Académique Documents

Professionnel Documents

Culture Documents

Fractografy

Transféré par

Enrique Alfaro OgarrioDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fractografy

Transféré par

Enrique Alfaro OgarrioDroits d'auteur :

Formats disponibles

Materials Science and Engineering A 462 (2007) 359362

Quantitative fractography in bending-torsion fatigue

Karel Sl me ka a , Petr Ponzil b , Jaroslav Pokluda c, a c

b

Department of Materials, Queen Mary, University of London, Mile End Road, London E1 4NS, United Kingdom Department of Physics and Materials Engineering, Tomas Bata University in Zlin, sq. TGM 588, 76272 Zlin, Czech Republic c Institute of Engineering Physics, Brno University of Technology, Technick 2, 61669 Brno, Czech Republic a Received 30 August 2005; received in revised form 26 February 2006; accepted 2 March 2006

Abstract The paper deals with a quantitative analysis of fracture surface roughness generated under combined bending-torsion fatigue in a high-strength low-alloy steel. Changes in several amplitude, spectral and hybrid prole roughness parameters are investigated for sets of proles parallel and perpendicular to the local crack propagation direction in dependence on the loading ratio. Prole fractal dimension is also calculated as a scaleindependent characteristic. Most of prole roughness parameters start to rapidly increase above the critical value rc 0.5 of the loading ratio r = a /( a + a ), where a is the bending amplitude and a is the torsion amplitude. 2006 Elsevier B.V. All rights reserved.

Keywords: Quantitative fractography; Roughness; Biaxial fatigue; Fractal dimension

1. Introduction It was pointed out by many researches that the fracture surface morphology plays a very important role in the analysis of fatigue crack propagation [17]. The surface roughness is usually extremely enhanced when applying a high portion of a lower to medium amplitudes of shear loading modes II and III [3]. In such cases the crack usually propagates in an extremely complicated manner making local arrests and forming branch/twist crack morphology or the so-called factory roof. On the contrary, a high amount of opening loading mode reduces the surface interaction, which leads to a visually at fracture surface appearance. A qualitatively similar result is produced by an intensive friction when applying a high-amplitude shear in modes II and III [1,2]. The effort to approach the fractography (and the roughness) in a more quantitative way has led to many interesting studies on the interconnection between the morphology and loading or ambient environment (e.g. [510]). Nevertheless, an unambiguous characterisation of the roughness remains still an unrealised goal [10]. It seems that in order to assess the roughness more precisely a rather high number of parameters is to be determined to identify those yielding the best information in each particular case [1014]. However, the most crucial problem in

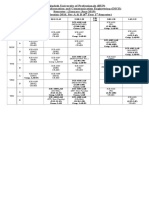

the quantitative fractography remains to be a signicant lack of experimental data from fracture surfaces created by multiaxial loading. To authors knowledge, detailed reports on quantitative analyses of roughness generated under biaxial fatigue have not been published hitherto. The current study is intended to ll the gap by reporting several types of roughness parameters characterising the morphology variation produced by a combined bendingtorsion (biaxial) loading. Here a special attention is focused on the effect of torsion (shear) loading component on roughness characteristics. Results of investigations of the variation of roughness parameters with the distance from the crack initiation site as well as of the 3D micromorphology of factory roofs were published elsewhere [15,16]. 2. Experimental procedure Five smooth specimens of a high strength low-alloy steel (ultimate tensile stress u = 950 MPa, yield strength y = 840 MPa) were fatigued until nal rapture. Symmetric (R = 1) bending and torsion loading (the frequency of 29 Hz) were applied at the room temperature. The experiments were conducted using the fatigue test machine MZGS-100. Loading settings and achieved fatigue life data are collected in Table 1, where a is the bending amplitude, a the torsion amplitude, r is the loading parameter dened as r = a /( a + a ) and Nf is the number of cycles to failure. For all investigated specimens

Corresponding author. Tel.: +420 541 142 827; fax: +420 541 142 842. E-mail address: pokluda@fme.vutbr.cz (J. Pokluda).

