Académique Documents

Professionnel Documents

Culture Documents

Horizontal "Flatbed" Router Table: MLCS Manual For #9767

Transféré par

teromandosDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Horizontal "Flatbed" Router Table: MLCS Manual For #9767

Transféré par

teromandosDroits d'auteur :

Formats disponibles

MLCS Manual for #9767

Horizontal “Flatbed” Router Table

Copyright 2008 MLCS Ltd 1

General Guidelines, Tips, and Safety:

Always wear your safety glasses, hearing and dust protection.

Read and understand the instructions for both the machinery and cutters before

starting to work.

Use safety devices such as pushblocks, featherboards or bit guards/blade guards

where appropriate.

As a general rule of safety, keep your fingers and hands at least one hand-length from

any cutting blade.

When using the router, pay particular attention to the condition of the collet.

Frequently, bit breakage and poor performance can be directly attributed to a worn or

damaged router collet.

Always inspect a router bit before use. Make sure the wax is removed from the

cutting blades and bearing. Check for chips in the carbide, frozen bearings, worn

shaft, and be sure set screws and nuts are tight in bit assemblies.

Always change bits or make adjustments with the router unplugged.

Make sure the router bit shaft is set at least 3/4” into the collet, but not bottomed out.

The end of the shank should be about 1/16” up from the bottom of the collet.

Two light passes cut more smoothly and easily than one heavy pass. Proper bit RPM

is important, especially with larger, heavier bits. In general, burning of the wood or

excessive vibration can be corrected with a slower rpm and a lighter cutting pass.

Use a variable speed router or speed control to reduce the speeds when cutting large

diameter bits, as follows: 1/4” to 2” Dia. --- 18,000 RPM; 2-1/8” to 2-1/2” Dia.---

16,000 RPM; 2-5/8” to 3-1/2” Dia. --- 12,000 RPM. Bits with a carbide height greater

than 1-1/2” should also be run at 16,000 RPM or less and it is EXTREMELY

IMPORTANT to make multiple passes with these router bits.

Be aware that some cleaning solvents can dissolve the lubricating oil in bit bearings.

Either remove the bearing or re-oil it after cleaning a bit.

Failure to follow all safety instructions and warnings can result in serious bodily

injury.

In no event shall we be liable for death, injuries to persons or property arising from

use of our products.

Defects from misuse, abuse, negligence, or alterations are not covered by the

warranty. Our liability is limited to replacement or refund of the product.

Copyright 2008 MLCS Ltd 2

Safety First: After assembly of the table. Secure the table to your work surface

before using as the table with the router mounted will be weighted toward the back

and could tip over backwards. We recommend either screwing it to your work

surface or using clamps. To ensure the safest operation, always make sure the

router bit is not positioned above your stock and feed your stock from left to right

into the rotation of the cutter.

Assembly of the Table Base Unit

1.) Start the assembly by installing the two vertical table supports (part#23) to the router

table base (part #24) using (8) screws (part #22). The table base should have the

countersunk holes on the bottom. The vertical table supports should have the threaded

inserts facing the rear of the table.

Preparing the Router Mounting Plate

2.) Remove the protective paper backing from both sides of the Router Mounting Plate

(part #25). Center your router over the hole in the Router Mounting Plate and mark the

mounting holes for your router. (Note: After marking these positions, it may be helpful

to remove the sub-base from the router and use it as a drilling guide. Line up the sub-

base with the marked mounting holes and attach with double sided tape.) Drill and

countersink the holes for the router. The countersinks for router mounting holes must be

drilled on the same face of the Router Plate as the countersunk holes for the drive block.

Installing the Router Plate to the Drive Block

The router plate is left uninstalled to ease preparing the router plate for router

installation.

3.) First, follow the instructions for marking and drilling the Router Plate (#25) to accept

your router.

