Académique Documents

Professionnel Documents

Culture Documents

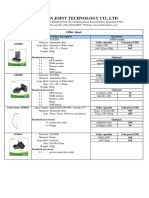

Catalog

Transféré par

san_sur20004987Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Catalog

Transféré par

san_sur20004987Droits d'auteur :

Formats disponibles

Custom Fabrication and Chambers

Section 1 Table of Contents

A&N CORPORATION Custom Fabrication and Chambers

Custom Fabrication and Chambers Introduction ..............................1.3

Custom Fabrication and Chambers

Manufacturing Capabilities .............................................................................................................................1.4 & 1.5

How to Specify a Chamber – Body Styles ................................................................................................................1.6

How to Specify a Chamber – Coordinate Systems .........................................................................................1.7 – 1.9

How to Specify a Chamber – Port Specifications .......................................................................................1.10 & 1.11

How to Specify a Chamber – Additional Considerations ............................................................................1.12 & 1.13

Custom Fabrication and Chamber Photo Gallery ................................................................................................... 1.14

A&N Corporation

707 Southwest 19th Avenue

Williston, Florida 32696

(352) 528-4100

1(800) FLANGE1

FAX (352) 528-3441

www.ancorp.com

1.2 (352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

Custom Fabrication and Chambers Section 1

High Vacuum Components Since 1965 A&N CORPORATION

Custom Fabrication

AND CHAMBERS

Overview:

A&N has been building high and ultra high vacuum chambers for over 25 years. Vacuum chambers

are employed in a variety of industries and applications. Our range of projects extends from one-

of-a-kind chambers for research applications through production quantity chambers for OEM’s.

You will find A&N vacuum chambers in materials research labs (mass spectrometry, energy

dispersive spectroscopy, Low Energy Electron Diffraction/Auger surface analysis), physics research

labs (particle accelerators, condensed matter, nanotechnology), and chemical engineering labs

(semiconductor processing). Our industrial customers are involved in coating (architectural glass,

automotive parts, compact disks), helium leak detection, and semiconductor processing (Chemical

Vapor Deposition, Physical Vapor Deposition, etching, ion implantation). A representative sampling

of our work can be found in the photo gallery at the end of this section.

QUOTATIONS: Please contact our technical sales team when requiring a quotation. Quotations can

be generated from simple, freehand sketches. Electronic files should be sent in DWG, DXF, or IGES

file formats. When needed, A&N can supply a complete set of engineered drawings. For assistance

with specifications and design communication, please see the section, “How to Specify a Vacuum

Chamber” on pages 1.6 - 1.13.

(352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

1.3

Section 1 Custom Fabrication and Chambers

A&N CORPORATION High Vacuum Components Since 1965

Overview of our capabilities:

High and ultra high vacuum chambers are engineered products that require a specialized set of

materials and fabrication processes. To help designers and practitioners better understand system

specifications, a brief overview of A&N’s capabilities and practices follows:

Materials

Standard materials: Because of its high corrosion resistance, low outgassing rates, wide range of applicable tempera-

tures, machinability, weldability, and relative cost, A&N’s standard material for tube sections, spheres and roll-ups

is 304L stainless steel. Many other materials are available upon request. A&N routinely works with 304, 316, and

316L stainless steels as wells as 6061 T6 aluminum; 360 free machining brass can also be supplied.

A&N specifies a magnetic permeability not to exceed 1.02µ when ordering raw 304 stainless materials. Welding and

machining processes may result in heat affected or cold-worked zones that may increase magnetic permeability in

these zones. Minimizing seams, joints, and bends in areas of high magnetic sensitivity should be considered during

the design process. For applications that require superior magnetic flux shielding, mu-metal can also be supplied.

Flanges: A&N’s flanges are made from specially manufactured raw stock that is designed to maximize the vacuum

capabilities of 304 stainless. These processes minimize impurities and inclusions that could adversely impact the

steel’s ability to maintain vacuum. Grain size, orientation, and density are also engineered to maximize the vacuum

performance of the raw stock.

