Académique Documents

Professionnel Documents

Culture Documents

Diablo Canyon: How Spent Nuclear Fuel Is Stored

Transféré par

The TribuneDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Diablo Canyon: How Spent Nuclear Fuel Is Stored

Transféré par

The TribuneDroits d'auteur :

Formats disponibles

HOW SPENT NUCLEAR FUEL IS STORED AT DIABLO CANYON

Each of the two nuclear reactors at Diablo Canyon uses 193 fuel assemblies at a time to produce power. Fuel assemblies are typically used for three 16-month cycles of operation before they no longer generate the appropriate levels of heat in the reactor. At the end of each cycle, the plant is brought offline and about a third of the fuel assemblies are cycled out into the plants spent fuel pools, which are built into the base rock under the facility. The fuel assemblies are stored there for at least five years before being considered cooled enough to transfer to Diablos aboveground dry storage casks, which are designed to function as interim storage for spent fuel until a federal facility is available. Diablo Canyon has moved 512 fuel assemblies into 16 dry storage casks, and the facility is designed to hold up to 138 storage casks, each containing 32 spent fuel assemblies. This is enough space to accommodate the fuel discharged from both reactors during the plants current 40-year licensed life, which expires in 2025. The next dry cask loading operation is scheduled for January 2012, when seven dry casks will be loaded.

KEY EVENTS AT DIABLO CANYON

1968 Construction of Diablo Canyon begins. 1969 1970 1971 1972 1973 1974 construction 1975 Initialcomplete. of plant 1976 First fuel shipment arrives. 1977 Carter administration eliminates the federal 1978 spent fuel reprocessing program. 1979 1980 1981 1982 Congress passes the Nuclear Waste Policy 1983 Act. It requires the Dept. of Energy to develop a repository for spent fuel 1984 by 1998. 1985 Unit 1 reactor begins operation in May 1986 Unit 2 reactor begins operation in March; in 1987 September the first 68 used fuel assemblies are placed into the Unit 1 1988 spent fuel pool. 1989 Spent fuel pools are 1990 reracked using highdensity storage racks, increasing capacity. 1991 Energy Department 1992 proceeds with plans to make Yucca Mountain, Nev., the federal 1993 repository for spent nuclear fuel. 1994 1995 1996 PG&E begins planning for temporary onsite 1997 storage, realizing Yucca Mountain may not be 1998 operational as scheduled. to 1999 PG&E decidesplans for proceed with onsite dry storage. 2000 Storage site 2001 engineering, licensing and permitting begin; First 8 dry casks are 2002 ordered. 2003 2004 2005 2006 First 8 dry casks are delivered to Diablo 2007 Canyon 2008 renew 2009 PG&E applies tofirst 8 Diablo licenses; casks are loaded. 2010 Second 8 casks loaded casks 2011 12 more dryin June.are set to arrive be 2012 7 casksinare toor Feb. loaded Jan. 2013 Construction of more foundation pads for dry 2014 casks is scheduled to begin. 12 dry casks are to 2015 be loaded and 10 more delivered. 2016 Dry cask loading 2017 campaigns continue every other year going forward (2015, 2017, etc.). 2018 2019 2020 2021 2022 2023 is sched2024 Reactor unit 1 down. uled to be shut Reactor is sched2025 uled to beunit 2down. shut

SPENT FUEL POOLS

Fuel assemblies in the plants spent fuel pools are stored in racks and covered by at least 23 feet of water at all times. When assemblies are ready for transfer to a dry cask, they are lifted from the racks and placed in a multi-purpose canister, which is positioned in the circular loading facilty at the upper left.

FUEL ASSEMBLIES

Each assembly holds 12-foot-tall rods that are filled with millions of uranium fuel pellets.

HOW SPENT FUEL IS HANDLED

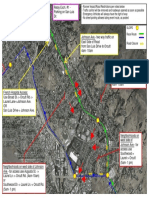

Spent fuel at Diablo Canyon moves from the reactors to two spent fuel pools in an adjacent building. Eventually, it is placed in casks and moved to the dry storage facility.

