Académique Documents

Professionnel Documents

Culture Documents

Ds 510

Transféré par

envitech72Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ds 510

Transféré par

envitech72Droits d'auteur :

Formats disponibles

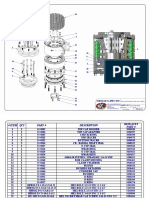

MASON INDUSTRIES, Inc.

Manufacturers of Vibration Control Products

350 Rabro Drive 2101 W. Crescent Ave., Suite D

ALL DIRECTIONAL

ANCHORS and VERTICAL

SLIDING GUIDES for

ADA

Hauppauge, NY 11788

631/348-0282

FAX 631/348-0279

Info@Mason-Ind.com

www.Mason-Ind.com

Anaheim, CA 92801

714/535-2727

FAX 714/535-5738

Info@MasonAnaheim.com

www.MasonAnaheim.com

RISERS with STRAIGHT

PIPE, OFFSETS or

EXPANSION JOINTS DATA SHEET DS-510-3

& VSG

“TH” “A” Square TYPE ADA and ADAH RATINGS

ADA TAPPED HOLE Top & Bottom Anchoring

All Directional Anchors Weld or Bolt Pipe Capacity Rated

Change designation to Clamp or Bracket per Pair Defl

ADAH when base plate to ADA Anchor Type Size (Ibs) (kg) (in) (mm)

with bolt holes is 75 1,000 453 0.1 2.5

required. Heavy Duty Neoprene &

Weld Duck or Neoprene Isolation ADA- 200 6,000 2722 0.1 2.5

Base to (min. thickness 1/2” 13mm) 350 24,000 10886 0.1 2.5

Support ADAH- 600 60,000 27216 0.1 2.5

HH Steel 800 100,000 45359 0.1 2.5

ADAH

Baseplate Each pair of ADA(H) all directional anchors provides

H for Bolting high frequency noise and vibration isolation for those

locations where movement must be controlled.

When the anchors are attached to piping as shown

in the illustrations below, all expansion will be direct-

HC L ed from this point.

T

Anchors are always used in pairs.

A

RBD

RBD-Required Bolt Dia.

TYPE ADA and ADAH DIMENSIONS (inches and mm) for Max. Loading

Type Size A H L T HC HH RBD TH

75 3 41/2 6 1/4 5 43/4 3/8 1/2-13UNC

76 114 152 6 127 121 10

ADA- 200 4 7 11 3/8 81/2 73/8 5/8 5/8-11UNC

102 178 279 10 216 187 16 Mason Bracket

Pipe Clamp

350 71/4 12 1/2 91/2 73/4 3/4 None (by others) Welded to Pipe

* 184 305 13 241 197 19 (custom designed

Welded to

ADAH- 600 9 11 141/2 3/4 12 113/4 11/4 None Pipe for wide or irregular

229 279 368 19 305 298 32 structural support spacing)

800 11 131/2 171/2 1 141/2 141/2 11/2 None *Size 350 –

279 343 445 25 368 368 38 Top is 5” 127mm x 5” 127mm, Bottom is 6” 152mm x 6” 152mm.

TYPE VSG and VSGH RATINGS

VSG “B” Square Bolt or Weld

Pipe Clamp or Horizontal Possible For use

Vertical Sliding Guide Bracket to Capacity Horizontal with

Change designation to VSG Guide per Pair Deflection Pipe Sizes

VSGH when base plate Type Size (Ibs) (kg) (in) (mm) (in) (mm)

with bolt holes “TH” TAPPED 75 1,000 453 0.1 2.5 thru 5 125

HOLE VSG-

200 8,000 3629 0.1 2.5 6 150 thru 12 300

VSGH- 350 11,300 5126 0.1 2.5 14 350 thru 24 600

Heavy Duty Neoprene

“RBD” Isolation (minimum Each pair of VSG guides provides high frequency noise and

Required thickness 1/2” 13mm) vibration isolation for those locations where movement must be

Bolt Dia. for guided in the axial direction.

Max. Horiz. SET SCREW

UHH Capacity Standard VSG Guides can be set to accommodate:

VSGH a) 0 Upward Movement and 31/4” 83mm Downward Movement.

Baseplate b) 31/4” 83mm Upward Movement and 0 Downward Movement.

for Bolting c) 15/8” 41mm Upward or Downward Movement.

UH d) Special settings as required and certified.

A Guides are always used in pairs.

T When pairs of VSG Guides are used as shown in the illustra-

HC tions below right, radial motion is controlled while axial motion is

A guided.