Fabrication

Welding Machining

A&N uses tungsten inert gas (TIG/GTAW) welding tech- State-of-the-art, multi-axis, CNC machine centers are

niques with high purity argon as the backfill/purge gas. at the heart of A&N’s operations. Our work processes

Both manual and automated orbital welding machines our built upon the dual goals of high quality and rapid

are employed. In accordance with good UHV fabrica- turnaround. Our machining coolants are sulphur free,

tion practices, non-filler material, internal fusion weld biodegradable, and recycled.

joints are utilized wherever possible. In those instances

where geometries preclude internal welds, one hundred Surface Finishes

percent, full penetration welds are provided. To minimize Flanges and machined components (faced, turned or

sources of virtual leaks, external welds are only used bored) come standard with a 32 micro-inch surface fin-

when required for structural reinforcement and are lim- ish. Chambers are internally and externally bead blasted.

ited to stitch, skip, span, or spot weld configurations. Electropolishing and manual polishing are additional options.

A&N Corporation

707 Southwest 19th Avenue

Williston, Florida 32696

(352) 528-4100

1(800) FLANGE1

FAX (352) 528-3441

www.ancorp.com

1.4 (352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

Custom Fabrication and Chambers Section 1

High Vacuum Components Since 1965 A&N CORPORATION

Cleaning and Packaging

Upon final machining, all components are washed in a

heated ultrasonic detergent bath followed by multiple

ultrasonic deionized water rinses to remove all residual

machining lubricants. After final rinse, parts are blown

dry with dry, heated, filtered air and packaged.

After cleaning and testing, flanges and small compo-

nents are hermetically sealed in vacuum board packag-

ing and are ready for UHV installation. Larger flanges

are covered with a layer of foil and protective plastic

shields. Weldments and assemblies are then bagged,

bubble-wrapped, and inserted into a shipping container

surrounded by void filling “pillow” wrap. Custom crating

is available.

Leak Testing and Quality Control

All weld joints and sealing surfaces are certified

with state-of-the-art helium mass spectrometer

leak detectors to a maximum rate of 1x10^-9 std. cc

helium. Leak testing is typically conducted in an

“outside-in” or tracer-probe configuration. Helium

(gas) bag tests are conducted as needed.

The highest standards of quality control inform every

aspect of our operational practices. We welcome

customer audits. Dimensional checks are confirmed

with a computer controlled coordinate measuring

machine (CMM). Material and CMM certifications

can be provided upon request.

(352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

1.5

Section 1 How to Specify a Vacuum Chamber

A&N CORPORATION High Vacuum Components Since 1965

How to specify a custom chamber

There are three basic steps to specifying a custom vacuum chamber:

1) Specify the main body style and dimensions;

2) Specify chamber ports (2a) and port mounting configurations (2b); and

3) Specify application specific design considerations.

Sperical Cylinder Box

Figure 1 Figure 2 Figure 3

STEP 1

There are essentially three main body styles that are commonly used in vacuum applications today:

1. Spheres and hemispheres: Two hemispheres are welded together to form a spherical chamber body.

A spherical configuration provides the highest surface area to volume ratio and is (often) lighter than a

cylindrical chamber of similar volume. However, manufacturing considerations often make spherical

chambers the least economical solution.

2. Cylinders with hemispherical ends, flat ends, or flanged ends: The body of these chambers is made of

either vacuum grade tubing or a custom tubing “roll-up” depending on the diameter required. The lid and

baseplate are made from a dish head, hemisphere or customized blank flange. Cylindrical chambers are the

most commonly chosen vacuum chamber configuration.

3. Rectangular or cubic boxes: These chambers are manufactured with metal plate material that is custom

machined and welded to form the chamber body.

Once a main body style is chosen, specify the appropriate overall outer dimension(s).

Figures 1 through 3 show examples of each main body style.

