Académique Documents

Professionnel Documents

Culture Documents

Siskal Abis

Transféré par

Dadang H MusthofaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Siskal Abis

Transféré par

Dadang H MusthofaDroits d'auteur :

Formats disponibles

1.

PIPING SYSTEMS on ships :

1. GENERAL SERVICE SYSTEMS:

Systems to provide general services regarding

safe-operations during sailing and

berthing.

2. ME & AE AUXILIARY SYSTEMS:

Systems that required to support and to properly

run ME & AE, on which they are not

attached/ included in ME & AE

3. DOMESTIC SYSTEMS FOR

ACCOMODATION:

Domestic systems required to supply crews’

needs during sailing.

4. CARGO OIL SYSTEM FOR TANKERS:

Systems on tankers that required to loading

/off-loading cargo oil, and to support

operation and safety.

GENERAL SERVICE SYSTEMS:

a. BILGE SYSTEM:

Systems to carry-out drainage in the

event of flooding and leaking on

the vessel due to grounding and /

or collision.

b. BALLAST SYSTEM:

System to manage ship’s stability by

means of managing the location

and weight of water ballast (hence,

the ship’s centre of gravity) to

provide safe operation during

sailing and cargoing.

c. FIRE MAIN SYSTEM:

Main fire-fighting systems using

seawater hydrant.

ME & AE AUXILIARY SYSTEMS :

a. F.O. SYSTEMS:

– FO Transfer System

– FO Purifying System

– FO Supply System

b. L.O. SYSTEM

– LO Transfer System

– Main Lubricating System

– LO Purifying System

c. COOLING SYSTEMS

– SW Cooling System

– FW Cooling System

– Central Cooling System

– Low and High Temp Cooling System

– Jacket Water Coolng System

d. STARTING AND COMPRESSED AIR

SYSTEMS:

– Engine Starting System

– Compressed air Services

CARGO OIL SYSTEM FOR TANKER :

1. Cargo Oil Systems

• Main Cargo Oil System

• Stripping System

2. Cargo Oil Supporting

System

For treatment and safe

operation of cargo oil:

• Cargo Heating System

• Cargo Tank Cleaning

System

• Inert Gas Generator

System (IGGS)

2. SCOPE OF CLASSRULES ON PIPING SYSTEMS

Apply to piping systems, including valves, fittings

and pumps, which are:

1. Necessary for the operation of the main

propulsion and its auxiliaries and equipment

2. Piping systems used in operation of the ship,

whose failure could directly or indirectly impair

the safety of the ship or cargo

3. Piping systems which are dealt with other

3. VALVES with respect to their function:

a.STOP VALVES

– stop valves are used to stop flow or isolate a portion of the system until

it is desirable to achieve flow downstream of the valve.

– The basic design requirement of stop valves is to offer minimum

resistance to flow in the fully open position and to exhibit tight shut-off

characteristics when fully closed.

b. REGULATING VALVES

– Regulating valves are used extensively in piping systems to regulate the

flow of fluid. Whether the desired effect is to control flow, pressure, or

temperature, the task is accomplished by increasing or decreasing the

flow through the valve in response to a signal from a pressure, flow, or

temperature controller.

– The primary requirement of a flow-control valve is to predictably regulate

the flow with respect to its open position and impart the required

pressure drop without sustaining damage.

c. SAFETY VALVES

– Pressure-relief devices are used to protect piping and equipment from

being subjected to pressures that exceed their design pressures.

– Generally, the seating of relief valves is accomplished by a compressed

spring, which exerts a force on the valve disc, pressing it against the

valve seat.

4. TANKS :

As a mean for storage any fluids except

Seawater :

�Name of tanks:

a.Acc to the fluid content of tank

ex: fuel oil tank, lub oil tank, freshwater tank, water

ballast tanks, etc

b. Acc to location of the tank

ex: double bottom tank, forepeak tank, afterpeak

tank

COMPONENTS of TANKS :

�Filling pipe

� Discharge pipe

� Drain pipe

� Vent pipe

� Sounding pipe

� Overflow pipe

� Manhole

Vous aimerez peut-être aussi

- 1 Piping Systems On ShipsDocument9 pages1 Piping Systems On ShipsBang NielPas encore d'évaluation

- Fire Fighting SystemDocument20 pagesFire Fighting Systemanuavi93Pas encore d'évaluation

- 2nd Week ReviseDocument15 pages2nd Week ReviseCarlo ValdezPas encore d'évaluation

