Académique Documents

Professionnel Documents

Culture Documents

Nutmeg Fat Extraction

Transféré par

mnariaz_11Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Nutmeg Fat Extraction

Transféré par

mnariaz_11Droits d'auteur :

Formats disponibles

Chemistry 214 Clark College

Trimyristin: A Fat from Nutmeg

This lab was developed by Dr. Tom Goodwin at the Toad Suck Institute for Green Organic Chemistry at

Hendrix College in Conway, Arkansas. (http://www.hendrix.edu/chemistry/green.htm)

REFERENCES

1. “Zero Effluent Laboratory”, L. R. Corwin, R. J. Roth, T. H. Morton, Brown University

2. “Soap from Nutmeg: An Integrated Introductory Organic Chemistry Laboratory Experiment”, M.

C. S. De Mattos, D. E. Nicodem, J. Chem. Educ. 2002, 79, 9495;

3. “Organic Chemistry”, 4th Ed., Brown, Foote and Iverson, Brooks/Cole Publishing, Belmont, CA,

2005.

INTRODUCTION

Nutmeg is the common name of the seed from female Myristica fragrans, a tree native to the Spice

Islands (the Moluccas, in the East Indies, now part of Indonesia). When the fruit of the tree matures, it

splits in two, exposing a single seed sheathed in a crimson aril. The aril, a fibrous covering, constitutes

the spice known as mace, and the seed is a whole nutmeg.

Nutmeg has been known as a spice in the Middle East for at least 2500 years, but it was not introduced

into Europe until the Middle Ages. Dutch and Portuguese merchants monopolized the European

nutmeg trade until 1843, when French and British interests succeeded in cultivating nutmeg trees in the

West Indies. There is a decided difference between East Indian and West Indian nutmeg.

Like many other spices, nutmeg has a long history of medicinal use. Preparations of nutmeg have

been used as analgesics, digestive stimulants, aphrodisiacs, amenorrheal agents, and hypnotics.

Medicinal use has declined since the 18th century, save for a brief period at the end of the 18th century,

when it was rumored to be an effective abortifacient. Several medical journals of this period reported a

high incidence of nutmeg poisoning among women.

The nutmeg is about half cellulose. The other major components are fats, 25-40%, and essential oils,

8-15%. The former constitute the major portion of the expressed oil of nutmeg (obtained by distilling

the seed with steam). Both of these components contain thousands of different compounds, only a

handful of which have been identified. The expressed oil, also known as nutmeg butter, is composed

principally of a lipid called trimyristin, the structural formula of which is illustrated in reaction 1. This fat

also occurs in other plant and animal products, such as coconut oil and cow’s milk.

Trimyristin is an example of fundamental type of fat known as a triglyceride. Hydrolysis of one mole of

a triglyceride affords one mole of 1,2,3-propanetriol (glycerin) and 3 moles of fatty acids, which are

carboxylic acids containing the functional group at the end of a long alkyl chain. In addition to

trimyristin (which is odorless when pure), solvent extraction of nutmeg yields as major components the

three compounds illustrated below, which are responsible for most of the characteristic nutmeg odor.

Myristicin occurs in much higher concentration than elemicin or safrole.

O O

H3CO

H3C(H2C)12 O O (CH2)12CH3

O

trimyristin O myristicin

H3C(H2C)12 O O

H3CO

elemicin safrole

H3CO O

OCH3 O

Trimyristin Extraction and Saponification Page 1 of 4

Chemistry 214 Clark College

Myristicin has been studied pharmacologically. In mice it inhibits the action of monoamine oxidase, an

important enzyme in the central nervous system, and a distinct psychotomimetic effect has been

detected in man. The effect of myristicin is reported to be stronger when the other constituents of the

volatile oil are present. It has been suggested that the other components do not themselves contribute

to the psychotropic activity, but promote absorption of myristicin by irritating the gastrointestinal tract.

One hypothesis regarding the hallucinogenic activity of allylbenzene derivatives is that they are

metabolized to compounds related to amphetamine. As for many pharmacologically active substances,

the difference between an effective dose and a toxic dose is not great. An after effect of ingestion of

large quantities of nutmeg or myristicin is a lasting aversion to its taste or smell.

