Académique Documents

Professionnel Documents

Culture Documents

Underground Fire Guidelines

Transféré par

dokundotDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Underground Fire Guidelines

Transféré par

dokundotDroits d'auteur :

Formats disponibles

RESOURCE MANAGEMENT AGENCY

DEPARTMENT OF FIRE PREVENTION FOR DEVELOPMENT

2037 W. Cleveland Avenue Madera, CA 93637-8720 (559) 661-5190 FAX (559) 675-7639 TDD (559) 675-8970 Rodger.Maggio@madera-county.com

Rodger Maggio, Fire Marshal

Underground Piping for Private Hydrants & Sprinkler Supply Line

Approved and Authorized by Rodger Maggio Fire Marshal : October 25, 2006

Underground Piping for Private Hydrants & Sprinkler Supply Line

PURPOSE

The purpose of this guideline is to provide the basic information necessary to meet minimum requirements for the design and installation of private hydrant and/or sprinkler supply underground piping in accordance with the provisions of 2001 California Fire Code (CFC), 2001 California Building Code (CBC), 1995 NFPA 24, 1999 NFPA 13, 1999 NFPA 13R, and locally adopted amendments to these codes.

SCOPE

This guideline is applicable to all private underground piping for hydrants and/or sprinkler supply lines within the jurisdiction of Madera County Fire Marshal(MCFM). This guideline is not applicable to underground piping serving fire sprinkler systems designed in accordance with 1999 NFPA 13D and some systems designed in accordance with 1999 NFPA 13R.

SUBMITTAL REQUIREMENTS

1. General A. Plans for all private underground piping for private hydrants and/or sprinkler supply line(s) shall be submitted to the County Resource Management Agency for review and approval prior to installation. B. Provide a minimum of three copies of the plans. C. Plans shall be legible, scaled to nationally recognized standards, and printed as a blue- or blackline drawing. The RMA does not accept either pen and ink plans or pen & ink changes to blueline plans. 2. Information to be provided on the title page A. Applicable codes and standards used for the system design (e.g., 2001 CFC, 2001 CBC, 1995 NFPA 24, AWWA, etc.). B. Project location, including the full legal address of the facility, and building number(s) if applicable; tract or parcel number.

C. The contractors name, telephone number, address, and California State contractors license number and classification. Contractors must possess an, C16, C34, or C36 license or be a registered professional engineer (RPE). Note: If the piping plan is designed by an RPE, the plan shall contain the name, license number, and classification of the installing contractor, along with the RPE wet stamp. If this information is not available at the time the plans are submitted, proof of compliance with this requirement must be provided to the Fire Marshal at the time of inspection. D. Fire Marshal underground notes, verbatim. See pages 4 - 6 of this guideline. 3. Additional Required Information A. Location of public mains. B. Location of all public hydrants within 300 feet of the project site. C. Location of all valves. Specify the type for each (e.g., post indicator valve (PIV), key gate valve, system control valve, double detector check (DDC), outside stem and yoke (OS&Y), etc.). D. PIVs or other approved indicating valves, shall be located a minimum of 40 feet from the building served. Where it is impractical to locate control valve(s) 40 feet from the building served, they may be permitted to be located closer utilizing one of the following methods: 1) Approved wall mount indicating valves, provided they are located on blank walls (i.e., no openings within 15 feet on either side of the valve and no openings above, clear to the sky). 2) Approved indicating valves may be placed in valve rooms accessible only from the exterior. An approved sign shall be provided for the door. 3) Approved indicating valves may be placed on exterior risers provided they are located on blank walls (i.e., no openings within 15 feet on either side of the valve and no openings above, clear to the roof). E. Pipe size, class, and type; specify lined or unlined, if applicable. F. Thrust block locations, or specify the means of restraint as approved by 1995 NFPA 24. G. Location of the fire department connection (FDC). FDCs shall be on the address side of building and located immediately adjacent to the approved fire department access road in a position allowing hose lines to be readily and conveniently attached. The fire department connection shall contain a minimum of two 2 inlets. When the sprinkler density design is 500 gpm or greater (including the interior hose stream demand) or a standpipe system is included, four 2 inlets shall be provided. H. FDCs shall be no more than 50 feet from a public hydrant. The FDC may be located within 50 feet of a private hydrant, if the FDC is connected to the fire sprinkler system by a dedicated pipe that connects on the system side (i.e., downstream) of the sprinkler system check valve. The size of piping and the number of inlets shall be approved by the chief as provided for by 1999 NFPA 13, Section 3-9.3, 1999 NFPA 2-4.2, and 1995 NFPA 24, Section 2-6.6. Fire department inlet connections shall be painted OSHA safety red. All FDCs shall have a durable sign clearly indicating the address of the facility they are attached to. I. Large private service mains shall have post indicating type sectional control valves at appropriate points in order to permit isolation of the system in the event of a break or

