the toggle

clamp caused the 1/4-in.-thick sled base to deflect, which messed

alignment of the rail-and-stile joints. solved the problem by adn

tot

This setup keeps the 1/4-in. base from bending when the toggle clamp is.

board

front of the sled, plus two top boards that bridge over my workpiece

clamped down,

Sources seepigei00 Fred Adams

Cool Tip

Changing the sanding sleeves on a spindle sander can beas tough as remov-

ing an old rusty bolt: Next time, try this trick: Put the drum in your freezer for

15 minutes. The cold will shrink the rubber drum and the sanding sleeve will

almost fall off

Alex K, Madler

RU CO RMU

De

OC Lh

Ree LK]

PAL Ro

i= slo) lem

Ce Fle

Workshop Tips

Pivoting Outfeed Support

I recently saw an outfved stand that had.a pivoting top. The pivoting action pre

vents a workpiece from ¢: p

top just pivots up level as the workpiece passes over it.I figured I could make

just as well

concrete block

something similar that would wo

with extra stability.

For the base | used a sawhors

from pivoti

by 36-in.-long melamine shelf that I boughtata home center for $6.

re set toward the back ofthe b o makethe

ard the tablesaw, The brackets are tothe horse with

The 1x4 end bracket

ouitfeed top tip

at e

it and the stop blocks. I trimmed the horse’s legs so the outfeed

a ser end. When the outfeed top is level, there is a 3/4-in

J with my tablesaw

David Dimiek

Teyou have an original Workshop Tip, end i wo us with «sketch oF phoro

Ie-ve print it, youl get $100! Send to: Workshop ‘Tips, American Woodworkes,

ers Drive, Suite 700, Eagan, MN 35121 or e-mail

2915 C H ocesal

rorkshoptipsGreaderodigest.com. Ssomsions an be rene

Ppopery upon aceetanee and payment We may ed submissions,

Frel print and eleeronie me

1d become our

se them

American Woodworker 23

OS Lee

e

Ca

a Gee

err

BRU 2 or BI

www.titebond.com

Cir ele] (9

Cet Fle

Workshop Tips

rd

Perfectly @y

Parallel *

Fence

Here’s a quick and

easy way toalign your

tablesaw fence with

your miter slot. Plane

down a board until it

fits into your miter

slot without pla

Now slide the fence

up to the board and

use a feeler gauge to

determine your fence

alignment. Its that

Dave Munkittrick

Tablesaw Tapering Jig

ww

Trecently built a

pair of garden

benches that

required several

identical parts

on ae

_

4 Cel

a

inst cur

Secon cut

Lock

that were tapered

con both sides. To

make the job

easier, built this

jig that worked

for both angles.

The two screws

make settin

angles quick and

precise. On the

first cut, the edge

of the board

rests against the

first screw head

‘CAUTION: Upper guard removed for

photo clarity. Use yours!

with the end of

the board resting on the second screw: For the second cut, just lip over the board

and move it to the second screw (as shown in the photo), and rest the end of the

mp holds the board in place dur

ing sawing. Once the screws are set you can cut perfect angles ll day long.

Sources seepa¢: 100

board against the wood stop block. The toggle

Fred Adams

ant

ETS CU TLIA

5

20 Minute Cordless Use

e

TON

FORMER

COs

1-800-347-4583

PAL RC

rele) iied

Poe FT

Te RA

oar

Ce

Cee ae

Cee eee

eee

of the blade kerf, a any angle, with or

enn oa ec

Dn og gts

Ce nets

Rete

tere

DELTA

SMe uel

7

soit edalal

Gra Bos ret Cae ces

pris force gia

crt

Ks ret ndooriouooe

Shure norveling

foe otc es

epi we neo

fe ol ee

ees

Keay oe

‘ie aarpost

for retailers near you

www.gorillaglue.com

1-800-966-3458

Workshop Tips

Laminate Flooring

for Zero-Clearance

Inserts

ee

FLOORING

Rather than mess with gluing up plastic

Taminate,1 use a piece of laminate flooring

when making zero-clearance inserts, Lam

inate flooring is great because it’s st

with anice stick surface. Its between 1/-

in.and 3/8-in. thick, which isjust right for

inserts. Italso saws and routs nicely.