- Ships SystemDocument3 pagesShips SystemRS Sporso GuptaPas encore d'évaluation

- Module 4: Valves, Pumps, Ballast and CoolersDocument22 pagesModule 4: Valves, Pumps, Ballast and CoolersEmerson LinconPas encore d'évaluation

- Ppt:-Piping SystemDocument35 pagesPpt:-Piping Systemaimri_cochin64% (11)

- Ship Piping Systems ExplainedDocument25 pagesShip Piping Systems ExplainedAaron NakpilPas encore d'évaluation

- CARGO-HANDLING EQUIPMENT AND DECK MACHINERYDocument31 pagesCARGO-HANDLING EQUIPMENT AND DECK MACHINERYChristian James OgabangPas encore d'évaluation

- Operational & Maintenance Manual For Cooling TowerDocument12 pagesOperational & Maintenance Manual For Cooling Towergoli bhand100% (1)

- Topside Processing SystemDocument9 pagesTopside Processing SystemasyrafPas encore d'évaluation

- STI Camden 1 (General)Document40 pagesSTI Camden 1 (General)somod95239Pas encore d'évaluation

- General Engineering Knowledge For Marine EngineersDocument31 pagesGeneral Engineering Knowledge For Marine EngineersSrini VasanPas encore d'évaluation

- IWCF Prep Refresher - Subsea Supplement - Well Control EquipmentDocument29 pagesIWCF Prep Refresher - Subsea Supplement - Well Control EquipmentAustine Ameh50% (2)

- Pipeline SystemDocument4 pagesPipeline SystemIkaw SiPas encore d'évaluation

- Single Stage Deepwell Cargo Pump ModuleDocument12 pagesSingle Stage Deepwell Cargo Pump ModulePrathikPas encore d'évaluation

- Industrial Training ReportDocument10 pagesIndustrial Training ReportMuhammad Firdaws100% (1)

- Preparations, Operation and Safety Measures For Main EngineDocument35 pagesPreparations, Operation and Safety Measures For Main Engineart estacioPas encore d'évaluation

- Auto Start GuidelinesDocument7 pagesAuto Start GuidelinesBabar Priyadi Mugi HangganaPas encore d'évaluation

- Types of Firemain SystemsDocument9 pagesTypes of Firemain SystemsmarkousvirusPas encore d'évaluation

- Control and Accessories in RAC SystemDocument3 pagesControl and Accessories in RAC SystemVaibhav Vithoba NaikPas encore d'évaluation

- O & M Manual of Cooling Tower-TMDocument11 pagesO & M Manual of Cooling Tower-TMpiyushsingh788102060% (5)

- Chapter 4Document4 pagesChapter 4AsrijaWafiqPas encore d'évaluation

- Aeroplanes 2 (Essay)Document13 pagesAeroplanes 2 (Essay)Kishan YashwardeoPas encore d'évaluation

- Relief ValvesDocument59 pagesRelief ValvesAli Naveed Farooki100% (2)

- Ballasting and Deballasting OperationDocument17 pagesBallasting and Deballasting OperationHeaven FelosopoPas encore d'évaluation

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingD'EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingÉvaluation : 5 sur 5 étoiles5/5 (3)

- Weight EstimationDocument36 pagesWeight EstimationparvejPas encore d'évaluation

- 2 Microprocessor Chiller Installation Technical SpecsDocument12 pages2 Microprocessor Chiller Installation Technical Specsoth369Pas encore d'évaluation

- LNG CARGO HANDLING EQUIPMENT (εργασία)Document22 pagesLNG CARGO HANDLING EQUIPMENT (εργασία)ΒΑΣΙΛΕΙΟΣ ΜΑΡΑΖΙΩΤΗΣPas encore d'évaluation

- Hydrant System For Data CenterDocument3 pagesHydrant System For Data CenterSidik mattganPas encore d'évaluation

- Systems Notes Final 2Document139 pagesSystems Notes Final 2Shreshth ChaddaPas encore d'évaluation

- Chief Officer Handing Over Note 14-May-2022Document5 pagesChief Officer Handing Over Note 14-May-2022Sriram SridharPas encore d'évaluation

- Swivel JointsDocument14 pagesSwivel JointsSushilPas encore d'évaluation

- Auxiliary Marine Machinery: Under ConstructionDocument55 pagesAuxiliary Marine Machinery: Under ConstructionAkpojosevbe SamuelPas encore d'évaluation

