Académique Documents

Professionnel Documents

Culture Documents

Control de Ruido en Fin Fan Cooler

Transféré par

margarelliDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Control de Ruido en Fin Fan Cooler

Transféré par

margarelliDroits d'auteur :

Formats disponibles

Noise Control of Air-Cooled Heat Exchangers

by K.V. Shipes

Hudson Products Corporation, Houston, Texas

Paper for a Presentation at a Session on Noise — Results of Various Approaches to Control

Presented at the

37th Midyear Meeting of the American Petroleum

Institute's Division of Refining

in the Waldorf-Astoria

New York, New York

May 10, 1972

NOISE CONTROL OF AIR-COOLED HEAT EXCHANGERS

by K. V. Shipes

Hudson Products Corporation, Houston, Texas

Paper for a Presentation at a Session on Noise — Results of Various Approaches to Control During the 37th

Midyear Meeting of the American Petroleum Institute's Division of Refining, in the Waldorf-Astoria,

New York, New York, May 10, 1972.

ABSTRACT

This paper deals with noise caused by air-cooled heat exchangers. Points discussed are the

source and mechanism involved, as well as the relationship of the variables affecting such noise.

Air-cooler directionality, specification objectives, available range of noise and costs of quieting

are discussed.

INTRODUCTION

Air-cooled heat exchangers (FIN-FAN® units) are being used more extensively year by year in

refineries, petrochemical plants and many other places where heat must be removed from a fluid.

At the same time, several factors are coinciding to focus attention on noise generated by these

exchangers. Normally speaking, FIN-FAN® units are less noisy than several other commonly

occurring noise sources in plants (vents, furnaces, gear pumps, etc.). However, due to the

dependency of air coolers on unrestricted air flow, it is more expensive to achieve a given noise

reduction on FIN-FAN® unit than on most other types of equipment. In many cases, one can

simply contain the noise. In the case of furnaces, the limited air flow can be conveyed through a

duct, which gives the required attenuation.

The literature reflects the variety of opinions presently held as to the cause of FIN-FAN® unit’s

noise. Several factors that have been considered are:

1) Rotating forces (blade pass frequency plus harmonics)

2) Random vortex shedding

3) Air turbulence

4) Air flow over fins

5) Bearing rumble

6) Resonant effect of air-cooler plenum chamber

Hudson Products Corporation Page 2 of 11

Houston, Texas Noise Control of Air-Cooled Heat Exchangers

There have also been several equations developed which attempt to predict the noise resulting

from FIN-FAN® units with large axial flow fans.

Beranek (1) gives:

PWL (overall) = 138 + 20 log hp - 10 log q (1)

Where:

PWL = sound power level (re 10-12 watts), dB

hp = motor shaft horsepower

q = acfm, fan discharge

(Intended for both axial flow and centrifugal fans)

Allen (2) gives:

PWL (overall) = 68 + 10 log q + 20 log p (2)

Where:

p = static pressure, inches H20

Gordon, et al (3) gives:

PWL (125 Hertz) = 60 log (Vt x 10-3)+10 log acfm -7 (3)

Where:

Vt = tip speed, ft/min

Underwood (4) gives:

PWL (125 Hertz) = 55 log10 (Vt x 10-3 )+ 20 log hp (abs) (4)

-10 log acfm + 10 log (N) - 96

Where:

N = number of blades

Hudson Products Corporation Page 3 of 11

Houston, Texas Noise Control of Air-Cooled Heat Exchangers

Seebold (5) gives:

An equation to predict the SPL at a specific point with respect to the unit. For induced-draft

units, at three feet below the tubes:

Vt

4/ 7

6 12

4/ 7

(5)

SPL( overall ) = 63 + 20 log hp ×

10000 N D

Where:

SPL = sound pressure level (re 0.0002 microbars), dB

hp = hp, consumed power basis

D = fan diameter, ft.

For forced-draft units, Seebold adds about 5 dB.

Sharland (6) gives:

PWL (overall) = 56 log Vt + 10 log [Cm 0.6 L N] + A2 (6)

Where:

Cm = blade mean chord width, ft.