during repair or extension. Note: A large system is one with over five connections, including hydrants, to the main. J. Only ductile iron pipe shall be used under buildings. Pipe under buildings shall terminate a maximum of 18 inches from the exterior wall and six inches above finished floor. A minimum of 2 inches clearance (interstitial space) shall be provided where the pipe passes through the floor or wall. K. The attached NOTES FOR UNDERGROUND PIPING FOR PRIVATE HYDRANTS AND SPRINKLERS shall be placed, verbatim, on all underground plans. The attached NOTES FOR THRUST BLOCK RESTRAINTS shall be placed, verbatim, on all underground plans that use thrust blocks as the restraining method. 4. Underground Service for NFPA 13R Systems A. Underground system/s serving more than one R-1 building shall comply with NFPA 13 and NFPA 24 (see 1 through 3 above). B. A single underground service not tied into the domestic water with the FDC installed upstream of the building sprinkler riser check valve shall comply with NFPA 13 and NFPA 24 (see 1 through 3 above). C. A single underground service not tied into the domestic water with the FDC downstream of sprinkler system riser check valve shall comply with NFPA 13R and the California Plumbing Code (CPC). D. A single underground service that is supplied with the domestic water feed shall comply with NFPA 13R and the CPC. The FDC shall be located downstream of the sprinkler system riser check valve.

MADERA COUNTY FIRE MARSHAL

NOTES FOR UNDERGROUND PIPING FOR PRIVATE HYDRANTS & SPRINKLERS

All of the notes listed below shall be placed, verbatim, on the plan under the heading FIRE AUTHORITY NOTES. INSPECTION REQUIREMENTS 1. A minimum of two inspections are required for underground piping serving sprinkler systems and/or private hydrants: 1) Hydro inspection; 2) Flush inspection. Please schedule all inspections at least 48 hours in advance. Inspections canceled after 1 p.m. on the day before the scheduled date will be subject to a re-inspection fee. Call MCFM Inspection Scheduling at (559) 661-5191. 2. Hydro inspection: All pipe shall be in place and exposed for visual inspection. Pipe shall be laid on a minimum twelve-inch bed of clean sand. Trench shall be of a sufficient depth to allow required cover above pipe. Ferrous pipe and fittings shall be encased in polyethylene tubing (not wrapped) and tightly taped to inhibit water infiltration. Bolts and ferrous joints shall be coated with asphaltic sealant or other corrosion retarding material. See items 12 17 and 22 below for detailed requirements. Thrust blocks shall be in place. Pipe shall be center-loaded with clean sand to prevent uplift, but all joints shall remain exposed. The system shall be hydrostatically tested at 200 psi (or 50 psi over maximum static pressure, whichever is greater) for at least two hours prior to arrival of the MCFM inspector. See items 12, 13, and 17 for detailed requirements. 3. Flush inspection: All portions of the underground system shall be flushed to remove debris prior to connection to overhead piping. Flow shall be through a minimum of a four-inch hose or pipe, unless otherwise approved by the MCFM inspector prior to scheduling the flush. Hose or pipe shall be restrained to prevent injury and damage. Discharged water shall be collected or diverted in accordance with applicable SWPPP/NPDES provisions. The local public works department, water district, and/or other applicable agency shall be notified of the scheduled flush by the contractor. The MCFM flush and hydro inspections may be scheduled concurrently. See items 12, 13, and 18 21 below for detailed requirements. 4. Upon flush inspection or prior to final sprinkler or site inspection, all detector check assemblies, control valves, and fire department connections (FDC) shall be clearly labeled with the address(es) served by the device. Address signs shall be securely attached to the device and be of a durable, fade resistant material and visible and legible from the fire lane. FDC and four-inch hydrant outlets shall be unobstructed and oriented toward the fire lane. Valves shall be locked in the open position with breakaway locks. All valves and private hydrants shall be painted safety red. Hydrant and FDC caps shall be in place. See items 6 9 and 18 23 for detailed requirements. GENERAL REQUIREMENTS 6. Installation, inspection, and testing shall conform to 1999 NFPA 13 and 1995 NFPA 24. Fire Department jurisdiction begins at the downstream side of the last valve on the detector check assembly. Verify design and installation requirements for the portion of the system preceding this point with the local water district. 7. Vegetation shall be selected and maintained in such a manner as to allow immediate location of and unobstructed access to all hydrants, control valves, fire department connections, and other devices or areas used for firefighting purposes. 8. A minimum three-foot clearance shall be provided around all hydrants and post indicating valves. A minimum three-foot clearance shall be provided on at least one side of a detector check assembly to allow proper operation of the device. No obstructions shall be located between the front of FDCs and the adjacent fire access roadway. 9. Valves serving 100 or more sprinklers shall be monitored. Monitoring plans shall be submitted under a separate Service Request.

