Académique Documents

Professionnel Documents

Culture Documents

Lecture 1

Transféré par

Syed Qaseem AliDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lecture 1

Transféré par

Syed Qaseem AliDroits d'auteur :

Formats disponibles

Institute of Professional Advancement 2/22/2011

Industrial Electronics

Institute of Professional Advancement

Industrial Electronics

Syed Qaseem Ali

qaseemali@gmail.com

0333-2347208

MSEE (Power and Control) IIT, Chicago, USA

BE (Electronics) NEDUET, Karachi, Pakistan

Introduction

• Name

• Student or Professional

• Qualification

• Experience and Affiliation

• Why are you attending this course?

• What do you expect to learn?

By Syed Qaseem Ali 1

Institute of Professional Advancement 2/22/2011

Industrial Electronics

Course Outline

• Introduction to Automation • Robotics and Applications

and Control

• Electric Load Calculations

• Industrial Safety

• Industrial Electrical Devices • LT/HT

• Industrial Control Devices • Cables and Types of Cables

• AC/DC Motors • Inverters

• Generators, Cooling Towers, • Troubleshooting with

Chillers and Burners

electrical and electronic

• PLC

devices

• HMI (Human Machine

Interface) • Identification and Bar Code

• Servo Systems systems

• Stepper/Servo Motors • Preventive and Corrective

• Sensors, Encoders and Maintenance of Machines

Transducers

• Instrument Calibration

Labs

• Different Types of sensors

• Encoders

• AC Motors

• DC Motors and types

• Stepper Motor and types

• Servo Motor

• PLC

• Different Types of Cables

• Frequency Drives

By Syed Qaseem Ali 2

Institute of Professional Advancement 2/22/2011

Industrial Electronics

Introduction to Automation and

Control

• What is Automation?

• The procedure of minimizing human

intervention/dependence in production of

goods and services is called automation.

• It is not merely Mechanization, but replaces

human sensory and mental dependence too.

• Example:

• Automated Software testing, Manufacturing Processes,

Automatic Assembly lines, Automatic Lifts, Automatic Cars,

Processes in a human body etc.

How to minimize human intervention?

• We can minimize human intervention by using

Control Devices.

• Control Devices may be mechanical,

electronic, electro-mechanical, Biological,

Organic.

• Examples:

• Relays, Motors, µ-Controller, µ-Processor, PLC, SCADA, DCS.

By Syed Qaseem Ali 3

Institute of Professional Advancement 2/22/2011

Industrial Electronics

Types of Automation

• There are three basic types of Automation

• Fixed automation

– For fixed sequence of operation and very high

production rates and volume.

• Programmable automation

– Can accommodate a specific kind of change, but

retrospectively has a fixed process, for medium

production rates and batch production.

• Flexible automation

– Designed for manufacturing variety of products low

production volume and rates, varying product designs.

Fixed Automation

• Applicability

– Mass production, Long Product Cycles.

• Advantages

Speed, Efficiency, Troubleshooting will be easy,

Low Unit Cost

• Disadvantages

– Rigid, Initial Investment will be high, Low Volume

production will be costly (Cost will vary)

By Syed Qaseem Ali 4

Institute of Professional Advancement 2/22/2011

Industrial Electronics

Programmable Automation

• Applicability

– Batch Production, Product with different options.

• Advantages

– Product Variants possible, Low Unit Cost for Large

Batches

• Disadvantages

– Changeover time reduces Efficiency, Limited

Variations possible, Higher cost than Fixed

Automation

Flexible Automation

• Applicability

– Varying production rates, varying demands, Short

product lifecycles.

• Advantages

– High level of Flexibility, One time investment for a

wide variety of products (including different designs),

Benefitial for prototyping

• Disadvantages

– Initial Investment, Changeover/Setup time Very high.

By Syed Qaseem Ali 5

Institute of Professional Advancement 2/22/2011

Industrial Electronics

Reasons for Automation

• Human error minimization, increased product

quality.