L = blade length, hub to tip, ft.

N = number of blades

A2 = constant

Another correlation by Lawrence (7) gives:

PWL (overall) = 95 + 10 log hp (7)

Considering these equations in order, equation (1) states that the noise energy is proportional to

the horsepower raised to a power of 2.0 and to acfm to a power of -1.0 and is unaffected by tip

speed, ∆P, fan size, number of blades, etc.

Equation (2) states that the noise energy is proportional to acfm to a power of 1.0 and ∆P to a

power of 2.0 and ignores all other factors.

Equation (3) states that the noise energy is proportional to tip speed to a power of 6.0 and acfm to

a power of 1.0 and ignores all other factors.

Equation (4) states that the noise energy is proportional to tip speed to a power of 5.5, hp to a

power of 2.0, acfm to a power of -1.0, number of blades to a power of 1.0 and ignores other

factors.

Equation (5) states that the noise energy is proportional to hp to a power of 2.0, tip speed to a

power of 1.143, fan diameter to a power of -1.143, and number of blades to a power of -2.0.

Hudson Products Corporation Page 4 of 11

Houston, Texas Noise Control of Air-Cooled Heat Exchangers

Equation (6) states that the noise energy is proportional to tip speed to a power of 5.6, mean

blade chord width to a power of 0.6, and blade length and number of blades to a power of 1.0.

Contributing to this diversity of opinion, data taken by one group may be evaluated with

considerably different results by another group. This problem arises because an air cooler is a

directional noise source, and does not lend itself readily to techniques, the aim of which is to

assign a PWL value to one or two points within its bounds.

The method behind most of these correlations is simply to develop an equation which is

reasonable and most closely matches test results. The work of Sharland reflects a wider range of

variables due to being based on a small scale setup in which the variables could be changed, one

at a time.

It is suggested that the method of correlating data on existing units is self-limiting, in a sense.

That is, no points are represented beyond present practice, whether tip speed, horsepower, acfm,

etc. No data has been made available in the literature in which one or more representative units

were tested, changing one variable at a time.

Only after such a program is carried out will there be reasonable agreement on the relative

influence of the several variables involved. In this respect, the work of Sharland is important

(even though his experiments were on a rotor of 6" diameter) because this rule was followed.

Following are several observations reflecting the writer's opinions as to the source of FIN-FAN®

unit’s noise and the relationship of the several variables.

1) FIN-FAN® unit’s noise is fan-generated noise. Less than one percent of the noise

energy can be related to panel or structural vibration. However, structural

components may influence fan-generated noise by creating additional turbulence

around the blades.

2) This fan-generated noise is caused by vortex shedding and air turbulence. It is

broad band without discrete peaks (other than the blade pass frequency, which is

normally below 31 hertz).

3) The evidence is that this noise is proportional to tip speed to a power of 5.6 to 5.8.

4) The parameter of next importance is neither horsepower nor acfm, but is pressure

differential across the fan. The exponent on ∆P is about 1.4 but varies inversely

with tip speed.

5) Acfm is of very little importance, as is horsepower. The acfm can be varied over a

10/1 range with very little effect on noise, assuming other variables are held

constant, and the stall range is not reached.

Hudson Products Corporation Page 5 of 11

Houston, Texas Noise Control of Air-Cooled Heat Exchangers

6) Regarding fan size, inadequate data exists to do more than make a guess at this

effect.

7) Regarding number of blades, the evidence is this is not significant if one avoids

the stall range. This point will be expanded later in the paper.

Regarding the previous seven statements pertaining to FIN-FAN® unit’s noise, some discussion

is in order. The fourth statement is that fan noise is proportional to the pressure differential

across the fan to an exponent of 1.4, and that this exponent varies inversely with tip speed. This

may readily be demonstrated by operating a given fan at four states as follows:

a) Vtl, ∆P1

b) Vtl, ∆P2

c) Vt2, ∆P1

d) Vt2, ∆P2

The pertinent noise data of these four tests will show a greater variation of noise caused by the

change in ∆P at the lower tip speed than at the higher tip speed.