PROCEDURE

Extraction of Trimyristin:

1. Add 20 ml of petroleum ether to powdered nutmeg (approx.10 g, weighed to nearest 0.1 g) in a

50 ml round-bottomed flask. (Note: “petroleum ether” is an historical name, and a misnomer.

This solvent is actually a mixture of low molecular weight alkanes, and not an ether at all. It has

properties much like gasoline, so you should avoid flames, keep the solvent vapors away from

hot surfaces, avoid inhalation, and avoid skin contact.)

2. Add a boiling stone, lightly grease the glass joint, and reflux the mixture GENTLY (keep the heat

low) for 30 minutes (30 minutes of actual boiling time) under a water-cooled condenser. Record

frequent observations in your notebook.

3. At the end of the reflux period, turn off the heat, and move the heating mantle away from the

round-bottomed flask so that the flask can cool. Allow the flask to remain undisturbed while it

cools, and the insolubles settle to the bottom.

4. When the flask is cool to the touch, pipet the liquid away from the solid. The liquid solution is

what we want to keep, since it contains the extracted trimyristin. Put a small latex bulb on a

short Pasteur pipet and, without disturbing the precipitate, transfer as much of the liquid as you

can to a pre-weighed, clean, dry, 100 mL round-bottomed flask. NOTE: YOU MUST MINIMIZE

THE TRANSFER DISTANCE FROM ONE ROUND-BOTTOMED FLASK TO ANOTHER, OR

RISK LOSING SOLUTION AS IT SQUIRTS OR DRIPS FROM THE PIPET. Try to avoid getting

solution on the ground glass joint of the flask.

5. Now to transfer the remaining liquid, your objective is to place the tip of the pipet on the inside

bottom of the round-bottomed flask, without getting any of the brown solid into the pipet. This

works best if, as you slowly plunge the tip through the liquid and solid, you slowly depress the

bulb so that bubbles are slowly expelled through the tip to expel any solid that tries to enter.

Once the pipet tip is seated on the flask bottom, gently expel any remaining air from the bulb,

then slowly allow the bulb to inflate. If you do this carefully, the solid particles will be excluded

from the pipet, and the liquid will slowly seep in. Once the latex bulb is fully inflated (i.e., no

longer sucking up liquid), you need to transfer the liquid to the 100 mL flask. Repeat the

transfer steps if necessary until all the solution is transferred. Dispose of the brown insolubles

in the labeled waste container in the hood; shake or scrape out as much as you can. Do not put

water into the disposal flask. Rinse flask with water and rinse down the sink. It will not hurt if

some brown nutmeg leftovers go down the sink. Remember, people eat this stuff (it’s a green

lab, with brown nutmeg!).

Trimyristin Extraction and Saponification Page 2 of 4

Chemistry 214 Clark College

Removal of Pet Ether by Distillation

1. Wipe any residue off of the ground glass joint of the 100 mL distilling flask if necessary, then

add a boiling stone. Distill the solvent using a simple distillation set-up. Collect the distilled

solvent in a 25 mL round-bottomed flask. Petroleum ether has a very low boiling point, so very

little heat is needed. Record boiling point in your lab notebook. You will need to watch carefully

to judge when to stop the distillation. Remember that you started with approximately 25 mL of

petroleum ether. At the end of your distillation, the 25 mL collection flask should be about 3/4

full. As soon as the liquid quits distilling and dripping into the collection flask, the heat should be

turned off and removed. Allow the distillation flask to cool so that it is not warm to the touch.

Dispose of the distilled petroleum ether in the waste container provided in one of the hoods.

Alternately, remove the petroleum ether by rotary evaporation.

2. Use a gentle stream of air to evaporate the last traces of petroleum ether from your solid

residue. Reweigh the flask to determine your crude yield.