• Labor Cost reduction

• Speeds up the process

• Increased Safety

• Data Acquisition becomes easy

• Lower Product Cost

• Changeover and setup time decreases

• In process inventory and wastage is reduced

Control Systems

• Open Loop without Feedback

– Examples

• Drill Machine, Car (without the human), Grass cutter,

Automatic Toaster, Garage door opener

• Close Loop with Feedback

– Examples

• Car (with the human), Thermostat in an AC, Automatic

Lifts, Cruise Control of a car

By Syed Qaseem Ali 6

Institute of Professional Advancement 2/22/2011

Industrial Electronics

Industrial Safety

• Hazard

– Any process, place, event, equipment or action

that could result in any type of injury to

personnel.

Types of Hazards

• Chemical

• Physical

– Electrical

– Thermal

– Environmental (Noise, Spatial)

• Biological

• Human Hazard (Stupidity, Human Needs)

• Ergonomic

By Syed Qaseem Ali 7

Institute of Professional Advancement 2/22/2011

Industrial Electronics

Most common Hazards in an industrial

setup

• Chemical

– Material Safety Datasheets

– NFPA 704

Chemical

• Liquifued oxygen container

• Petrol Pump

By Syed Qaseem Ali 8

Institute of Professional Advancement 2/22/2011

Industrial Electronics

Safety Equipment / PPEs (Personal

Protective Equipment)

• Safety Glasses

• Bunny Suits / Hazmat Suits

• Gloves

• Air purifying respirator

• Hard Hat / Helmet

• Face guard

• Safety Shoes

• Ear Plugs / Ear Muffs

• Fire Resistant Clothing

• Safety Harness (to prevent falling from high places)

• Reflective Vest

• First Aid Kit

• Fire Extinguisher

* For a comprehensive list visit http://www.protecdirect.co.uk/Personal-Protective-PPE.htm

Most common Hazards in an industrial

setup

• Electrical Hazard

– High Voltage

– High Current

– Loose/Naked Wiring

By Syed Qaseem Ali 9

Institute of Professional Advancement 2/22/2011

Industrial Electronics

Most common Hazards in an industrial

setup

• Mechanical

– Uncovered moving parts

– Rotating parts

Most common Hazards in an industrial

setup

• Thermal and Ergonomic

– Hot or cold surfaces

– Hot or Cold environments

– Repetitive tasks – RSSI

– Work environment

– Continuous Noise

By Syed Qaseem Ali 10

Institute of Professional Advancement 2/22/2011

Industrial Electronics

References

• http://www.seas.upenn.edu/~meam520/slides/intautoslides.pdf

• http://www.inverter-china.com/blog/articles/Automation/83.html

• http://www.scribd.com/doc/37526868/Lect-1-Introduction-to-

Industrial-Safety

• http://en.wikipedia.org/wiki/Industrial_safety_system

• http://industrialplantsafety.com/

• http://www.acusafe.com/Hazard_Analysis/HAZOP_Technique.pdf

• http://en.wikipedia.org/wiki/Hazard_and_operability_study

• http://www-

ssrl.slac.stanford.edu/safety/acceleratorwork/documents/7_10_ge

neral_industrial.pdf

• http://www.lanl.gov/safety/electrical/docs/arc_flash_safety.pdf

• http://en.wikipedia.org/wiki/Hazard_symbol

By Syed Qaseem Ali 11

Vous aimerez peut-être aussi

- Icl7667 DatasheetDocument10 pagesIcl7667 DatasheetSyed Qaseem AliPas encore d'évaluation

- Analysis of Fault Conditions in Permanent-Magnet In-Wheel MotorsDocument81 pagesAnalysis of Fault Conditions in Permanent-Magnet In-Wheel MotorsSyed Qaseem AliPas encore d'évaluation

- Boost PFC Preregulator DesignDocument16 pagesBoost PFC Preregulator DesignSyed Qaseem AliPas encore d'évaluation

- MC13783 Buck and Boost Inductor Sizing: Application NoteDocument8 pagesMC13783 Buck and Boost Inductor Sizing: Application NoteSyed Qaseem AliPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- A Simulation-Based Process Model For Managing Complex Design ProcessDocument13 pagesA Simulation-Based Process Model For Managing Complex Design ProcessMetehan AgacaPas encore d'évaluation

- PS1Document2 pagesPS1Nitesh Kumar DubeyPas encore d'évaluation

- MicrowaveDocument41 pagesMicrowaveMaryem MostafaPas encore d'évaluation

- Tribology Module 01 NotesDocument19 pagesTribology Module 01 NotesVinayaka G P89% (9)