The fifth statement is that both acfm and horsepower are of little importance. While this appears

to be contrary to the mass of field data accumulated by others, it is suggested that this field data

reflects a narrow range of fan performance as to pressure differential, fan horsepower, and blade

pitch angles. While it may be argued that this narrow range covers 95% of the useful range as far

as FIN-FAN® units are concerned, any misleading assumptions will delay progress toward a

more precise understanding of fan noise. It is suggested that this question may be fairly easily

resolved by varying the air quantity on a fan under test while holding other factors essentially

constant. A variation of horsepower while holding other factors essentially constant poses a

problem. Therefore, evaluation of horsepower effects may require cross-checking two setups in

which horsepower and other variables were allowed to change.

The seventh statement is that the number of blades in a fan is not significant if one avoids the

stall range. On this point, the literature reflects opinions in both directions. Some contend that an

increase in the number of blades increases noise, while others hold that noise is decreased.

Again, this point may be resolved by tests in which the only variable is the number of blades.

Hudson Products Corporation Page 6 of 11

Houston, Texas Noise Control of Air-Cooled Heat Exchangers

It is pertinent to inject, at this point, that one must not equate the blades of different design. That

is, a 14 ft. diameter fan with 4 blades from manufacturer A may be more efficient and have a

higher pressure capability at a given tip speed than a comparable six-blade fan from manufacturer

B.

Regarding the noise field around a FIN-FAN® unit, several observations are in order. Since the

noise generated is proportional to blade velocity to a power of 5.8, a point at the tip of a blade is

generating 1.8 times as much noise as a point 9/10 out from the center toward the tip. Thus,

approximately 80% of fan noise is generated in the outermost 20% of the fan diameter. On a 14

foot diameter fan, this zone would be defined as being 11.2 ft. I.D. and 14 ft. O.D., or the outer

1.4 ft. of each blade.

Several factors are important to an understanding of the directionality of FIN-FAN® units. First,

the previous paragraph discussed the importance of the outer segments of the blades as the origin

of most of the noise. Each blade, therefore, may be considered as having a point noise source

located at a point 9/10 from the hub to the tip and rotating with the blade. Second, the tube

bundle causes no significant attenuation of the noise passing through it. One must remember that

the tube bundle is relatively porous, having approximately 50% free area at the most restrictive

points. Third, the sheet metal containing the air flow between the fan and bundle also contains

the noise so that most of the noise must escape through the air inlet or exit areas. Therefore, only

if the noise is measured very close to the containing panels (less than three feet) will the noise

transmitted through the panels exceed the noise from the fan which passes through the air inlet or

exit. Exceptions to this rule will occur if the panel material used is too thin. There may be panel

rattle or "popping" of panel areas due to passing from a convex to a concave state, if light

material is used. The author's company presently uses 8 gauge (.164) material or heavier to

eliminate this possibility.

Tests show that a point 25 feet horizontally from a fan will indicate 5-8 dB less than a point 25

feet above or below a fan, assuming one layer of sheet metal of normal construction serves to

baffle the horizontal case. Therefore, any specification which covers a zone not shielded from the

fan by continuous sheet metal must take these factors into account. Many specifications are

written to require testing for maximum SPL at three feet from any bounding surface. This

translates into three feet below the fan guard on forced-draft units, and three feet below the tubes

on induced-draft units. (The area above the fan on induced-draft units is excluded from the

specification.)

Thus, on induced-draft units, the measurement point is 8-9 feet (average) from each rotating

noise source, and on forced-draft units, 6-7 feet. Therefore, the latter case will give readings

about 3 dB higher than the former.

Hudson Products Corporation Page 7 of 11

Houston, Texas Noise Control of Air-Cooled Heat Exchangers

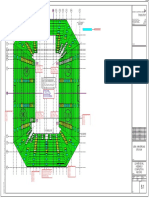

In order to better visualize the pattern of noise surrounding a FIN-FAN® unit, consider Figure 1.

This is a scale drawing of an induced-draft unit. It is assumed that each unit (2 fans) is generating

a sound power level of 100 dB (97 dB per fan). This power level would be based on one of

several hemispherical evaluation procedures. The frequency could be any one of the first five

octave bands.