- Auxiliary Marine Machinery: Under ConstructionDocument55 pagesAuxiliary Marine Machinery: Under ConstructionAbhinavPas encore d'évaluation

- Brief Instruction of FSRUDocument21 pagesBrief Instruction of FSRUwutigarPas encore d'évaluation

- Auxiliary Marine Machinery: Under ConstructionDocument55 pagesAuxiliary Marine Machinery: Under ConstructionArunPas encore d'évaluation

- Marine SystemsDocument44 pagesMarine Systemsvikrantgulhane83% (6)

- Power Plant Operations GuideDocument118 pagesPower Plant Operations GuideArvind Shukla100% (1)

- HW 1 SolutionDocument5 pagesHW 1 SolutionNisargPatelPas encore d'évaluation

- Water Distribution - BetterBricksDocument11 pagesWater Distribution - BetterBricksdimchienPas encore d'évaluation

- All About Marine Enginnering OralsDocument76 pagesAll About Marine Enginnering OralsUdana Hettiarachchi100% (3)

- Oil Tanker Cargo WorkDocument12 pagesOil Tanker Cargo WorkAshutosh Singh100% (3)

- WATER and Waste SystemsDocument12 pagesWATER and Waste SystemsKumaraShanPas encore d'évaluation

- Introduction To Gas Removal Systems and Liquid Ring Vacuum PumpsDocument3 pagesIntroduction To Gas Removal Systems and Liquid Ring Vacuum PumpsDheeraj ShuklaPas encore d'évaluation

- Commissioning of HydroDocument59 pagesCommissioning of Hydropawannhpc100% (3)

- ERT 322 Safety & Loss Prevention Introduction To ReliefDocument47 pagesERT 322 Safety & Loss Prevention Introduction To Relief12mchc07Pas encore d'évaluation

- Work Execution Plan For Surface Well TestingDocument12 pagesWork Execution Plan For Surface Well Testinginyene ekere100% (1)

- Process Plant Layout and Piping DesignDocument106 pagesProcess Plant Layout and Piping DesignGaurav GuptaPas encore d'évaluation

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsD'EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsPas encore d'évaluation

- Boiler Mountings & AccessoriesDocument4 pagesBoiler Mountings & Accessoriesshiraj36Pas encore d'évaluation

- Assembly and Operation of Shipboard Pumps and CompressorsDocument5 pagesAssembly and Operation of Shipboard Pumps and CompressorsKelly RobinPas encore d'évaluation

- Marine Steam Propulsion Systems Course OutlineDocument12 pagesMarine Steam Propulsion Systems Course OutlineKylePas encore d'évaluation

- Jerwin AssgnmntDocument6 pagesJerwin AssgnmntErmercadoPas encore d'évaluation

- SPM OverviewDocument56 pagesSPM OverviewSumitAggarwalPas encore d'évaluation

- Candu SystemDocument214 pagesCandu SystemGuruxyzPas encore d'évaluation

- Spe 1241 GDocument8 pagesSpe 1241 GPaul MezaPas encore d'évaluation

- Part 4 Thermal Cycle and Turbine Aux.: Chapter DescriptionDocument27 pagesPart 4 Thermal Cycle and Turbine Aux.: Chapter Descriptionkeerthi dayarathnaPas encore d'évaluation

- Prevention of Actuator Emissions in the Oil and Gas IndustryD'EverandPrevention of Actuator Emissions in the Oil and Gas IndustryPas encore d'évaluation

- Subsea Valves and Actuators for the Oil and Gas IndustryD'EverandSubsea Valves and Actuators for the Oil and Gas IndustryÉvaluation : 5 sur 5 étoiles5/5 (1)

- Detention Pond Design Using MASMADocument72 pagesDetention Pond Design Using MASMAezarul fitri50% (2)

- PRD Calculations RFCDocument12 pagesPRD Calculations RFCRicardo HernandezPas encore d'évaluation

- Item No Description Length Quantity Unit RemarksDocument1 pageItem No Description Length Quantity Unit RemarksDeepak JoyPas encore d'évaluation

- Transport PhenomenaDocument8 pagesTransport PhenomenaShivaniPas encore d'évaluation

- Astrohydro2014 III 2 PDFDocument27 pagesAstrohydro2014 III 2 PDFمصطفى العباديPas encore d'évaluation