bought a couple of sample pieces of

laminate flooring for $6 per 8-in. by48-in,

piece. You can find it at home centers and

flooring stores. Each plank makes four

inserts

To make my inserts I followed the

directions in “Zero-Clearance Inserts”

AW #95, September 2002, page 50. The

only change I made was to use #10-24 by

3/8-in.-long socket-head setscrews for

the leveling screws rather than flat-head

screws. I prefer setserews because I don't

have to drill a countersink, Some sas

require a 1/2-in. long setscrew because

the support flanges thatthe insert resis on

are lower. To determine the screw's size,

‘measure ftom the top of your saw table

down to the:

upport flange. Buy setscrews

that are about 1/16-in, to 1/8-in, shorter

than this measurement. You can buy

socket setscrews at most hardware stores

for about 25 cents each

Jack Mar

26 American Woodworke :

Hold It! Roll It! Hang It! Store It! Edited by Randy Johnson

all Shop

Double-Duty

Roller Tables

[like getting double duty out of

my tools whenever possible, So,

when I decided to build outfeed

tables for my miter saw and table-

saw, T worked up this dual-use

design. The roller tables are sim-

ple to switch between machines

and take up very litle space when

T store them against the wall

Tmade the roller frames from

232s, a 1x4 and eight rollers. I just

clamp the rollers to a pair of

sawhorses when I use them with

my tablesav.Ladjusted the height of

my sawhorses so the tops of the

rollers sit about 1/8-in. below the

top of my tablesaw When I use them

with my miter saw [add a couple of

spacer boards to. make the rollers

level with the miter saw’ table It

cost me about $100 to build the

roller frames, not including

iaceaprorses J {you have an original Small Shop

Jim Norby a “Tip, send ico Us With askerch

cx pc. Ive prt ie youl ge

$160! Send sour ipo: Small Shop

_ ‘Tips, American Woodworker,

2915 Commers rive, Sate 700,

‘Eagan, MN 55121 or e-mail to

ney smallshoptips@readersdigest.com.

Simic entire

ou OP On a

aol eae aye

mee et

cree Seer

"iON. VERN JOHNSON « SHOTOGRAPHY: BILL 2UEHLAE

cies wars

_ Small Shop’

Suspended

Thisisone of my Esvorteshop upgrades BY

adding his suspended outlet over my work

area Lalayshave electricity close athand. sure to followacal building =e

It sure beats running an extension cord! codes and use a ground fault With CENTER

acrosstheloor and getting my eettangled circuit interrupter (GEC), if required,

"\ sTRAN-RELIEF CONNECTOR

Ifyouhave any doubts, hire 2

licensed electrician

components inchide:

*ametal electrical box

+abox cover with a center

knock-out

+ asteain-raief cord connector

+ a section of stranded wire

electrical cord

+ acord receptacle

All of these parts can be

purchased at ahome center or

hardhare store for about $15.f

youre hooking into a 20-amp

circuit, use 12-3 stranded-wire

electrical cord and a20-amp-

rated plug. If you're hooking

into.a15-amp circuit, use 14-3

stranded-wire electrical cord

and a 15-amp-rated plug. 1

installed my outlet so the plug

end isabout 6ft.off the floor

so I don't bump my head

4 oni,

Doug Bailie

Small Shop Tips

Blade Caddy

Here's handy tote for scrollsaw blades that

[fashioned from a scrap of 2x6, piece of

plywood,and two Peg-Board multiple-tool

holders. I cut the curved tips off the multi-

ple-tool holders with a hacksaw so they

would sit flat against the plywood.

Just ONE Tool For All

Your Rabbeting Needs!

[attached the holders to the caddy with cable

staples. These smal plastic tubes are perfect

forholding scrollsw blades, Lwrapped

some masking tape around each tube

and wrote the blade size on it.

Richard Bombard

Sources seemee 0

INSERT SUPERABBET, JR.™ #xc-49355

sled replaceable carbide knives.

113 aiferet depts with one tol using optional calls.

‘Maintain exat tolerances.