The horizontal plane three feet below the tubes yields maximum SPL readings of 81.4 dB, while

a point three feet above the fan ring gives 83.9 dB. Also, notice that a point three feet out from

the transition gives 75.2 dB, even though it is much closer to the noise source, but is shielded

from the line of sight transmission. Figure 2 shows similar information for a forced-draft unit.

Equipment noise specifications usually are intended to limit the noise either immediately

adjacent to the equipment or in a zone such as a neighborhood some distance away. The control

of noise near the equipment may be motivated by one of several federal and state laws such as

the Walsh-Healey Act. A limit of 90 dB(A) on walkways beneath FIN-FAN® units calls for little

or no decrease of noise with respect to induced-draft units of standard design and only 3-4 dB

decrease on forced-draft units.

Hudson Products Corporation Page 8 of 11

Houston, Texas Noise Control of Air-Cooled Heat Exchangers

However, controlling neighborhood noise in areas adjacent to the plant boundary may impose

much more extreme limitations on equipment design. For instance, a refinery in England is

located adjacent to a housing project in which the noise level is approximately 70 dB(A). It

would be necessary to reduce the refinery noise to 1% of its present level to achieve 50 dB(A) in

the housing project, based on the assumption that the refinery is the primary cause of the present

noise levels. It is very doubtful that the expense of such a change can be justified. It is more

likely that the refinery would be salvaged and relocated, or continue to operate on a reduced

basis.

Several refineries now in either the planning or construction stage have total sound power level

limits which are designed to insure maximum sound levels in adjacent communities of 35 dB(A)

(at night), 40 dB(A), and 50 dB(A). If a law exists governing noise in a residential area, it is not

likely to allow noise in excess of 50 dB(A). A common practice is to allot 50% of the allowable

noise to FIN-FAN® units when the noise specification requires that the total plant noise PWL be

110-120 dB (A).

If it is assumed that a plant has an overall PWL limit of 115 dB (A) and a limit of 112 dB(A) is

applied to 50 FIN-FAN® units, then the limit per FIN-FAN® unit is 95 dB(A). This means that

each FIN-FAN® unit must cause 2.5% as much noise as one of standard design. (Standard design

is approximately 3 dB(A) PWL per FIN-FAN® unit.) This decrease of 16 dB will increase both

Hudson Products Corporation Page 9 of 11

Houston, Texas Noise Control of Air-Cooled Heat Exchangers

the capital cost and plot plan of the FIN-FAN® unit for a given duty. The increase should fall in

the range of 20-30%.

Recent progress in fan development promises a reduction in the added cost to achieve a given

noise decrease, as well as reducing the required increase in plot plan. In fact, it is now possible to

achieve 8-10 dB reduction below standard design noise levels with no increase in plot plan.

Both in the United States and in Europe, legal limits are being imposed at the boundaries of

installations that require 5-10 dB less noise at night than in the daytime. Variable pitch fans give

some reduction of noise (as well as saving power) as the ambient temperature decreases at night.

For instance, based on the assumption that the MTD of a group of FIN-FAN® units is 50ºF or

less, an ambient temperature decrease of 15ºF would permit a fan power reduction of 40-45%.

SUMMARY

The control of FIN-FAN® unit’s noise (and, indeed, practically all noise) is primarily an exercise

in economics, since it is possible to achieve any desired noise level if the cost of the noise

reduction is justifiable. This becomes obvious if one considers that somewhere between

minimum cost equipment (having a relatively high air flow) and maximum equipment size and

cost (no fans), one must span the entire range of possible FIN-FAN® unit’s noise down to 0 dB.

As a partial illustration of this point, the author's Company has built and demonstrated FIN-

FAN® units having reasonable air flow levels which generated 1/1000 as much noise as a

standard unit. This is a reduction of 30 dB.

Further developments in this field will probably bring forth a new generation of fans, these fan

designs being aimed at not only moving air efficiently but quietly. Therefore, the better we

understand axial flow fan noise, the more effective our efforts at reducing it will be.