0921-5093/$ see front matter 2006 Elsevier B.V. All rights reserved. doi:10.1016/j.msea.2006.03.153

360 Table 1 Experimental data Specimen 1 2 3 4 5 Pure bending Combined bending-torsion Pure torsion

K. Sl me ka et al. / Materials Science and Engineering A 462 (2007) 359362 a c

a (MPa) 738.00 559.86 329.37 135.95 0

a (MPa) 0 203,38 330,30 372,82 399.00

r 0.00 0.27 0.50 0.73 1.00

Nf (cycles) 102,560 14,880 68,400 100,160 100,400

all analysed areas: the rst one in the crack propagation direction (y-direction in Fig. 1) and the second one in the perpendicular direction (x-direction in Fig. 1) marking thus different positions of the progressing crack front. Several types of roughness parameters were adopted. Prole amplitude parameters inuenced only by changes in the vertical z-co-ordinate are represented here by the vertical prole range Rz (the difference between the highest and the lowest prole points), and by the arithmetic roughness Ra . The latter quantity, also known as the centre line average, is dened as Ra = 1 N

N

the fatigue life of Nf (104 , 105 ) cycles lies within a transition region between the high-cycle and the low-cycle fatigue. The differences in the fatigue life are small enough to enable a mutual comparison of fracture morphologies of the investigated specimens. Topographical 3D data of selected parts on each fracture surface were obtained by means of stereophotogrammetry (e.g. [17,18]) using the scanning electron microscope for the acquirement of stereopairs and the commercial software package MeX for their subsequent processing. Output digital elevation model (DEM) data les consisted of up to 300,000 non-equidistantly localised points. For each specimen the square area of size 0.25 mm2 was chosen with its centre at the distance of 0.8 mm from the fatigue crack initiation site on the specimen surface. After a careful microscopic examination, square sites were oriented parallel with (or perpendicular to) the local direction of the fatigue crack propagation (Fig. 1). Using Delaunay triangulation, two sets, each consisting of 100 proles, were traced for

(zi z ),

i=1

(1)

where N is the number of valid data points and z is the mean height value. Other determined amplitude parameters, the skewness and the kurtosis, did not reveal any connection to the loading mode and their values seemed to be more or less random. Hybrid parameters affected by both the asperity amplitudes and spacing are represented by linear roughness RL [11] as the ratio of the true prole length L and its projected length L : RL = L . L (2)

The spectral character of proles was evaluated using the elevation power spectrum density (EPSD) curves calculated via a fast Fourier transformation (FFT) algorithm. Each EPSD curve constitutes prole transformation to the frequency space [10].

Fig. 1. Analysed areas(a) the pure bending: r = 0, (b) r = 0.27, (c) r = 0.50, (d) r = 0.73 and (e) the pure torsion: r = 1. Each image represents a 0.5 mm 0.5 mm area of fracture surface with its centre located at the distance of 0.8 mm from the fatigue crack initiation site on the specimen surface.

K. Sl me ka et al. / Materials Science and Engineering A 462 (2007) 359362 a c

361

Fig. 2. Roughness characteristics in the direction perpendicular to the local crack propagation direction. (a) The vertical range Rz ; (b) the arithmetic roughness Ra .

Fig. 3. Linear roughness RL of proles perpendicular and parallel to the local crack propagation direction.

A self-similarity of fracture morphology can be quantied, for example, by its linear fractal dimension DL by measuring the dependence: RL () = C0 (DL 1) (3)

where is the used measurement unit and C0 is the dimensionless constant. Before the calculation of roughness parameters, each prole was smoothed in a spatial domain using the mean ltering with three-element kernel to reduce errors possibly introduced by the stereophotogrammetrical reconstruction [17,18]. EPSD curves were calculated using original unltered proles rearranged to obtain equidistant data sets required by the FFT algorithm. 3. Results and discussion The vertical range Rz parameter for proles perpendicular to the crack propagation direction (x-direction) is shown in Fig. 2a. The proles in the y-direction exhibited a very similar geometry. Curves for particular specimens are labelled by the loading ratio r, see Table 1. As expected, the highest Rz values and highest oscillations in both directions are achieved for specimens 4 and 5. Despite of visual differences, the parameter Rz becomes nearly the same value for specimens 13 (r 0.5). Although Ra

is expected to be much less sensitive to extremes than Rz , both these characteristics reveal similar behaviour as can be seen from Fig. 2b (x-direction). Again, there was no signicant difference between proles in the x- and y-direction. The highest value of the parameter RL is achieved for the specimen 4 followed, most frequently, by the specimen 5, as shown in Fig. 3. The linear roughness RL demonstrates a

Fig. 4. EPSD curves averaged for proles parallel to the local crack propagation direction, and passing through the middle of analysed areas. Polynomial tting curves are shown as well.