Purification by Recrystallization

1. Weigh 1 g of the crude, unpurified trimyristin into a clean, dry, large test tube. Add 4 mL of 95%

ethanol and a boiling stone, and then heat the mixture in a hot water bath. You may hold the

tube with a test tube clamp as it heats in the water. You should stir with a small metal spatula to

mix and to aid in dissolving.

2. Once the solid is completely dissolved, remove the test tube from the hot water, remove the

boiling stone, and clamp the test tube or set it in a small beaker (to avoid tipping over) to allow

the solution to cool to room temperature, or until you see white solid trimyristin begin to

precipitate. Then, cool the test tube in ice to complete the precipitation.

3. Vacuum filter to separate the solid trimyristin.

4. Transfer your white, solid, odorless trimyristin carefully onto a pre-weighed watch glass and

save it in your lab drawer. This product will be used for taking melting point and as the starting

material for our next reaction, saponification (soap making) of the fat. [NOTE: Before taking the

melting point, the recrystallized trimyristin should dry exposed to the air for at least overnight.]

This is likely going to be the stopping point for the first week of lab.

Trimyristin Extraction and Saponification Page 3 of 4

Chemistry 214 Clark College

Saponification (“Soap-making” by Alkaline Hydrolysis of an Ester)

(Be sure to read the section on base-promoted ester hydrolysis in your text.)

O O

O

H3C(H2C) 12 O O (CH2)12CH3 NaOH, ! 3 ONa

O

ethanol sodium myristate

H3C(H2C) 12 O (! = heat)

+ HO OH

trimyristin OH glycerin (glycerol)

(a triglyceride)

(1,2,3-propanetriol)

You will need to save around 25 mg of recrystallized trimyristin for a melting point determination.

[NOTE: Before taking the melting point, the recrystallized trimyristin should dry exposed to the air for at

least overnight, so you will need to wait until the next lab period to obtain the melting point.]

1. Weigh out your remaining recrystallized trimyristin for the saponification and transfer it to a

clean 25 mL round-bottomed flask. You need 1.25 equiv of NaOH for the saponification;

calculate the volume of 0.25 M NaOH needed to equal this after you get a mass of dried,

recrystallized trimyristin. To the round-bottomed flask, add the calculated volume of a 0.25 M

solution of NaOH in 95% ethanol. Add a boiling stone and gently reflux the mixture for 15 min

(i.e., 15 min of actual gentle boiling). During the reflux period, a white solid precipitate should

appear.

2. After cooling to room temperature, use ~5 mL of water to aid in the transfer of the mixture from

the round-bottomed flask to a small clean beaker. Add 5 mL of saturated NaCl solution, mix

well, and then vacuum-filter the solid soap with a Büchner funnel. Rinse the solid on the filter

paper with 4 mL of cold water, then continue to draw air through it for a few minutes to dry the

soap.

3. Determine the mass of your product.

Tests on Sodium Myristate

1. Dissolve ~200 mg of your sodium myristate in 20 mL of water. Transfer 5 mL of the soap

solution to each of 2 small test tubes. To one test tube, add a drop of vegetable oil, cork the

tube, and shake to mix. Record your observations. To the other test tube, add several drops of

a 1% aqueous solution of CaCl2 (“hard water”). Record your observations.

For your report

1. Tabulate your results. Include %fat content from the nutmeg and a percent yield for the

saponification reaction

2. Write out the mechanism for the base-catalyzed saponification of trimyristin. Include all steps to

go completely from trimyristin to 3 equivalents of sodium myristate and glycerin.

3. Write an experimental section for this experiment. Remember – each new compound should

have its own paragraph, but only each new compound!

4. Discuss your observations from the tests on sodium myristate. What did you see? What do you

think occurred in each case? How does the structure of sodium myristate account for this

behavior? (Note – your answer to this question should be a decent paragraph…. A few short

statements are not satisfactory. Structures and diagrams would help!)