10. Any future modification to the approved private underground piping system shall require review, inspection, and approval by the Madera County Fire Marshals Office. 11. Approval of this plan shall not be construed as approval of any information or project conditions other than those items and requirements identified in this Guideline, and applicable sections of NFPA 13 and NFPA 24. This project may be subject to additional requirements not stated herein upon examination of actual site and project conditions or disclosure of additional information. PIPE AND TRENCH REQUIREMENTS 12. A twelve-inch bed of clean fill sand shall be provided both below and above the pipe (total of 24 inches plus outer diameter of the pipe). 13. A minimum of 30 inches of cover, from finish grade to the top of the pipe, shall be provided. When surface loads are expected, a minimum of 36 inches of cover shall be provided. 14. All pipe shall be approved for use in fire service systems. Class 150 will be used at a minimum, and class 200 pipe shall be used where the pressure may exceed 150 psi. Galvanized pipe shall not be used for portions of the system that are buried. 15. All ferrous pipe and fittings shall be protected with a loose 8-mil polyethylene tube. Wrapping the pipe in polyethylene sheeting is not acceptable. The ends of the tube and any splices made for tees or other piping components shall be tightly sealed with two-inch tape, approved for underground use. 16. All bolts used for underground connections, including T bolts, shall be stainless steel. All bolts and ferrous fittings shall be cleaned and thoroughly coated with asphalt or other corrosion retarding material after assembly and prior to polytube installation. 17. Thrust blocks, or another approved method of thrust restraint, shall be provided wherever pipe changes direction. 18. Minimum two-inch clearance shall be provided where the pipe passes through slabs or walls. Underground system shall terminate at the riser flange, which shall be located a maximum of 18 inches from an exterior wall and 6 inches above the slab. 19. The FDC shall contain a minimum of two two-and-one-half-inch inlets. When the system design demand is 500 gpm, including the interior hose stream demand, or greater, or a standpipe system is included, four two-and-one-half-inch inlets shall be provided. FDCs shall be painted OSHA safety red. HYDRANT REQUIREMENTS 20. Private fire hydrants shall be an approved dry barrel style with a minimum of one two-and-one-halfinch and one four and one-half-inch outlet. The 4 outlet shall face the fire department access road. All outlets shall be provided with National Standard Threads (NST). 21. Fire hydrant supply piping shall be a minimum of six inches in diameter. The lowest valve operating nut shall be a minimum of eighteen inches above grade and the hydrant flange shall be a minimum of two inches above grade. 22. A keyed gate valve shall be provided for each hydrant in an accessible location. Keyed gate valves shall be located within ten feet of the hydrant in an area that is unobstructed and clearly visible. Valves shall not be located in parking stalls. 23. All fire hydrants shall have a Blue Reflective Pavement Marker indicating their location. Private hydrants and markers are to be maintained in good condition by the property owner. Private hydrants shall be painted OSHA safety red.