A&N Corporation

707 Southwest 19th Avenue

Williston, Florida 32696

(352) 528-4100

1(800) FLANGE1

FAX (352) 528-3441

www.ancorp.com

1.6 (352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

How to Specify a Vacuum Chamber Section 1

High Vacuum Components Since 1965 A&N CORPORATION

STEP 2a:

Choose the appropriate three-dimensional coordinate system (spherical, modified cylindrical, or cartesian) and

specify each port center in coordinates of the chosen system. A complete specification of a port center includes:

1) The center point of the port in the appropriate coordinate system, 2) The focal length, 3) The focal point.

Examples of how these coordinate systems are applied to each of the typical main body styles are provided in

Figures 4 through 6. A complete port specification example for a cylindrical chamber is provided in Figure 7 and in

the table on p. 1.10. z

0˚ Polar

Spherical Chamber

Figure 4

1 Sample port

specification data

- see pg. 1.10 for a

full explanation

Port Number: 1

Flange Size (1): CF275

x origin

Flange Style (2): R

0˚ AZ

90˚ Polar Bolt Hole Style (3): H

A Mounting Config. (4): T

Tube O.D. (in): 1.50

Tube Thickness (5): Standard

1

y

h

Focal Point: A

gt

90˚ AZ

en

Notes Focal Length (in): 16.00

ll

ca

Azimuthal Angle: 135˚

fo

focal points: (0,0+ z) Polar Angle: 60˚

ex: A = (0,0,-4")

focal length 1 = 16"

180˚ Polar

z Box Chamber

Figure 5

Coordinates of the point

P = P(x,y,z) specify the

center of the flange.

(352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

1.7

Section 1 How to Specify a Vacuum Chamber

A&N CORPORATION High Vacuum Components Since 1965

STEP 2a:

Choose the appropriate three-dimensional coordinate system (spherical, modified cylindrical, or cartesian) and

specify each port center in coordinates of the chosen system. A complete specification of a port center includes:

1) The center point of the port in the appropriate coordinate system, 2) The focal length, 3) The focal point.

Examples of how these coordinate systems are applied to each of the typical main body styles are provided in

Figures 4 through 6. A complete port specification example for a cylindrical chamber is provided in Figure 7 and

in the table on p. 1.10. Z

0˚ Polar

Polar Cylindrical Chamber

angle Port 3

Figure 6A

1

en gth

c al L

Fo

Azimuthal

angle

2

h

gt

en

lL

A

ca

Fo

B

Notes

focal points: (0,0, z)

Port 1

(x=0, y=0,z)

examples:

Port 2

A= (0,0,24")

90˚ AZ

B= (0,0,20") 180˚ AZ Y

General chamber

nomenclature

Reference Plane

(0,0,0)

Port 4

Cylindrical Chamber 270˚ AZ X

0˚ AZ

Figure 6B

180˚ Azimuthal

180˚ Polar

1

Focal Azimuthal angle

Length 1 2

2

270˚ 1

Azimuthal Y 90˚ Azimuthal

A&N Corporation Z

707 Southwest 19th Avenue

Williston, Florida 32696

Focal

(352) 528-4100 Length 2

1(800) FLANGE1

FAX (352) 528-3441 Plane through origin

www.ancorp.com

X

0˚ Azimuthal

1.8 (352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

How to Specify a Vacuum Chamber Section 1

High Vacuum Components Since 1965 A&N CORPORATION

STEP 2a:

Using the conventions provided in this section, steps 2a and 2b have been completed for the seven ports

shown on the cylindrical chamber below (Figure 7). The data have been summarized in the table on p. 1.10.

Notes Cylindrical Chamber

Figure 7

focal points: (0,0,z)

examples: "A" 0,0,0

"B" 0,0,10 z

0˚ Polar

"C" 0,0,8

4 5

6

2

1 C

A

0,0

90˚ Polar

x y

0˚ AZ 90˚ AZ

Port labels 1-7 are references for the port specification table.

