Académique Documents

Professionnel Documents

Culture Documents

EXAMPLE1 UASBTreatment Process SWUST

Transféré par

Yannis ThomasDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

EXAMPLE1 UASBTreatment Process SWUST

Transféré par

Yannis ThomasDroits d'auteur :

Formats disponibles

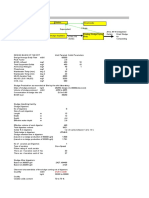

EXAMPLE 1 UASB Treatment Process Design For a UASB treatment process treating an industrial wastewater; determine the (1)

size and dimensions of the reactor, (2) detention time, (3) reactor SRT(4) average VSS concentration in biomass zone of the reactor, (5) methane gas production; (6) energy available from methane production, and (7) alkalinity requirements for a wastewater with the characteristics given below to achieve greater than 90 percent soluble COD removal: The wastewater is mainly soluble; containing carbohydrate compounds, and a granular sludge is expected. Assume 50 percent of the influent pCOD and VSS is Wastewater characteristics

Item

Flow rate COD sCOD TSS VSS Alkalinity SO4 Temperature

Unit

m /d 3 g/m 3 g/m 3 g/m 3 g/m 3 g / m as CaCO3 3 g/m

3

Value

1000 2300 2000 200 150 500 200 30

degraded, 90 percent of the influent sulfate is reduced biologically, and the effluent VSS concentration is 150 g/m3. Assume the design parameters given below and the typical values given in Tables 10-10 and 10-12 are applicable. Design parameters and assumptions: 1. From Table 1 Table 1 Summary of design parameters for completely mixed suspended growth reactors treating soluble COD Value Parameter Solids yield, Y Fermentation Methanogenesis Overall combined Decay coefficient, kd Fermentation Methanogenesis Overall combined Maximum rate ,um specific growth Unit g VSS/g COD g VSS/g COD g VSS/g COD Range 0.06-0.12 0.02-0.06 0.05-0.10 Typical 0.10 0.04 0.08

g/gd g/gd g/gd

0.02-0.06 0.01-0.04 0.02-0.04

0.04 0.02 0.03

35 30 25 Hal velocity constant, KS

g/gd g/gd g/gd

0.30-0.38 0.22-0.28 0.18-0.24

0.35 0.25 0.20

35 30 25 Methane Production at 35 Density at 35 Content of gas Energy content

mg/L mg/L mg/L

60-200 300-500 800-1100

160 360 900

M3 /kg COD kg / m3 % kJ/g

0.4 0.6346 60-70 50.1

0.4 0.6346 65 50.1

Note: m3 /kg 16.0185 = ft3 /lb. kg / m3 62.4280 = lb/103 ft3

Y = 0.08 g VSS/g COD kd = 0.03 g VSS/g VSS d

m = 0.25 g VSS/g VSS d

2. 3. 4. 5.

fd = 0.15 d VSS cell debris/g VSS biomass decay

Methane production at 35 = 0.40 L CH 4 / g COD Reactor volume effectiveness factor = 85 percent Height for gas collection = 2.5 m Determine the reactor volume based on the design organic loading and the use of Eq. Vn =

Solution

1.

QSo Lorg

a. From Table 2 select the average organic loading of 10 kg s COD/m3 . Table 2 Eecommended volumetric organic loadings as a function of temperature for soluble COD substrates for 85 to 95 percent COD removal. Average sludge

concentration is 25 g/l Table 2 Temperature, 15 20 25 30 35 40

a

Volumetric loading, kg sCOD/m VFA wastewater Range 2-4 4-6 6-12 10-18 15-24 20-32 Typical 3 5 6 12 18 25

Mon-VFA Wastewater Range 2-3 2-4 4-8 8-12 12-18 15-24 Typical 2 3 4 10 14 18

Adapted from Lettinga and Hulshoff Pol (1991).

3 3 3

Note: kg/m d 62.4280 = lb /10 ft d .