31/4” 83mm L

MH 31/4” 83mm

UPWARD DOWNWARD

MOVEMENT MHH MOVEMENT

DH SETTING

SETTING

DHH

15/8” 41mm

UPWARD or

DOWNWARD

TYPE VSG and VSGH DIMENSIONS (inches and mm) MOVEMENT SETTING

Pipe Clamp

31/4” 83mm 31/4” 83mm 15/8” 41mm (by others)

Downward Upward Up or Down Welded to

Movement Movement Movement Pipe

Type Size

A B L T HC RBD TH DH DHH UH UHH MH MHH

753 3 61/4 1/4 5 3/8 1/2-13UNC 101/4 101/2 7 71/4 85/8 87/8

76 76 159 6 127 10 260 267 178 184 219 225

VSG- 200 41/2 4 93/4 3/8 8 5/8 7/8-9UNC 101/2 107/8 71/4 75/8 87/8 91/4 Mason Bracket

114 102 248 6 203 16 267 276 184 194 225 235 Welded to Pipe

VSGH- 350 6 5 11 1/2 9 3/4 1-8UNC 103/4 111/4 71/2 8 91/8 95/8 (custom designed

152 127 280 13 229 19 273 286 191 203 232 244 for wide or irregular

structural support spacing)

ADA & VSG MASON INDUSTRIES

RECOMMENDED ANCHOR SIZE SELECTIONS & MAXIMUM RECOMMENDED VERTICAL GUIDE SPACING

SIZE SELECTIONS TO PREVENT PIPE BUCKLING

Straight Offset

GUIDE SIZES Solid Riser Solid Risers Having Expansion Joints

Pair of Riser

Anchors A Pairs of Stainless Steel Neoprene C Balance of

Used to Anchors One Guide One Anchor Guides

Resist Used to Each End Each End One Anchor One Anchor Distance

Expansion Resist and and Each End Each End Between Joint

Joint Thrust Offset Maximum Maximum of Pipeline of Pipeline and Anchor

Illustration 1 Thrust Theoretical Distance Distance D

Illustration 1 Non-Supportive Between Between B B

Operating Directional Guides Guides Distance Distance Distance Operating

Pressures Guides D D Joint First Joint to Pressures

Pipe Up to 151- Illustration 2 to to First Guide up to 151-

Size 150 psi 300 psi First Second Second not 150 psi 300 psi

(in) 10kg/cm 20kg/cm2 Offset

2

Guide Guide Required 1 10kg/cm 20kg/cm2

2

(mm) Size Size (ft) (m) Size Size 2 (ft) (m) 1 (ft) (m) D 1 D D (ft) (m) (ft) (m)