NOTES FOR THRUST BLOCK RESTRAINTS PLACE THE FOLLOWING NOTES, VERBATIM, ON THE PLAN: NOTES

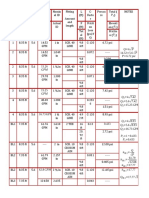

1. Thrust block areas based on 225 PSI and 2, 000 PSF soil pressure with 2 feet of cover minimum. 2. Thrust block bearing faces shall be placed against undisturbed soil, approved compacted backfill, or Class 100-E-100 slurry. 3. Thrust blocks shall be Class 560-C-3250 concrete, unless specified otherwise. 4. To facilitate future removal of thrust blocks and line extension use cardboard separators between blocks, if needed.

Vous aimerez peut-être aussi

- NFPA 1521 Skill TestDocument31 pagesNFPA 1521 Skill TestPaoloFregonaraPas encore d'évaluation

- Foods To Fight Cancer - What To Eat PDFDocument242 pagesFoods To Fight Cancer - What To Eat PDFdokundot83% (6)

- Swimming Pool DesignDocument111 pagesSwimming Pool Designdokundot75% (4)

- Electrical Thumb Rules (Part 4)Document4 pagesElectrical Thumb Rules (Part 4)Manish TiwariPas encore d'évaluation

- Fire Protection Engineering Summer 2001Document33 pagesFire Protection Engineering Summer 2001Hany RifaatPas encore d'évaluation

- Di and SiadhDocument15 pagesDi and SiadhSandra Martini SimmonsPas encore d'évaluation

- Service Manual For High Efficiency Amazon 20161108 PDFDocument355 pagesService Manual For High Efficiency Amazon 20161108 PDFdokundot67% (3)

- Welding Personal Protection and Safety Equipment: Expert GuideDocument15 pagesWelding Personal Protection and Safety Equipment: Expert GuidedokundotPas encore d'évaluation

- FIre and Life Safety Ebook PDFDocument69 pagesFIre and Life Safety Ebook PDFAmritraj CharlesPas encore d'évaluation

- Quiz No. 03 Plumbing Code (10%)Document30 pagesQuiz No. 03 Plumbing Code (10%)ShadowPas encore d'évaluation

- PRE - Eurocode Concerning To Fire - 0268Document62 pagesPRE - Eurocode Concerning To Fire - 0268nebojsadj6411Pas encore d'évaluation

- Fs2011 FullDocument242 pagesFs2011 FullryankckoPas encore d'évaluation

- Plumbing Specifications: 185 N. Domingo St. San Juan City M.M. LocationDocument10 pagesPlumbing Specifications: 185 N. Domingo St. San Juan City M.M. LocationPaulo Pancho100% (3)

- Variable Air Volume SystemDocument62 pagesVariable Air Volume SystemdokundotPas encore d'évaluation

- VRV Inspection and Pre-Commissioning FormDocument1 pageVRV Inspection and Pre-Commissioning Formdokundot89% (9)

- Service Manual For High Efficiency High Ambient Amazon 20160805 NXPDocument401 pagesService Manual For High Efficiency High Ambient Amazon 20160805 NXPdokundot83% (6)

- Dehumidification Calculation 2 PDFDocument4 pagesDehumidification Calculation 2 PDFdokundot100% (1)

- Careers in Fire EngineeringDocument6 pagesCareers in Fire EngineeringEntranzzPas encore d'évaluation

- Plumbing - Specification 2011.Document8 pagesPlumbing - Specification 2011.Ponz MadianoPas encore d'évaluation

- To Ensure Sprinkler System InstallationsDocument20 pagesTo Ensure Sprinkler System Installationsspecial_nazPas encore d'évaluation

- Car Park Ventilation DemystifiedDocument12 pagesCar Park Ventilation DemystifieddokundotPas encore d'évaluation

- Hydraulic Calculations For Small RoomsDocument4 pagesHydraulic Calculations For Small RoomsAnonymous qrSsYuxyoYPas encore d'évaluation

- Mazzei Ag Product - CatelogueDocument16 pagesMazzei Ag Product - CateloguebillpaparounisPas encore d'évaluation

- For 500 GPM CalDocument56 pagesFor 500 GPM CalNeal JohnsonPas encore d'évaluation

- Fire Protection CourseDocument41 pagesFire Protection CourseyoussryPas encore d'évaluation

- FireSuppression Review #1 27-7-2015Document18 pagesFireSuppression Review #1 27-7-2015riyasudheenmh100% (1)

- Handbook On Building Fire CodesDocument287 pagesHandbook On Building Fire Codesmz1234567100% (1)