4.) The Drive Block (#8) must be predrilled to accept the Router Plate mounting screws

(#16). Use the template on the last page to mark and pre-drill the mounting locations on

the face of the Drive Block (#8). The template is the same size as the face of the Drive

Block. Use an 1/8” drill bit to pre-drill the mounting holes.

Copyright 2008 MLCS Ltd 3

5.) After the Drive Block (#8) has been predrilled, slide two 5/16” Hex Bolt (#17) into

the t-slot on each aluminum column. Place the Router Plate (#25) onto the Horizontal

Router Table with the four 5/16” Hex Bolts (#17) protruding through the holes near the

edge of the Router Plate (#25). Secure the Router Plate (#25) loosely using the four 5/16”

Locking Knobs (#20). Slide the Router Plate (#25) to position where the mounting holes

in the Router Plate (#25) are aligned with the predrilled holes (from step 5.) in the Drive

Block (#8). Secure the Router Plate (#25) to the Drive Block (#8) using six 3/16” Wood

Screws (#16). Tighten securely but do not over tighten as you may either strip the

wooden Drive Block or crack the acrylic Router Plate. If your router plate is not flush

with the aluminum extrusion, a few pieces of masking tape or slick tape may be applied to

the back of the plate where the plate contacts the extrusions to shim the plate flush.

Attaching the Router Mechanism

6.) Attach the router mechanism (pre-assembled from the factory) (part numbers 3, 4, 5,

6, 7, 8, 9, 10, 15, 16 +18) to the base assembly with (6) hex bolts & washers (part #26).

Do not over-tighten as you may bend the aluminum columns (part #10 + #18)

7.) Continue by installing the router table top (part #21) to the vertical table supports (part

#23) using the (8) remaining screws (part #22). The countersunk holes will be facing up

on the router tabletop.

Attaching the Extension Fences

8.) Attach extension fences (part #13 + #19) to the table top using (4) screws (parts #22).

Complete this step by attaching the top of the extension fences (part #13 + #19) to the

aluminum columns (part #10 + #18) using screws (part #12) and screwing through the

angle support brackets (part #11)

Assembly of the Knob and Wheel

9.) The knob (part #2) will already have male threads protruding out of the base of it. See

figure 1.

(figure 1)

Copyright 2008 MLCS Ltd 4

10.) Take the hex nut and thread it onto the knob (part #2), securing it hand tight against

the base of the knob (part #2). See figure 2.

11.) Screw the knob (part #2) into the threaded insert in the wheel (part #1) from the top

of the wheel (part #1). Do not completely tighten the knob (part #2) against the top of the

wheel (part #1). See figure 3.

(figure 2) (figure 3)

12.) Use an open ended wrench to secure the hex nut down tightly against the wheel (part

#1). See figure 4.

13.) The knob (part #2) should now be able to turn freely. It should not be tightened up

against the wheel (part #1). If it is tightened up against the wheel, unthread the knob

from the wheel. See figure 5.

(figure 4) (figure 5)

Copyright 2008 MLCS Ltd 5

Attaching the Handle to the Drive Rod

14.) Place Handle (part #1) and Height Wheel (part # 2) assembly onto the drive rod (part

#3) so that the allen set screw is oriented towards the flat spot on the drive rod. Secure by

tightening the setscrew.

You may now install your router on the Horizontal Table after completing the full

assembly instructions.

Mounting to the MLCS #9680 Stand

If you want to mount the bench top Horizontal Router Table, you could use the MLCS

#9680 stand. See below for the proper mounting orientation.