Trimyristin Extraction and Saponification Page 4 of 4

Vous aimerez peut-être aussi

- Susan Oyama The Ontogeny of Information Developmental Systems and Evolution Science and Cultural Theory 2000Document297 pagesSusan Oyama The Ontogeny of Information Developmental Systems and Evolution Science and Cultural Theory 2000Marelin Hernández SaPas encore d'évaluation

- Trimyristin From NutmegDocument5 pagesTrimyristin From NutmegArsandi Widitya0% (1)

- Universiti Teknologi MARA Faculty of Applied Science B.SC (Hons) Environmental Technology (AS 229)Document4 pagesUniversiti Teknologi MARA Faculty of Applied Science B.SC (Hons) Environmental Technology (AS 229)TarikTaliHidungPas encore d'évaluation

- Nor Amalia Ismin As2012a Bms533Document4 pagesNor Amalia Ismin As2012a Bms533Amalia IsminPas encore d'évaluation

- Lab Report PDFDocument21 pagesLab Report PDFLutfi Azmi0% (2)

- Second Order KineticsDocument6 pagesSecond Order Kineticseppalapally sharath chandra vardhanPas encore d'évaluation

- Associate Building Construction Engineer: Passbooks Study GuideD'EverandAssociate Building Construction Engineer: Passbooks Study GuidePas encore d'évaluation

- Present Tense Exercises. Polish A1Document6 pagesPresent Tense Exercises. Polish A1Pilar Moreno DíezPas encore d'évaluation

- Bracketing MethodsDocument13 pagesBracketing Methodsasd dsa100% (1)

- Anomeric CarbonDocument6 pagesAnomeric CarbonMuhammad FaiqPas encore d'évaluation

- Isolation of Trimyristin from NutmegDocument7 pagesIsolation of Trimyristin from Nutmegjuana lopesPas encore d'évaluation

- The Mechanism For The Esterification ReactionDocument5 pagesThe Mechanism For The Esterification Reactionuocmogiandi_aPas encore d'évaluation

- Ester LabDocument5 pagesEster LabDea YusufPas encore d'évaluation

- Positive and Normative Statements WorksheetDocument1 pagePositive and Normative Statements Worksheetapi-320972635Pas encore d'évaluation

- Chem 213 FFR 4Document10 pagesChem 213 FFR 4bts176Pas encore d'évaluation

- Binary Eutetic SystemsDocument10 pagesBinary Eutetic SystemsRaja AKPas encore d'évaluation

- Microscopic Analysis of Rock Thin SectionDocument17 pagesMicroscopic Analysis of Rock Thin SectionNurshazwani syuhada bt al- badriPas encore d'évaluation

- Optimize Communications and Relationships with Customers Using CRMDocument9 pagesOptimize Communications and Relationships with Customers Using CRMPritom TariqPas encore d'évaluation

- Esterification of Methyl BenzoateDocument5 pagesEsterification of Methyl BenzoateCyrene MBolaños100% (1)

- Introduction To Microeconomics: ECO162:SABAH - SSDocument65 pagesIntroduction To Microeconomics: ECO162:SABAH - SSPredelly Maxx100% (1)

- Aldol Condensation and Synthesis of DibenzalacetoneDocument8 pagesAldol Condensation and Synthesis of DibenzalacetoneArturo CamañoPas encore d'évaluation

- Density and Specific Gravity LabDocument3 pagesDensity and Specific Gravity Labapi-312004413Pas encore d'évaluation

- Full Math MicrosoftDocument23 pagesFull Math MicrosoftajakprotelaPas encore d'évaluation

- Dilution and Molarity ExperimentsDocument5 pagesDilution and Molarity Experimentsfuyuki miharuPas encore d'évaluation

- Lab Report 3.0Document7 pagesLab Report 3.0Husna Insyirah Bt SamadPas encore d'évaluation

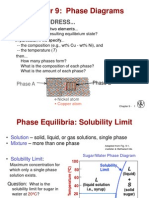

- Chapter 9: Phase Diagrams: Issues To Address..Document38 pagesChapter 9: Phase Diagrams: Issues To Address..yunlu0705Pas encore d'évaluation

- LabReport CpDistributionOfAerofoil PDFDocument12 pagesLabReport CpDistributionOfAerofoil PDFmatthias.s.sommer3656Pas encore d'évaluation