1 7.4 40 24 8” 2’-0” 8” 12 1 12

25 ADA-75 ADA-75 2.26 ADA-75 VSG-75 12 7 .20 0.61 0.20 3.66 3.66

11/4 ADA-75 ADA-75 8.2 ADA-75 40 24 8” 2’-0” 8” 12 12

VSG-75

35 2.5 12 7 .20 0.61 0.20 3.66 3.66

11/2 ADA-75 ADA-75 9.0 ADA-75 40 D 24 D 10” 3’-0” 10” 12 12 D

VSG-75

40 2.7 12 7 .25 0.91 0.25 3.66 3.66

2 9.8 2 40 2 24 10” 2 3’-0” 10” 2 12 2 12

ADA-75 ADA-75 3.0 ADA-75 VSG-75

50 12 7 .25 0.91 0.25 3.66 3.66

21/2 ADA-200 11.0 40 30 12” 3’-6” 12” 12 12

ADA-75 3.4 ADA-75 VSG-75

65 12 9 .31 1.07 0.31 3.66 3.66

3 12.3 40 36 12” 3’-6” 12” 17 14

ADA-75 ADA-200 3.7 ADA-75 VSG-75

80 12 11 .31 1.07 0.31 5.18 4.27

4 40 D 36 D

ADA-200 13.9 1’-4” 4’-8” D 1’-4” 25 19

ADA-75 4.2 ADA-75 VSG-75

100 12 11 .41 1.42 0.41 7.62 5.80

5 15.0 2 50 2 36 2’-0” 2 7’-0” 2’-0” 2 30 2 23

ADA-75 ADA-200 4.6 ADA-75 VSG-75

125 15 11 .61 2.134 0.61 9.14 7.01

6 ADA-350 16.8 50 36 2’-0” 7’-0” 2’-0” 37 27

ADA-200 5.1 ADA-200 VSG-200 D .61 D 0.61

150 15 11 2.134 11.28 8.23

8 18.8 50 50 2’-6” 9’-4” 2’-6” 45 33

ADA-200 ADA-350 5.7 ADA-200 VSG-200

200 15 15 .76 2.85 0.76 13.72 10.06

10 ADA-350 21.3 60 D 60 3’-4” 11’-8” 3’-4” 58 42

ADA-200 6.5 ADA-200 VSG-200

250 18 18 1.0 3.56 1.07 17.68 12.80

12 23.0 72 72 2 D 4’-0” 2 14’-0” D 4’-0” 2 60 2 48

ADA-350 ADA-600 7.0 ADA-350 VSG-200 2

300 22 22 4.0 4.27 0.41 18.29 14.63

14 ADA-350 ADA-600 24.0 85 85 4’-8” 16’-4” 4’-8” 71 51

7.3 ADA-350 VSG-200

350 26 26 1.4 4.98 1.43 21.64 15.55

16 25.8 85 85 5’-4” 18’-8” 5’-4” 78 56

ADA-350 ADA-600 7.9 ADA-350 VSG-200

400 26 26 1.6 5.69 1.63 23.75 17.07

18 ADA-600 ADA-800 27.5 85 D D 85 6’-0” 21’-0” D 6’-0” 85 61

8.4 ADA-350 VSG-200

450 26 26 1.8 6.40 1.83 25.91 18.95

20 29.0 2 120 120 2 6’-8” 23’-4” 6’-8” 91 2 65

ADA-600 ADA-800 8.8 ADA-350 VSG-200

500 37 37 2.0 2 7.11 2.03 2 27.74 19.81

24 — ADA-600 120 120 8’-0” 28’-0” 8’-0” 103 75

ADA-800 VSG-350

600 37 37 2.4 8.53 2.44 31.40 22.86

26 Special — ADA-600 120 120 10’-0” 35’-0” 10’-0” 118 85

ADA-800 Designs

650 37 37 3.0 10.67 3.05 35.97 25.91

28 as — ADA-600 Special Designs 120 D D 120 10’-0” 35’-0” 10’-0” 118 85 D

ADA-800 Required As Required

700 37 37 3.05 10.67 3.05 35.97 25.91

30 — ADA-600 2 120 120 1 10’-0” 1 35’-0” 10’-0” 1 118 1 85

ADA-800

750 37 37 3.05 10.67 3.05 35.97 25.91

A

Reference forces calculated on standard reference for 1” 25mm movement at pipe stress of 15000 psi 1050 kgcm2.

B

If the anchor is next to the joint on one side, no guide is needed on that side.

C

Guides beyond the anchor may be spaced as in a straight solid run since there is no thrust force.

Illustration 1 Illustration 2

ADA ANCHOR VSG SLIDING GUIDE

Pipe Clamp Mason Bracket Pipe Clamp

Welded to Mason Bracket

Welded to Pipe Welded to Welded to Pipe

Pipe (custom designed Pipe (custom designed

for wide or irregular for wide or irregular

structural support spacing) structural support spacing)

To more clearly define and control riser load shifts caused by pipe expansion and contraction, strategically

placed spring supports may be incorporated. See Hanger Bulletin H-610 (page 13) for a detailed

description of this method using type SLFH Steel Spring Mounts or type HES Pipe Expansion Hangers.

Vous aimerez peut-être aussi

- Bathtub - Pay1580d Pay1780dDocument1 pageBathtub - Pay1580d Pay1780denvitech72Pas encore d'évaluation

- Swimming Pools PDFDocument75 pagesSwimming Pools PDFYazPas encore d'évaluation

- (Englishaction - Edu.vn) CV Giai 1Document4 pages(Englishaction - Edu.vn) CV Giai 1Hoang Ngoc HungPas encore d'évaluation

- TB Ve Viec Khu Vuc SX Cam Hut ThuocDocument1 pageTB Ve Viec Khu Vuc SX Cam Hut Thuocenvitech72Pas encore d'évaluation

- A Proficiency Course in English With Key, by F.v.bywaterDocument129 pagesA Proficiency Course in English With Key, by F.v.bywatermariobbskPas encore d'évaluation

- Be Bright and Polite: WWW - Orient-AtionDocument12 pagesBe Bright and Polite: WWW - Orient-Ationenvitech72Pas encore d'évaluation

- T VGSGroovedPipingSystemDocument9 pagesT VGSGroovedPipingSystemenvitech72Pas encore d'évaluation

- Obama State Union 13 Feb 2013Document13 pagesObama State Union 13 Feb 2013envitech72Pas encore d'évaluation

- Grinnell Aus Mech PB 07-20-12 v1Document132 pagesGrinnell Aus Mech PB 07-20-12 v1envitech72Pas encore d'évaluation