Copyright 2008 MLCS Ltd 6

Router Table 9767 Part List

REF NO. PART NAME QTY NOTE

1 Handle 1

2 Height wheel 1

3 Drive rod (3/4"-16tpi) 1

4 Nylon bushing 3

5 Top support 1

6 Machine screw (1/4"-20tpi x 2") 4

7 Hex nut (3/4"-16tpi) 2

8 Drive block 1

9 Lock nut (3/4"-16tpi) 1

10 Aluminum column (Right) 1

11 Angle support bracket 2

12 Screws (3/16" x 5/16") 4

13 Extension fence (right) 1

14 Screws (1/4"-20tpi x 2") plus flat washer 6

15 Screws (1/4" x 5/8") 1

16 Plate mounting screw (3/16" x 5/8") 6

17 Hex bolt (5/16"-18tpi x 1") 4

18 Aluminum column (left) 1

19 Extension fence (left) 1

20 Lock knob (5/16" x 18tpi) 4

21 Router table top 1

22 Screws (1/4"-20tpi x 1-1/4") 20

23 Vertical table support 2

24 Router table base 1

25 Plate 1

26 Hex wrench (Accessory) 1

Copyright 2008 MLCS Ltd 7

Copyright 2008 MLCS Ltd 8

Copyright 2008 MLCS Ltd 9

Making Raised Panels on the HORIZONTAL ROUTER TABLE #9767

Note: The Horizontal Router Table cannot be used to

make cathedral doors.

1) Start by cutting your panel to its finished size. You may choose to allow a small 1/16”

to 1/8” gap inside the rail & stile for seasonal wood movement.

2) After you have cut your panel to its finished dimension, install a vertical raised panel

bit in your router.

3) Adjust the router bit depth so the router bit will cut a 3/8” depth flat cut before the

profile cut starts. Position the router plate height so that the router bit’s edge is just above

the surface of the tabletop. Turn the locking knobs to secure the router and plate in place.

4) Turn on the router and working from left to right, make the first pass on the end grain

of the panel. Cut the end grain first so that any tear out can be cleaned up when you cut

with the grain.

5) After cutting the end grain on the panel, cut the two remaining edges (with grain cuts).

6) Turn off the router and wait for the router bit to come to a complete stop.

7) Loosen the two locking knobs on the router plate and adjust the bit up a small amount.

Lock the knobs to secure the plate and make your second pass on the panel.

8) Repeat until you have a 1/4” tongue to fit into the slot on the rails and stiles. TIP:

Taking many shallow passes will yield a better cut than trying to cut too aggressively

which may lead to a poor cut quality or excessive tear-out.

Remember Safety Rules: Wear proper eye protection, keep hands away from router

bit and never rout with the router bit above your workpiece – always keep your

workpiece above the router bit.

Copyright 2008 MLCS Ltd 10

Copyright 2008 MLCS Ltd 11

Vous aimerez peut-être aussi

- Boring Bars PDFDocument44 pagesBoring Bars PDFmnamkyPas encore d'évaluation

- Drilling Boring Reaming and TappingDocument24 pagesDrilling Boring Reaming and TappingPuneeth KumarPas encore d'évaluation

- Kearney and Trecker Installation ManualDocument12 pagesKearney and Trecker Installation Manualaa987100% (1)

- Axminster CMB115 ManualDocument24 pagesAxminster CMB115 Manualmikka26Pas encore d'évaluation

- A Few Project Images: Tool Posts Lathe Cutting ToolsDocument4 pagesA Few Project Images: Tool Posts Lathe Cutting ToolsAnonymous mKdAfWifPas encore d'évaluation

- 47158Document16 pages47158Rosania SanchesPas encore d'évaluation

- Operating: Maintenance ManualDocument18 pagesOperating: Maintenance ManualAnonymous reYe6iCCPas encore d'évaluation

- Axminster Lathe ManualDocument24 pagesAxminster Lathe ManualGary SmithPas encore d'évaluation

- Triton-Powered Saw TableDocument32 pagesTriton-Powered Saw Tableauger88Pas encore d'évaluation

- Sams ComputerFacts - Apple IIeDocument73 pagesSams ComputerFacts - Apple IIeOscar Arthur KoepkePas encore d'évaluation

- WB the+Awesome+MF+WorkbenchDocument72 pagesWB the+Awesome+MF+WorkbenchZé MarcoPas encore d'évaluation

- Ironworker E600C Dec2019Document40 pagesIronworker E600C Dec2019italotma100% (1)

