Académique Documents

Professionnel Documents

Culture Documents

Remus Ion Poster - 2nd International Slag Ion Symposium - Belgia, Leuven 18-20.04

Transféré par

George N. AngelopoulosDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Remus Ion Poster - 2nd International Slag Ion Symposium - Belgia, Leuven 18-20.04

Transféré par

George N. AngelopoulosDroits d'auteur :

Formats disponibles

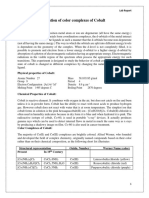

Electric arc furnace steel slag as a raw material towards

the production of “green” cements

R. I. Iacobescu1, D. Koumpouri2, R. Saban1, Y. Pontikes3, G. N. Angelopoulos2*

1Department of Materials Science and Engineering, Politehnica University of Bucharest, 060032 Bucharest, Romania

2Laboratory of Materials and Metallurgy, Department of Chemical Engineering, University of Patras, 26500 Rio,Greece

3Department of Metallurgy and Materials Engineering, KULeuven, 3001 Heverlee, Belgium

Abstract

Two types of “green” cements, a belite (BC) and a ferroalumino-belite (FABC) one were produced, using 10wt.% electric arc furnace steel slag (EAFS)

as a raw material. Raw materials, produced clinkers and hydrated products of the cement pastes were characterized by XRF, XRD, TG, SEM-EDS

techniques and the physical and mechanical properties of the produced cements were measured.

Introduction

Nowadays, more than 40% of the global steel production takes place in EAF. It is associated with the generation of 20 million tones EAFS. In Europe

only 16.7% is used for cement production. Belite and FAB cements can be characterized as “green” ones as they require lower firing temperatures

and the CO2 emission is reduced. Utilization of EAFS in belite cements will reduce their environmental impact.

Raw materials analysis Hydration studies

1

3 1

2 1day 3days

1 1d 3d 7d 28d

1 1

1 1

1,3 100

2 1

2 11

4

3 7 1

1 1 3 1

3 1,3 3

2

1 2

1 1 2

1,3 1 3 1

2 1

1 1 11

4

77

5 55 1 1 11 1 1 1 3

1

1 1 6

63

6 5 4 3

22 2

1

2 2 95

21 2

1 1 1 2 3

10 20 30 40 50 60 70

10 20 30 40 50 60 70 10 20 30 40 50 60 70 10 20 30 40 50 60 70 10 20 30 40 50 60 70

o o

2, ( ) o 2 )

2, ( ) o

2, ( ) 2, ( )

o

XRD pattern of flysch:

Mass loss, %

XRD pattern of XRD pattern of EAFS: 1 – XRD pattern of gypsum: XRD pattern of bauxite: 90

limestone: 1-calcite, larnite, 2 – gehlenite, 3 – 1 –gypsum, 2 – quartz, 3 1 – diaspore, 2 – 1 – calcite, 2 – quartz, 7µm 10µm

2 – quartz wüstite, 4 – magnetite, 5 – – dolomite boehmite, 3 – hematite 3 – illite, 4 – dolomite ,

85

brownmillerite 5 – albite, 6 – clinochlore

7days 28days

80

Chemical composition of the raw materials, XRF analysis (wt.%)

0 200 400 600 800 1000

o

Temperature, C

Raw

CaO Fe2O3 SiO2 Al2O3 MnO MgO Cr2O3 P2O5 TiO2 SO3 Cl BaO Na2O K2O V2O5 LOI Total TG results of FABC after 1, 3, 7 and 28

materials

days of hydration

EAFS 32.5 26.3* 18.1 13.3 3.94 2.53 1.38 0.48 0.47 0.44 0.14 0.14 0.13 n.d. 0.06 0.00 99.91

10µm 10µm

Limestone 48.9 1.00 9.00 1.36 n.d. 0.65 n.d. n.d. n.d. n.d. n.d. n.d. 0.10 0.15 n.d. 38.00 97.16 1d 7d 28d

100

Flysch 5.55 5.90 58.25 13.75 n.d. 2.86 n.d. n.d. n.d. 0.05 n.d. n.d. 1.10 2.50 n.d. 9.80 99.76

Bauxite 3.62 23.00 14.30 49.20 n.d. n.d. n.d. n.d. n.d. 0.23 n.d. n.d. n.d. n.d. n.d. 13.89 104.24 99 SEM, secondary micrographs of FABC after 1 day, 3 days , 7