Vn =

QSo (1000 m3 / d )(2 kg sCOD/m3 ) = Lorg (10 kg s COD/m3 d)

Vn = 200m3

b. Determine the total reactor liquid volume using Eq.(10-15)

Vn 200 m3 VL = = = 235 m3 E 0.85

2. Determine the reactor dimensions. a. First determine the reactor cross-sectional area using Eq A =

based on the

design superficial velocity. Use the upflow velocity data given in Table 3. Because the wastewater is highly soluble ,select a velocity of 1.5 m/h. Table 3 Upflow velocities and reactor heights recommended for UASB reactors r Upflow velocity, m/h Wastewater type COD nearly 100% soluble Range 1.0-3.0 Typical 1.5

a

Reactor height, m Range 6-10 Typical 8

COD partially soluble Domestic wastewater

a

1.0-1.25 0.8-1.0

1.0 0.7

3-7 3-5

6 5

adapted from Lettinga and Hulshoff Pol (1991). Note: m 3.2808 = ft

m / h 3.2808 = ft / h .

Q (1000 m3 / d ) = 27.8 m 2 (1.5 m/h)(24 h/d)

A=

A=

b.

D2

4

= 27.8 m 2

D =6m

Determine the reactor liquid height using.

VL 235 m3 HL = = = 8.4 m A 27.8 m 2

c. d. Determine the total height of the reactor using

HT = HL + HG = 8.4 m + 2.5 m = 10.9 m

Reactor dimensions. Diameter = 6 m Height = 10.9 m Determine the reactor hydraulic detention time .

3.

=

4.

VL (235 m3 )(24 h/d) = = 5.64 h Q (1000 m 3 / d )

Determine the reactor SRT. a. The value of the SRT can be estimated by assuming that all the wasted bio-Logical solids are in the effluent flow .A conservative design approach is to assume that the given effluent VSS concentration consists of biomass. Thus, the following relationship applies:

QXe = PX , VSS = solids wasted per day

Both Q and Xe are known . The value of PX , VSS is given by Eq.

PX , VSS =

b.

Q(Y )( So S ) fd ( kd )Q(Y )( So S ) SRT + + Q(nbVSS ) QXe 1 + (kd ) SRT 1 + (kd ) SRT

Develop the data needed to solve the above equation. .The effluent soluble COD concentration at 90% COD removal is

S = (1.0 0.9)(2000 g/m3 ) = 200 g/m3

.The effluent nbVSS concentration given that 50 percent of the influent VSS is degraded is :

nbVSS = 0.50(150 g/m3 ) = 75 g/m3

.The pCOD degraded is

pCOD degraded = 0.50(2300 2000) g/m3 = 150 g/m3

.Total degraded influent COD ,So

So = (2000 + 150) g / m3 = 2150 g / m3

c. Substitute the given parameter values and solve the expression given above for SRT .

QXe = (1000 m3 / d )(150 g/m3 ) = + (1000 m3 / d )(0.08 g VSS/g COD)[(2150 200)g/m3 ] [1 + (0.03 g VSS/g VSS d )SRT ]

(0.15 g VSS/g VSS)(0.03 g VSS/g VSS d )(1000 m3 / d )(0.08 g VSS/g COD)[(2150 200)g/m3 ]SRT [1 + (0.03 g VSS/g VSS d )SRT

+(1000 m3 / d )(75 g/m3 ) 150,000 g/d = 156,144,000/[1 + (0.03)SRT ] + 702,648 SRT/[1 + (0.03)SRT ] + 75,000 g/d SRT = 52 d

5.

Estimate the effluent soluble COD at an SRT of 52 d at 30 using Eq. and the given coefficients.

S=

K s [1 + (kd ) SRT ] SRT (Yk kd ) 1

k=

m

Y

(0.25 g VSS/g VSS d) = 3.125 g COD/g VSS d (0.08 g VSS/g COD)

S=

(360 mg/L)[1 + (0.03 g/g d] [(52 d)[(0.08 g/g)(3.125 g/g d) (0.03g/g d)] 1]

S = 88.3 mg/L

6. Determine if the computed SRT value is adequate. The fraction of the influent sCOD in effluent =

(88.3 mg/L) = 0.044 = 4.4%S (2000 mg/L)

Because 4.4 percent is less than 10 percent (specified in problem statement), the process SRT is adequate.

7. Determine the average X TSS concentration in biomass zone of the reactor. a. The value of the X TSS can be estimated by using Eq.(7-35) developed previously in Chap. 7 for the SRT.