- Malleable Iron Threaded FittingsDocument16 pagesMalleable Iron Threaded Fittingsenvitech72Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- HP Deskjet 2320 - AIODocument2 pagesHP Deskjet 2320 - AIOToma ObretenovPas encore d'évaluation

- G2YM400VL20Document4 pagesG2YM400VL20luis gonzalezPas encore d'évaluation

- New Microsoft Word DocumentDocument14 pagesNew Microsoft Word DocumentgurusammyPas encore d'évaluation

- Motor Protection PDFDocument49 pagesMotor Protection PDFEslamPas encore d'évaluation

- SACE Tmax XT7 Technical Data Sheet 1SXU210261D0201Document2 pagesSACE Tmax XT7 Technical Data Sheet 1SXU210261D0201mohamed salehPas encore d'évaluation

- Each Generation of Computer Is Characterized by A Major Technological Development That Fundamentally Changed The Way Computers OperateDocument8 pagesEach Generation of Computer Is Characterized by A Major Technological Development That Fundamentally Changed The Way Computers OperatefaysiiPas encore d'évaluation

- Bahasa InggrisDocument4 pagesBahasa InggrisMelindaAyunitaPas encore d'évaluation

- Rigging GuideDocument142 pagesRigging GuideJB MadeleinePas encore d'évaluation

- B25D/B30D Mk7.0: Pieces Entretiens/Service PartsDocument1 pageB25D/B30D Mk7.0: Pieces Entretiens/Service PartskandukissPas encore d'évaluation

- Fiber Optic Interconnects: AmphenolDocument26 pagesFiber Optic Interconnects: Amphenolsrikanth NakkaPas encore d'évaluation

- 12hh ClampDocument2 pages12hh ClampNelson de la Rosa100% (1)

- Volvo S40 L4-1.9T Diagrams1Document33 pagesVolvo S40 L4-1.9T Diagrams1rodolfodiazPas encore d'évaluation

- Caribbean Examinations Council: Caribbean Secondary Education Certificate ExaminationDocument24 pagesCaribbean Examinations Council: Caribbean Secondary Education Certificate ExaminationMarco McleanPas encore d'évaluation

- Sony Discman D-E305Document2 pagesSony Discman D-E305GeorgeFlowersPas encore d'évaluation

- Plumbing and Carpentary Workshop Report Week 1Document27 pagesPlumbing and Carpentary Workshop Report Week 1F1042 HaikalPas encore d'évaluation

- TYA9455EKSDocument1 pageTYA9455EKSMathias LedesmaPas encore d'évaluation

- Motors | Assembly and Disassembly Procedures for WEG AlternatorsDocument43 pagesMotors | Assembly and Disassembly Procedures for WEG Alternatorsrooies13Pas encore d'évaluation

- RS-550PC/VC: Output: 5.0W 100W (Approx)Document1 pageRS-550PC/VC: Output: 5.0W 100W (Approx)Mahesa SanggadipaPas encore d'évaluation

- Hydraulic drill support for longhole drillingDocument1 pageHydraulic drill support for longhole drillingBruno BritoPas encore d'évaluation

- D D D I J 0: ChunghopDocument16 pagesD D D I J 0: ChunghopAndrow ZerounPas encore d'évaluation

- 3 Month Internship ReportDocument38 pages3 Month Internship Reportprajapati dhavalPas encore d'évaluation

- RG 8/U Type: Coaxial Cable ElectronicsDocument1 pageRG 8/U Type: Coaxial Cable ElectronicsLUISPas encore d'évaluation

- Glsii Ba en 0106Document27 pagesGlsii Ba en 0106Jesus Roberto De La Vega GermanPas encore d'évaluation

- Physics Experiment 07 (Convex Mirror) - 1Document2 pagesPhysics Experiment 07 (Convex Mirror) - 1yubraj sethPas encore d'évaluation

- Rooftop Series: Complete PackageDocument4 pagesRooftop Series: Complete Packageyusuf mohd sallehPas encore d'évaluation

- Sitransl - lr150 DatasheetDocument1 pageSitransl - lr150 DatasheetManuelMackenziePas encore d'évaluation

- Huck Aerospace Tool CatalogDocument116 pagesHuck Aerospace Tool CatalogTony C.Pas encore d'évaluation

- Invensys ECH 400S English - ReductDocument24 pagesInvensys ECH 400S English - ReductAl BerchevPas encore d'évaluation

- AXIpremium X HC BLK 120 cell solar module with 15 year warrantyDocument2 pagesAXIpremium X HC BLK 120 cell solar module with 15 year warrantyatılay demirezerPas encore d'évaluation

- Safety Rules For Air Rifle Shooting RangesDocument26 pagesSafety Rules For Air Rifle Shooting Rangesgenije72973Pas encore d'évaluation