- Piping Guide b03Document8 pagesPiping Guide b03Jeferson Binay-anPas encore d'évaluation

- Inergen SpecDocument19 pagesInergen SpecMargaret DaughertyPas encore d'évaluation

- Checklist For Fire Alarm DrawingDocument4 pagesChecklist For Fire Alarm DrawingMskp PuthurPas encore d'évaluation

- Koko Refrigerant Piping Sizing GuideDocument9 pagesKoko Refrigerant Piping Sizing Guidedokundot0% (1)

- Automatic Fire Sprinkler SystemDocument16 pagesAutomatic Fire Sprinkler SystemArnel ArnaoPas encore d'évaluation

- Hydraulic NodeDocument4 pagesHydraulic NodeRenzhel MamaclayPas encore d'évaluation

- Building UtilitiesDocument41 pagesBuilding UtilitiesJara Mi SerinoPas encore d'évaluation

- Code Notes Standpipe SystemsDocument11 pagesCode Notes Standpipe SystemsJhoPas encore d'évaluation

- Fire Hydrant TestDocument3 pagesFire Hydrant TesthfrankiePas encore d'évaluation

- Fire BookletDocument8 pagesFire BookletRichard HollidayPas encore d'évaluation

- Fire Protection SystemsDocument26 pagesFire Protection Systemsmahdi_gPas encore d'évaluation

- NFPA 13 - 2016 Edition: - Specifically Permit Stainless Steel in Accordance With Schedule 10S or Schedule 40SDocument8 pagesNFPA 13 - 2016 Edition: - Specifically Permit Stainless Steel in Accordance With Schedule 10S or Schedule 40SAhmed Nabil100% (1)

- York Cond Unit Piping GuidelinesDocument128 pagesYork Cond Unit Piping Guidelinesdokundot100% (1)

- Fire Protection Module 2020 PDFDocument60 pagesFire Protection Module 2020 PDFVELASCO JULIE-ANN G.100% (1)

- Check List For CommissioningDocument18 pagesCheck List For CommissioningAnil RadheshwarPas encore d'évaluation

- Section 21 00 00 - Fire Sprinkler SystemsDocument11 pagesSection 21 00 00 - Fire Sprinkler SystemsAditya Rizky PratamaPas encore d'évaluation

- 02645s01 Fire Hydrant RequirementsDocument2 pages02645s01 Fire Hydrant RequirementsJurie_sk3608Pas encore d'évaluation

- Fire Sprinklers in An Electrical RoomDocument4 pagesFire Sprinklers in An Electrical RoomNiong David100% (1)

- Fire-Suppression Piping System-13915 PDFDocument21 pagesFire-Suppression Piping System-13915 PDFMohammad Jugnu100% (1)

- Victaulic G 105Document116 pagesVictaulic G 105lolochoPas encore d'évaluation

- NF Pa 13 Acceptance TestDocument4 pagesNF Pa 13 Acceptance Testaxl1Pas encore d'évaluation

- Code Notes SprinklerDocument13 pagesCode Notes Sprinklernarasimha raoPas encore d'évaluation

- PotterSprinkler CatalogDocument36 pagesPotterSprinkler CatalogSaleh Mohamed100% (1)

- Fire Service Underground Standards 2017 PDFDocument4 pagesFire Service Underground Standards 2017 PDFMathiyalakan RengasamyPas encore d'évaluation

- Fire Sprinkler Pipe and Fittings NotesDocument6 pagesFire Sprinkler Pipe and Fittings Notesmary joy Panama100% (1)

- Inspection, Testing and Maintenance of Fire Protection SystemsDocument126 pagesInspection, Testing and Maintenance of Fire Protection SystemsGee MacawilePas encore d'évaluation

- Maximum Distance Between HangersDocument2 pagesMaximum Distance Between HangersAhmed Ali100% (1)

- Requirements For Underground Fire Service LinesDocument4 pagesRequirements For Underground Fire Service LinesAgus Salim AnshoriPas encore d'évaluation

- High-Rise Fire Protection System Design - Zoning & Series PumpingDocument4 pagesHigh-Rise Fire Protection System Design - Zoning & Series PumpingminiongskyPas encore d'évaluation

