Académique Documents

Professionnel Documents

Culture Documents

Except From Henleys On Gold Alloys

Transféré par

b_carsonDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Except From Henleys On Gold Alloys

Transféré par

b_carsonDroits d'auteur :

Formats disponibles

Matthiessen found that when weights are suspended to spirals of hard-drawn wire made of copper, gold, or platinum, they

become nearly straightened when stretched by a moderate weight; but wires of equal dimensions composed of copper-tin (12 per cent of tin), silverplatinum (36 per cent of platinum), and gold-copper (84 percent of copper) scarcely undergo any permanent change in form when subjected to tension by the same weight. The same chemist gives the following approximate results upon the tenacity of certain metals and wires hard-drawn through the same gauge (No. 23) : Pounds Copper, breaking strain 25-30 Tin, breaking strain under 7 Lead, breaking strain under 7 Tin-lead (20% lead) about 7 Tin-copper (12% copper). . .about 7 Copper-tin (12% tin) about 80-90 Gold (12% tin) 20-25 Gold-copper (8.4% copper) 70-75 Silver (8.4% copper) 45-50 Platinum (8.4% copper) 45-50 Silver-platinum (30% platinum) . 75-80 On the other hand, the malleability, ductility, and power of resisting oxygen of alloys is generally diminished. The alloy formed of two brittle metals is always brittle; that of a brittle and a ductile metal, generally so; and even two ductile metals sometimes unite to form a brittle compound. The alloys formed of metals having different fusing points are usually malleable while cold and brittle while hot. The action of the air on alloys is generally less than on their simple metals, unless the former are heated. A mixture of 1 part of tin and 3 parts of lead is scarcely acted on at common temperatures; but at a red heat it readily takes fire, and continues to

burn for some time like turf. In like manner, a and zinc, when strongly composes both moist air rapidity.

a piece of bad mixture of tin heated, deand steam with

The specific gravity of alloys is rarely

48

ALLOYS

the arithmetical mean of that of their constituents, as commonly taught; and in many cases considerable condensation or expansion occurs. When there is a strong affinity between two metals, the density of their alloy is generally greater than the calculated mean; and vice versa, as may be seen in the following table: ALLOYS HAVING A DENSITY Greater than the Mean of their Constituents: Copper and bismuth, Copper and palladium, Copper and tin, Copper and zinc, Gold and antimony, Gold and bismuth, Gold and cobalt, Gold and tin, Gold and zinc, Lead and antimony, Palladium and bismuth, Silver and antimony, Silver and bismuth, Silver and lead, Silver and tin, Silver and zinc. Less than the Mean of their Constituents: Gold and copper, Gold and iridium, Gold and iron, Gold and lead, Gold and nickel, Gold and silver, Iron and antimony, Iron and bismuth, Iron and lead, Nickel and arsenic, Silver and copper,

Tin and antimony, Tin and lead, Tin and palladium, Zinc and antimony. Compounding Alloys. Considerable experience is necessary to insure success in compounding alloys, especially when the metals employed vary greatly in fusibility and volatility. The following are rules supplied by an experienced workman: 1. Melt the least fusible, oxidizable, and volatile first, and then add the others heated to their point of fusion or near it. Thus, if it is desired to make an alloy of exactly 1 part of copper and 3 of zinc, it will be impossible to do so by putting proportions of the metals in a crucible and exposing the whole to heat. Much of the zinc would fly off in vapor before the copper was melted. First, melt the copper and add the zinc, which has been melted in another crucible. The zinc

should be in excess, as some of it will be lost anyway. 2. Some alloys, as copper and zinc, copper and arsenic, may be formed by exposing heated plates of the least fusible metal to the vapor of the other. In making brass in the large way, thin plates of copper are dissolved, as it were, in melted zinc until the proper proportions have been obtained. 3. The surface of all oxidizable metals should be covered with some protecting agent, as tallow for very fusible ones, rosin for lead and tin, charcoal for zinc, copper, etc. ^4. Stir the metal before casting and if possible, when casting, with a whitewood stick; this is much better for the purpose than an iron rod. 5. If possible, add a small portion of old alloy to the new. If the alloy is required to make sharp castings and strength is not a very great oVject, the proportion of old alloy to the new should be increased. In all cases a new or thoroughly well-cleansed crucible should be used.