SRT =

V ( X TSS ) (Q Qw ) X e + Qw X R

Because it was assumed that all the wasted solids are in the effluent flow, the term Qw = 0 and the value of X TSS can be estimated as follows:

SRT

VX TSS QX e

and

X TSS

QX eSRT V

b.

Solve for the value of X TSS ,with the volume V equal to the effective volume,

Vn . X TSS (1000 m3 / d)(150 g/m3 )(52 d)(1 kg/103g) = 39.0 kg/m3 3 200 m

The computed value is within the range of solids concentration values given earlier for the UASB process. 8. Determine the methane gas production and energy produced. a. Determine the COD degraded.

COD = (2150 200) g/m3 = 1950 g/m3

b. Determine the COD removed with sulfate as the electron acceptor. From Sec.10-3, 0.67 g COD removed /g SO 4 reduced

COD SR = 0.90(200 g SO4 /m3 ) (0.67 g COD/g SO 4 ) = 120.6 g/m3

c. Determine the COD used by methanogenic bacteria.

COD MB = (1950 120.6) g/m3 (1000 m3 /d) = 1,829, 400 g/d

d. Determine the methane production rate. Methane production at 30 = (0.40 L/g)(

273.15 + 30 ) = 0.3935 L/g 273.15 + 35

Amount of CH 4 produced/d = 0. 3935 L/g(1,829,400 g COD/d)

= 719,869 L/d = 719.9 m3 /d

Total gas volume produced (used 65% methane per Table 1

= (719.9 m3 /d)/(0.65) = 1107.5 m3 /d

9. Determine energy produced from methane. To determine the energy produced, determine the density of methane at 30 and use the factor of 50.1 kJ/g methane (Table 1). a. Determine density. Density at 35 = 0.6346 g/L (Table 10 10) Methane density at 30 = 0.6346 g/L ( b. Determine energy produced. Energy produced = (719,869 L CH 4 /d)(0.6451 g/L)(50.1 kJ/g)

273.15 + 35 ) = 0.6451 g/L 273.15 + 30

= 23.3 106 kJ/d)

10. Determine the alkalinity requirements. the estimated alkalinity concentration required at 30 and 35% CO 2 in the gas phase is 1800 mg/L. Because the alkalinity in the influent is 500 mg/L, the amount of alkalinity that has to be added is alkalinity required = (1800 500) mg/L as Ca CO3 = 1300 mg/L as Ca CO3 Daily addition =(1300 g/m )(1000 m /d)(1 kg/10 g)=1300 kg/d as Ca CO3

3 3 3

Comments

A significant amount of methane gas is produced daily. If the methane can be used for the production of energy by the industrial facility, it could help to offset the cost of adding a considerable amount of alkalinity to maintain the anaerobic reactor pH near 7. Also it is important to note the significance of the effluent solids concentration in determining the system SRT. Anaerobic processes generally produce higher-effluent VSS concentrations compared to aerobic processes. For weak wastewater for which solids production is lower, it may be difficult to maintain long SRT values for high treatment efficiency due to effluent solids loss. Also, in contrast to the situation presented in this example, manual wasting of sludge may be necessary. If the wastewater had a higher-influent COD concentration; and the effluent VSS concentration remained the same, the concentration of solids (X TSS ) in the sludge blanket would have to increase and the blanket level would have to be higher. To avoid a rising sludge blanket; manual wasting of sludge would have to be initiated and the SRT value would have to be less than the computed value of 52 d. For design, it is best to assume that the average VSS concentration of the sludge blanket would be less than 25 to 35

kg/m3.

Vous aimerez peut-être aussi

- Exercise 3 - Water Treatment2Document8 pagesExercise 3 - Water Treatment2Vivekka Olivia John100% (1)

- 2015 CVL300 Tutorial 4 SolutionDocument7 pages2015 CVL300 Tutorial 4 SolutionAhmed Abuzour100% (2)

- Preliminar Calculo BlowerDocument3 pagesPreliminar Calculo BlowerAlejo BaronPas encore d'évaluation

- Activated SludgeDocument14 pagesActivated Sludgemosaad khadrPas encore d'évaluation

- Activated Sسمعيلثludge Calculation SheetDocument14 pagesActivated Sسمعيلثludge Calculation SheetYasser Fathy Aly100% (1)

- Design a Completely Mixed Activated Sludge SystemDocument2 pagesDesign a Completely Mixed Activated Sludge SystemVipin YadavPas encore d'évaluation