REFERENCES

1. Beranek, L. L., Noise Reduction, 1960, page 544.

2. Allen, C. H., "Noise From Air Conditioning Fans", Noise Control, Vol. 3, pages 28-34,

January, 1957.

3. Gordon, C. G., and Randall, M. D., "The Noise of Air Fin Coolers", I.Mech.E.

Symposium, September 24, 1970.

4. Underwood, P. C. V., "Working to Noise Specifications - A Contractor's Approach", I.

Mech. E. Symposium, April 27, 1971.

5. Seebold, James G., "Process Plant Noise Control at the Design Engineering Stage",

ASME Paper No. 70-Pet-11.

Hudson Products Corporation Page 10 of 11

Houston, Texas Noise Control of Air-Cooled Heat Exchangers

6. Sharland, I. J., "Sources of Noise in Axial Flow Fans", J. Sound and Vibration (1964), I

(3), 302-322.

7. Lawrence, H. R., "Near Field Sound Pressure Measurements Around an Air Cooled Heat

Exchanger", American Industrial Hygiene Conference,

May 14,1969.

Hudson Products Corporation Page 11 of 11

Houston, Texas Noise Control of Air-Cooled Heat Exchangers

Vous aimerez peut-être aussi

- JBL Audio Engineering for Sound ReinforcementD'EverandJBL Audio Engineering for Sound ReinforcementÉvaluation : 5 sur 5 étoiles5/5 (2)

- CG Photo Editing2Document3 pagesCG Photo Editing2Mylene55% (11)

- PSV NoiseDocument8 pagesPSV Noisechemsac2Pas encore d'évaluation

- Api 661Document6 pagesApi 661margarelliPas encore d'évaluation

- Tuma Research ManualDocument57 pagesTuma Research ManualKashinde Learner Centered Mandari100% (1)

- 11 FanDocument5 pages11 Faniso026Pas encore d'évaluation

- BPF Noise of A FanDocument15 pagesBPF Noise of A Fanrabea matoukPas encore d'évaluation

- Air Cooled Head Exchagers - Axial FansDocument20 pagesAir Cooled Head Exchagers - Axial FansVILLANUEVA_DANIEL2064Pas encore d'évaluation

- Design of Blower PDFDocument35 pagesDesign of Blower PDFMurali Kuna Shekaran100% (1)

- Analysis of Acoustic Characteristics of The MufflerAnalysis of Acoustic Characteristics of The MufflerDocument6 pagesAnalysis of Acoustic Characteristics of The MufflerAnalysis of Acoustic Characteristics of The MufflervilukPas encore d'évaluation

- Sound Generated AerodynamicallyDocument33 pagesSound Generated AerodynamicallyAbraham Benjamin Britto100% (1)

- Acoustic Optimization For Centrifugal Fans: 379 Noise Control Engr. J. 60 (4), July-August 2012Document13 pagesAcoustic Optimization For Centrifugal Fans: 379 Noise Control Engr. J. 60 (4), July-August 2012esra sorgüvenPas encore d'évaluation

- Design and Performance of High Pressure Blowoff SilencersDocument8 pagesDesign and Performance of High Pressure Blowoff SilencersBrent100% (1)

- Comparing in Site and On Lab Measurements PDFDocument10 pagesComparing in Site and On Lab Measurements PDFDomenico VizzariPas encore d'évaluation

- A Method For Estimating Noise From Full-Scale Distributed Exhaust NozzlesDocument9 pagesA Method For Estimating Noise From Full-Scale Distributed Exhaust NozzlesBuican GeorgePas encore d'évaluation

- 04p RAynsley Paper PDFDocument14 pages04p RAynsley Paper PDFJimmy LaricoPas encore d'évaluation

- Etc2015 248 PDFDocument13 pagesEtc2015 248 PDFShridhar RaskarPas encore d'évaluation

- Fan PDFDocument28 pagesFan PDFpequenita34Pas encore d'évaluation

- Exhaust Silencer Using Water InjectionDocument10 pagesExhaust Silencer Using Water InjectionLê Vy mạcPas encore d'évaluation

- Acoustic Properties of Heated Twin Jets?: KantolaDocument28 pagesAcoustic Properties of Heated Twin Jets?: Kantolaila_368684492Pas encore d'évaluation

