Académique Documents

Professionnel Documents

Culture Documents

1996 - Misplon - Pinhole Grate Conversions of

Transféré par

mchoi23Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1996 - Misplon - Pinhole Grate Conversions of

Transféré par

mchoi23Droits d'auteur :

Formats disponibles

PINHOLE GRATE CONVERSIONS OF TWO 30 T/H BOILERS AT

SOUTH NYANZA SUGAR COMPANY; KENYA

B MISPLON, H VERBANCK AND P MCINTYRE

John Thompson Africa (Pty) Limited, PO Box 129, Bellville 7535

Abstract The final gas temperature increased by approximately

The paper discusses experience gained from rehabilitating 40°C due to the higher heat load and the slightly lower effi-

two 30 tlh ISGEC John Thompson boilers at South Nyanza ciency. The steam side required no modifications as the steam

Sugar Company (SONY) in Kenya. The conversion included drum release rate, superheater pressure drop and the final

the replacement of the existing dumpgrate stokers with steam steam temperature all proved to be within reasonable limits.

cleaned air, cooled stationary grates (pinhole grates), new

Table 1

forced and induced draught fans, three drum bagasse feeders, Some important upgrading parameters

pneumatic spreader equipment and automatic boiler controls.

Parameter Units Existing Uprated

Furnace exit temperature °C 916 956

Introduction Grate heat release rate GJ/m2h 9,1 11,0

The steam requirements at SONY are supplied by two Final gas temperature °C 246 262

Efficiency on gross calorific value % 65 63

ISGEC John Thompson boilers. The boilers are of the three

pass configuration fitted with dump grates, and were origi-

nally designed to supply 30 t/h of steam at 320°C and 20 bar.

During the 1994 crushing season, the boiler plant proved to The scope of supply

be the limiting factor in overall mill production. The authors' The scope of supply to achieve the upgraded condition

company was approached to engineer a solution to increase consisted of the following:

the total steam output and improve the availability of the

plant for the 1995 season. This paper describes in detail the Combustion equipment

modifications made to the boilers with particular emphasis on Three new bagasse feeders were fitted to each boiler re-

the steam cleaned, air cooled grates that were installed. placing the original single drum feeders. The new feeders are

of the three drum type, driven by geared motors and control-

led with AC inverter drives. The feeders are of a non-standard

The design stage width to suit the narrower, existing upper bagasse chutes. The

The objective was to increase the boiler output by 20% installed power for the three drum feeders is approximately

from 30 t/h to 36 tlh while maintaining the final steam pres- 50% of that of single drum feeders which, although a small

sure. This was a considerable increase and detailed design saving, still adds to the overall plant efficiency. The metering

calculations were performed to ensure that the mechanical characteristics are also considerably better. New pneumatic

performance and availability would not be jeopardised. spreaders were also installed. These are also a non-standard

size to suit the front wall tube manipulations.

The main areas of concern were the following:

• Gas temperature leaving the furnace Grate

• Grate and furnace heat release rate The existing dump grate was removed and replaced with a

• Gas velocities new steam cleaned, air cooled stationary grate, more com-

monly known as a pinhole grate (see next section).

• Final gas temperature

• Steam release rate Draught plant

• Final steam temperature The decrease in the final gas densities and the subsequent

• Superheater pressure drop. increase in the volume flow rates and gas side pressure drops

Table 1 lists some of these figures for the initial and final warranted new, more powerful induced draught (ID) fans.

The original idea was to decrease the fan speed from 990 rpm

conditions. The gas temperature leaving the furnace remained

to 740 rpm to reduce the erosion rate.

below the 1050°C mark, above which furnace slagging and

superheater fouling can become a problem. The grate heat On further investigation, the diameter of fan required to

release rate was marginally higher than the design ratings produce the same head at the lower speed had the same tip

used for dump grates and revolving grates. The volumetric speed as the fan operating at 990 rpm. The advantage of hav-

heat release rate was within accepted design parameters, en- ing the slower speed fan was therefore abrogated.

suring sufficient residence time to minimise carryover and The slower speed fan would also have been considerably

unburnt carbon losses. larger and therefore more expensive. The decision was made

The gas velocities increased by approximately 20-25% but to install an ID fan running at 990 rpm. The forced draught

were still maintained below 20 m/s, and even lower, in the fans were also replaced to handle the larger volumes of under

critical erosion region of the main bank second to third pass grate air that were required. The existing secondary air fan

baffle. was changed from a 'hot' fan to a 'cold' fan.