- CE384 Homework PacketDocument57 pagesCE384 Homework PacketRenika Baruah0% (1)

- 371hw06s (Rapid Mix Tank Design-Sample 1)Document5 pages371hw06s (Rapid Mix Tank Design-Sample 1)Yang Ching HianPas encore d'évaluation

- Circular Trickling Filter Design for 5MLD Sewage TreatmentDocument11 pagesCircular Trickling Filter Design for 5MLD Sewage TreatmentAsegid Bezabih100% (2)

- Grit Removal & Treatment for Sustainable Grit RecyclingDocument47 pagesGrit Removal & Treatment for Sustainable Grit RecyclingRavena RemaditaPas encore d'évaluation

- Sewage Treatment WorksheetDocument18 pagesSewage Treatment WorksheetRemedanPas encore d'évaluation

- 40 KLD MBR QuoteDocument15 pages40 KLD MBR QuoteV Narasimha RajuPas encore d'évaluation

- Designing water treatment processesDocument7 pagesDesigning water treatment processesMohamad IrfanPas encore d'évaluation

- MBR Membrane Offer for 30 MLD STPDocument8 pagesMBR Membrane Offer for 30 MLD STPakshay salviPas encore d'évaluation

- CT4485 Exam 31-01-2012 With AnswersDocument7 pagesCT4485 Exam 31-01-2012 With AnswersVali100% (1)

- Mini Project ReportDocument5 pagesMini Project ReportSaj BhaiPas encore d'évaluation

- 150 KLD fecal sludge treatment plant design basisDocument56 pages150 KLD fecal sludge treatment plant design basissharan kommi100% (1)

- Water Softening (IR)Document15 pagesWater Softening (IR)Iser100% (2)

- Liu Yi-Design and Construction of Biogas Digester 2017Document74 pagesLiu Yi-Design and Construction of Biogas Digester 2017Stanley Wishmore MukuraPas encore d'évaluation

- Sludge Dewatering Screw Press Szk1Document2 pagesSludge Dewatering Screw Press Szk1MariusCapraPas encore d'évaluation

- Sample WW QuestionsDocument10 pagesSample WW QuestionsKrishna Kumar MeenaPas encore d'évaluation

- Waste Water AssignmentDocument4 pagesWaste Water Assignmentermias100% (2)

- Hyd - Cal. WTP BaggiDocument27 pagesHyd - Cal. WTP BaggiChief Engineer PMUPas encore d'évaluation

- Design and Calculation UASB Reactor For Sludge TreatmentDocument3 pagesDesign and Calculation UASB Reactor For Sludge TreatmentDavid LambertPas encore d'évaluation

- Colligative Properties ExplainedDocument26 pagesColligative Properties ExplainedYAWAR SAEED100% (1)

- 1295 - Offer 50 KLD Package Type STP 27.08.2022 - RemovedDocument11 pages1295 - Offer 50 KLD Package Type STP 27.08.2022 - RemovedsanjeevPas encore d'évaluation

- 04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFDocument8 pages04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFVic KeyPas encore d'évaluation

- Water Treatment Plant Pretreatment ProcessDocument79 pagesWater Treatment Plant Pretreatment Processsuleman247Pas encore d'évaluation

- Description Unit Qty Rate Amount G+1 Multi Purpose Building: A-Sub StructureDocument7 pagesDescription Unit Qty Rate Amount G+1 Multi Purpose Building: A-Sub StructureYosiPas encore d'évaluation

- Hospital Waste Water TreatmentDocument5 pagesHospital Waste Water TreatmentNP100% (1)

- UASB DesignDocument17 pagesUASB DesignQuốc TuyênPas encore d'évaluation

- CIP Procedure of RO MembraneDocument2 pagesCIP Procedure of RO MembraneTanzila SiddiquiPas encore d'évaluation

- Environmental Engineering QuestionsDocument10 pagesEnvironmental Engineering QuestionsSuresh Raju0% (1)

- Today'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"Document57 pagesToday'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"saravan1891Pas encore d'évaluation

- Distillery Wastwater Treatment-CDM Project-2012Document60 pagesDistillery Wastwater Treatment-CDM Project-2012tsrinivasan5083Pas encore d'évaluation