- Tread Hammer RahulDocument36 pagesTread Hammer RahulHemant MaheshwariPas encore d'évaluation

- Build MI's Tornado!: by John CapotostoDocument3 pagesBuild MI's Tornado!: by John CapotostoJim100% (1)

- Detector Es de MetalDocument4 pagesDetector Es de Metalfredy8704100% (1)

- Drill Vise MillDocument2 pagesDrill Vise MillFrenchwolf420Pas encore d'évaluation

- Standalone Motion Controller DDCS V3.1 User's Guide: Shenzhen Digital Dream Numerical Technology Co., LTDDocument44 pagesStandalone Motion Controller DDCS V3.1 User's Guide: Shenzhen Digital Dream Numerical Technology Co., LTDFarhan Ashraf AliPas encore d'évaluation

- SphericalturninglathetoolDocument14 pagesSphericalturninglathetoolFrenchwolf420Pas encore d'évaluation

- Pedal Power in Work Leisure and TransportationDocument143 pagesPedal Power in Work Leisure and Transportationtariq76Pas encore d'évaluation

- Gemco Metal Shaper BrochureDocument16 pagesGemco Metal Shaper Brochureaa987100% (1)

- Strung de LemnDocument3 pagesStrung de LemnJohn JohnbPas encore d'évaluation

- Metal SpinningDocument4 pagesMetal SpinningfranklynPas encore d'évaluation

- Cowells Manuals PDFDocument16 pagesCowells Manuals PDFpedjaPas encore d'évaluation

- 05 - Milling Operations in The LatheDocument125 pages05 - Milling Operations in The Lathej43951048Pas encore d'évaluation

- Tent Pitching NotesDocument21 pagesTent Pitching NotessnguidemynahPas encore d'évaluation

- SICS ... : Basic Gear DesignDocument9 pagesSICS ... : Basic Gear DesignadamtuongPas encore d'évaluation

- Building With PapercreteDocument3 pagesBuilding With PapercreteMiguel PayanoPas encore d'évaluation

- Art of BendingDocument29 pagesArt of BendingKhin Aung Shwe100% (1)

- Southbend South Bend Sb1027 Users Manual 447654Document84 pagesSouthbend South Bend Sb1027 Users Manual 447654Maximiliano Alvarez RinconPas encore d'évaluation

- ACESORIOScatalog PDFDocument80 pagesACESORIOScatalog PDFlmelmelmePas encore d'évaluation

- Don't Be A Cart-Aleck: Materials: ToolsDocument5 pagesDon't Be A Cart-Aleck: Materials: ToolsKeith WesleyPas encore d'évaluation

- Mini Lathe Angular Contact Bearing Change GuideDocument5 pagesMini Lathe Angular Contact Bearing Change GuidemallardfirstPas encore d'évaluation

- Auto-Powered Arc Welder: by Norman E. SchuttzDocument60 pagesAuto-Powered Arc Welder: by Norman E. SchuttzPierre799es100% (1)

- Complete EDM Handbook - 12Document10 pagesComplete EDM Handbook - 12ks2000n1Pas encore d'évaluation

- Chan 1: 11211takct ClitDocument52 pagesChan 1: 11211takct Clitmagatsu2099Pas encore d'évaluation

- Manual Torno South BendDocument76 pagesManual Torno South BendPeter MongollPas encore d'évaluation

- Design and Fabrication of Crop ReaperDocument9 pagesDesign and Fabrication of Crop ReaperIJRASETPublicationsPas encore d'évaluation

- PDFDocument44 pagesPDFBaSzarPas encore d'évaluation

- Colour Genera%) Digital Tunin G Scale Mini Drill Conitro: Up To - Date Electronics For Lab and LeisureDocument49 pagesColour Genera%) Digital Tunin G Scale Mini Drill Conitro: Up To - Date Electronics For Lab and Leisuretecchese3996Pas encore d'évaluation

- Lathe Cross-Sli Olders.: " DuplexDocument3 pagesLathe Cross-Sli Olders.: " Duplexjohnboy183100% (1)