362

K. Sl me ka et al. / Materials Science and Engineering A 462 (2007) 359362 a c

Fig. 5. Examples of fractal charts in the crack propagation direction. (a) The dependence of the linear roughness RL on the measuring scale (sigmoidal tting curves are shown as well); (b) the fractal dimension DL .

different character of proles taken in x- and y-direction. There are distinct increasing trends for specimens 13 and 5 and a decreasing trend for specimen 4 in the x-direction, contrary to more or less random values for proles taken perpendicularly to the crack front. The higher sensitivity is probably caused by the fact, that the parameter RL reects both the vertical heights and the spatial connections of surface points. Due to the extremely time-consuming analysis, EPSD curves were calculated for only ve proles passing through the middle of each area. Averaged EPSD curves for the y-direction are shown as grey oscillating curves together with their exponential ttings in Fig. 4. All tting curves are found to be almost parallel for spatial wavelengths in the range of 3090 m with the highest energy for the specimen 4. For higher spatial frequencies, the highest energies correspond to specimens 4 and 5 (r 0.5). Proles taken in the x-direction did not reveal any signicant difference. Examples of fractal plots are shown in Fig. 5a and b. The three different proles, exhibiting a typical sigmoidal curvature [12], are oriented perpendicularly to the crack propagation direction and located at y = 0, e.g. on the bottom edges of Fig. 1(a), (c) and (e). Eq. (3) is fullled in the range of (2, 10) m for the prole from the specimen 1, and in a wider range of (2, 20) m for proles of specimens 3 and 5. Similar behaviour can be expected also for specimens 2 and 4. Values of DL were extracted as a linear t of log RL log dependencies in the range of (2, 10) m. Fractal dimension values are shown for y-direction in Fig. 5b and resemble the RL -curves in Fig. 3. Again, both specimens 4 and 5 (r 0.5) reveal the highest geometrical tortuosity from the fractal point of view. The curves for the x-direction were qualitatively similar but quantitatively slightly different. 4. Conclusion The quantitative study of biaxial-fatigued fracture surfaces roughness yielded the following main results: (i) Results conrm the great inuence of torsion loading component on the surface topography. The critical value of the loading ration rc 0.5 can clearly be distinguished.

For loadings of r < 0.5 (the bending prevails), the surface roughness remains nearly on the same level. Once the critical value is exceeded (torsion prevails), the fatigue crack propagates in much more complicated manner resulting in a distinctly higher surface roughness. (ii) Some of studied roughness parameters, namely the hybrid linear roughness RL and the linear fractal dimension DL , have shown a good sensitivity to the prole orientation. This is assumed to be caused by their dependence on both amplitude and spacing of the asperities. Acknowledgement The research was supported by the Czech Science Foundation in the frame of the project no. 106/05/0055. References

[1] A. Vaziri, H. Nayeb-Hashemi, Eng. Fract. Mech. 72 (2005) 617629. [2] D.F. Socie, G.B. Marquis, Multiaxial Fatigue, Society of Automotive Engineers Inc., Warrendale, PA, 2000. [3] J. Pokluda, Pippan Fatigue Fract. Eng. Mater. Struct. 28 (2005) 179 185. [4] L.P. Pook, Crack Paths, Wit Press, 2002. [5] F.V. Antunes, A. Ramalho, J.M. Ferreira, Int. J. Fatigue 22 (2000) 781788. [6] T. Kobayashi, D.A. Shockey, Int. J. Fatigue 23 (2001) S135S142. [7] X.W. Li, J.F. Tian, N.L. Han, Z. Kang, Z.G. Wang, Mater. Lett. 29 (1996) 235240. [8] H. Lauschmann, I. Nedbal, Image Anal. Stereol. 21 (2002) 139144. [9] J. Pokluda, P. Sandera, in: A. Carpintieri (Ed.), International Congress on Fracture (ICF 11), Centro Congressi Internazionale, Torino, 2005 (CD). [10] P. Dooley, S.L. Bernasek, Surf. Sci. 406 (1998) 206220. [11] E.E. Underwood, K. Banerjee, Metals Handbook, vol. 12, ASM International, Metals Park, OH, USA, 1992, pp. 193210. [12] E.E. Underwood, K. Banerjee, Metals Handbook, vol. 12, ASM International, Metals Park, OH, USA, 1992, pp. 212215. [13] E. Charkaluk, M. Bigerelle, A. Iost, Eng. Fract. Mech. 61 (1998) 119 139. [14] E.S. Gadelmawla, M.M. Koura, T.M.A. Maksoud, I.M. Elewa, H.H. Soliman, J. Mater. Proc. Technol. 123 (2002) 133145. [15] K. Sl me ka, J. Pokluda, Advanced Fracture Mechanics for Life and Safety a c Assessments (ECF15), KTH, Stockholm, 2004 (CD). [16] K. Sl me ka, J. Pokluda, Mater. Sci. Forum 482 (2005) 263266. a c [17] S. Scherer, O. Kolednik, Eur. Microsc. Anal. (2001) 1517. [18] W.D. Lockwood, A.P. Reynolds, Mater. Charact. 42 (1999) 123134.