- (EDITED-FINAL) Sludge - Storage CalculationDocument17 pages(EDITED-FINAL) Sludge - Storage CalculationIftikhar KamranPas encore d'évaluation

- STP Design (With Aeration Tank)Document16 pagesSTP Design (With Aeration Tank)Sagar Patel.Pas encore d'évaluation

- Chlorine Energy 2520 BalanceDocument4 pagesChlorine Energy 2520 Balancetonzz10Pas encore d'évaluation

- 1) (15 PTS) A 10 Inch Diameter Sanitary Sewer Is Designed Such That ItDocument13 pages1) (15 PTS) A 10 Inch Diameter Sanitary Sewer Is Designed Such That ItZeyad Tareq Al Sarori100% (1)

- Chapter 9 Primary SedimentationDocument21 pagesChapter 9 Primary SedimentationAce ThunderPas encore d'évaluation

- Design Standards for Membrane BioreactorsDocument14 pagesDesign Standards for Membrane BioreactorsAudrius100% (2)

- Assignment 1Document3 pagesAssignment 1Victor Megong JakiPas encore d'évaluation

- CVL723PS1Document5 pagesCVL723PS1Ronald Ewa100% (1)

- Mass balance hydrated lime SBP productionDocument2 pagesMass balance hydrated lime SBP productionNikhil GoelPas encore d'évaluation

- Flocculator Eng PDFDocument2 pagesFlocculator Eng PDFAbdul LatifPas encore d'évaluation

- Al Ain Sludge Status - BwiDocument1 pageAl Ain Sludge Status - BwiHRK65Pas encore d'évaluation

- Filter Design ParameterDocument3 pagesFilter Design ParameteruemaaplPas encore d'évaluation

- Principle of Working of Grit ChamberDocument11 pagesPrinciple of Working of Grit ChamberAhmed Amedi100% (3)

- Design FMR HighDensityDocument2 pagesDesign FMR HighDensityPandiaraj MkPas encore d'évaluation

- National Green Tribunal Upholds Stricter Sewage Treatment StandardsDocument14 pagesNational Green Tribunal Upholds Stricter Sewage Treatment StandardsBhaskar Challa100% (1)

- Faecal Sludge Treatment Technologies in IndiaDocument44 pagesFaecal Sludge Treatment Technologies in Indianeeraj sharmaPas encore d'évaluation

- Treatment of Pre-Treated Textile Wastewater Using Moving Bed Bio-Film ReactorDocument8 pagesTreatment of Pre-Treated Textile Wastewater Using Moving Bed Bio-Film ReactorIna SitaPas encore d'évaluation

- Design of WTP and STPDocument14 pagesDesign of WTP and STPVenu Ch100% (1)

- Activated Sludge Calculations With Excel QuizDocument2 pagesActivated Sludge Calculations With Excel Quiztrantrunghoa290784Pas encore d'évaluation

- Sludge Treatment of WaterDocument11 pagesSludge Treatment of WaterWinsam Amiel Cejudo100% (1)

- In This Project We Will Design A Treatment Station, So We: - Pond ClassificationDocument16 pagesIn This Project We Will Design A Treatment Station, So We: - Pond ClassificationSayed Abo ElkhairPas encore d'évaluation

- 1.0 Industrial - Waste - Water - Treatment-M. - SC - Student-2023-NewDocument63 pages1.0 Industrial - Waste - Water - Treatment-M. - SC - Student-2023-NewUday Kumar DasPas encore d'évaluation

- Trikling FiltersDocument16 pagesTrikling Filtersmosaad khadrPas encore d'évaluation

- Introduction To Air Pollution - WorkbookDocument10 pagesIntroduction To Air Pollution - Workbookrocky21stPas encore d'évaluation

- Himmeblau Chp1 (WWW - Myuet.net - TC)Document23 pagesHimmeblau Chp1 (WWW - Myuet.net - TC)redj288Pas encore d'évaluation

- Copper Red Fs EPADocument6 pagesCopper Red Fs EPAEric CheahPas encore d'évaluation

- Kamareddy DEP PlanDocument15 pagesKamareddy DEP PlanArun Jyothi CPas encore d'évaluation

- Facilities Directorate The University of Hull Energy and Water PolicyDocument3 pagesFacilities Directorate The University of Hull Energy and Water Policygerald077Pas encore d'évaluation

