Académique Documents

Professionnel Documents

Culture Documents

AquaProtect T

Transféré par

Ridwan PramudyaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

AquaProtect T

Transféré par

Ridwan PramudyaDroits d'auteur :

Formats disponibles

AquaProtect T

Heat exchanger system – Anti-legionella

AquaProtect T

Studies have shown that many hot water systems contain

legionella bacteria. The AquaProtect system is designed for

thermal disinfection of hot water to eliminate these bacteria.

Since the system includes heat recovery, the disinfection

process consumes no extra energy. In systems in which

previous attempts were made to reduce the bacteria count

by raising the system temperature, the energy costs can be

substantially reduced by installing the AquaProtect system

and lowering the water temperature back to its original value.

How do bacteria cause infection?

The legionella bacterium occurs naturally in lakes and water

sources and enters our water systems with the cold water.

Different materials, deposits that promote growth, and certain

temperature levels encourage legionella bacteria to propagate.

These bacteria breed most actively at temperatures between

20 and 45°C. People are infected by inhaling the bacteria

with water vapour when showering or washing. Legionella

bacteria cause Legionnaires’ disease, the symptoms of which

are similar to pneumonia, and the disease may be fatal unless

treated in time.

AquaProtect T

Which systems should be disinfected?

The larger and the more complex the hot water system, Advantages

the greater the probability or risk of high bacteria contents. – Safe eradication of the legionella at a temperature of 70ºC

If the hot water temperature in the system is low and if the at six minutes holding time.

system has been modified so that the water is stagnant in – Continuous disinfection of all circulating water

certain pipe connections, the risk of infection will be very – Temperature safety function, e.g. low capacity on primary

high. The hot water systems in hospitals, hotels, schools, side or worse heat transfer. Depending on the set point of

public baths and also in shower rooms in work places and the controller the distribution valve limits the flow entering

sports facilities are typical examples of systems that should the combined reaction tank at the right temperature of 70ºC

be checked and remedied as necessary. all other flow is recirculated to the charging loop.

– Net disinfection

Reliable performance – Heat exchangers for waters with low/high lime content

Legionella bacteria are temperature sensitive. The Aqua- – Standardised capacity ranges for different tapping flow rates

Protect system heats the water to 70°C and keeps it at this – Compact-system ready to be connected

temperature for about six minutes, which kills the bacteria. – Electronic control device

The water is then cooled to the required system temperature.

The AquaProtect system is rated so that it has the capacity for Options

periodic disinfection of the entire hot water system by heating – Protection against capacity overload, shut-off valve on the

the water to a high temperature. inlet of the storage tank, while the charging capacity is still

available for the tapping.

– AlfaNova compact heat exchanger (100% stainless steel)

Operation of the AquaProtect system

The cold water entering the hot water system is heated to In the AquaProtect system, the hot water recirculation

70°C in a heat exchanger. This water then flows through a connection is made at the incoming cold water. This means

reaction tank which is rated and designed so that the water that hot water which has been out in the system and may

takes six minutes to flow through it. Legionella bacteria are possibly have been ’infected’ on contact with cold water,

temperature sensitive and are killed during these six minutes. such as in a shower mixer, will partially be disinfected

From the reaction tank, the water flows to a storage tank in afresh. The legionella bacteria count is thus maintained at a

the usual manner. very low level in the entire system.

When hot water is drawn off in the system, the 70°C hot When the AquaProtect system is commissioned, the

water is taken from the storage tank. However, instead of entire hot water system is usually disinfected by the whole

being diluted with cold water to the appropriate system tem- of the plumbing being flushed with water at 70°C or pos-

perature, the 70°C water gives up some of its heat in a heat sibly even higher for a certain period of time. The AquaPro-

exchanger to the incoming cold water. The cold water is thus tect system is rated so that such flushing can be carried

preheated before being heated to the disinfection tempera- out periodically, if necessary.