This is step 2b. See ppg. 1.10 & 1.11

(352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

1.9

Section 1 How to Specify a Vacuum Chamber

A&N CORPORATION High Vacuum Components Since 1965

STEP 2b

Once the port center coordinates are determined, fill out the following

port matrix to complete the port specifications:

Table A

Step 2b Step 2a

PORT FLANGE FLANGE BOLT HOLE MOUNTING TUBE TUBE FOCAL FOCAL AZIMUTHAL POLAR

NUMBER SIZE 1 STYLE 2 STYLE 3 CONFIG. 4 O.D. (IN) THICKNESS 5 POINT LENGTH(IN) ANGLE ANGLE

1 CF800 R H T 6.00 Standard B 9.00 0˚ 90˚

2 CF800 R H T 6.00 Standard B 12.00 90˚ 90˚

3 CF275 F H T 1.50 Standard B 8.00 45˚ 90˚

4 CF800 F H T 6.00 Standard B 12.00 270˚ 90˚

5 CF600 R H T 4.00 Standard A 22.00 N/A 0˚

6 CF450 R H T 2.50 Standard B 12.00 330˚ 30˚

7 CF275 R H T 1.50 Standard C 12.00 90˚ 45˚

1 - Flange Size: Please refer to the catalog for all possible flange sizes.

Representative examples are provided here:

Small ISO: QF 25, QF40, etc.

Large, Clamp or Bolted ISO: LF80, LFB100, etc.

Conflat: CF275, CF1200, etc.

2 - Flange Style (applicable to CF and ASA only):

R –Rotatable

F –Fixed

Table B 3 - Bolt Hole Style (applicable to CF and ASA only):

T –Tapped

TUBE O.D. TYPICAL TUBE WALL

(INCHES) THICKNESS (INCHES) H –Through hole

4 - Mounting Configuration:

0.25 0.039

0.38 0.049 F –Flush Mount

0.5 to 3.0 0.065 ZF –Zero Length Fixed

4.0 to 6.0 0.083 ZR –Zero Length Rotatable

6.0 to 12.75 0.120

T –Tubulated

M –Machined

Examples of the each of the mounting configurations are provided on the facing page.

A&N Corporation 5 - Tube Thickness: Specify if known or state “Standard” if A&N should select tube thicknesses.

707 Southwest 19th Avenue Table B provides some guidelines on tube thicknesses.

Williston, Florida 32696

(352) 528-4100

1(800) FLANGE1

FAX (352) 528-3441

www.ancorp.com

1.10 (352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

How to Specify a Vacuum Chamber Section 1

High Vacuum Components Since 1965 A&N CORPORATION

Tubulated (Rotatable & Non-Rotatable)

Internal weld

Port Mounting Configurations

(reference pg. 1.10, step 2b, note 4) I.D.

4 Port Configurations Flush Mount

Zero Length

Fixed or

Rotatable Flush Mount Internal weld

I.D.

Zero Length (Fixed)

Internal weld

I.D.

Zero Length (Rotatable)

Machined Tubulated

Machined

Smaller flange detail machined

into air-side of larger flange,

including blind tapped holes

I.D.

(352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

1.11

Section 1 How to Specify a Vacuum Chamber

A&N CORPORATION High Vacuum Components Since 1965

STEP 3

Specify application specific design considerations. A minimum set of criteria are provided here:

a. Material: Specify if other than 304L stainless steel.

b. Main body wall thickness: Specify if known or state “Standard” if A&N should select the thickness.

c. Bolt hole orientation: Specify, as shown in Figure 7 below, if known or state “Standard” if A&N

should select the bolt hole orientation (for non-rotatable flanges). The orientation of leak check grooves

on CF flanges should be indicated if critical.

