Académique Documents

Professionnel Documents

Culture Documents

Emisarios (Sea Outfall)

Transféré par

Luis Alejandro Hueicha RaimapoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Emisarios (Sea Outfall)

Transféré par

Luis Alejandro Hueicha RaimapoDroits d'auteur :

Formats disponibles

622

COASTAL ENGINEERING

15.7

15.7.1

Sea outfalls

General

The oceans have a great capacity to assimilate wastes and to make them harmless and they are being exploited as receivers of wastes from outfalls. A typical outfall consists of a pipe discharging efuents from the land to the sea and laid on or buried in the sea bed (or housed in a tunnel). It is extremely important that the design of outfall should take account not only of its hydraulic function but also of the environmental impact. Some of the short outfalls constructed have failed from the environmental standpoint since efuents have found their way back polluting the beaches. Even long outfalls may sometimes be unsatisfactory since efuents can return to the beach depending upon the direction of currents that are produced by the tidal ow, waves and wind. There are essentially two outfall types. One consists of a pipe with a diffuser at its seaward end, both above the sea bed, and the wall ports, through which the efuent discharges, are just holes through the wall of the pipe; the second type, buried under the sea bed, has a number of risers from the diffuser. The outfall pipe and the risers must be protected from ship anchors and shing lines. In large outfall schemes and in schemes involving conned waters, the concentrations of the pollutants discharged should be checked periodically by sampling the quality of water which is usually characterized by the biological oxygen demand (BOD), bacterial content, suspended matter, turbidity, pH, temperature, toxic chemicals, minerals and organic and inorganic matter. The impact of these various constituents on the environment is often complex and not necessarily immediate. When the efuent is discharged into the sea, it is diluted rapidly by initial dilution and subsequently by the secondary dispersion. The BOD and the suspended solids are reduced quickly by these processes. It is, however, necessary that the ambient currents are favourable and that the site is at a sufcient distance from the shore to reduce the bacterial content still further through dilution, mortality and sedimentation before the diluted sewage may reach the shore. Apart from the above environmental aspects, the design of the outfall system will depend on the characteristics of the sewage system, storm overows, the outfall site, the headworks and the outfall itself. The storm overows on combined systems (collecting both sewage and rainwater run-off) are designed to reduce the ow in the sewers to about 6 times the dry weather ow and may also be a cause of pollution whose impact on the environment has to be assessed. The preliminary treatment of the wastewater on land and the subsequent marine treatment should complement each other in order to

SEA OUTFALLS achieve environmentally acceptable standards. Before the efuent is discharged into the sea, the grit is removed to avoid its deposition in the outfall pipe and the suspended matter is reduced to small sizes (the screens should pass a maximum particle size of 56 mm). If the suspended load in the efuent is such that the marine treatment is not very effective environmentally, then primary sedimentation may be incorporated before discharging the efuent into the sea. If the effectiveness of the outfall falls short of the acceptable bacterial content, then disinfection may be recommended. It is worth noting that the sludge produced in primary sedimentation may be difcult to dispose of and that disinfection of the efuent can be detrimental to the aquatic life. In this concise text many aspects of sea outfalls could be touched on only briey; for a fuller treatment of the subject, the reader is referred to Charlton (1985) and Neville-Jones and Dorling (1986).

623

15.7.2

Site surveys

For effective design of outfalls, site surveys should be undertaken to assess the quality of receiving water, tides and currents, and environmental conditions (e.g. seaweed, animal life, bacteria, etc.). Charlton (1985) describes the methods used to obtain a form of tidal atlas in which the current variation throughout the tidal cycle is presented on an hourly basis. The overall performance of the outfall is predicted by tracer tests. These tests are carried out usually in normal conditions of the sea by introducing tracers at the site and the dispersion and dilution of the tracer are continuously monitored mainly at a depth less than 1 m.