- Aerodynamic Noise Prediction of A Horizontal Axis Wind Turbine Using Improved Delayed Detached Eddy Simulation and Acoustic AnalogyDocument11 pagesAerodynamic Noise Prediction of A Horizontal Axis Wind Turbine Using Improved Delayed Detached Eddy Simulation and Acoustic AnalogynimakarimpurPas encore d'évaluation

- Active Control of Fan Tones by Means of Trailing Edge BlowingDocument21 pagesActive Control of Fan Tones by Means of Trailing Edge BlowingNouredineAboufarisPas encore d'évaluation

- LES Investigation of Wake Development in A Transonic Fan Stage For Aeroacoustic AnalysisDocument12 pagesLES Investigation of Wake Development in A Transonic Fan Stage For Aeroacoustic AnalysisMiguelMazzucchelliPas encore d'évaluation

- Aiaa Airfoiljet 03Document11 pagesAiaa Airfoiljet 03Namrata VermaPas encore d'évaluation

- Explicit Formulas For The Calculation of Regenerated Noise in DuctsDocument5 pagesExplicit Formulas For The Calculation of Regenerated Noise in DuctsKevin TsuiPas encore d'évaluation

- International Journal of Heat and Fluid Flow: Jason Stafford, Ed Walsh, Vanessa EganDocument13 pagesInternational Journal of Heat and Fluid Flow: Jason Stafford, Ed Walsh, Vanessa Eganbakri10101Pas encore d'évaluation

- Modifications of A Handheld Vacuum Cleaner For Noise ControlDocument7 pagesModifications of A Handheld Vacuum Cleaner For Noise ControlJason fuPas encore d'évaluation

- 15 Forward-Curved Blades Centrifugal FanDocument10 pages15 Forward-Curved Blades Centrifugal FanPrashantPas encore d'évaluation

- High Frequency Aerodynamic Noise Improvement of Variable Speed SCDocument9 pagesHigh Frequency Aerodynamic Noise Improvement of Variable Speed SCGokuPas encore d'évaluation

- NFPA 13 Sprinkler System Design Density Curves - Where Did They Come From - Sprinklers Content From Fire Protection Engineering PDFDocument7 pagesNFPA 13 Sprinkler System Design Density Curves - Where Did They Come From - Sprinklers Content From Fire Protection Engineering PDFBùi Trần Trung HậuPas encore d'évaluation

- Heat Exchanger VibrationDocument3 pagesHeat Exchanger VibrationTim KuPas encore d'évaluation

- Noise Reduction in Centrifugal Fans: A Literature SurveyDocument29 pagesNoise Reduction in Centrifugal Fans: A Literature SurveyPooria1989Pas encore d'évaluation

- Noise Reduction in Centrifugal Fans: A Literature SurveyDocument29 pagesNoise Reduction in Centrifugal Fans: A Literature SurveyPooria1989Pas encore d'évaluation

- Database Evaluation For Semi-Empirical Methods Applied To Coaxial Jet Noise PredictionDocument10 pagesDatabase Evaluation For Semi-Empirical Methods Applied To Coaxial Jet Noise PredictionAnds ProençaPas encore d'évaluation

- Building AcousticsDocument29 pagesBuilding AcousticsdeepscubPas encore d'évaluation

- Uaet Industrial Noise Series Viii Absorptive Silencer DesignDocument9 pagesUaet Industrial Noise Series Viii Absorptive Silencer DesignSérgio AmorimPas encore d'évaluation

- Numerical Investigation of Tandem-Cylinder Noise Reduction Using Plasma-Based Flow ControlDocument30 pagesNumerical Investigation of Tandem-Cylinder Noise Reduction Using Plasma-Based Flow Controlvarun karthikeyanPas encore d'évaluation

- H Darrieus TurbineDocument8 pagesH Darrieus TurbineGhada OrabiPas encore d'évaluation

- Effects of Tip Clearance On Rotor/Stator In-Teraction Tonal Noise of Axial FanDocument8 pagesEffects of Tip Clearance On Rotor/Stator In-Teraction Tonal Noise of Axial FanCanan DönmezPas encore d'évaluation