ture. All of the energy used for the disinfection process is thus Boiler water at a temperature of at least 75°C is used

recovered, and energy consumed by the AquaProtect system as the primary medium for the AquaProtect system. If the

is merely that needed for driving the pump. AquaProtect is connected to the district heating system, it

The water between the heat exchanger, reaction tank is important to check that the water temperature is suffi-

and storage tank is continuously kept in circulation. When ciently high throughout the year. If not, an electric boiler, for

hot water is drawn off, the storage tank or tanks are used for instance, may have to be added.

storing the preheated water. When draw-off has ceased, the The AquaProtect system is available in a number of

circulation is reversed and the stored preheated water flows to standard sizes, but it can also be rated and customized for

the heat exchanger, where it is heated to 70°C and then flows specific applications.

through the reaction tank for disinfection. The water then The production is certificated to the ISO 9001 quality

returns to the storage tank, but now to the top of the tank. standard, and our laboratory is accredited by SWEDAC.

HV HR F D E C B

Charging

Cooling

Storage tank Reaction tank

A Hot water to storage

B Cold water to storage/re-load

C Cold water in

D Hot water out (net)

E Circulation

F Hot water from storage

PCT00027EN 0705 All rights reserved for changes in specifications

How to contact Alfa Laval

Up-to-date Alfa Laval contact details

for all countries are always available

on our website at www.alfalaval.com

Vous aimerez peut-être aussi

- Alfa LavalDocument29 pagesAlfa LavallipovanychPas encore d'évaluation

- Hot Water SupplyDocument56 pagesHot Water SupplyVismithaPas encore d'évaluation

- Rotex - Sanicube 300 & 500 2007Document8 pagesRotex - Sanicube 300 & 500 2007Kim Duy DoanPas encore d'évaluation

- Group 02 - Hot Water SupplyDocument20 pagesGroup 02 - Hot Water SupplyfelistasPas encore d'évaluation

- Hot and Cold Water Supply AMGDDocument26 pagesHot and Cold Water Supply AMGDJasleenPas encore d'évaluation

- Owner'S Manual: Solar Water HeatersDocument56 pagesOwner'S Manual: Solar Water Heatersraditanka aobakwePas encore d'évaluation

- CH2. Hot Water SupplyDocument13 pagesCH2. Hot Water SupplyPubudu KalpagePas encore d'évaluation

- GreenDocument12 pagesGreenselvin_singhPas encore d'évaluation

- Paw Friwa PDFDocument2 pagesPaw Friwa PDFGoheimPas encore d'évaluation

- Cooling Water System 1Document18 pagesCooling Water System 1anupam01013787Pas encore d'évaluation

- Hot Water SupplyDocument32 pagesHot Water SupplyRishikesh Wadekar100% (1)

- CPL R2S Managers LegionellaDocument1 pageCPL R2S Managers LegionelladnfPas encore d'évaluation

- Tank Booster Pro Brochure WebDocument6 pagesTank Booster Pro Brochure WebCarlClousePas encore d'évaluation

- Cooling Tower Efficiency ManualDocument26 pagesCooling Tower Efficiency ManualSyed Alwi AlattasPas encore d'évaluation

- Owner'S Manual: Solar Water HeatersDocument60 pagesOwner'S Manual: Solar Water HeatersoptimiPas encore d'évaluation

- Domestic Hot Water Recirculation Systems: Application, Selection & Installation GuideDocument8 pagesDomestic Hot Water Recirculation Systems: Application, Selection & Installation GuideradusettPas encore d'évaluation

- Lecture - 10 - Hot Water SupplyDocument17 pagesLecture - 10 - Hot Water SupplyNoor HaziqahPas encore d'évaluation

- Tempering Units G3802: Guardian EquipmentDocument2 pagesTempering Units G3802: Guardian Equipmenteisenbarger5607Pas encore d'évaluation

- Evaporator E-2000: Technical InformationDocument2 pagesEvaporator E-2000: Technical InformationsarahPas encore d'évaluation