15.7.3

Initial dilution and secondary dispersion

The efuent passing through a port is lighter than the surrounding sea water; the density of sea water is typically 1.026 kg m 3 and depends on the ambient temperature and salt content. Thus a density gradient across the depth may exist due to variations of temperature and salinity with the density increasing in depth. The density stratication is likely to be more pronounced in summer than in winter. Consider that the efuent from the port exhausts in the vertical direction into the sea of uniform density without ambient currents. The resulting buoyant jet spreads owing to its initial momentum rate and the buoyancy effects. Without the momentum rate, the efuent from the port will spread as pure plume driven only by the buoyancy. As the jet rises to the surface, entrainment of the surrounding water takes place with the

624

COASTAL ENGINEERING maximum velocity and concentration along the centreline of the jet decaying in the streamwise direction. Instead of concentration, the term dilution is commonly used. If, say, 99 ml of pure salt water mixes with 1 ml of the efuent, then the dilution is 100:1 or simply 100. On reaching the surface of the sea the efuent tends to spread horizontally. The density of the efuent increases through dilution. If the receiving water is density stratied, then the efuent may not even reach the surface as, when it reaches a value at some depth equal to the density of the surrounding water, the plume is arrested and spreads horizontally. The next phase of the efuent transport is the advection by ocean currents and turbulent diffusion. The phase, called the secondary dispersion, depends on the current and the turbulence structure of the ocean. Ports generally discharge efuents horizontally to achieve the best dilution (Fig. 15.11). Figure 15.11 also shows the spread of the jet to be discussed further in Section 15.7.6. For horizontally discharged efuent, about 20% to 50% greater dilutions are obtained at the water surface than for vertical discharge.

Fig. 15.11 1985)

The spread of horizontal jets in still water (after Charlton,

SEA OUTFALLS 15.7.4 Still ambient uid

625

The initial dilution of the efuent Sm along the centreline of the jet issuing from the port may be expressed in still water conditions in a functional form as Sm f0 Vp (g Dp)

1/2

y0 Dp

(15.34)

where Vp is the velocity at the exit of the port, y0 is the depth of the port exit below the surface and Dp is the diameter of the port. g g( a 0)/ 0 where a is the density of the ambient uid and 0 is the density of the efuent. The rst term in the brackets on the right-hand side of equation (15.34) is the densimetric Froude number denoted as FD (equation (8.20)). The spread of the buoyant jet horizontally discharged in still surrounding uid has been studied extensively and the results are presented in the form of equation (15.34) as charts or equations. Figure 15.12 shows the graphical expression of the functional form due to Fan and Brooks (1966). Cederwall (1968) expresses the dilution in the form of equations as Sm 0.54 FD y0 DpFD

7/16

for

y0 Dp

0.5 FD

(15.35)

Fig. 15.12

Centreline dilution as a function of y0/Dp and FD

626

COASTAL ENGINEERING and Sm 0.54 FD 0.38y0 DpFD 0.66

5/3

for

y0 Dp

0.5 FD.

(15.36)

Sm is the minimum dilution occurring along the centreline of the plume. For vertical port discharges, the average plume dilutions Sa in the initial mixing region can be determined by the equations due to Muellnoff et al. (1985) with Qp being the port discharge: Sa 0.13 g1/3Qp 2/3y5/3 0

which can be written in non-dimensional form as Sa 0.13 4

2/3

1 FD

2/3

y0 Dp

5/3

(15.37)

The average plume dilution Sa is approximately 1.8 times the minimum dilution Sm at the centreline. Figure 15.12 shows that the same dilution can be obtained for either low or high exit densimetric Froude numbers. Low velocities mean low driving heads while large velocities need large heads. The choice of low velocities can lead to malfunctions of the outfall if deposits of sediments on the bed occur or if the densimetric Froude number is below the critical limit of unity when salt water intrusion reducing the efuent ow will develop.

15.7.5

Moving receiving water

When the efuent is discharged into receiving water moving with velocity Va the dilution is signicantly modied from that in calm water. Field studies (Agg and Wakeford, 1972) give an equation for an additional dilution factor which is a ratio of the dilution in moving water to the dilution applicable in the range in still water. The empirical equation for 0.1 Va/Vp 2.0 is log 1.107 0.938 log(Va/Vp). (15.38)

(The dilution in moving water is determined by multiplying the dilution in still water of Fig. 15.12 by the factor .) Lee and Neville-Jones (1987) present the following equations for dilution in moving water: Sm 0.31B1/3y5/3 0 for y0 Qp 5B V3 a , (15.39)

SEA OUTFALLS 0.32Va y 2 0 for y0 Qp 5B V3 a

627

Sm and B

(15.40)