200 Proc S Afr Sug TechnolAss (1996) 70

P Mcintyre, H Verbanck and B Misplon Pinhole Grate Conversions at South Nyanza Sugar Company, Kenya

Controls then introduced into the furnace through nozzles as rear

New boiler automatic controls were installed to comple- secondary air or into the air plenum as preheated primary

ment the existing controls. These consist of a new furnace air. A general arrangement is shown in Figure 2.

pressure control loop and a master pressure control loop that

controlled the bagasse feeder inverter drives and the ID fan

inlet dampers. In addition, an uninterruptible power supply

(UPS) was installed to protect the boiler instrumentation sup-

ply.

The pinhole grate conversion 11111111I111111111111111111111

iiiiiiiiiiiiiiliiiiiiiiiiiiiii

Many grates in the sugar industry were actually designed iiiiiiiiiiiiiiiiiiiiiiiiiiiiii

for the fixed bed firing of solid fuels and not the suspension iiiiiiiiiiiiiiiiiiiiiiiiiiiiii

firing of fibrous fuels. The fuel/ash layer on the grate pro- lililliliiiiiiiiiliiiliiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiii

vided the protection from the luminous radiation and was also iiiiiiiiiiiiiiiiiiiiiiiiiiiiii

responsible for the combustion air pressure drop. These fuels iiiiiiiiiiiiiiiiiiiiiiiiiiiiii

T~ "-'~~"p+DIrjljJJPJ]JJ+r

also invariably had a high ash content, so one of the main

features of the design was to incorporate a definite mechani-

cal means of discarding the ash. Suspension fired boilers, par-

ticularly bagasse fired units, are quite different. The ash con-

tent is low and the bulk of the fuel burns in suspension. This

means that the grate is largely exposed to furnace radiation

and the grate configuration has to generate the under grate air

pressure drop. Discarding of the ash is not as serious a prob-

lem as with solid fuels.

The stationary grate provides an elegant solution to these

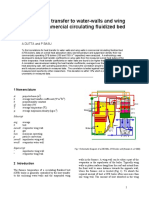

problems. It is not new technology, however, and the Hawai- FIGURE 2: A general arrangementof an air cooled pinhole grate

ian sugar industry has been using the pinhole grate since the

seventies, while the Australian sugar industry has been advo-

cating the use of pinhole grates for the suspension firing of

bagasse since the early eighties.

The basic grate construction consists of an array of tubes

onto which the grate bars are clamped. The grate can be ar-

ranged in one of two ways:

• The tubes can form part of the pressure parts, which is nor-

mally an extension of the furnace rear wall across the

depth of the boiler to a front wall header. The grate support

now becomes an integral part of the natural circulation

system. This arrangement, as shown in Figure 1, is com-

monly referred to as a water cooled pinhole grate.

I I

111111111111111111111111111 1111 III 1111111 i

iiiiiliiiiii!iiiii!i!i!iii! iiii iii iiiiiii

1I111111111111111111111111 iiii iii iiiiii

iiiiiiiiiiiiiiiiiiiiiiiiii iiii iii

iiiiiiiiiiiiiiiililiiiiiii iii I iii

iiiiiiiiiiiiiiiiiiiiiiiiii iiii iii l1illii:

iiiiiiiiiiliiiiiiiiiiiiiii iiii iii 1111I1

I iiii!i!!i!iii!iiiiiiiiiiii iiii iii iiiiii

i 11I11111111111111111111111 iiii iii

iiiiiiiiiiiiiiliiliiiiiiii !iii Iii

tiii iiiii iiiii iiiiiii iiiii IIII Iii

I ' iiii iii iiiiiii

iiiili~ _.

i

!!iiiiii!iiii!iiiiiiii!!lt!!!!"",·:·,,··:··:·

<, .. - UJ~I~','II,'II,'I~.~IIII~11111111111111 ~!I.II .