- New Microsoft Word DocumentDocument6 pagesNew Microsoft Word DocumentMohamed Gamal GemyPas encore d'évaluation

- Chap2 Fan DesignDocument12 pagesChap2 Fan Designshehbazi2001Pas encore d'évaluation

- Huber Et Al 2014 Understanding and Reduction of Cruise Jet Noise at Aircraft LevelDocument24 pagesHuber Et Al 2014 Understanding and Reduction of Cruise Jet Noise at Aircraft Levelllhleo666Pas encore d'évaluation

- Prediction and Reduction of Noise From A 2.3 MW Wind TurbineDocument10 pagesPrediction and Reduction of Noise From A 2.3 MW Wind TurbineJennyfer GalindezPas encore d'évaluation

- Acoustic GuideDocument17 pagesAcoustic GuideMohamad ShabeerPas encore d'évaluation

- Heat ExchangerDocument6 pagesHeat ExchangerAfif FakhrurPas encore d'évaluation

- Fedsm2009 78070Document10 pagesFedsm2009 78070BensinghdhasPas encore d'évaluation

- The Influence of Wind On The Performance of Forced Draught Air-Cooled Heat ExchangersDocument19 pagesThe Influence of Wind On The Performance of Forced Draught Air-Cooled Heat ExchangersArdian P NoviatmokoPas encore d'évaluation

- Lee 2013 International Journal of Heat and Fluid FlowDocument13 pagesLee 2013 International Journal of Heat and Fluid FlowalexandreburanPas encore d'évaluation

- Fan Sound Sound Ratings Fe 300Document8 pagesFan Sound Sound Ratings Fe 300hardik033Pas encore d'évaluation

- Ngineering ATA: Fan Sound & Sound RatingsDocument8 pagesNgineering ATA: Fan Sound & Sound RatingsRavi DeshmukhPas encore d'évaluation

- Heat Pumps Noise Level CalcDocument10 pagesHeat Pumps Noise Level CalcZaid Al RayesPas encore d'évaluation

- Overall Shape and Dimensions: GeneralDocument40 pagesOverall Shape and Dimensions: GeneralvrgohilPas encore d'évaluation

- The Effects of Using Noise Reduction Turbofan Engine Exhaust Nozzle Designs On A Turbojet Engine.00002Document12 pagesThe Effects of Using Noise Reduction Turbofan Engine Exhaust Nozzle Designs On A Turbojet Engine.0000221951a2183Pas encore d'évaluation

- Airfoile Noise OptimizationDocument10 pagesAirfoile Noise OptimizationLuca AnzideiPas encore d'évaluation

- Machinery Noise ReductionDocument8 pagesMachinery Noise Reductionjoao manuel 12Pas encore d'évaluation

- Applied Thermal Engineering: Research PaperDocument10 pagesApplied Thermal Engineering: Research PaperOnur GençoğluPas encore d'évaluation

- M J Clifton-Smith 2007 J. Phys. - Conf. Ser. 75 012017Document10 pagesM J Clifton-Smith 2007 J. Phys. - Conf. Ser. 75 012017Iman SaberiPas encore d'évaluation

- Southern Marine Engineering Desk Reference: Second Edition Volume ID'EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IPas encore d'évaluation

- Fundamentals of Aeroacoustics with Applications to Aeropropulsion Systems: Elsevier and Shanghai Jiao Tong University Press Aerospace SeriesD'EverandFundamentals of Aeroacoustics with Applications to Aeropropulsion Systems: Elsevier and Shanghai Jiao Tong University Press Aerospace SeriesPas encore d'évaluation

- 50 Astm D-1142-95 Humedad PDFDocument11 pages50 Astm D-1142-95 Humedad PDFmargarelliPas encore d'évaluation

- Diseño de Plantas AlimentosDocument7 pagesDiseño de Plantas AlimentosmargarelliPas encore d'évaluation

- Katdc: BAUR KalibratorDocument2 pagesKatdc: BAUR KalibratormargarelliPas encore d'évaluation