A Figure 7

A/2

Primary

American European

Axis

d. Clamp and bolt kit clearances: Be sure that tubulated flange mounts have the minimum clearances

as shown in Table C & D below: .57

A

Table C - ISO Clamp Clearance B

FLANGE MIN. DIA. MAX. DIA. MIN. DIA. C

SIZE TO INSTALL A CLOSED B CLOSED C

QF-10 2.86 2.65 1.75

QF-16 2.86 2.65 1.75

QF-25 3.32 3.00 2.24

QF-40 4.00 3.72 2.90

QF-50 5.45 4.62 3.69

Table D - CF and ASA/ANSI Clearance

FLANGE FLANGE RECOMMENDED MINIMUM

TYPE SIZES CLEARANCE TO BACK OF FLANGE

Table E

CF All 1/2”

STANDARD

ASA/ANSI 100 to 400 1”

TOLERANCES

ASA/ANSI 600 to 1000 1 1/2”

If your design cannot accommodate these distances

A&N recommends tapped bolt holes for your flanges. Machined Dimensions:

.XXX +/- 0.005"

.XX +/- 0.010"

A&N Corporation .X +/- 0.025"

e. Tolerances: Specify if known or state “Standard”

Fraction +/- 1/16"

707 Southwest 19th Avenue

if A&N standard tolerances should be applied. Welded Dimensions:

Williston, Florida 32696

(352) 528-4100 A&N’s standard tolerances are provided in Table E (to the right): <= 24" +/- 0.030"

1(800) FLANGE1

FAX (352) 528-3441 > 24" +/- 0.060"

www.ancorp.com Angle (port alignments):

+/- 0.5 degrees

1.12 (352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

How to Specify a Vacuum Chamber Section 1

High Vacuum Components Since 1965 A&N CORPORATION

f. Water-cooled jacketing: A&N manufactures two styles of water-cooled chambers for high temperature

or high heat flux applications:

1. Double-Wall Construction: Double-wall construction is most often used in those applications requir-

ing uniform internal chamber temperatures. Typically, double-wall, water-cooled chambers are made with

internal baffles that help provide uniform, laminar water circulation.

2. Channel Construction: Channel construction is most often used in those applications requiring local-

ized or targeted cooling. Because it involves a fair amount of hand fitting work to install, channel con-

struction is often more expensive than double-wall construction.

Outer H2O Jacket Wall Water Outlet

Inner H2O / Chamber Wall

Double Wall

Construction

Baffles Water Inlet

Water Outlet

Channel

Construction

Water Inlet

(352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

1.13

Section 1 Custom Fabrication and Chambers

A&N CORPORATION High Vacuum Components Since 1965

A&N Corporation

707 Southwest 19th Avenue

Williston, Florida 32696

(352) 528-4100

1(800) FLANGE1

FAX (352) 528-3441

www.ancorp.com

1.14 (352) 528-4100 • 1(800) FLANGE1 • www.ancorp.com

Vous aimerez peut-être aussi

- Furnace LeafletDocument4 pagesFurnace Leafletsan_sur20004987Pas encore d'évaluation

- SYLLABUSDocument2 pagesSYLLABUSsan_sur20004987Pas encore d'évaluation

- Geometrical Boundaries StoreDocument10 pagesGeometrical Boundaries Storesan_sur20004987Pas encore d'évaluation

- Viewports CatalogDocument20 pagesViewports Catalogsan_sur20004987Pas encore d'évaluation

- Dry PumpDocument1 pageDry Pumpsan_sur20004987Pas encore d'évaluation

- Engineering Mathematics-I Jan 2006Document3 pagesEngineering Mathematics-I Jan 2006san_sur20004987Pas encore d'évaluation

- Vacuum System Design for SESAME Particle AcceleratorDocument15 pagesVacuum System Design for SESAME Particle Acceleratorsan_sur20004987Pas encore d'évaluation

- 08-020 ProtectionGateValveDocument4 pages08-020 ProtectionGateValvesan_sur20004987Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Lead Funnels On Funnel Swipe File - TrelloDocument5 pagesLead Funnels On Funnel Swipe File - TrelloKatherie BriersPas encore d'évaluation

- Formal Analysis of Timeliness in Electronic Commerce ProtocolsDocument5 pagesFormal Analysis of Timeliness in Electronic Commerce Protocolsjuan david arteagaPas encore d'évaluation

- Assembly Transmission Volvo A40GDocument52 pagesAssembly Transmission Volvo A40GNanang SetiawanPas encore d'évaluation