*Chacse trom 4 diferent carbide aad nies for

diferent apleatins:

(Ur et sre

SMA12 (sof and hort wood) MFA-12 (al purpose)

le

Tackle Box Storage

This is my all-time favorite way to store

go

*BASIC TOOL,

screws, small hardware and router bit

Fishing tackle boxes come in a variety of

| sizes and shapes but I picked this one

because the inner utility boxes have lids to

keep stuff from spilling and the adjustable

ividers allow me to use the trays for both

short and long items. This tackle box,

including the three big lower utility boxes,

cost $25. The five small upper utility bos

are sold separately for $2 each. Ihave over

70 different items stored in my tackle box!

Randy Johnson

DAIVER-BIT,

‘STORAGE

"*BASICTOOL

0”

32

American Woodworker

Vous aimerez peut-être aussi

- ShopNotes 138 - Nov 2014Document60 pagesShopNotes 138 - Nov 2014clevesanders100% (17)

- ShopNotes #12 (Vol. 02) - Shop Built Disk SanderDocument0 pageShopNotes #12 (Vol. 02) - Shop Built Disk Sandercxrxixsx100% (1)

- American Woodworker - 115 (July 2005)Document67 pagesAmerican Woodworker - 115 (July 2005)Emilian Baluta100% (1)

- The New Bandsaw Box Book: Techniques & Patterns for the Modern WoodworkerD'EverandThe New Bandsaw Box Book: Techniques & Patterns for the Modern WoodworkerÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Woodworker's Journal - December 2015Document92 pagesWoodworker's Journal - December 2015Lagman T. Celestino100% (2)

- American Woodworker - 099 (03-2003)Document65 pagesAmerican Woodworker - 099 (03-2003)api-19759721100% (6)

- Woodcraft Magazine USA - Issue # 075 - February, March 2017 - Build This Classic Spice BoxDocument76 pagesWoodcraft Magazine USA - Issue # 075 - February, March 2017 - Build This Classic Spice BoxKen Lock100% (4)

- ShopNotes Issue 89Document58 pagesShopNotes Issue 89Patricio Guardia100% (9)

- ShopNotes Vol.18 Issue 107Document52 pagesShopNotes Vol.18 Issue 107rftoto100% (3)

- ShopNotes 120 PDFDocument52 pagesShopNotes 120 PDFbenigno100% (3)

- Intarsia Woodworking Projects: 21 Original Designs with Full-Size Plans and Expert Instruction for All Skill LevelsD'EverandIntarsia Woodworking Projects: 21 Original Designs with Full-Size Plans and Expert Instruction for All Skill LevelsPas encore d'évaluation

- Wooden Utensils from the Bandsaw: 60+ Patterns for Spatulas, Spoons, Spreaders & MoreD'EverandWooden Utensils from the Bandsaw: 60+ Patterns for Spatulas, Spoons, Spreaders & MorePas encore d'évaluation

- Traditional Country Woodworking Projects: Plans for 18 Practical Indoor and Outdoor ProjectsD'EverandTraditional Country Woodworking Projects: Plans for 18 Practical Indoor and Outdoor ProjectsPas encore d'évaluation

- American Woodworker 140 (FebMar 2009)Document84 pagesAmerican Woodworker 140 (FebMar 2009)Emilian Baluta100% (8)

- Woodcraft Magazine 016 (May - 2007)Document84 pagesWoodcraft Magazine 016 (May - 2007)Anonymous MwulYRw2L100% (2)

- Woodworkers Journal - June 2014 USADocument68 pagesWoodworkers Journal - June 2014 USAZeferin-o100% (2)

- The Woodworker Woodturner - January 2020Document102 pagesThe Woodworker Woodturner - January 2020carlos latrePas encore d'évaluation

- American Woodworker - 086-2001-04Document74 pagesAmerican Woodworker - 086-2001-04api-19759721100% (4)

- Woodsmith CW - Shop-Built MachinesDocument130 pagesWoodsmith CW - Shop-Built Machinesaurelherman100% (5)

- Woodsmith Oct 2020Document72 pagesWoodsmith Oct 2020Jorge Carlos Lazaney100% (1)

- Fine Woodworking - Gluing and Clamping StrategiesDocument7 pagesFine Woodworking - Gluing and Clamping Strategiescajunhillbilly100% (1)

- Layout and MeasuringDocument10 pagesLayout and MeasuringRobbie van Leeuwen100% (3)

- Woodsmith Drill Press TableDocument3 pagesWoodsmith Drill Press Tablericheklund100% (6)

- DPROJ02Document13 pagesDPROJ02VhomBoris75% (4)