- Redbook Vol1part1 LPCBDocument755 pagesRedbook Vol1part1 LPCBvbgiri0% (1)

- S-SHIELD Fire Protection Products - ReducedDocument178 pagesS-SHIELD Fire Protection Products - ReducedMANDAR DHANDE100% (1)

- Bukel Fire Aircraft - HangarsDocument7 pagesBukel Fire Aircraft - HangarsmukeshsinghtomarPas encore d'évaluation

- Chemguard FoamDocument7 pagesChemguard FoamSuhail EhtishamPas encore d'évaluation

- Sprinkler System DesignDocument19 pagesSprinkler System DesignRajahi Moahmed100% (1)

- SprinklersDocument16 pagesSprinklersAdel Suker100% (1)

- Annex Building SPINKLER & FAS TECH SPEC PDFDocument21 pagesAnnex Building SPINKLER & FAS TECH SPEC PDFmanishxlriPas encore d'évaluation

- Hose Stream Demands Part-1 PDFDocument4 pagesHose Stream Demands Part-1 PDFHugo Mario Ariza PalacioPas encore d'évaluation

- Comparison of Sprinkler Design Criteria 1. Sprinkler Installation Nfpa 13Document16 pagesComparison of Sprinkler Design Criteria 1. Sprinkler Installation Nfpa 13coolth2Pas encore d'évaluation

- Session 07 - Automatic Fire Alarm System (19-20) With MarkingDocument38 pagesSession 07 - Automatic Fire Alarm System (19-20) With Markingtimho yuPas encore d'évaluation

- General Fire Safety ReportDocument48 pagesGeneral Fire Safety ReportBalgo BalgobinPas encore d'évaluation

- Terms of Reference: Philippine Science High School-Bicol Region CampusDocument16 pagesTerms of Reference: Philippine Science High School-Bicol Region CampusMichael Jorge BernalesPas encore d'évaluation

- 04b FSI Design GuidesDocument23 pages04b FSI Design GuidesLai Kwok Kwan100% (1)

- PP Emergency Guide PDFDocument6 pagesPP Emergency Guide PDFgilbertomjcPas encore d'évaluation

- Distance From Sprinkler To HangerDocument1 pageDistance From Sprinkler To Hangerahmaborashed100% (1)

- Fire Protection Design GuidelinesDocument11 pagesFire Protection Design GuidelinesMarck Gheson InacayPas encore d'évaluation

- Fire Alarm Detection SystemDocument36 pagesFire Alarm Detection SystemSachin GaikwadPas encore d'évaluation

- Fpe Cwsi Wireless Fire Alarm SystemsDocument43 pagesFpe Cwsi Wireless Fire Alarm SystemsRandy BjorensenPas encore d'évaluation

- NPR280-JockeyPump Rev.A PDFDocument9 pagesNPR280-JockeyPump Rev.A PDFSaw MyintaungPas encore d'évaluation

- Rule 1230Document29 pagesRule 1230Jennie VicentaPas encore d'évaluation

- Nfpa 13D Fire Sprinkler Systems (Installation of Sprinkler Systems in One-And Two-Family Dwellings and Manufactured Homes)Document5 pagesNfpa 13D Fire Sprinkler Systems (Installation of Sprinkler Systems in One-And Two-Family Dwellings and Manufactured Homes)kklikojiPas encore d'évaluation

- RefrigPipingHandbook SuvaDocument161 pagesRefrigPipingHandbook SuvaDaveB11WhitPas encore d'évaluation

- TECNAIR Serie P PDFDocument28 pagesTECNAIR Serie P PDFdokundotPas encore d'évaluation

- EV Majax PDFDocument7 pagesEV Majax PDFdokundotPas encore d'évaluation

- Maksal Copper Pipes CatalogDocument4 pagesMaksal Copper Pipes Catalogdokundot50% (2)

- Caleffi Decoupler PipingDocument1 pageCaleffi Decoupler PipingdokundotPas encore d'évaluation

- Dutypoint Dirt & Air SeparatorsDocument12 pagesDutypoint Dirt & Air SeparatorsdokundotPas encore d'évaluation

- Dutypoint Dirt & Air SeparatorsDocument12 pagesDutypoint Dirt & Air SeparatorsdokundotPas encore d'évaluation

- Profit en Catalogue PE 2017Document54 pagesProfit en Catalogue PE 2017dokundotPas encore d'évaluation