I ............. j . . --~., ...~ .. - mt,

I I

f1-

L ~I ~

.. L. ..

~ l\f

r,"l r,'--,

i . ·• • •

1r r ,"l r

I

" I

"T">',"i"'. I > ....

I , ' '. i ...•.

"'::";,:' >".":.,.':,',' ,I

FIGURE 1: A general arrangementof a water cooled pinholegrate

• The tubes can alternatively be arranged on a self support-

ing structure and be connected to a cold air ducting system.

The incoming air is distributed into the grate tubes and FIGURE 3a and b: A typical pinholegrate bar

Proc S Afr Sug Technol Ass (1996) 70 201

Pinhole Grate Conversions at SouthNyanza Sugar Company, Kenya P McIntyre, H Verbanck and B Misplon

Figures 3a and 3b are photographs of a typical grate bar, four sections. Each section was actuated by a ball valve lo-

the material of which should be of a very high quality cast cated in front of the boiler on firing floor level. The manifold

iron with good resistance to creep, high temperature oxida- on firing floor level was in turn fed by an existing saturated

tion and embrittlement. The bars are profiled to provide a steam line.

conductive seating surface with the support tubes.

The cooling mechanism is twofold and is explained as fol-

lows: Operating experience

(a) The grate bars are cooled by conduction to the tubes The front end at SONY sugar consists of one set of cane

which in turn are convectionally cooled by the fluid knives and a four mill tandem. Although the extraction rate

within the tube and the primary combustion air flowing and final bagasse moisture are on a par with the other mills in

over the tubes. The effectiveness of this mechanism Kenya, the cane preparation for use in suspension fired boil-

would obviously depend on how good the surface contact ers was not ideal. The coarseness of the bagasse and the fibre

is between the grate bar and the tube surface. length meant that a large proportion of the bagasse actually

burnt on the grate and not in suspension. In the initial com-

(b) The major cooling mechanism is by convectional cooling missioning stages there was a tendency towards slag build up

from the primary under grate air that is forced through the on the refractory lined rear wall at grate level. The wall effect

grate bars. The detail of Figure 3b also shows the cooling in this relatively small furnace also contributed towards slag-

fins that form part of the bottom of the grate bar. The high ging in the furnace. This was rectified by introducing the rear

pressure drop through the 'pinholes' in the grate not only secondary air at a lower point in the furnace.

ensures even air distribution, but also uniform cooling

over the whole grate area. The under grate air temperature was in the region of 225°C.

The air side pressure drop across the grate was ±260 Pa at

Ash is removed in batches similar to the method employed maximum continuous rating (MCR) conditions. The combus-

on the dump grates. Instead of dumping a section, a series of tion was stable and did not demonstrate any pulsations. The

steam jets are actuated to propel the ash along the grate into a secondary air was running at an average of 2000 Pa at the

corrosion resistant, refractory lined hopper traversing the inlet box and exiting the grate cooling support tubes at ap-

front of the boiler. The steam is issued through a series of low proximately 120°C.

profile nozzles that protrude through the grate at spaced inter-

vals. The cleaning is done in a set sequence to maintain good The steam cleaning was found to be ineffective at first.

combustion and minimise the unburnt carbon loss. This was due to insufficient pressure available at the grate

steam header. The problem was resolved by increasing the

line size from the saturated steam header to reduce the pres-

The grate conversion at SONY sure drop. Grate cleaning proved to be successful after this

The SONY boilers were retro-fitted with air cooled grates. modification.