- Integrated Solid Waste Management HierarchyDocument7 pagesIntegrated Solid Waste Management HierarchyFadzrilPas encore d'évaluation

- How car exhaust fumes cause suffocation by binding to haemoglobinDocument3 pagesHow car exhaust fumes cause suffocation by binding to haemoglobinSkefadiutoPas encore d'évaluation

- Lab 1 Fst606Document12 pagesLab 1 Fst606fatiniPas encore d'évaluation

- CALORIMETRY HESS’S LAW EXPERIMENTDocument7 pagesCALORIMETRY HESS’S LAW EXPERIMENTaqielah shaifulPas encore d'évaluation

- CHM 256 - Lab ReportDocument6 pagesCHM 256 - Lab ReportLia ZafPas encore d'évaluation

- Lab Report Chm256 Exp 4Document6 pagesLab Report Chm256 Exp 4Miss KillerPas encore d'évaluation

- CHM 421 Analytical Chemistry Experiment 2: Analysis of An Unknown Vinegar SampleDocument14 pagesCHM 421 Analytical Chemistry Experiment 2: Analysis of An Unknown Vinegar SampleIntan SapuraPas encore d'évaluation

- Uka MExer03Document14 pagesUka MExer03johannie ukaPas encore d'évaluation

- AS/CHM420 Equilibrium Constants and Reaction EffectsDocument2 pagesAS/CHM420 Equilibrium Constants and Reaction EffectssyazaPas encore d'évaluation

- REACTIONS OF AMINESDocument8 pagesREACTIONS OF AMINESYulPas encore d'évaluation

- Determination of Lead in Anchovies by Cold Vapour Generation Atomic Absorption SpectrometryDocument30 pagesDetermination of Lead in Anchovies by Cold Vapour Generation Atomic Absorption SpectrometryIbrahim Muhamad100% (2)

- Amino AcidsDocument52 pagesAmino AcidsDrbee10Pas encore d'évaluation

- Basic Instrumental Analysis Experiment 2: Uv-Visible Determination of An Unknown Concentration of Kmno4 SolutionDocument7 pagesBasic Instrumental Analysis Experiment 2: Uv-Visible Determination of An Unknown Concentration of Kmno4 SolutionSiti Maizatul AkmaPas encore d'évaluation

- Experiment 16Document5 pagesExperiment 16Alex NgPas encore d'évaluation

- Experiment 1Document16 pagesExperiment 1Izhharuddin100% (2)

- Tutorial Chapter 2 (CHM421)Document4 pagesTutorial Chapter 2 (CHM421)Shahirah AmiraPas encore d'évaluation

- Exercise Chapter 1Document2 pagesExercise Chapter 1ellina safianPas encore d'évaluation

- CHM 260 UV-Vis Determination of KMnO4 ConcentrationDocument11 pagesCHM 260 UV-Vis Determination of KMnO4 ConcentrationAwathif Wawa100% (1)

- Determination of The Percentage of Ligands in Coordination CompoundDocument5 pagesDetermination of The Percentage of Ligands in Coordination CompoundafifiPas encore d'évaluation

- Nur Sarah Hannis - Exp3Document1 pageNur Sarah Hannis - Exp3Sarah HannisPas encore d'évaluation

- Ninhydrin TestDocument10 pagesNinhydrin TestLui Yalong Jr.Pas encore d'évaluation

- Data Sheet Experiment 3 Synthesis of Potassium Tris (Oxalato) Ferrate (III) TrihydrateDocument1 pageData Sheet Experiment 3 Synthesis of Potassium Tris (Oxalato) Ferrate (III) TrihydrateELF SJPas encore d'évaluation

- Exp 4 FlowabilityDocument4 pagesExp 4 FlowabilityNur SyahirahPas encore d'évaluation

- (Review) Promises and Challenges of Perovskite Solar CellsDocument7 pages(Review) Promises and Challenges of Perovskite Solar CellsTeddyFengPas encore d'évaluation