- Carbon Steel Pipe Catalogue HebeiDocument8 pagesCarbon Steel Pipe Catalogue HebeidokundotPas encore d'évaluation

- York Split LargeDocument28 pagesYork Split LargedokundotPas encore d'évaluation

- Daikin VRV IV Co BrochureDocument52 pagesDaikin VRV IV Co Brochuredokundot100% (1)

- Carrier Water Piping Systems and PumpsDocument33 pagesCarrier Water Piping Systems and PumpsdokundotPas encore d'évaluation

- LG 26lx2r-Te Chassis Ml-051a SMDocument36 pagesLG 26lx2r-Te Chassis Ml-051a SMdokundotPas encore d'évaluation

- Mullaperiyar DamDocument20 pagesMullaperiyar Damanander08Pas encore d'évaluation

- KSB PUMP CO. Amarex KRTDocument2 pagesKSB PUMP CO. Amarex KRTHuzaifa KhanPas encore d'évaluation

- 2019 Brigada Eskwela Validation FormDocument3 pages2019 Brigada Eskwela Validation FormJennet PerezPas encore d'évaluation

- Tirupur Water Supply and Sanitation Project: An Impediment To Sustainable Water Management?Document17 pagesTirupur Water Supply and Sanitation Project: An Impediment To Sustainable Water Management?ObaidUrRehmanPas encore d'évaluation

- Leed Qualification GuideDocument1 pageLeed Qualification GuideLương Ngọc Trung HậuPas encore d'évaluation

- CV-Agus Nugraha - (Mercy Corps 181106)Document10 pagesCV-Agus Nugraha - (Mercy Corps 181106)Agus NugrahaPas encore d'évaluation

- DMV SystemDocument4 pagesDMV Systemgerard.banlasanPas encore d'évaluation

- 8904 UNESCOGo ZAdaptation Fund Projectproposal 170221 CleanmodeDocument200 pages8904 UNESCOGo ZAdaptation Fund Projectproposal 170221 Cleanmodeمهندس ابينPas encore d'évaluation

- 165 Series: Water SoftenerDocument36 pages165 Series: Water Softenernermeen ahmedPas encore d'évaluation

- General SpecificationsDocument216 pagesGeneral Specificationspuwe qihePas encore d'évaluation

- SABI Norms - Agricultural-2021Document26 pagesSABI Norms - Agricultural-2021MichaelPas encore d'évaluation

- TamorDocument3 pagesTamorBidur GautamPas encore d'évaluation

- Objective Questions (106 To 120) : SSC-JE, AE (PSC), RRB EtcDocument35 pagesObjective Questions (106 To 120) : SSC-JE, AE (PSC), RRB EtcSuvendu ParidaPas encore d'évaluation

- Saline Water Conversion CorporationDocument21 pagesSaline Water Conversion CorporationNguyen Van DzungPas encore d'évaluation

- Unit - II: Environmental Engineering-I: TopicDocument53 pagesUnit - II: Environmental Engineering-I: Topicbharatiya technologyPas encore d'évaluation

- Wastewater Engineering:: Instructor DR Sher Jamal KhanDocument53 pagesWastewater Engineering:: Instructor DR Sher Jamal KhanZahid FarooqPas encore d'évaluation

- Hydrology NotesDocument2 pagesHydrology NotesYna MaravillaPas encore d'évaluation

- Desalting As An Environmentally Friendly Water Treatment ProcessDocument152 pagesDesalting As An Environmentally Friendly Water Treatment ProcessMonica UrbietaPas encore d'évaluation

- LAS Earth Science 9Document9 pagesLAS Earth Science 9Precious NicolePas encore d'évaluation

- Calculating Fixture Unit LoadDocument2 pagesCalculating Fixture Unit LoadKarin Aca OviPas encore d'évaluation

- Final Future Urban Land Supply Strategy PlanDocument32 pagesFinal Future Urban Land Supply Strategy PlanHenry HuangPas encore d'évaluation

- Case Study - ALBANIA - ENDocument9 pagesCase Study - ALBANIA - ENYemi FajingbesiPas encore d'évaluation

- Abcor s8 HFM 183 LPFDocument2 pagesAbcor s8 HFM 183 LPFdalton2004Pas encore d'évaluation