- Torrent Pumps: 6 KNB 2900 6 - 0701 5 " K 2,4Document1 pageTorrent Pumps: 6 KNB 2900 6 - 0701 5 " K 2,4Yiannis KontominasPas encore d'évaluation

- F 9197Document4 pagesF 9197lipetrol007Pas encore d'évaluation

- CWR4202 Open Channel Flow Chap 5Document63 pagesCWR4202 Open Channel Flow Chap 5Semir KolarevićPas encore d'évaluation

- Reynolds ExperimentDocument4 pagesReynolds ExperimentShubhangi Bansude100% (1)

- Elliott Upstream Solutions For Oil and Gas: Markets & ApplicationsDocument8 pagesElliott Upstream Solutions For Oil and Gas: Markets & Applicationsyusuf alamerPas encore d'évaluation

- Storage Tank LPGDocument1 pageStorage Tank LPGAang SA100% (1)

- HITACHI Hydraulic - Oil - 5000 - KO-EN092EUQ - 2014Document2 pagesHITACHI Hydraulic - Oil - 5000 - KO-EN092EUQ - 2014dnoaisaps67% (3)

- Linear Momentum Equation Problems WWW - Engineering.purdue - Edu PDFDocument49 pagesLinear Momentum Equation Problems WWW - Engineering.purdue - Edu PDFVijendraAgarPas encore d'évaluation

- Name of TraineeDocument6 pagesName of TraineeGab Beb HaPas encore d'évaluation

- Low-Reynolds-Number Airfoil DesignDocument9 pagesLow-Reynolds-Number Airfoil Designamir_karimiPas encore d'évaluation

- Performance Analysis and Comparison of High Lift Airfoil For Low-Speed Unmanned Aerial VehicleDocument6 pagesPerformance Analysis and Comparison of High Lift Airfoil For Low-Speed Unmanned Aerial VehicleMd Abdullah Al KhosruPas encore d'évaluation

- Cooling Water System : Daily Log Sheet Date: .. Shift TimeDocument4 pagesCooling Water System : Daily Log Sheet Date: .. Shift TimeNata ChaPas encore d'évaluation

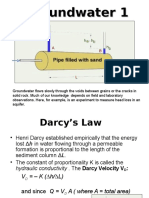

- Lecture 19w Groundwater 1 Darcy PowerpointDocument19 pagesLecture 19w Groundwater 1 Darcy PowerpointAmir ShahzadPas encore d'évaluation

- Applied Fluid Mechanics (MECH 2002)Document16 pagesApplied Fluid Mechanics (MECH 2002)chandan VishvakarmaPas encore d'évaluation

- Pump System Analysis and Centrifugal Pump SizingDocument158 pagesPump System Analysis and Centrifugal Pump Sizingme24370100% (4)

- Energy Equation: Head Losses in Pipes (MajorDocument40 pagesEnergy Equation: Head Losses in Pipes (MajorLottiibelsPas encore d'évaluation

- Guidelines for Optimal Pump System DesignDocument2 pagesGuidelines for Optimal Pump System Designdhanu_aquaPas encore d'évaluation

- MAPUA HYDRAULICS LAB ENERGY LOSSES IN BENDSDocument7 pagesMAPUA HYDRAULICS LAB ENERGY LOSSES IN BENDSJohn Michael Menoza ZapantaPas encore d'évaluation

- Fluid Dynamics Verification Manual PDFDocument194 pagesFluid Dynamics Verification Manual PDFNui Computercenter Swu OnkPas encore d'évaluation

- 300 MicroglassDocument2 pages300 MicroglassDavid BaylissPas encore d'évaluation

- An Introduction To ANSYSY Fluent 2020Document32 pagesAn Introduction To ANSYSY Fluent 2020Emma Suali100% (1)

- Saudi Aramco centrifugal pump data sheetDocument7 pagesSaudi Aramco centrifugal pump data sheetBilel MahjoubPas encore d'évaluation

- Waukesha Cherry-Burrell centrifugal pump performance curvesDocument4 pagesWaukesha Cherry-Burrell centrifugal pump performance curvesjokishPas encore d'évaluation

- Flow in Closed Conduits: Laminar and Turbulent FlowDocument54 pagesFlow in Closed Conduits: Laminar and Turbulent Flowashoku2Pas encore d'évaluation

- Modeling and FE Analysis OverallDocument54 pagesModeling and FE Analysis OverallBunny Goud PerumandlaPas encore d'évaluation