- American Woodworker 156 (Oct-Nov 2011)Document68 pagesAmerican Woodworker 156 (Oct-Nov 2011)Emilian Baluta100% (5)

- Woodcraft Magazine 029 (JuneJuly 2009) PDFDocument66 pagesWoodcraft Magazine 029 (JuneJuly 2009) PDFdragosg100% (2)

- Wood 217 March 2013 PDFDocument84 pagesWood 217 March 2013 PDFAn Bn100% (1)

- Wood #135 - ENGDocument63 pagesWood #135 - ENGLaura Bukonte100% (5)

- American Woodworker - 120 (March 2006)Document65 pagesAmerican Woodworker - 120 (March 2006)Emilian Baluta100% (7)

- Woodsmith - 044Document24 pagesWoodsmith - 044rsotoqpPas encore d'évaluation

- ShopNotes #129 (Vol22) - (May-Jun.2013)Document56 pagesShopNotes #129 (Vol22) - (May-Jun.2013)Dragan Cvetkovic100% (6)

- American Woodworker - 82 (October 2000)Document78 pagesAmerican Woodworker - 82 (October 2000)Emilian Baluta100% (3)

- American Woodworker 168 October-November 2013Document76 pagesAmerican Woodworker 168 October-November 2013Gabriel Florin100% (3)

- Dovetail Key JoineryDocument3 pagesDovetail Key Joineryricheklund100% (4)

- WS 202 8-9 - 2012Document53 pagesWS 202 8-9 - 2012Patricia Arias GPas encore d'évaluation

- American Woodworker - 130 (September 2007)Document68 pagesAmerican Woodworker - 130 (September 2007)Emilian Baluta100% (4)

- American Woodworker APl 2013Document76 pagesAmerican Woodworker APl 2013Emilian Baluta100% (2)

- WSmithSpets MustHaveHandTools PDFDocument119 pagesWSmithSpets MustHaveHandTools PDFpeter100% (1)

- American Woodworker - 101 (July 2003)Document62 pagesAmerican Woodworker - 101 (July 2003)Emilian BalutaPas encore d'évaluation

- Shopnotes 88 Dovetailed Shoulder PlaneDocument8 pagesShopnotes 88 Dovetailed Shoulder PlaneJulio Cesar OliveiraPas encore d'évaluation

- Woodsmith Index 1-174Document24 pagesWoodsmith Index 1-174jlpicardPas encore d'évaluation

- 99 PDFDocument52 pages99 PDFrobotrmu100% (2)

- Wood No.200 2010Document96 pagesWood No.200 2010Francisco Sanchez100% (1)

- Good Woodworking February 2018Document92 pagesGood Woodworking February 2018kaka_02468100% (3)

- ShopNotes Issue 130 PDFDocument56 pagesShopNotes Issue 130 PDFKen Lock100% (1)

- Handwork Issue3Document92 pagesHandwork Issue3Joel Turner67% (3)

- SN11424 - Shop Made Hand PlanesDocument15 pagesSN11424 - Shop Made Hand PlanesCarlos100% (2)

- Woodworking Mag 2008Document36 pagesWoodworking Mag 2008wahomelngari1746Pas encore d'évaluation

- WWJ #2 1989Document60 pagesWWJ #2 1989ayamPas encore d'évaluation

- Wood 127 2000 10Document75 pagesWood 127 2000 10bobguv100% (2)

- Popular Woodworking 219 August-2015Document68 pagesPopular Woodworking 219 August-2015chrix80% (5)

- Popular Woodworking 2003-10 No. 136Document106 pagesPopular Woodworking 2003-10 No. 136Miguel A. Ramirez100% (7)

- American Woodworker - 122 (July 2006)Document64 pagesAmerican Woodworker - 122 (July 2006)Emilian Baluta100% (1)

- Woodwork AMFAW - 063 - May-June 2000Document84 pagesWoodwork AMFAW - 063 - May-June 2000Tanto TenPas encore d'évaluation

- American Woodworker - 100 Woodworking Tips & Techniques PDFDocument84 pagesAmerican Woodworker - 100 Woodworking Tips & Techniques PDFmvb100% (2)

- Woodsmith - 063Document24 pagesWoodsmith - 063rsotoqp100% (2)