The existing dump grate steel work was modified to support There is a general shortage of power in Kenya, and the

the new grate. Care had to be taken to allow for thermal ex- sugar mills have to rely heavily on their own generating sets

pansion of the grate components by utilising sliding beam to provide energy for the mill. During peak demand periods,

supports. The boilers are bottom supported so the bottom fur- the 415 V line voltage can drop to as low as 340 volts. This

nace seal does not have to cater for any relative movement. posed a significant problem for starting the high inertia ID

Details of the conversion are shown in Figure 2. fans during peak hours. The normal procedure was to black

The secondary air fan delivery ducting was rerouted and out the entire mill and use all the available power to start one

connected into the grate inlet box which traversed the width boiler. Once the boiler was on pressure, the turbo-alternator

of the boiler. The air that has then passed through the grate (TA) set turbine was brought up to operating speed. At this

tubing is introduced into the rear of the furnace as secondary point, the power to the boiler was shut down and the TA set

air. The nozzles had to be relocated relative to the grate, in switched on line. Having the UPS at this stage was a major

line with standard practice. advantage, as the boiler controls and dampers had a continu-

ous power supply during this switching period. The other

Since the boiler was originally designed with a dump grate, problem that caused many delays was the fact that the ba-

there is no vestibule beneath the front wall for collecting the gasse feeder inverter drives kept tripping out on low voltage

coarse ash. The ash hopper therefore had to be located within during the pressure raising stage.

the furnace plan area. A nose section had to be built just be-

low the spreaders to prevent significant quantities of unburnt Once the TA set and the one boiler were on line, it was a

bagasse falling into the front ash hopper. This section had to matter of normal procedure to start the second boiler. Boiler

be cast with refractory to withstand the high furnace tempera- No 2 steamed successfully at the uprated conditions without

tures. This in itself posed another problem. How was the re- any adverse affects. Boiler No 1 only managed to reach 32 t/h

fractory nose going to be supported and cooled? A novel solu- with the ID fan damper fully open. The large number of tubes

tion was proposed, and the nose was cast around another sec- blanked off in the main bank, and the by-passing of gas

ondary air duct that fulfilled three purposes: through damaged baffles, resulted in high back end tempera-

tures. There was also a significant quantity of air ingress con-

• To create a rigid support beam, around which to cast the firmed by the low CO2 content at the ID fan inlet.

nose.

There is no doubt that this boiler will attain it's uprated

• A cooling duct to dissipate the heat energy absorbed by the design condition once the main bank, gas baffles and rear

nose. duct work are repaired.

• A secondary air duct that allowed the placement of drib-

bling nozzles along the furnace side of the nose to mini-

mise the bagasse falling into the coarse ash hopper. Projects experience

A new riddlings hopper was fitted onto the grate steel It was an extremely fast track project, with only 17 weeks

work. The grate steam cleaning pipe work was divided into from the placement of the order to final commissioning and

202 Proc S Afr Sug Technol Ass (1996) 70

P McIntyre, H Verbanck and B Misplon Pinhole Grate Conversions at South Nyanza Sugar Company, Kenya

handing over. The scheduled offcrop was only five weeks, o The water cooled grate resolves the problem of having ex-

and the erection and commissioning had to be completed pansion seals at the furnace to grate interface on girt and

within this period. The bulk of the plate work and steel work top supported boilers.

was manufactured locally in Kenya while all the other com- o There is essentially no limit to the size of grate that can be

ponents were either sourced or manufactured in South Africa. built.

The consignments that were shipped via Mombasa took an

o The initial capital outlay for a new boiler fitted with a pin-

average of 40 days to reach the site. In order to keep to the

hole grate will be slightly higher than the same boiler fitted

short delivery date, the authors' company airfreighted a

with a dump grate, but considerably lower than a revolving

number of consignments to Nairobi. These consignments in-

grate.

cluded the ID fans, FD fans and refractories. The project was

completed on time and within budget. o A well designed and erected grate has the potential of re-

ducing annual offcrop maintenance costs to a very low

level and unscheduled maintenance costs to zero.