- Raspberry Pi Alamode CNC Controller - 13 Steps (With Pictures)Document27 pagesRaspberry Pi Alamode CNC Controller - 13 Steps (With Pictures)orangota100% (1)

- Machinists Tools by Williams 1944Document32 pagesMachinists Tools by Williams 1944OSEAS GOMEZPas encore d'évaluation

- From Industry To Alchemy - Burgmaster A Machine Tool Company PDFDocument408 pagesFrom Industry To Alchemy - Burgmaster A Machine Tool Company PDFLaurence DutertePas encore d'évaluation

- Mini Bike LightDocument2 pagesMini Bike LightperacPas encore d'évaluation

- Rose EngineDocument8 pagesRose EnginePSantos11Pas encore d'évaluation

- CE3458 Parts ManualDocument84 pagesCE3458 Parts ManualMrbigg10Pas encore d'évaluation

- Notes, Parts List & Drawings: Easy DIY Biomass GrinderDocument16 pagesNotes, Parts List & Drawings: Easy DIY Biomass GrinderCalfos SaririPas encore d'évaluation

- Tricking Out Asian 9x20 LatheDocument48 pagesTricking Out Asian 9x20 Lathearanicki8587Pas encore d'évaluation

- 2886-Stud Fitting & Removal PDFDocument1 page2886-Stud Fitting & Removal PDFsyllavethyjimPas encore d'évaluation

- Table Saw AlingmentDocument8 pagesTable Saw AlingmentEd BozmanPas encore d'évaluation

- ACIERA Milling Machine 1Document11 pagesACIERA Milling Machine 1adhencandraPas encore d'évaluation

- Balanci GrindingDocument18 pagesBalanci GrindingAnonymous JzEb8CXErPas encore d'évaluation

- Homemade Bandsaw From Pipe Fittings and Auto PartsDocument4 pagesHomemade Bandsaw From Pipe Fittings and Auto PartsJan Steinman100% (2)

- Diagrama de Parachoques DelanteroDocument9 pagesDiagrama de Parachoques DelanteroAbel Mario ArévaloPas encore d'évaluation

- (Filmmaking Technique) - CAMERA STABILIZER PLANS, STEADY, STEADI, STEADICAM, STEDYDocument81 pages(Filmmaking Technique) - CAMERA STABILIZER PLANS, STEADY, STEADI, STEADICAM, STEDYTaproot Photog100% (1)

- ELME 817 Manual PDFDocument20 pagesELME 817 Manual PDFniko67% (3)

- Sigrc 74 Kadetlt 25Document34 pagesSigrc 74 Kadetlt 25carlosulloa100% (1)

- Taig Lathe ManualDocument12 pagesTaig Lathe Manualpeter smithPas encore d'évaluation

- Elitech LMC-300Document2 pagesElitech LMC-300teromandosPas encore d'évaluation

- Elitech LMC-300 Refrigerant Charging Scale User ManualDocument65 pagesElitech LMC-300 Refrigerant Charging Scale User ManualteromandosPas encore d'évaluation

- Sold Secure 2016 Approved Product CatalogueDocument86 pagesSold Secure 2016 Approved Product CatalogueteromandosPas encore d'évaluation

- msd-8910 frm28850Document2 pagesmsd-8910 frm28850teromandosPas encore d'évaluation

- How To Make A Mini Milling Machine-Manual or CNC!Document31 pagesHow To Make A Mini Milling Machine-Manual or CNC!Cosmin Ionut100% (2)

- Woodworking A Step by Step Guide To Essential Woodworking Skills Tips and ProjectsDocument105 pagesWoodworking A Step by Step Guide To Essential Woodworking Skills Tips and ProjectsTomasthc AitPas encore d'évaluation

- Sweet Oddity Art: Sunny The Elephant Crochet PatternDocument20 pagesSweet Oddity Art: Sunny The Elephant Crochet PatternDrey Tabilog100% (3)