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersD'EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- In the Greene & Greene Style: Projects and Details for the WoodworkerD'EverandIn the Greene & Greene Style: Projects and Details for the WoodworkerPas encore d'évaluation

- 011018052Document3 pages011018052Adrian Cocis100% (1)

- ShopNotes #04 (Vol. 01) - Shop Built Panel SawDocument0 pageShopNotes #04 (Vol. 01) - Shop Built Panel Sawcxrxixsx100% (1)

- ShopNotes #04 (Vol. 01) - Shop Built Panel SawDocument0 pageShopNotes #04 (Vol. 01) - Shop Built Panel Sawcxrxixsx100% (1)

- ShopNotes #05Document32 pagesShopNotes #05Luminita Ungureanu100% (2)

- Stanley QuickSquareDocument64 pagesStanley QuickSquareAdrian Cocis100% (1)

- Pompa ABT330 2.8Document1 pagePompa ABT330 2.8Adrian CocisPas encore d'évaluation

- Bolt Together LatheDocument7 pagesBolt Together Lathe69x4Pas encore d'évaluation

- 17 - Gears and Gear CuttingDocument69 pages17 - Gears and Gear CuttingPardeep Singh100% (1)

- Showcase Cabinets: The Delicate Interplay of Glass and WoodDocument7 pagesShowcase Cabinets: The Delicate Interplay of Glass and WoodAdrian Cocis100% (1)

- Metal Bending Machine 1978Document24 pagesMetal Bending Machine 1978Adrian CocisPas encore d'évaluation

- Fine Woodworking Magazine - November & December 2010-TVDocument100 pagesFine Woodworking Magazine - November & December 2010-TVAdrian Cocis100% (1)

- HELLASMED - Integral Dental UnitDocument32 pagesHELLASMED - Integral Dental UnithellasmedPas encore d'évaluation

- American Woodworker 100 200305Document65 pagesAmerican Woodworker 100 200305Adrian Cocis100% (1)

- Garden Japanese Torii Gate How ToDocument8 pagesGarden Japanese Torii Gate How ToAdrian Cocis100% (1)

- Metal Bending Machine 1978Document24 pagesMetal Bending Machine 1978Adrian CocisPas encore d'évaluation

- Metal Bending Machine 1978Document24 pagesMetal Bending Machine 1978Adrian CocisPas encore d'évaluation

- Bend Allowance FormulasDocument5 pagesBend Allowance FormulasNeeraj Sharma0% (1)

- DentalEZ® Delivery Units 3 10 1Document12 pagesDentalEZ® Delivery Units 3 10 1Adrian CocisPas encore d'évaluation

- Art of BendingDocument29 pagesArt of Bendingkhk007100% (1)

- Metal Bending Machine 1978Document24 pagesMetal Bending Machine 1978Adrian CocisPas encore d'évaluation

- DentalEZ® Delivery Units 3 10 1Document12 pagesDentalEZ® Delivery Units 3 10 1Adrian CocisPas encore d'évaluation

- DentalEZ® Delivery Units 3 10 1Document12 pagesDentalEZ® Delivery Units 3 10 1Adrian CocisPas encore d'évaluation

- HELLASMED - Integral Dental UnitDocument32 pagesHELLASMED - Integral Dental UnithellasmedPas encore d'évaluation

- Popular Woodworking November 2007Document68 pagesPopular Woodworking November 2007Mitchelo Debei100% (3)

- HELLASMED - Integral Dental UnitDocument32 pagesHELLASMED - Integral Dental UnithellasmedPas encore d'évaluation

- Manual Narsis Eng Dental UnitDocument37 pagesManual Narsis Eng Dental UnitAdrian CocisPas encore d'évaluation

- Manual Narsis Eng Dental UnitDocument37 pagesManual Narsis Eng Dental UnitAdrian CocisPas encore d'évaluation

- Human Power Lathe - N.van de Ven - NL 1977Document6 pagesHuman Power Lathe - N.van de Ven - NL 1977SPYDERSKILL100% (2)

- Compressor SizingDocument84 pagesCompressor SizingAdrian CocisPas encore d'évaluation

- Human Power Lathe - N.van de Ven - NL 1977Document6 pagesHuman Power Lathe - N.van de Ven - NL 1977SPYDERSKILL100% (2)