Conclusions o The air cooled stationary grate is better suited to retro-fits

where more flexibility is required and the boiler design

The steam cleaned stationary grate offers a number of ad-

does not allow for much freedom in modifying the pressure

vantages over conventional grates for the suspension firing of

parts. Even the old hearth or Dutch oven type furnaces are

bagasse. Experience with these grates has proved to be more

easily retro-fitted with air cooled pinhole grates and sus-

than satisfactory in the Australian industry and has now been

pension firing equipment. The relative cost of the grate is

proved in the African industry. More specifically, some of the

much the same as a dumping grate.

major advantages are:

In conclusion, the stationary steam cleaned grate is an at-

o The method of disposing of the ash does not embody any

dynamic components and therefore none of the associated tractive proposition both technically and economically,

where conventional grate installation and maintenance costs

problems of mechanisms operating in a harsh mechanical

environment. are high, and the boiler is essentially fired on bagasse.

o The efficient grate cooling system allows the use of rela-

tively high temperature under grate air without danger of Acknowledgements

damage to the grate. This also eliminates the problem of The authors would like to thank South Nyanza Sugar Com-

'puffing' that is often associated with large load swings pany and John Thompson Africa (Pty) Ltd for allowing them

and high fuel moisture content. to publish this paper and our colleague Rob Merry for his

o The uniformity of the grate ensures a long term, even dis- valuable input on the operational aspects.

tribution of air over the full grate area.

o The dual cooling mechanism allows for increased turn

BIBLIOGRAPHY

down without overheating the grate, provided all the air Levy, PW (1983). Suspension fired boilers and their grates. Proc int Soc Sug Cane

Technol XVIII: 1076-1093.

settings are correct and there is good contact between the Levy, PW and Kenny, DA (1984). The steam cleaned stationary grate. ProcAus Soc

grate bars and the cooling tubes. Sug Cane Techno!'

Proc S Afr Sug Technol Ass (1996) 70 203

Vous aimerez peut-être aussi

- The Implementation of A Steam Transformer PDFDocument9 pagesThe Implementation of A Steam Transformer PDFASHIL PRABHAKARPas encore d'évaluation

- Taijune Fire Tube Steam BoilerDocument8 pagesTaijune Fire Tube Steam BoilerAjay GoswamiPas encore d'évaluation

- Controlling Ejector Performance with Steam Bleed ControlDocument9 pagesControlling Ejector Performance with Steam Bleed ControlCan YıldırımPas encore d'évaluation

- Over Water WingDocument7 pagesOver Water WingtsaipeterPas encore d'évaluation

- Pressure Testing Request FormDocument1 pagePressure Testing Request FormSyed Mahmud Habibur RahmanPas encore d'évaluation

- Glaxo Vol IDocument164 pagesGlaxo Vol IPrakash WarrierPas encore d'évaluation

- A Guide To Assist in Evaluating Liquid Fuel FlamesDocument16 pagesA Guide To Assist in Evaluating Liquid Fuel FlamestinuvalsapaulPas encore d'évaluation

- Note - All Yellow Cells Are Manditory To Be FilledDocument2 pagesNote - All Yellow Cells Are Manditory To Be FilledPrashant SinghPas encore d'évaluation

- 1 TPH 10.54 KG, Vapi Care PharmaDocument16 pages1 TPH 10.54 KG, Vapi Care PharmashastrysnPas encore d'évaluation

- YOSHIMINE WASTE HEAT RECOVERY BOILERSDocument12 pagesYOSHIMINE WASTE HEAT RECOVERY BOILERSardiansyahhandikaPas encore d'évaluation

- FD Fan Sizing CalculationDocument3 pagesFD Fan Sizing CalculationkumarananyarupeshPas encore d'évaluation

- Furnace 01490Document83 pagesFurnace 01490JKKPas encore d'évaluation

- Blowdown Economizer CalculationDocument2 pagesBlowdown Economizer CalculationSajjad AhmedPas encore d'évaluation