- Ch-10 Human Eye Notes FinalDocument27 pagesCh-10 Human Eye Notes Finalkilemas494Pas encore d'évaluation

- Img 20150510 0001Document2 pagesImg 20150510 0001api-284663984Pas encore d'évaluation

- Debate ReportDocument15 pagesDebate Reportapi-435309716Pas encore d'évaluation

- ICMApprovedCentres - Ghana PDFDocument8 pagesICMApprovedCentres - Ghana PDFPrince Kelly100% (2)

- European Asphalt Standards DatasheetDocument1 pageEuropean Asphalt Standards DatasheetmandraktrecePas encore d'évaluation

- Img 20201010 0005Document1 pageImg 20201010 0005Tarek SalehPas encore d'évaluation

- Traditional Perceptions and Treatment of Mental Illness in EthiopiaDocument7 pagesTraditional Perceptions and Treatment of Mental Illness in EthiopiaifriqiyahPas encore d'évaluation

- Gis Data Creation in Bih: Digital Topographic Maps For Bosnia and HerzegovinaDocument9 pagesGis Data Creation in Bih: Digital Topographic Maps For Bosnia and HerzegovinaGrantPas encore d'évaluation

- Precursor Effects of Citric Acid and Citrates On Zno Crystal FormationDocument7 pagesPrecursor Effects of Citric Acid and Citrates On Zno Crystal FormationAlv R GraciaPas encore d'évaluation

- Worst of Autocall Certificate With Memory EffectDocument1 pageWorst of Autocall Certificate With Memory Effectapi-25889552Pas encore d'évaluation

- Soft Skills & Personality DevelopmentDocument62 pagesSoft Skills & Personality DevelopmentSajid PashaPas encore d'évaluation

- Department of Education: Template No. 1 Teacher'S Report On The Results of The Regional Mid-Year AssessmentDocument3 pagesDepartment of Education: Template No. 1 Teacher'S Report On The Results of The Regional Mid-Year Assessmentkathrine cadalsoPas encore d'évaluation

- ABARI-Volunteer Guide BookDocument10 pagesABARI-Volunteer Guide BookEla Mercado0% (1)

- A Literature Review of Retailing Sector and BusineDocument21 pagesA Literature Review of Retailing Sector and BusineSid MichaelPas encore d'évaluation

- APA Vs Harvard Referencing - PDFDocument4 pagesAPA Vs Harvard Referencing - PDFTalo Contajazz Chileshe50% (2)

- Conducting Focus GroupsDocument4 pagesConducting Focus GroupsOxfam100% (1)

- Niveshdaily: From Research DeskDocument53 pagesNiveshdaily: From Research DeskADPas encore d'évaluation

- Multinational MarketingDocument11 pagesMultinational MarketingraghavelluruPas encore d'évaluation

- Toh736 - 84000 The Dharani of Parnasavari PDFDocument24 pagesToh736 - 84000 The Dharani of Parnasavari PDFJames LeePas encore d'évaluation

- John DrydenDocument3 pagesJohn DrydenDunas SvetlanaPas encore d'évaluation

- Sundar Pichai PDFDocument6 pagesSundar Pichai PDFHimanshi Patle100% (1)

- View All Callouts: Function Isolation ToolsDocument29 pagesView All Callouts: Function Isolation Toolsمهدي شقرونPas encore d'évaluation

- Grade 7 Nap MayDocument6 pagesGrade 7 Nap Mayesivaks2000Pas encore d'évaluation

- Plastic Properties HandbookDocument15 pagesPlastic Properties HandbookguilloteARGPas encore d'évaluation

- Mushroom Project - Part 1Document53 pagesMushroom Project - Part 1Seshadev PandaPas encore d'évaluation

- SDSSSSDDocument1 pageSDSSSSDmirfanjpcgmailcomPas encore d'évaluation

- PD3 - Strategic Supply Chain Management: Exam Exemplar QuestionsDocument20 pagesPD3 - Strategic Supply Chain Management: Exam Exemplar QuestionsHazel Jael HernandezPas encore d'évaluation

- Cobol v1Document334 pagesCobol v1Nagaraju BPas encore d'évaluation