- Rich's MEEB Quiz NotesDocument16 pagesRich's MEEB Quiz NotesSk Abdul RavoofPas encore d'évaluation

- Roles and Functions of FestivalsDocument5 pagesRoles and Functions of FestivalsCristina Rodica100% (1)

- Environment and Problems Vocabulary Activities Promoting Classroom Dynamics Group Form - 64882Document1 pageEnvironment and Problems Vocabulary Activities Promoting Classroom Dynamics Group Form - 64882Celia CunhaPas encore d'évaluation

- General Reporting ProtocolV3Document70 pagesGeneral Reporting ProtocolV3Inoa KonsultindoPas encore d'évaluation

- Oil & Gas Industry Course Outline on Environmental IssuesDocument68 pagesOil & Gas Industry Course Outline on Environmental IssuesDaniel InemughaPas encore d'évaluation

- Coal Beneficiation PDFDocument36 pagesCoal Beneficiation PDFSolai NathanPas encore d'évaluation

- Pollution Control Acts and Regulations of India For Chloro Alkali Industry by S. AliDocument14 pagesPollution Control Acts and Regulations of India For Chloro Alkali Industry by S. AliPikuramPas encore d'évaluation

- Waste WaterDocument9 pagesWaste WaternayyarkmlPas encore d'évaluation

- Sample Poster For ReferenceDocument1 pageSample Poster For ReferenceAnand UpadhyayPas encore d'évaluation

- Septic Tank AdtorialDocument1 pageSeptic Tank AdtorialJune AlapaPas encore d'évaluation

- DYPNF BrochureDocument16 pagesDYPNF BrochureJaeyoung LeePas encore d'évaluation

- Multi Genre Persuasive Essay Ready For UploadDocument5 pagesMulti Genre Persuasive Essay Ready For Uploadapi-340304907Pas encore d'évaluation

- Exam 1 Cheat SheetDocument2 pagesExam 1 Cheat SheetJustin BrownPas encore d'évaluation

- CVL 425Document20 pagesCVL 425Shahil AlamPas encore d'évaluation

- Module 1.1 Phillipine Environmental LawsDocument9 pagesModule 1.1 Phillipine Environmental LawsArbeeChrystelV.AleraPas encore d'évaluation

- Kwinana Refinery 2007 2009Document249 pagesKwinana Refinery 2007 2009Khalid Mahmood100% (2)

- ZN BR CA BR CaCl Solution Safety SheetDocument5 pagesZN BR CA BR CaCl Solution Safety SheetAric NgPas encore d'évaluation

- IES Civil Engineering Paper II 2012Document21 pagesIES Civil Engineering Paper II 2012neela94Pas encore d'évaluation

- Kajang Local Plan For Sustainable DevelopmentDocument49 pagesKajang Local Plan For Sustainable DevelopmentReshmi KaurPas encore d'évaluation

- FOCGB3 Utest DLR 5BDocument2 pagesFOCGB3 Utest DLR 5BGyurácz GyulaPas encore d'évaluation

- Is Recycling Worth ItDocument21 pagesIs Recycling Worth Itapi-252236011100% (1)

- Aashto M304 2Document2 pagesAashto M304 2David SolisPas encore d'évaluation

- Governing Climate Change Post-2012: The Role of Global Cities Case-Study: Los AngelesDocument22 pagesGoverning Climate Change Post-2012: The Role of Global Cities Case-Study: Los AngelesTyndall Centre for Climate Change Research100% (5)

- Environmental Impact AssessmentDocument7 pagesEnvironmental Impact AssessmentGaurav YadavPas encore d'évaluation

- Toolbox On Drum Handling: Facilitator: Kikile Masomese Henry. Date: 5 August, 2014Document1 pageToolbox On Drum Handling: Facilitator: Kikile Masomese Henry. Date: 5 August, 2014Masomese Henry KikilePas encore d'évaluation

- Road Detailed EstimateDocument8 pagesRoad Detailed Estimatenageshwarraobandi100% (1)

- Indian Standards For Controlling Pollution of Marine Coastal Areas 1 PDFDocument16 pagesIndian Standards For Controlling Pollution of Marine Coastal Areas 1 PDFVishnu S DasPas encore d'évaluation