- Blowdown TankDocument1 pageBlowdown TankShameer Majeed0% (1)

- ENMAS ANDRITZ Document Date CalculationsDocument3 pagesENMAS ANDRITZ Document Date CalculationsPablo ApasionadoPas encore d'évaluation

- Random Packing CatalogDocument32 pagesRandom Packing CatalogNurul NadirahPas encore d'évaluation

- 3194 PDF PDFDocument7 pages3194 PDF PDFdillipsh123Pas encore d'évaluation

- DraughtDocument33 pagesDraughtNipun SabharwalPas encore d'évaluation

- BioEnergy VKKDocument24 pagesBioEnergy VKKdane05Pas encore d'évaluation

- Bps-06 NOx ControlDocument4 pagesBps-06 NOx ControlLTE002Pas encore d'évaluation

- Cop Forth S Safe Thermal Oil HeatersDocument48 pagesCop Forth S Safe Thermal Oil HeatersMochammad Nur HidayatPas encore d'évaluation

- General Boiler Information on Low-Emission Firetube ModelsDocument10 pagesGeneral Boiler Information on Low-Emission Firetube Modelsnecio77Pas encore d'évaluation

- Sugarcane ComputeDocument12 pagesSugarcane ComputeJun Burias Padilla100% (1)

- Mroy Pump Catalogue PDFDocument6 pagesMroy Pump Catalogue PDFTitus FelixPas encore d'évaluation

- Self Priming PumpDocument3 pagesSelf Priming Pumpmoejamal80Pas encore d'évaluation

- Design of Boiler Forced Draft FanDocument5 pagesDesign of Boiler Forced Draft FanAu TagolimotPas encore d'évaluation

- Energy Balanc HHV GPHR Asme PTCDocument2 pagesEnergy Balanc HHV GPHR Asme PTCramli123Pas encore d'évaluation

- 880 Series Inverted Bucket Steam TrapsDocument2 pages880 Series Inverted Bucket Steam TrapsCherbee FerrerPas encore d'évaluation

- Calculation of Electrical Power Output From EFBDocument2 pagesCalculation of Electrical Power Output From EFBczteePas encore d'évaluation

- Evaluation of Steam Jet EjectorsDocument11 pagesEvaluation of Steam Jet EjectorsRajeh Somrani100% (3)

- Mehran University of Engineering and Technology SZAB Campus Khairpur Mir'sDocument64 pagesMehran University of Engineering and Technology SZAB Campus Khairpur Mir'sMarcusHuynh88Pas encore d'évaluation

- Chimney Sizing PDFDocument13 pagesChimney Sizing PDFtitiePas encore d'évaluation

- Presentation on Thermal Oxidation Technologies for Process Combustion CorporationDocument35 pagesPresentation on Thermal Oxidation Technologies for Process Combustion CorporationSteve WanPas encore d'évaluation

- Fan Flow Calculation For FBC BoilerDocument3 pagesFan Flow Calculation For FBC BoilerOmprakaash MokidePas encore d'évaluation

- CE Refresher: Steam Tables and Typical Liquid VelocitiesDocument1 pageCE Refresher: Steam Tables and Typical Liquid Velocitieshugo mendozaPas encore d'évaluation

- Steam Boiler ProjectDocument32 pagesSteam Boiler ProjectSwastik BhokarePas encore d'évaluation

- CH-14 Design Fundamentals of BoilerDocument15 pagesCH-14 Design Fundamentals of BoilerRavi ShankarPas encore d'évaluation

- Waste Heat Recovery Devices and ApplicationsDocument18 pagesWaste Heat Recovery Devices and Applicationsdivyank3dPas encore d'évaluation

- Heat Rate of Thermal Power PlantDocument15 pagesHeat Rate of Thermal Power Plantsameer betal100% (1)

- AX5 Vaporizer Electric Water Bath Type LPG VaporizerDocument2 pagesAX5 Vaporizer Electric Water Bath Type LPG VaporizerRicky DermawanPas encore d'évaluation