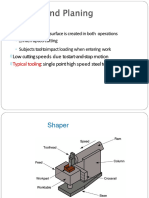

- Lecture 7 (Week 4)Document19 pagesLecture 7 (Week 4)Mian MubeenPas encore d'évaluation

- Launie "Kris" Hansen: Work ExperienceDocument3 pagesLaunie "Kris" Hansen: Work ExperienceKris HansenPas encore d'évaluation

- LumberjackDocument10 pagesLumberjackelziputriPas encore d'évaluation

- 4 Conversion of TimberDocument26 pages4 Conversion of TimberKemaro Morgan100% (1)

- Marche: Knit in - Skill LevelDocument3 pagesMarche: Knit in - Skill LeveldrgnstelaPas encore d'évaluation

- Jis G4051Document7 pagesJis G4051tnchsgPas encore d'évaluation

- Real Estate Business PowerPoint TemplatesDocument48 pagesReal Estate Business PowerPoint Templatesdu muc KePas encore d'évaluation

- Kenmore 385.17026 Sewing Machine Instruction ManualDocument128 pagesKenmore 385.17026 Sewing Machine Instruction ManualiliiexpugnansPas encore d'évaluation

- Friendship BraceletsDocument5 pagesFriendship Braceletskanuncio4Pas encore d'évaluation

- Ejot WN-1451Document1 pageEjot WN-1451Diogo DoiPas encore d'évaluation

- 2020.03 Corporate Presentation VF1Document31 pages2020.03 Corporate Presentation VF1Paul Medios AudiovisualesPas encore d'évaluation

- Semi Detailed Lesson Plan in Technology Livelihood Education-CarpentryDocument4 pagesSemi Detailed Lesson Plan in Technology Livelihood Education-CarpentryDhoruthy Ann Lumbre100% (2)

- ME8351-Manufacturing Technology-IDocument12 pagesME8351-Manufacturing Technology-IDayon MathewPas encore d'évaluation

- Shaper and PlannerDocument11 pagesShaper and PlannerAmman ButtPas encore d'évaluation

- Spiral Filigree KraidmanDocument2 pagesSpiral Filigree KraidmanSona Mei100% (2)

- Carpentry - Recitation #2Document3 pagesCarpentry - Recitation #2Mark Angelo Belza SotoPas encore d'évaluation

- Quilting Arts August-September 2008Document1 pageQuilting Arts August-September 2008InterweavePas encore d'évaluation

- Crochet Owl Amigurumi Pattern - MR Murasaki - Craft PassionDocument4 pagesCrochet Owl Amigurumi Pattern - MR Murasaki - Craft PassionVinícius BaraúnaPas encore d'évaluation

- Crochet: Kitsch BaublesDocument108 pagesCrochet: Kitsch BaublesAitikys Ro100% (4)

- Sachin Solanki CNC/IPC/13 Summary SupportDocument61 pagesSachin Solanki CNC/IPC/13 Summary Supportshivam modanwalPas encore d'évaluation

- Needlework Through HistoryDocument258 pagesNeedlework Through HistoryIrisGuiang100% (5)

- ReferenceaaaDocument23 pagesReferenceaaaĐinh Thiện SỹPas encore d'évaluation

- MCQ MPDocument27 pagesMCQ MPEr Vishal Divya Jagadale67% (3)

- MP8s Marzo 2023Document4 pagesMP8s Marzo 2023Christian RodriguezPas encore d'évaluation

- FIGLIA SOCKS - Construction Chart: Yarn NeedlesDocument17 pagesFIGLIA SOCKS - Construction Chart: Yarn Needlesfrida diPas encore d'évaluation

- Circular Work in Carpentry and Joinery PDFDocument145 pagesCircular Work in Carpentry and Joinery PDFcaf_desknote100% (1)

- Multi-Master Indexable - Low ResDocument28 pagesMulti-Master Indexable - Low ResrianrurePas encore d'évaluation