Cayucos Atascadero Morro Bay Avila Beach

101

San Luis Obispo Arroyo Grande

Diablo Canyon

UNIT 2 REACTOR UNIT 2 SPENT FUEL POOL

Currently holds 1,104 fuel assemblies Capacity is 1,324 assemblies

UNIT 1 REACTOR UNIT 1 SPENT FUEL POOL

Currently holds 1,072 fuel assemblies Capacity is 1,324 assemblies

DRY STORAGE FACILITY

Currently stores 16 casks, each holding 32 fuel assemblies, on two foundation pads capable of holding 20 casks each. Can hold 138 casks stored on seven foundation pads. When filled, each cask weighs 340,000 pounds, equivalent to nearly 70 cars. Cost to buy and load each cask is almost $2 million.

EMERGENCY WATER SUPPLY

In an emergency, 5 million gallons can be added via pumps or gravity to cool spent fuel pools or the reactors themselves.

DRY STORAGE

Dry storage of spent fuel is considered a passive system in that it doesnt rely on external actions to remove residual heat being emitted from the stored spent fuel. Air is naturally drawn into each cask through vents at the bottom of the container, passes by the multi-purpose canister, which holds the spent fuel assemblies, and exits out of vents at the top of the cask. This convective process removes the heat and prevents the system from overheating.

THE DRY STORAGE CASK

Each cask is 19 feet tall and 11 feet in diameter. The cask holds the multipurpose canister (MPC), which holds the spent fuel assemblies. After the MPC is loaded, a 9-inch thick stainless steel lid is welded to the top. The fuel inside is then dried using a forced helium dehydration process and then the container is back-filled with helium to provide a protective inert environment. The MPC is then placed into the cask.

SHIELD BLOCK

CASK LID

The concrete-and-steel lid is held onto the cask by 2-1/2-inch diameter bolts.

VENTS

MPC LID

A 9-inch thick stainless steel lid is welded to the top of the canister.

MULTI-PURPOSE CANISTER (MPC)

Constructed of 1/2-inch thick stainless steel,

CASK SPENT FUEL ASSEMBLIES

Each assembly is 12 ft. tall.

the canister is 15 feet tall and 5-1/2 feet in diameter. Each container has a basket structure inside that creates compartments to hold up to 32 spent fuel assemblies. The MPC is designed for both dry storage and eventual transport to an offsite federal storage facility.

RADIAL SHIELD

A 28-inch layer of concrete surrounds the multi-purpose canister.

INNER SHELL

A 1-inch layer of steel

OUTER SHELL

A 1-inch layer of steel

MPC BASEPLATE BOTTOM PLATE

In 2006, project manager Kath Kunz talked about the first two 270,000 pound storage casks that had recently arrived at Diablo Canyon.

VENTS PEDESTAL SHIELD

Elevates the MPC above the bottom vents

SOURCE: PG&E TRIBUNE GRAPHIC BY BETH ANDERSON; FUEL ASSEMBLY PHOTO BY JAYSON MELLOM; SPENT FUEL POOL AND DRY CASK PHOTOS BY JOE JOHNSTON; PLANT PHOTO COURTESY OF PG&E

Vous aimerez peut-être aussi

- William Gamba Civil LawsuitDocument17 pagesWilliam Gamba Civil LawsuitThe TribunePas encore d'évaluation

- SLO County Sheriff's Office Response To DOJ Jail InvestigationDocument34 pagesSLO County Sheriff's Office Response To DOJ Jail InvestigationThe TribunePas encore d'évaluation

- Paso Robles Interim Superintendent LetterDocument1 pagePaso Robles Interim Superintendent LetterThe TribunePas encore d'évaluation

- Debbie Peterson, Grover Beach City Council Resignation LetterDocument1 pageDebbie Peterson, Grover Beach City Council Resignation LetterThe TribunePas encore d'évaluation

- AUSD Chris Berdoll Title IX ReportDocument9 pagesAUSD Chris Berdoll Title IX ReportThe TribunePas encore d'évaluation