- Heat Transfer and Pressure Drop Characteristics of Finned Tube Banks in Forced Convection (Comparison of The Heat Transfer Characteristics Between Spiral Fin and Serrated Fin)Document14 pagesHeat Transfer and Pressure Drop Characteristics of Finned Tube Banks in Forced Convection (Comparison of The Heat Transfer Characteristics Between Spiral Fin and Serrated Fin)nadir adel100% (1)

- Delivering Excellence in Combustion and Process Heating SystemsDocument11 pagesDelivering Excellence in Combustion and Process Heating SystemssajjadyasinPas encore d'évaluation

- Phosphate Hideout PDFDocument4 pagesPhosphate Hideout PDFAHMAD DZAKYPas encore d'évaluation

- Description Materials: Cast Iron For Horizontal InstallationDocument2 pagesDescription Materials: Cast Iron For Horizontal InstallationParth GosaiPas encore d'évaluation

- 9 - Axial Flow Turbines For Organic Rankine Cycle ApplicationsDocument21 pages9 - Axial Flow Turbines For Organic Rankine Cycle ApplicationsFranklin Najarro SolarPas encore d'évaluation

- Expansion Vessel CalculationDocument4 pagesExpansion Vessel CalculationTsouki TsoukiPas encore d'évaluation

- Centrifugal Pumps NPSHDocument6 pagesCentrifugal Pumps NPSHSubrata MukherjeePas encore d'évaluation

- Difference Between Nm3 Vs Sm3Document1 pageDifference Between Nm3 Vs Sm3Arun kumarPas encore d'évaluation

- Aeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramDocument4 pagesAeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramAshraf KamalPas encore d'évaluation

- Vacuum and Heat Transfer Barometric Condenser ManualDocument11 pagesVacuum and Heat Transfer Barometric Condenser ManualNick Smith100% (1)

- High Efficiency Packaged Boilers and Modular Boiler HousesDocument6 pagesHigh Efficiency Packaged Boilers and Modular Boiler Housesdnageshm4n244Pas encore d'évaluation

- New CalculationDocument9 pagesNew CalculationDeepak Shakya100% (1)

- Boiler: Sabari Girish N Sr. Engineer (O)Document37 pagesBoiler: Sabari Girish N Sr. Engineer (O)Deepak SinghPas encore d'évaluation

- Flare Gas Recovery - by Reliance Industries Ltd. (Refinery Division)Document3 pagesFlare Gas Recovery - by Reliance Industries Ltd. (Refinery Division)sriram84Pas encore d'évaluation

- Dry Wet Cooling Systems and Flue Gas System ENEXIODocument55 pagesDry Wet Cooling Systems and Flue Gas System ENEXIOAmir AbbaszadehPas encore d'évaluation

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesD'EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesPas encore d'évaluation

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7D'EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Pas encore d'évaluation

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationD'EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationPas encore d'évaluation

- Duet Embedded Memories and Logic Libraries For TSMC 28HP: HighlightsDocument5 pagesDuet Embedded Memories and Logic Libraries For TSMC 28HP: HighlightsmanojkumarPas encore d'évaluation

- Kina23744ens 002-Seisracks1Document147 pagesKina23744ens 002-Seisracks1Adrian_Condrea_4281Pas encore d'évaluation

- Megneto TherapyDocument15 pagesMegneto TherapyedcanalPas encore d'évaluation

- Organization & Management: Manuel L. Hermosa, RN, Mba, Man, Edd, LPT, MaedcDocument32 pagesOrganization & Management: Manuel L. Hermosa, RN, Mba, Man, Edd, LPT, MaedcManny HermosaPas encore d'évaluation

- Cross-Sectional Tomography: Oral and Maxillofacial RadiologyDocument7 pagesCross-Sectional Tomography: Oral and Maxillofacial RadiologyPhanQuangHuyPas encore d'évaluation