To obtain metals and metallic alloys from their compounds, such as oxides, sulphides, chlorides, etc., a process lately patented makes use of the reducing qualities of aluminum or its alloys with magnesium. The finely powdered material (e. g., chromic oxide) is placed in a crucible mixed with aluminum oxide. The mixture is set afire by means of a soldering pipe or a burning magnesium wire, and the desired reaction takes place. For igniting, one may also employ with advantage a special priming cartridge consisting of pulverized aluminum to which a little magnesium may be mixed, and peroxide of magnesia, which is shaped into balls and lighted with a magnesium wire. By suitable additions to the pulverized mixture, alloys containing aluminum, magnetism, chromium, manganese, copper, iron, boron, silicic acid, etc., are obtained.

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- DuplexDocument3 pagesDuplexmaladix01100% (1)

- Msds FranciumDocument6 pagesMsds FranciumVenz Timothy Wesley LandichoPas encore d'évaluation

- BS6588 1996Document17 pagesBS6588 1996kushanPas encore d'évaluation

- Heat Exchanger Anti-VibrationDocument6 pagesHeat Exchanger Anti-VibrationAnonymous v5uipH100% (1)

- Computer Aided Machine Drawing ManualDocument74 pagesComputer Aided Machine Drawing ManualSengottaiyan Malaisamy0% (1)

- TIPT Metal and Wood Shop VisitDocument38 pagesTIPT Metal and Wood Shop Visitメルヴリッ クズルエタPas encore d'évaluation

- Earth Science Quarter 1 Module 1Document4 pagesEarth Science Quarter 1 Module 1Shelly Ryn SaligumbaPas encore d'évaluation

- The Red Lion Updated10!24!10Document12 pagesThe Red Lion Updated10!24!10Jordan Bz100% (1)

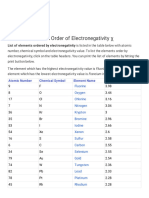

- List of Elements in Order of Electronegativity χDocument4 pagesList of Elements in Order of Electronegativity χkumarlavesh469Pas encore d'évaluation

- BCSWFRP CatalogDocument24 pagesBCSWFRP CatalogFranklin JprstPas encore d'évaluation

- Desing and Analysis of Alloy Wheels by Using AnsysDocument33 pagesDesing and Analysis of Alloy Wheels by Using Ansyslavanya0% (1)

- Corrosion Behaviour of Orthodontic Alloys - A Review: Faculty of Dental SciencesDocument27 pagesCorrosion Behaviour of Orthodontic Alloys - A Review: Faculty of Dental SciencesCPForman100% (1)

- Experiment 7 - Heterogenous Equilibria FWR PDFDocument6 pagesExperiment 7 - Heterogenous Equilibria FWR PDFkm3197100% (1)

- Shaking Table ConcentratorDocument2 pagesShaking Table ConcentratorMgn SanPas encore d'évaluation

- Nickel and Its AlloysDocument164 pagesNickel and Its Alloysgacm98100% (2)

- Astm A 90-A90mDocument4 pagesAstm A 90-A90mIngJGM100% (2)

- J. BacteriolDocument12 pagesJ. BacteriolMehran IsgandarliPas encore d'évaluation

- 1.chapter 01 Structure of MetalsDocument40 pages1.chapter 01 Structure of MetalsmuhammadPas encore d'évaluation

- Degradation of MaterialsDocument29 pagesDegradation of MaterialsjamesPas encore d'évaluation

- Formwork Presentation (Final)Document28 pagesFormwork Presentation (Final)John Jordan Villarias GuintoPas encore d'évaluation

- Ferrous and Non-Ferrous MetalDocument8 pagesFerrous and Non-Ferrous MetalJayChristian QuimsonPas encore d'évaluation

- 0 - High-Grade Granite-Related Molybdenum Systems PDFDocument34 pages0 - High-Grade Granite-Related Molybdenum Systems PDFjunior.geologiaPas encore d'évaluation

- Lesson 2 - Lemon BatteryDocument4 pagesLesson 2 - Lemon Batteryapi-296195922Pas encore d'évaluation

- Tetrapotassium PyrophosphateDocument2 pagesTetrapotassium PyrophosphateAftab S. MirzaPas encore d'évaluation

- Electron ConfigurationDocument24 pagesElectron Configurationarunasagar_2011Pas encore d'évaluation

- Hilti Light Steel Framing ManualDocument158 pagesHilti Light Steel Framing ManualAlejandro Rocha100% (2)

- Precipitation Reactions BasicDocument2 pagesPrecipitation Reactions BasicRana Hassan TariqPas encore d'évaluation

- A2 How Do You Do FerroxylDocument118 pagesA2 How Do You Do FerroxylRamon PachecoPas encore d'évaluation

- ThinnerDocument9 pagesThinnereiribooksPas encore d'évaluation

- Bullet, Carthridge Case, FirearmsDocument15 pagesBullet, Carthridge Case, FirearmsWarlito D CabangPas encore d'évaluation