Qp g

a 0

For small values of y0/Dp, the results of Agg and Wakeford are comparable with equations (15.39) and (15.40) but, for y0/Dp between 50 and 100, they underpredict the initial dilution (Neville Jones and Dorling, 1986). For vertical single ports discharging into moving receiving water, Muellenhoff et al. (1985) present the following equation for average dilution Sa: Sa 0.49 Va y2 0 . Qp (15.41)

15.7.6

Spacing of ports

The spacing of the ports depends on the geometry of the plume as it spreads. Under still water conditions the buoyant rising plumes should not overlap till they reach the surface. The geometry of the buoyant plume in still water according to Brooks (1970) is shown in Fig. 15.11. The dimensionless radial extent of the plume W/Dp at the free surface is presented in Fig. 15.11 as a function of the densimetric Froude number FD and y0/Dp. The spacing of the ports should be greater than W. In moving receiving water, the size of the plume is increased with the increased degree of dilution. Neville-Jones and Dorling (1986) suggest that for Va/Vp 0.2, W 0.5y0 for y0 2B/V3. The width W 0.9y0 for a Va/Vp 0.2.

15.7.7

Diffuser design

The ow through the outfall may be due to gravity depending on the head available between the headworks and the highest water level at the discharge location in the sea. If enough head is not available, then the wastewater is pumped through the outfall. The frictional loss in the straight pipe of the outfall leading to the diffuser is calculated using the DarcyWeisbach equation (equation (8.4)) with friction factor computed by equation (8.5) or the ColebrookWhite equation (Worked example 13.1). During the operation of the outfall,

628

COASTAL ENGINEERING

Fig. 15.13

Diffuser with risers

slime builds up on the wall of the pipe increasing the roughness height and reducing the effective diameter of the pipe; this should be taken into account in headloss calculations. Figure 15.13 shows typically a diffuser with three ports with vertical risers. An expression for the discharge through a port is obtained by applying the energy equation between the exit of the port and the centreline of the diffuser at the junction. Consider for example, port 2: p2 g V2 2 2g pa2 g V2 p2 2g lp2 V2 p2 2g (ke kst kb) (15.42)

where p2 and V2 are the pressure and velocity respectively just before the junction at 2. lp2 is the vertical distance between the port exit and the centreline of the diffuser and pa2 is the ambient pressure at the port exit. ke, kst and kb are respectively the coefcients for the headlosses at entry to the riser, along the straight riser and in the bend (Miller, 1994). The discharge through the second port Qp2 is then Qp2 ap2Vp2. Wall ports are simply holes through the wall of the diffuser and may have a rounded or sharp-edged entrance. Equation (15.42) applies with lp2 kst kb 0. Therefore for Vp2 Vp2 1 1 ke 2gE2

1/2

(15.43)

SEA OUTFALLS where E2 p2 g V2 2 2g pa2 g (15.44)

629

and the ow rate is Qp2 with cd c 1 1 ke

1/2

c ap2Vp2

cdap2(2gE2)1/2

(15.45)

An empirical equation (Koh and Brooks, 1975) based on laboratory experiments for port diameters less than one-tenth of the diameter of the diffuser for a bell-mouth entrance is cd 0.975 1 V2 j 2gEj

3/8

(15.46)

and for a sharp-edged entrance is cd 0.63 0.58 V2 j 2gEj . (15.47)

Ej is as given by equation (15.44). (Vj is the velocity in the diffuser just before the junction j and Vpj is the velocity through the port at junction j.) For the riser ports the experimental discharge coefcients vary from 0.648 to 0.848 (Grace, 1978). These coefcients may be used for the preliminary design; for detailed calculations equation (15.42) taking account of the losses in the individual components of the riser assembly has to be followed.

(a)

Analysis of ow in the diffuser

Referring to Fig. 15.13, the energy equation for the segment of the diffuser between ports 2 and 3 is p3 g V3 2 2g Z23 p2 g V2 2 2g hf23 hc. (15.48)

p 3 and V 3 are respectively the pressure and velocity in the diffuser at the section immediately downstream of junction 3 (Fig. 15.13). p2 and V2 refer respectively to pressure and velocity occurring upstream of junction 2