- GMS60CSDocument6 pagesGMS60CSAustinPas encore d'évaluation

- Water Levels Forecast in Thailand: A Case Study of Chao Phraya RiverDocument6 pagesWater Levels Forecast in Thailand: A Case Study of Chao Phraya RiverErna UtamiPas encore d'évaluation

- SC Perthub Single Cell OmicsDocument34 pagesSC Perthub Single Cell OmicsGANYA U 2022 Batch,PES UniversityPas encore d'évaluation

- Symmetries and Conservation Laws-Consequences of Noether TheoremDocument8 pagesSymmetries and Conservation Laws-Consequences of Noether TheoremmastinaropuruPas encore d'évaluation

- Appraisal Assistant User ManualDocument55 pagesAppraisal Assistant User ManualDamian Padilla100% (3)

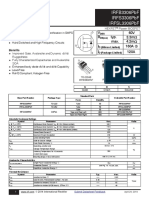

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADocument12 pagesIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligPas encore d'évaluation

- OK Flux 231 (F7AZ-EL12) PDFDocument2 pagesOK Flux 231 (F7AZ-EL12) PDFborovniskiPas encore d'évaluation

- Lecture 8cDocument29 pagesLecture 8cs_paraisoPas encore d'évaluation

- Faculty: Geology Exploration Specialty: Geology Engineering Group: 123.6 Student: Asef Sadiqov Teacher: Afet Israfilova Theme: The EarthDocument16 pagesFaculty: Geology Exploration Specialty: Geology Engineering Group: 123.6 Student: Asef Sadiqov Teacher: Afet Israfilova Theme: The EarthKenan RehmanPas encore d'évaluation

- Fiber SyllabusDocument1 pageFiber SyllabusPaurav NayakPas encore d'évaluation

- Dynamic Force AnalysisDocument13 pagesDynamic Force AnalysisJakesPas encore d'évaluation

- Unit Exam 5Document3 pagesUnit Exam 5Rose AstoPas encore d'évaluation

- Infinera Ds Isfp Timedivision Multiplexing ModulesDocument3 pagesInfinera Ds Isfp Timedivision Multiplexing ModulesAnonymous bpf0OZSd9Pas encore d'évaluation

- Creating Attachments To Work Items or To User Decisions in WorkflowsDocument20 pagesCreating Attachments To Work Items or To User Decisions in Workflowselampe100% (1)

- LBX 6513DS VTMDocument4 pagesLBX 6513DS VTMsergiocuencascribPas encore d'évaluation

- 2018 AniketDocument60 pages2018 Aniketaniket chakiPas encore d'évaluation

- DCM-I&II Lab Equipments ListDocument2 pagesDCM-I&II Lab Equipments ListPrashant ChinamalliPas encore d'évaluation

- 1.summative-Test Math7Document1 page1.summative-Test Math7Jaylor GaridoPas encore d'évaluation

- 3PAR DISK MatrixDocument6 pages3PAR DISK MatrixShaun PhelpsPas encore d'évaluation

- Chapter 7 Analysis of Stress and StrainDocument20 pagesChapter 7 Analysis of Stress and StrainLong Nguyễn HoàngPas encore d'évaluation

- Sqluser v11r1Document199 pagesSqluser v11r1samnolenPas encore d'évaluation

- Java Lab Assignment.Document2 pagesJava Lab Assignment.KAYPas encore d'évaluation

- Chem 1211 Lab ReportDocument9 pagesChem 1211 Lab Reportansleybarfield0% (1)

- Illiquidity and Stock Returns - Cross-Section and Time-Series Effects - Yakov AmihudDocument50 pagesIlliquidity and Stock Returns - Cross-Section and Time-Series Effects - Yakov AmihudKim PhượngPas encore d'évaluation

- Como Desarmar Sony Vaio VGN-FE PDFDocument14 pagesComo Desarmar Sony Vaio VGN-FE PDFPeruInalambrico Redes InalambricasPas encore d'évaluation

- 3 DB RDMDocument49 pages3 DB RDMfaisal shahzadPas encore d'évaluation