- Thermostatic Mixing ValveDocument12 pagesThermostatic Mixing ValveAbey VettoorPas encore d'évaluation

- Water BathDocument3 pagesWater BathMohamed AlhamdaniPas encore d'évaluation

- Aqua FlowDocument4 pagesAqua FlowDamian OvidiuPas encore d'évaluation

- Week 5 - HOT WATER SUPPLYDocument19 pagesWeek 5 - HOT WATER SUPPLYAmila AqielaPas encore d'évaluation

- Cool Tunes: Run An Efficient Cooling TowerDocument26 pagesCool Tunes: Run An Efficient Cooling TowerОливер АндовскиPas encore d'évaluation

- Evaporators: Waste Heat RecoveryDocument8 pagesEvaporators: Waste Heat RecoveryJitendra KumarPas encore d'évaluation

- Operation & Manual L200GVFM-150kW (SEPCO) - CompressedDocument11 pagesOperation & Manual L200GVFM-150kW (SEPCO) - CompressedWASSIM SUNNAPas encore d'évaluation

- District Cooling Plant 1696416191Document11 pagesDistrict Cooling Plant 1696416191mohd rafiq mohd haniPas encore d'évaluation

- Circulating Pump For Hot WaterDocument8 pagesCirculating Pump For Hot WaterAbo MohammedPas encore d'évaluation

- Pd10016 Tetra Therm Lacta 1Document4 pagesPd10016 Tetra Therm Lacta 1Omar ArguelloPas encore d'évaluation

- 01.BAC HBii Maintenance of Crossflow TowersDocument32 pages01.BAC HBii Maintenance of Crossflow TowersJehuty88Pas encore d'évaluation

- Tempering Units G3850: Guardian EquipmentDocument2 pagesTempering Units G3850: Guardian Equipmenteisenbarger5607Pas encore d'évaluation

- Domestic Water Heating: Engineering Utilities 2 (Basic Mechanical Engineering) ME 223Document11 pagesDomestic Water Heating: Engineering Utilities 2 (Basic Mechanical Engineering) ME 223Marifher Kate Dela CruzPas encore d'évaluation

- Table 6-4, ContinuationDocument1 pageTable 6-4, ContinuationAlsayed Rabiea MiesalamPas encore d'évaluation

- HE Operating InstructionsDocument2 pagesHE Operating InstructionsChrestien Faith PavillarPas encore d'évaluation

- Hot & Cold Water SystemDocument5 pagesHot & Cold Water SystemSyamimi Hana100% (1)

- Tempering Units G3600: Guardian EquipmentDocument2 pagesTempering Units G3600: Guardian Equipmenteisenbarger5607Pas encore d'évaluation

- Sunway Practical Lab Bicarbonate Decomposition 2012Document11 pagesSunway Practical Lab Bicarbonate Decomposition 2012venkieePas encore d'évaluation

- Saxon Copperflow Electric-Installermanual PDFDocument20 pagesSaxon Copperflow Electric-Installermanual PDFWayne AshPas encore d'évaluation

- 004 Plumbing Systems - Jun-19Document8 pages004 Plumbing Systems - Jun-19Đức Huấn ĐỗPas encore d'évaluation

- Naval DiagramsDocument39 pagesNaval DiagramsAsif AliPas encore d'évaluation

- Apv H35Document18 pagesApv H35petrakou aglaia100% (1)

- OperationDocument4 pagesOperationAruna MadhuchinthakaPas encore d'évaluation

- Temperatures HW and The CodeDocument9 pagesTemperatures HW and The CodeDavid DelonPas encore d'évaluation

- Installation and Operation Manual: IMPORTANT: Please Keep This Manual On Site With The Sol-Reliant SystemDocument28 pagesInstallation and Operation Manual: IMPORTANT: Please Keep This Manual On Site With The Sol-Reliant SystemYass CosmeticsPas encore d'évaluation