- Report For The 1997 East Village Walking Tour of Cambria by The Cambria Historical SocietyDocument4 pagesReport For The 1997 East Village Walking Tour of Cambria by The Cambria Historical SocietyThe TribunePas encore d'évaluation

- 2018 SLO Marathon Madonna Higuera ImpactDocument1 page2018 SLO Marathon Madonna Higuera ImpactThe TribunePas encore d'évaluation

- CCAA Leagues 2018-19Document1 pageCCAA Leagues 2018-19The TribunePas encore d'évaluation

- 2018.09.11 EVC MOU LetterDocument5 pages2018.09.11 EVC MOU LetterThe TribunePas encore d'évaluation

- Spring PAC-8 All-League 2018Document7 pagesSpring PAC-8 All-League 2018The TribunePas encore d'évaluation

- Heal The Bay 2017-18 Beach Report CardDocument77 pagesHeal The Bay 2017-18 Beach Report CardThe TribunePas encore d'évaluation

- CA SanLuisObispoCounty AEP5 CustomizedReportDocument36 pagesCA SanLuisObispoCounty AEP5 CustomizedReportThe TribunePas encore d'évaluation

- Shenkman Letter To Paso RoblesDocument4 pagesShenkman Letter To Paso RoblesThe TribunePas encore d'évaluation

- 2018 SLO Marathon Overall MapDocument1 page2018 SLO Marathon Overall MapThe TribunePas encore d'évaluation

- Giddens LetterDocument2 pagesGiddens LetterThe TribunePas encore d'évaluation

- 2018 SLO Marathon Downtown ImpactDocument1 page2018 SLO Marathon Downtown ImpactThe TribunePas encore d'évaluation

- 2018 SLO Marathon Edna Valley ImpactDocument1 page2018 SLO Marathon Edna Valley ImpactThe TribunePas encore d'évaluation

- SLO-Cal Poly Town-Gown MemoDocument30 pagesSLO-Cal Poly Town-Gown MemoThe TribunePas encore d'évaluation

- Road Closures For 2018 SLO MarathonDocument1 pageRoad Closures For 2018 SLO MarathonThe TribunePas encore d'évaluation

- SLO Marathon Race Access MapDocument1 pageSLO Marathon Race Access MapThe TribunePas encore d'évaluation

- Amended Coroner's Report For Baylee GatlinDocument3 pagesAmended Coroner's Report For Baylee GatlinThe TribunePas encore d'évaluation

- Garth Brooks LetterDocument1 pageGarth Brooks LetterThe TribunePas encore d'évaluation

- Garth Brooks LetterDocument1 pageGarth Brooks LetterThe TribunePas encore d'évaluation

- 2018 SLO Marathon Johnson Orcutt ImpactDocument1 page2018 SLO Marathon Johnson Orcutt ImpactThe TribunePas encore d'évaluation

- Judge Peter Allen's Ruling On Diablo Canyon Closure ApplicationDocument71 pagesJudge Peter Allen's Ruling On Diablo Canyon Closure ApplicationThe TribunePas encore d'évaluation

- Mission Plaza: Proposed RenovationsDocument2 pagesMission Plaza: Proposed RenovationsThe TribunePas encore d'évaluation

- SSLO Scanne17050515160Document3 pagesSSLO Scanne17050515160The TribunePas encore d'évaluation

- Memo On Pumping From Santa Maria Groundwater BasinDocument18 pagesMemo On Pumping From Santa Maria Groundwater BasinThe TribunePas encore d'évaluation

- Statement From Lynda and Stewart ResnickDocument2 pagesStatement From Lynda and Stewart ResnickThe Tribune100% (1)

- What The Paso Robles Groundwater Basin Crisis Looks LikeDocument1 pageWhat The Paso Robles Groundwater Basin Crisis Looks LikeThe TribunePas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Physics Definitions, Laws and PrinciplesDocument22 pagesPhysics Definitions, Laws and Principleskaziba stephen100% (1)

- AP1000 Nuclear Power Plant Overview Gianfranco Saiu, Monica Linda FrogheriDocument21 pagesAP1000 Nuclear Power Plant Overview Gianfranco Saiu, Monica Linda FrogheriKonathala RajashekarPas encore d'évaluation