- Experiment4 CHM 420Document4 pagesExperiment4 CHM 420bellaamin75% (4)

- Lab CHM 420 Exp 2Document4 pagesLab CHM 420 Exp 2nana izzPas encore d'évaluation

- ObjectiveDocument8 pagesObjectivenaim rashidPas encore d'évaluation

- Lab Report CHM420Document10 pagesLab Report CHM420Hani Nadh100% (1)

- Characterization of E. coli and environmental bacteria through growth studiesDocument12 pagesCharacterization of E. coli and environmental bacteria through growth studiesCeruleanBeingPas encore d'évaluation

- Exp TS, Tss and VssDocument7 pagesExp TS, Tss and VssNurulHaidahPas encore d'évaluation

- Neutralization Capacity of Antacid TabletDocument3 pagesNeutralization Capacity of Antacid TabletMsShu9367% (3)

- Spectrophotometric Analysis of Transition Metal CationsDocument5 pagesSpectrophotometric Analysis of Transition Metal CationsFAtma HAnysPas encore d'évaluation

- BOD Lab Report (Full)Document15 pagesBOD Lab Report (Full)Syamimi Fsa100% (1)

- Introductory Titrimetric and Gravimetric Analysis: The Commonwealth and International Library: Chemistry DivisionD'EverandIntroductory Titrimetric and Gravimetric Analysis: The Commonwealth and International Library: Chemistry DivisionPas encore d'évaluation

- TrimyristinDocument3 pagesTrimyristindinna_dinunPas encore d'évaluation

- SteamDistDocument4 pagesSteamDistgnaequiPas encore d'évaluation

- Drugs NamesDocument15 pagesDrugs Namesmnariaz_11Pas encore d'évaluation

- Material Handling and Storage: Occupational Health and Safety November 7, 2005Document31 pagesMaterial Handling and Storage: Occupational Health and Safety November 7, 2005Essej ZneasPas encore d'évaluation

- Lec82 PDFDocument6 pagesLec82 PDFmnariaz_11Pas encore d'évaluation

- TracertechniqueDocument14 pagesTracertechniquemnariaz_11Pas encore d'évaluation

- 9.1 FenicalDocument5 pages9.1 Fenicalmnariaz_11Pas encore d'évaluation

- Adverse Events ReportingDocument21 pagesAdverse Events Reportingmnariaz_11Pas encore d'évaluation

- List of Medicinal PlantsDocument126 pagesList of Medicinal Plantsmnariaz_11Pas encore d'évaluation

- TracertechniqueDocument14 pagesTracertechniquemnariaz_11Pas encore d'évaluation

- 09 Test PharmacognosyDocument49 pages09 Test PharmacognosyChristiane Jordão100% (3)

- Presentation GlycoidesDocument12 pagesPresentation Glycoidesmnariaz_11Pas encore d'évaluation

- PotentiometryDocument37 pagesPotentiometrymnariaz_11Pas encore d'évaluation

- Pilot Plant Desigfor Tabletsand CapsulesDocument61 pagesPilot Plant Desigfor Tabletsand Capsulesmnariaz_11Pas encore d'évaluation

- WHO Monographs On Selected Medicinal PlantsDocument295 pagesWHO Monographs On Selected Medicinal PlantsHrvoje Horvat BillyPas encore d'évaluation

- Introduction To Biopharmaceutics and Its Role in Drug DevelopmentDocument25 pagesIntroduction To Biopharmaceutics and Its Role in Drug Developmentmnariaz_11Pas encore d'évaluation

- RITL 2007 (Full Text)Document366 pagesRITL 2007 (Full Text)Institutul de Istorie și Teorie LiterarăPas encore d'évaluation

- January 2008 Ecobon Newsletter Hilton Head Island Audubon SocietyDocument6 pagesJanuary 2008 Ecobon Newsletter Hilton Head Island Audubon SocietyHilton Head Island Audubon SocietyPas encore d'évaluation