- ARCH 203 Building Services Week 2: Cold Water Supply Direct System Indirect SystemDocument52 pagesARCH 203 Building Services Week 2: Cold Water Supply Direct System Indirect SystemaalokeroyPas encore d'évaluation

- Versati DC Inverter Heatpump TSGDocument26 pagesVersati DC Inverter Heatpump TSGnikipshPas encore d'évaluation

- Heat Pump Brochure ZH CN 5083406Document20 pagesHeat Pump Brochure ZH CN 5083406Claudio ZuffiPas encore d'évaluation

- Saxon Copper Flow Electric-InstallerManualDocument20 pagesSaxon Copper Flow Electric-InstallerManualMichael FortePas encore d'évaluation

- 08 HotWaterNavigatorDocument6 pages08 HotWaterNavigatorHung Quoc DangPas encore d'évaluation

- Cooling Circulating Water, Purge Water & Cooling Tower SystemDocument22 pagesCooling Circulating Water, Purge Water & Cooling Tower SystemSCE CCGT3Pas encore d'évaluation

- TPC 24 - 03 - 2023Document2 pagesTPC 24 - 03 - 2023Soniya DattiPas encore d'évaluation

- Water Softeners Residential ProFloSXT Downflow Upflow Valve Softeners US ManualDocument16 pagesWater Softeners Residential ProFloSXT Downflow Upflow Valve Softeners US ManualPromagEnviro.comPas encore d'évaluation

- JTL Book Hot Water SupplyDocument14 pagesJTL Book Hot Water SupplybendeniPas encore d'évaluation

- Discussion 7 - Domestic Water HeatingDocument20 pagesDiscussion 7 - Domestic Water HeatingShan Troy Jamero IbarraPas encore d'évaluation

- Rotexsanicube EngDocument8 pagesRotexsanicube EngalvinchuanPas encore d'évaluation

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesD'EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesPas encore d'évaluation

- Hot Water Heater Installation and Repair: A Step-by-Step Guide to DIY Installation, Maintenance, and Troubleshooting for Homeowners: Homeowner Plumbing Help, #4D'EverandHot Water Heater Installation and Repair: A Step-by-Step Guide to DIY Installation, Maintenance, and Troubleshooting for Homeowners: Homeowner Plumbing Help, #4Pas encore d'évaluation

- Batch and Semi-batch Reactors: Practical Guides in Chemical EngineeringD'EverandBatch and Semi-batch Reactors: Practical Guides in Chemical EngineeringPas encore d'évaluation

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceD'EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformancePas encore d'évaluation

- 09aw, Az 2siDocument28 pages09aw, Az 2siRidwan PramudyaPas encore d'évaluation

- XR06CXDocument3 pagesXR06CXRidwan PramudyaPas encore d'évaluation

- Compressor Cross ReferenceDocument8 pagesCompressor Cross ReferenceRidwan PramudyaPas encore d'évaluation

- Water Comfort: A Complete Range of Hot Water SolutionsDocument4 pagesWater Comfort: A Complete Range of Hot Water SolutionsRidwan PramudyaPas encore d'évaluation

- Fcu Chilled WaterDocument2 pagesFcu Chilled WaterRidwan PramudyaPas encore d'évaluation

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraPas encore d'évaluation

- 11443FR TKSA ShaftAlignmentTools UnlockedDocument8 pages11443FR TKSA ShaftAlignmentTools UnlockedRobertoVianaCardosoPas encore d'évaluation

- Manual Inversor Powest All in One 3 y 5kva On GridDocument50 pagesManual Inversor Powest All in One 3 y 5kva On GridOrlando Suarez CabreraPas encore d'évaluation

- Abstract-Piezoelectric Energy HarvestingDocument2 pagesAbstract-Piezoelectric Energy HarvestingGanesh Venugopal100% (5)

- Full ReportDocument44 pagesFull ReportCes ShengPas encore d'évaluation

- Lube Blending Plants: Global Market Study and Performance EvaluationDocument25 pagesLube Blending Plants: Global Market Study and Performance Evaluationmgamal1080Pas encore d'évaluation