- Fees Structure For Government Sponsored (KUCCPS) Students: University of Eastern Africa, BaratonDocument3 pagesFees Structure For Government Sponsored (KUCCPS) Students: University of Eastern Africa, BaratonGiddy LerionkaPas encore d'évaluation

- Physics Force and BuoyancyDocument28 pagesPhysics Force and BuoyancySohan PattanayakPas encore d'évaluation

- Affidavit of 2 Disinterested Persons (Haidee Gullodo)Document1 pageAffidavit of 2 Disinterested Persons (Haidee Gullodo)GersonGamasPas encore d'évaluation

- 09 Bloom Gardner Matrix Example 2009Document2 pages09 Bloom Gardner Matrix Example 2009Ellen Jaye BensonPas encore d'évaluation

- Chapter - 2 Fish MongeryDocument10 pagesChapter - 2 Fish MongeryKrishna ChaudharyPas encore d'évaluation

- Case NoDocument13 pagesCase NoLaurente JessicaPas encore d'évaluation

- Audit AP TestsDocument3 pagesAudit AP TestsSweet Emme100% (1)

- Construction Internship ReportDocument8 pagesConstruction Internship ReportDreaminnPas encore d'évaluation

- Remembering Manoj ShuklaDocument2 pagesRemembering Manoj ShuklamadhukarshuklaPas encore d'évaluation

- 45 - Altivar 61 Plus Variable Speed DrivesDocument130 pages45 - Altivar 61 Plus Variable Speed Drivesabdul aziz alfiPas encore d'évaluation

- Canberra As A Planned CityDocument12 pagesCanberra As A Planned Citybrumbies15100% (1)

- Chenab Railway Bridge Project ReportDocument50 pagesChenab Railway Bridge Project ReportPreet Chahal100% (1)

- Ôn tập và kiểm tra học kì Tiếng anh 6 ĐÁP ÁNDocument143 pagesÔn tập và kiểm tra học kì Tiếng anh 6 ĐÁP ÁNThùy TinaPas encore d'évaluation

- EMB 690-1 SM Course Outline Spring 21Document8 pagesEMB 690-1 SM Course Outline Spring 21HasanPas encore d'évaluation

- Audi A3 Audi A3 Audi A3 Audi A3 No. 2 / 1 No. 2 / 1 No. 2 / 1 No. 2 / 1Document18 pagesAudi A3 Audi A3 Audi A3 Audi A3 No. 2 / 1 No. 2 / 1 No. 2 / 1 No. 2 / 1Crisedu VasriPas encore d'évaluation

- RPH Sains DLP Y3 2018Document29 pagesRPH Sains DLP Y3 2018Sukhveer Kaur0% (1)

- CHEMOREMEDIATIONDocument8 pagesCHEMOREMEDIATIONdeltababsPas encore d'évaluation

- JMC250Document2 pagesJMC250abhijit99541623974426Pas encore d'évaluation

- Dxgbvi Abdor Rahim OsmanmrDocument1 pageDxgbvi Abdor Rahim OsmanmrSakhipur TravelsPas encore d'évaluation

- Lesson Plan Earth & SpaceDocument5 pagesLesson Plan Earth & SpaceSol Vega PagdangananPas encore d'évaluation

- PhysicsLab PreReport201Document9 pagesPhysicsLab PreReport201Giuliana SchulzPas encore d'évaluation

- Protección Fuego MetalDocument16 pagesProtección Fuego MetalTracy Mora ChPas encore d'évaluation

- Living in a digital age unit review and digital toolsDocument1 pageLiving in a digital age unit review and digital toolsLulaPas encore d'évaluation

- EMC Design Guide For PCBDocument78 pagesEMC Design Guide For PCBFaruq AhmedPas encore d'évaluation

- PENGARUH CYBERBULLYING BODY SHAMING TERHADAP KEPERCAYAAN DIRIDocument15 pagesPENGARUH CYBERBULLYING BODY SHAMING TERHADAP KEPERCAYAAN DIRIRizky Hizrah WumuPas encore d'évaluation