- Uk GeographyDocument9 pagesUk GeographyStainbok MihaiPas encore d'évaluation

- Polystylism in The Context of Postmodern Music. Alfred Schnittke's Concerti GrossiDocument17 pagesPolystylism in The Context of Postmodern Music. Alfred Schnittke's Concerti Grossiwei wuPas encore d'évaluation

- Extra Grammar Exercises (Unit 6, Page 64) : Top Notch 3, Third EditionDocument4 pagesExtra Grammar Exercises (Unit 6, Page 64) : Top Notch 3, Third EditionA2020Pas encore d'évaluation

- Hays Grading System: Group Activity 3 Groups KH PS Acct TS JG PGDocument1 pageHays Grading System: Group Activity 3 Groups KH PS Acct TS JG PGkuku129Pas encore d'évaluation

- AdmitCard 1688037Document1 pageAdmitCard 1688037P.Supreeth ReddyPas encore d'évaluation

- Glowing Stones in Ancient LoreDocument16 pagesGlowing Stones in Ancient LorerippvannPas encore d'évaluation

- Group Handling - Pre Registration Activity: Submited To-Submitted byDocument12 pagesGroup Handling - Pre Registration Activity: Submited To-Submitted byharshal kushwahPas encore d'évaluation

- PCC ConfigDocument345 pagesPCC ConfigVamsi SuriPas encore d'évaluation

- Design and Construction of Food PremisesDocument62 pagesDesign and Construction of Food PremisesAkhila MpPas encore d'évaluation

- Bach Invention No9 in F Minor - pdf845725625Document2 pagesBach Invention No9 in F Minor - pdf845725625ArocatrumpetPas encore d'évaluation

- The Basic Philosophical and Theological Notions of Saint Augustine - John C. Cooper PDFDocument21 pagesThe Basic Philosophical and Theological Notions of Saint Augustine - John C. Cooper PDFjusrmyrPas encore d'évaluation

- 01 ElectricalDocument15 pages01 ElectricalKrishna KrishPas encore d'évaluation

- Causes of WWI: Alliances, Militarism & AssassinationDocument4 pagesCauses of WWI: Alliances, Militarism & AssassinationJoshua De Leon TuasonPas encore d'évaluation

- JSP - How To Edit Table of Data Displayed Using JSP When Clicked On Edit ButtonDocument8 pagesJSP - How To Edit Table of Data Displayed Using JSP When Clicked On Edit Buttonrithuik1598Pas encore d'évaluation

- Magnetic Suspension System With Electricity Generation Ijariie5381Document11 pagesMagnetic Suspension System With Electricity Generation Ijariie5381Jahnavi ChinnuPas encore d'évaluation

- Managing Remuneration MCQDocument5 pagesManaging Remuneration MCQlol100% (1)

- Electrical Power System Protection BookDocument2 pagesElectrical Power System Protection BookHimanshu Kumar SagarPas encore d'évaluation

- SEED TREATMENT WITH BOTANICAL EXTRACTSDocument18 pagesSEED TREATMENT WITH BOTANICAL EXTRACTSRohitPas encore d'évaluation

- APFC Accountancy Basic Study Material For APFCEPFO ExamDocument3 pagesAPFC Accountancy Basic Study Material For APFCEPFO ExamIliasPas encore d'évaluation

- Life of a VoyageurDocument8 pagesLife of a VoyageurBruce GuthriePas encore d'évaluation

- Chapter 6 Sequence PakistanDocument16 pagesChapter 6 Sequence PakistanAsif Ullah0% (1)

- Natural Science subject curriculumDocument15 pagesNatural Science subject curriculum4porte3Pas encore d'évaluation

- Connotative Vs Denotative Lesson Plan PDFDocument5 pagesConnotative Vs Denotative Lesson Plan PDFangiela goc-ongPas encore d'évaluation

- HOTC 1 TheFoundingoftheChurchandtheEarlyChristians PPPDocument42 pagesHOTC 1 TheFoundingoftheChurchandtheEarlyChristians PPPSuma HashmiPas encore d'évaluation

- 1995 - Legacy SystemsDocument5 pages1995 - Legacy SystemsJosé MªPas encore d'évaluation