Gypsum 24.73 0.04 12.76 0.18 n.d. n.d. n.d. n.d. n.d. 39.30 n.d. n.d. n.d. n.d. n.d. 23.14 102.00 98 days and 28 days of hydration

Mass loss, %

LOI: loss on ignitions, n.d.: not determined, * - FeO, Fe2O3 97 7days

2days 28days

96

95

Clinker production 94

93 30µm 7µm 30µm

200 400 600 800 1000

Raw materials content in the raw meal, quality indexes and estimated mineralogical phases o

Temperature, ( C)

TG results of BC after 2, 7 and 28 days of SEM, secondary micrographs of BC after 2 days, 7 days and 28 days of

Clinker

Raw material proportions Quality indexes Mineralogical phases hydration hydration

types

EAFS Limestone Flysch Bauxite Gypsum LSF AM SM C3S C3A C2S C4AF C4A3Ŝ CŜ C

BC 10 77.00 13.0 - - 78.10 1.00 1.96 17.59 6.01 57.32 19.13 - - 0

FABC 10 64.50 - 18.70 6.8 70.45 1.51 0.59 - - 45.70 32.88 18.65 2.6 0.21

Laboratory scale clinker production procedure

Physical and mechanical properties

water addition Milling time for 50g of clinker vs. particle size a) BC, b) FABC 50

Milling of the hand made 45 BC

mixed in resulted pellets’ Firing temperature: BC 1380⁰C FABC

compressive strength (MPa)

raw materials pellets with a) BC b) FABC 40

amounts from dehydration at FABC 1320⁰C

at particles size diameter milling time particle size milling time particle size 35

Bogue estimation 110°C/24 hours soaking time 40min

< 90µm 15mm-20mm (sec) (mm) (sec) (mm) 30

Fast cooling : hammer crushing 97 1.25 71 1.25 25

103 1.25 - 1.8 73 1.25 - 1.8 20

air blowing 15

Physical properties of the cements and cements pastes, EN 196-3

10

and EN 196-6

5

Cement Specific surface Initial setting Water demand Soundness

Clinker characterisation

0

types (cm2/g) time (min.) (wt.%) (mm) 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32

BC 4057 20 27.6 1 curing time (days)

Compressive strength results of the cement

FABC 4100 7 45 0.9

2 paste after different curing time

SEM backscattered

1 2 image with EDS

1

spectra of BC clinker in

3

keV

3

polished section, nital

1% etched: 1-C2S, 2-C3S

Conclusions

• A BC and a FABC cement were produced with 10% EAFS addition.

keV

and 3-C4AF

60µm

keV

• At 7 days, higher early strength was developed for the FABC

1 3

(13,9MPa) than the BC (5MPa), due to the ettringite formation.

SEM backscattered 3 • At 28 days, BC (42,8MPa) develops higher compressive strength

image with EDS

spectrua of than FABC (18,3MPa) due to the late belite hydration.

keV keV

1

FABC clinker, polished

2 4

section: 1,4-C2S, 2- 2 4

C4AF, 3-C4A3Ŝ

keV

40µm

keV

Acknowledgements

2 XRD pattern of BC: Sectoral Operational Programme Human Resources Development

2,3

1 - alite (C3S), 2-belite (C2S),

3 - calcium aluminate (C3A) 2007-2013 of the Romanian Ministry of Labour, Family and Social

4,1

4 4- brownmillerite (C4AF) 1,3

2

Protection through the Financial Agreement POSDRU/6/1.5/S/16.

4

1

2 1,2

3,2,1 2

4

2

3,4

1,2 2

1 11 XRD pattern of FABC:

3

2 1

1 University of Patras through “Karatheodoris” 2011 research

24 2 1 1 1 1

10 20 30

1

40 50 60

1 - brownmillerite (C4AF),

2 - larnite (C2S),

1 22 2 21 program.