- Grade 12 Physics Module5Document75 pagesGrade 12 Physics Module5Epay Castañares LascuñaPas encore d'évaluation

- Atomic Number and Synthesis of New ElementsDocument11 pagesAtomic Number and Synthesis of New ElementsAldren Atal AgoPas encore d'évaluation

- Trends in The Periodic TableDocument34 pagesTrends in The Periodic TableCaribelatinaPas encore d'évaluation

- 1-Phenylethanol H-NMR PDFDocument2 pages1-Phenylethanol H-NMR PDFkobir960% (1)

- Doorway 3rd EditionDocument528 pagesDoorway 3rd Editionmfje65Pas encore d'évaluation

- Binding EnergyDocument3 pagesBinding EnergysivagamipalaniPas encore d'évaluation

- hsc-4210 Final Risk AssessmentDocument12 pageshsc-4210 Final Risk Assessmentapi-589919774Pas encore d'évaluation

- Cape ChemistryDocument12 pagesCape ChemistryRovina Narayan DiasPas encore d'évaluation

- Physics Cheat Sheet 2Document1 pagePhysics Cheat Sheet 2mifewpmfewpoPas encore d'évaluation

- 4PH0 2PR Que 20180616 PDFDocument16 pages4PH0 2PR Que 20180616 PDFShuvashis BiswasPas encore d'évaluation

- Carbon 14 Project Phase 1 ReportDocument175 pagesCarbon 14 Project Phase 1 ReportChristopher GarciaPas encore d'évaluation

- NEET UG Physics Atom and Nucleus MCQsDocument36 pagesNEET UG Physics Atom and Nucleus MCQsKapila KarthikeyanPas encore d'évaluation

- SlayyDocument16 pagesSlayyAsli GoncPas encore d'évaluation

- Nuclear PhysicsDocument42 pagesNuclear PhysicsJennie Rose KomalaPas encore d'évaluation

- Earth and Life Science WEEK 1Document17 pagesEarth and Life Science WEEK 1Raphonzel AlvaradoPas encore d'évaluation

- Chem Chemical KineticsDocument44 pagesChem Chemical KineticsbE SpAciAlPas encore d'évaluation

- 2 Fundamental Principles of RadiobiologyDocument28 pages2 Fundamental Principles of RadiobiologyAngelo RamosPas encore d'évaluation

- SWX-238 2018.2Document2 pagesSWX-238 2018.2JuanPas encore d'évaluation

- Video Guide White Light Black Rain Destruction of Hiroshima Nagasaki - Full Video GuideDocument2 pagesVideo Guide White Light Black Rain Destruction of Hiroshima Nagasaki - Full Video GuideAws FadhilPas encore d'évaluation

- 0843 0856 PDFDocument14 pages0843 0856 PDFArun BabuPas encore d'évaluation

- 2.class Test Nuclear & Particle Physics (Liquid Drop Model)Document4 pages2.class Test Nuclear & Particle Physics (Liquid Drop Model)Krittika AdhikariPas encore d'évaluation

- Aukus-Cmp MCQDocument10 pagesAukus-Cmp MCQSwetarth YadavPas encore d'évaluation

- Analysis of LiverpoolDocument2 pagesAnalysis of LiverpoolDamon HelthPas encore d'évaluation

- CH 2Document14 pagesCH 2dwarriorsPas encore d'évaluation

- Introduction To Neutrino Physics: Paolo LipariDocument85 pagesIntroduction To Neutrino Physics: Paolo LipariSubhankar HowladerPas encore d'évaluation

- Bataan Nuclear Power PlantDocument6 pagesBataan Nuclear Power PlantIvy Joy Campos100% (1)

- Atomic Structure: 4.2 Structure of The Nuclear AtomDocument54 pagesAtomic Structure: 4.2 Structure of The Nuclear AtomEric AbaoPas encore d'évaluation

- Diagnostic Test in PhySciDocument4 pagesDiagnostic Test in PhySciJuliane Rebecca PitlongayPas encore d'évaluation