630

COASTAL ENGINEERING (Fig. 15.13). Z23 is the change in elevation . hf23 is the frictional head loss in the straight pipe and hc is the head loss in the contraction which is usually negligible. Z2 and Z3 are the elevations of junctions 1 and 2 respectively (Fig. 15.13). The pressure across the junction (Fig. 15.13) is determined using the energy equation which, as an example, for junction 2 is p2 g Note that Q2 Q2 Qp2 (15.50) V2 2 2g p2 g V2 2 g k2 V2 2 . 2g (15.49)

where Q2, Q 2 and Qp2 are respectively the discharges upstream and downstream of the junction and through the port. The analysis of ow in the diffuser is a step-by-step procedure starting from the extreme seaward end. The calculation procedure for the wall ports (or ports with risers) is as follows. 1. Estimate E1 relevant to port 1 in the diffuser at the junction with the rst port for the discharge Qp1 through the rst port, using equation (15.44); determine p1. Determine the pressure p2 just downstream of junction 2 from equation (15.48). Solve equations (15.49) and (15.50) or (15.45) to nd the pressure p2 just upstream of the junction and the ow Qp2 through the second port. Continue the procedure to port 3 and so on. Check whether the sum of the discharges through all the ports is the same as the design discharge.

2. 3.

4. 5.

The calculation procedure can be carried out using computer programs. It is difcult to avoid at all times deposition of sediments in the outfall pipe and the diffuser (at low ows) as a small pipe diameter increasing the ow velocity would result in large energy losses and greater pump power requirements. Usually some sediments are allowed to deposit at low ows to be ushed out at high ows. Generally velocities in excess of about 0.9 m s 1 will be required at high ows. For further information on sediment transport in sewers and outfall see Novak and Nalluri (1987) and Ackers (1991). In order that the velocities along the diffuser are sufciently large to dislodge the sediments from the bed and transport them, the diffuser diameter is reduced progressively as shown in Fig. 15.13. An outline of a preliminary outfall design is given in Worked example 15.4.

Vous aimerez peut-être aussi

- Surveying Made Easy: Karl ZeiskeDocument36 pagesSurveying Made Easy: Karl ZeiskeLuis Alejandro Hueicha RaimapoPas encore d'évaluation

- Website Calibracivil - 1366Document1 pageWebsite Calibracivil - 1366Luis Alejandro Hueicha RaimapoPas encore d'évaluation

- Trimble R4 Gnss System: Key FeaturesDocument2 pagesTrimble R4 Gnss System: Key FeaturesAnonymous r8jDxNqMl0% (1)

- Rock Blasting OutlineDocument2 pagesRock Blasting OutlineLuis Alejandro Hueicha RaimapoPas encore d'évaluation

- Rock Blasting OutlineDocument2 pagesRock Blasting OutlineLuis Alejandro Hueicha RaimapoPas encore d'évaluation

- 1 s2.0 S1365160917304653 MainDocument11 pages1 s2.0 S1365160917304653 MainLuis Alejandro Hueicha RaimapoPas encore d'évaluation

- A Comprehensive and Flexible Slope Stability Program PDFDocument33 pagesA Comprehensive and Flexible Slope Stability Program PDFLuis Alejandro Hueicha RaimapoPas encore d'évaluation

- Non-Associated Plasticity For Soils, Concrete and RockDocument64 pagesNon-Associated Plasticity For Soils, Concrete and RockErnest NsabimanaPas encore d'évaluation

- Moczo Etal 2004 SPICE BookDocument161 pagesMoczo Etal 2004 SPICE BookLuis Alejandro Hueicha RaimapoPas encore d'évaluation

- Analytical Methods For Slope Stability Analysis PDFDocument22 pagesAnalytical Methods For Slope Stability Analysis PDFLuis Alejandro Hueicha RaimapoPas encore d'évaluation

- V84 2 TutorialDocument110 pagesV84 2 TutorialValentina Mohora-ConstandachePas encore d'évaluation

- Practical Estimates of Rock Mass - StrengthHoek & Brown V V ExcellentDocument26 pagesPractical Estimates of Rock Mass - StrengthHoek & Brown V V ExcellentGEOMAHESHPas encore d'évaluation

- 2D 3 Material Models 02Document216 pages2D 3 Material Models 02Triki SamirPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- MandlaDocument1 pageMandlaShorya HardahaPas encore d'évaluation

- Aspects of The Geology and Groundwater Conditions of Asaba NigeriaDocument14 pagesAspects of The Geology and Groundwater Conditions of Asaba NigeriaIgwe, Emmanuel A.Pas encore d'évaluation

- Plumbing CodeDocument104 pagesPlumbing CodeParashuram Patil100% (1)