Y.P. is thankful to the Research Foundation - Flanders for the post-

o

2, ( ) 3 - yeelimite (C4A3Ŝ) 10 20 30 40 50 60

o

2, ( )

doctoral fellowship.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Solutions: Long Answer Questions - 5MDocument13 pagesSolutions: Long Answer Questions - 5MSaksham RohillaPas encore d'évaluation

- Formation of Color Complexes of CobaltDocument4 pagesFormation of Color Complexes of Cobaltsidra tariqPas encore d'évaluation

- Yeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Document8 pagesYeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Mohammed AsherPas encore d'évaluation

- Precautions in Handling, Acceptance and Fixation of SpecimenDocument5 pagesPrecautions in Handling, Acceptance and Fixation of SpecimenMary ChristellePas encore d'évaluation

- KProselect Lubricants B GBDocument4 pagesKProselect Lubricants B GByovannyPas encore d'évaluation

- Water Analysis ReportDocument4 pagesWater Analysis ReportAamirMalikPas encore d'évaluation

- Ranjeet ShahiDocument11 pagesRanjeet Shahisabhari_ram100% (1)

- JBL Brochure Biotope Aquarium Water en PDFDocument21 pagesJBL Brochure Biotope Aquarium Water en PDFGeorge PotoleaPas encore d'évaluation

- Stoichiometry WorksheetexcessDocument1 pageStoichiometry WorksheetexcessKamariah IsmailPas encore d'évaluation

- 620oswaal CBSE Class-10, Term-1 Science - Revision NotesDocument22 pages620oswaal CBSE Class-10, Term-1 Science - Revision NotesDivyam RohillaPas encore d'évaluation

- Stress Cracking Corrosion of Duplex Stainless SteelDocument288 pagesStress Cracking Corrosion of Duplex Stainless Steelboypai100% (1)

- 00 B 7 D 518 B 57865 e 961000000Document20 pages00 B 7 D 518 B 57865 e 961000000aminPas encore d'évaluation

- Acids and Bases: Section 4 NeutralizationDocument4 pagesAcids and Bases: Section 4 NeutralizationDevine RawlsPas encore d'évaluation

- Lab ReportDocument8 pagesLab ReportNurin BatrisyiaPas encore d'évaluation

- Astm D4809Document9 pagesAstm D4809Kamruzaman MiahPas encore d'évaluation

- Boiler Chemicals Untuk Pabrik CPO PDFDocument7 pagesBoiler Chemicals Untuk Pabrik CPO PDFMuhammad Abdurrokhim APas encore d'évaluation

- Microsorb Tech RF Absorbers-Jyoti ElectronicsDocument3 pagesMicrosorb Tech RF Absorbers-Jyoti ElectronicsRajendra AgarwalPas encore d'évaluation

- Gpa 2261Document19 pagesGpa 2261Ceciliagorra100% (1)

- CHM 302 UneditedDocument89 pagesCHM 302 Uneditedibrahim muhammad saniPas encore d'évaluation

- PDB VIASOL EP-T703engDocument3 pagesPDB VIASOL EP-T703engZeljkoPas encore d'évaluation

- Experiment 1 - Kinetics Study of The Hydrolysis of Methyl Acetate by Acid-Base Titration.Document11 pagesExperiment 1 - Kinetics Study of The Hydrolysis of Methyl Acetate by Acid-Base Titration.KhAi En75% (16)

- Veolia Pure Water Guide LR 2021 v08-USDocument36 pagesVeolia Pure Water Guide LR 2021 v08-USBulent Inan100% (1)

- OREAS 603 CertificateDocument16 pagesOREAS 603 CertificateDenis Alvarez RiveraPas encore d'évaluation

- Mechanical Seals Mechanical Seals For Pumps Pusher Seals M3NDocument4 pagesMechanical Seals Mechanical Seals For Pumps Pusher Seals M3NVolodymyrPas encore d'évaluation

- Tech Data: Ralube 40 Cfs Locomotive Engine OilDocument2 pagesTech Data: Ralube 40 Cfs Locomotive Engine OilJeremias UtreraPas encore d'évaluation

- BioplasticDocument14 pagesBioplasticRachna Sinha100% (1)

- Tonicity Determination: Hypertonicity, Hypotonicity and IsotonicityDocument4 pagesTonicity Determination: Hypertonicity, Hypotonicity and IsotonicityAbegailPas encore d'évaluation

- Ui CuroxDocument5 pagesUi CuroxHuber AlvaradoPas encore d'évaluation

- Chapter 3 Synthetic Fibres and Plastics: Samved SchoolDocument5 pagesChapter 3 Synthetic Fibres and Plastics: Samved SchoolAgent NorsePas encore d'évaluation

- SIC1011 OrganicDocument6 pagesSIC1011 OrganicNor AtiyahPas encore d'évaluation