- Unit - 3 Solar Photovoltaic SystemDocument15 pagesUnit - 3 Solar Photovoltaic SystemSudhir MallampatiPas encore d'évaluation

- Lugs and Ferrules Technical Information PDFDocument2 pagesLugs and Ferrules Technical Information PDFkwagga125Pas encore d'évaluation

- A GCE Physics B 2865 01 January 2006 Question PaperDocument24 pagesA GCE Physics B 2865 01 January 2006 Question PaperMitul KaziPas encore d'évaluation

- Hirarki Detail Engineering Design (DED)Document1 pageHirarki Detail Engineering Design (DED)Agus SusantoPas encore d'évaluation

- Boardworks - Magnetic FieldsDocument43 pagesBoardworks - Magnetic Fieldsdiane hoyles100% (6)

- Mass BalanceDocument8 pagesMass BalanceShiraz NajatPas encore d'évaluation

- Aermec PXA E INSTALLATION MANUAL EngDocument8 pagesAermec PXA E INSTALLATION MANUAL EngMauricio Andres Vidal ColomaPas encore d'évaluation

- 06 Ba Exakt 80eplus EnglischDocument154 pages06 Ba Exakt 80eplus EnglischAya adelPas encore d'évaluation

- Dinli ATV Electrical System ManualDocument15 pagesDinli ATV Electrical System ManualgryzzlyPas encore d'évaluation

- VLT2800 Quick Guide PDFDocument2 pagesVLT2800 Quick Guide PDFlieldPas encore d'évaluation

- SM 18Document16 pagesSM 18Uriel HerreraPas encore d'évaluation

- EnTF CEM Course E-BrochureDocument2 pagesEnTF CEM Course E-BrochureSidhartha MallickPas encore d'évaluation

- Group Practice GP 34-00 Machinery: Use and Interpretation of This DocumentDocument40 pagesGroup Practice GP 34-00 Machinery: Use and Interpretation of This DocumentSuresh Kumar A P80% (5)

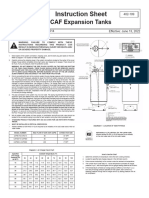

- Taco CAF Expansion Tank Install ManualDocument3 pagesTaco CAF Expansion Tank Install ManualTEMPPas encore d'évaluation

- Test Report GroutDocument2 pagesTest Report GroutKuldeep ChakerwartiPas encore d'évaluation

- Phy Sci PartIDocument318 pagesPhy Sci PartIsollu786_889163149Pas encore d'évaluation

- EGY D 22 06311 - R1 - ReviewerDocument101 pagesEGY D 22 06311 - R1 - ReviewerWEIWEI YANGPas encore d'évaluation

- Universal State Plumbing CodeDocument118 pagesUniversal State Plumbing CodecruzserPas encore d'évaluation

- EN13480-3 Chap12 ModificationsDocument37 pagesEN13480-3 Chap12 ModificationsPrashant ChauhanPas encore d'évaluation

- SSGCDocument20 pagesSSGCAdnan119Pas encore d'évaluation

- Smpling - Storage - Transportation - Installation ProcedureDocument75 pagesSmpling - Storage - Transportation - Installation ProcedurePaddyPas encore d'évaluation

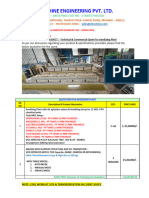

- Kashimali Aluminium - Karnataka - Anodizing Plant - 18.11.2023Document7 pagesKashimali Aluminium - Karnataka - Anodizing Plant - 18.11.2023Manjunath NemagoudarPas encore d'évaluation

- APD345C-6 CompressedDocument5 pagesAPD345C-6 CompressedKelvinVelasquezPascualPas encore d'évaluation

- Safety According To Iec 60364-7-710.2002-11Document70 pagesSafety According To Iec 60364-7-710.2002-11ahloyeah100% (1)