- Water Supply StatisticsDocument5 pagesWater Supply StatisticsEjiga Fredrick APas encore d'évaluation

- Embankment Assignment TwoDocument25 pagesEmbankment Assignment TwoBelay MekonenPas encore d'évaluation

- Why There Is No Water in Palar?Document5 pagesWhy There Is No Water in Palar?guruPas encore d'évaluation

- Dav Public School, Ludhiana Session - (2021-2022) Chapter-5 Community Services Class-V Name - Roll No. - DateDocument3 pagesDav Public School, Ludhiana Session - (2021-2022) Chapter-5 Community Services Class-V Name - Roll No. - Dategurinder pal singhPas encore d'évaluation

- Design of AqueductDocument49 pagesDesign of AqueductGarg Tj100% (3)

- Domestic Grey Water Reuse in CisternsDocument14 pagesDomestic Grey Water Reuse in CisternssomeshPas encore d'évaluation

- Rceia Executive Summary 210612Document9 pagesRceia Executive Summary 210612VelmuruganPas encore d'évaluation

- Rain Harvesting Maintenance ChecklistDocument2 pagesRain Harvesting Maintenance ChecklistAbu MohammedPas encore d'évaluation

- Geographical Location of Body of Water in ThailandDocument13 pagesGeographical Location of Body of Water in ThailandShanidy de GuzmanPas encore d'évaluation

- Dimensioning of Branching Irrigation Networks by Means of Linear ProgrammingDocument9 pagesDimensioning of Branching Irrigation Networks by Means of Linear ProgrammingjhdmssPas encore d'évaluation

- Domestic Wastewater Facilities Manual (PRE-DRAFT 2017-09-21 Clean) PDFDocument333 pagesDomestic Wastewater Facilities Manual (PRE-DRAFT 2017-09-21 Clean) PDFahaddi58Pas encore d'évaluation

- EvaporationDocument15 pagesEvaporationJomarie AlcanoPas encore d'évaluation

- Vijay Singh - Handbook of Hydraulic Geometry - Theories and Advances-Cambridge University Press (2022)Document590 pagesVijay Singh - Handbook of Hydraulic Geometry - Theories and Advances-Cambridge University Press (2022)Edgar ChuquipiondoPas encore d'évaluation

- Ipp Problems and QuestionsDocument16 pagesIpp Problems and QuestionsSecret DuhhhPas encore d'évaluation

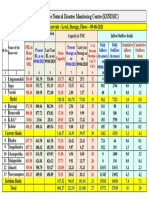

- Karnataka State Natural Disaster Monitoring Centre (KSNDMC) : Major Reservoir - Level, Storage, Flows - 09-06-2021Document1 pageKarnataka State Natural Disaster Monitoring Centre (KSNDMC) : Major Reservoir - Level, Storage, Flows - 09-06-2021true callPas encore d'évaluation

- Nemmeli DesalDocument4 pagesNemmeli DesalTushar NeelratanPas encore d'évaluation

- 2015 DELWP-commissioned ReportDocument98 pages2015 DELWP-commissioned ReportJoe HinchliffePas encore d'évaluation

- LimnologyDocument57 pagesLimnologyShakina TalkahPas encore d'évaluation

- GeomoDocument18 pagesGeomoNkhensani HlungwaniPas encore d'évaluation

- MagtibayDocument5 pagesMagtibayMohammad Ali MaunaPas encore d'évaluation

- Ce - HydrologyDocument9 pagesCe - HydrologyMadelyn MorilloPas encore d'évaluation

- Clarification in Water TreatmentDocument7 pagesClarification in Water TreatmentIsa musaPas encore d'évaluation

- Role of The Sun PowerpointDocument21 pagesRole of The Sun PowerpointJulie Ann Sanchez100% (1)

- Tugas 2 Rekayasa Bendungan SpillwayDocument2 pagesTugas 2 Rekayasa Bendungan SpillwayYunsiyPas encore d'évaluation

- ISSS AC Program (For Participants)Document3 pagesISSS AC Program (For Participants)Dien NoelPas encore d'évaluation

- Bridge - 2001 - Characterization of Fluvial Hydrocarbon Reservoirs and Aquifers Problems and SolutionsDocument28 pagesBridge - 2001 - Characterization of Fluvial Hydrocarbon Reservoirs and Aquifers Problems and SolutionsHERiTAGE1981100% (1)