- Obeid Specialized Hospital - Riyadh: Inpatient DeptsDocument4 pagesObeid Specialized Hospital - Riyadh: Inpatient DeptsLovelydePerioPas encore d'évaluation

- ManupptDocument65 pagesManupptKrishanarju VenkatesanPas encore d'évaluation

- Dayal Bagh: Spircon 2013: Book of AbstractsDocument202 pagesDayal Bagh: Spircon 2013: Book of AbstractsSant Mat100% (2)

- Active-Passive VoiceDocument18 pagesActive-Passive VoiceDivya JainPas encore d'évaluation

- Vehicle Tracker Offer SheetDocument1 pageVehicle Tracker Offer SheetBihun PandaPas encore d'évaluation

- Training Needs Analysis (Managing Training & Development)Document78 pagesTraining Needs Analysis (Managing Training & Development)Henrico Impola100% (1)

- American With Disabilities Act AdaDocument16 pagesAmerican With Disabilities Act Adaapi-376186426Pas encore d'évaluation

- Forensic Pharmacy: Dr. Zirwa AsimDocument35 pagesForensic Pharmacy: Dr. Zirwa AsimZirwa AsimPas encore d'évaluation

- Chlor Rid SlidesDocument47 pagesChlor Rid Slidesmohammed goudaPas encore d'évaluation

- DLP IN ICT 9 1st MeetingDocument2 pagesDLP IN ICT 9 1st MeetingHEDDA FULOPas encore d'évaluation

- Five Sheets For Technology PlanDocument16 pagesFive Sheets For Technology Planapi-200984070Pas encore d'évaluation

- The Machine-Room-Less Elevator: Kone E MonospaceDocument8 pagesThe Machine-Room-Less Elevator: Kone E MonospaceAbdelmuneimPas encore d'évaluation

- Effective-Plant-Course Brochure NovDocument8 pagesEffective-Plant-Course Brochure NovAzri HafiziPas encore d'évaluation

- Delhi University SEC Exam Date Sheet March 2023Document2 pagesDelhi University SEC Exam Date Sheet March 2023aamir9ali-42Pas encore d'évaluation

- CP QB PT-3 Harish KumarDocument3 pagesCP QB PT-3 Harish KumarVISHNU7 77Pas encore d'évaluation

- Samsung GT-I8160 Galaxy Ace 2 08 Level 3 Repair - Block-, PCB Diagrams, Flow Chart of TroubleshootingDocument47 pagesSamsung GT-I8160 Galaxy Ace 2 08 Level 3 Repair - Block-, PCB Diagrams, Flow Chart of TroubleshootingOuadghiri Badre Ddine50% (2)

- CA Ashish Dewani - Resume-1Document2 pagesCA Ashish Dewani - Resume-1Payal JainPas encore d'évaluation

- Frame Fit Specs SramDocument22 pagesFrame Fit Specs SramJanekPas encore d'évaluation

- PC 5400 PC 5500Document53 pagesPC 5400 PC 5500ArturHeisePas encore d'évaluation

- Nature vs Nurture DebateDocument3 pagesNature vs Nurture DebateSam GoldbergPas encore d'évaluation

- Green Screen Background Remover Using CV SystemDocument20 pagesGreen Screen Background Remover Using CV SystemSubhamPas encore d'évaluation

- Table of Material Properties For Structural Steel S235, S275, S355, S420Document4 pagesTable of Material Properties For Structural Steel S235, S275, S355, S420Mouhssine BrahmiaPas encore d'évaluation

- Sri Dwi Mutiara-Jurnal CRSS OSNE 1Document11 pagesSri Dwi Mutiara-Jurnal CRSS OSNE 1sri dwi mutiaraPas encore d'évaluation

- 5 Axis MachinesDocument33 pages5 Axis MachinesgsPas encore d'évaluation

- 3ADW000379R0301 DCS550 Manual e CDocument310 pages3ADW000379R0301 DCS550 Manual e CLaura SelvaPas encore d'évaluation

- 3.0 Wrap Up and SummaryDocument4 pages3.0 Wrap Up and SummaryGian SanchezPas encore d'évaluation