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Davis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersDocument8 pagesDavis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersAngeloPas encore d'évaluation

- Scope and Sequence 2020 2021...Document91 pagesScope and Sequence 2020 2021...Ngọc Viễn NguyễnPas encore d'évaluation

- Headlight Washer System: Current Flow DiagramDocument3 pagesHeadlight Washer System: Current Flow DiagramLtBesimPas encore d'évaluation

- Visual Metaphor Process BookDocument18 pagesVisual Metaphor Process Bookmatt8859Pas encore d'évaluation

- Learning Plans in The Context of The 21 ST CenturyDocument29 pagesLearning Plans in The Context of The 21 ST CenturyHaidee F. PatalinghugPas encore d'évaluation

- DTS 600 GDO Installation ManualDocument12 pagesDTS 600 GDO Installation Manualpiesang007Pas encore d'évaluation

- SD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore FacilitiesDocument33 pagesSD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore Facilitiestho03103261100% (1)

- ANNEXESDocument6 pagesANNEXESKyzer Calix LaguitPas encore d'évaluation

- Dayco-Timing Belt Training - Entrenamiento Correa DentadaDocument9 pagesDayco-Timing Belt Training - Entrenamiento Correa DentadaDeiby CeleminPas encore d'évaluation

- Mba633 Road To Hell Case AnalysisDocument3 pagesMba633 Road To Hell Case AnalysisAditi VarshneyPas encore d'évaluation

- Program of ActivitiesDocument2 pagesProgram of ActivitiesVon Limuel LopezPas encore d'évaluation

- Class Routine Final 13.12.18Document7 pagesClass Routine Final 13.12.18RakibPas encore d'évaluation

- ISO-50001-JK-WhiteDocument24 pagesISO-50001-JK-WhiteAgustinusDwiSusantoPas encore d'évaluation

- 1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Document880 pages1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Mike Marquez100% (2)

- A First Etymological Dictionary of BasquDocument29 pagesA First Etymological Dictionary of BasquDaily MailPas encore d'évaluation

- Paper Ed Mid TermDocument2 pagesPaper Ed Mid Termarun7sharma78Pas encore d'évaluation

- Research Project Presentation of Jobairul Karim ArmanDocument17 pagesResearch Project Presentation of Jobairul Karim ArmanJobairul Karim ArmanPas encore d'évaluation

- Control System PPT DO1Document11 pagesControl System PPT DO1Luis AndersonPas encore d'évaluation

- A New Procedure For Generalized Star Modeling Using Iacm ApproachDocument15 pagesA New Procedure For Generalized Star Modeling Using Iacm ApproachEdom LazarPas encore d'évaluation

- Handbook On National Spectrum Management 2015Document333 pagesHandbook On National Spectrum Management 2015Marisela AlvarezPas encore d'évaluation

- How To Install 64 Bits IDES On 32 Bits OSDocument1 pageHow To Install 64 Bits IDES On 32 Bits OSMuhammad JaveedPas encore d'évaluation

- 20235UGSEM2206Document2 pages20235UGSEM2206Lovepreet KaurPas encore d'évaluation

- Auto CadDocument67 pagesAuto CadkltowerPas encore d'évaluation

- Causal Emergence - HoelDocument18 pagesCausal Emergence - HoelFelipe LopesPas encore d'évaluation

- Use The Analysis ToolPak To Perform Complex Data Analysis - Excel - OfficeDocument5 pagesUse The Analysis ToolPak To Perform Complex Data Analysis - Excel - OfficedakingPas encore d'évaluation

- Operation and Service 69UG15: Diesel Generator SetDocument72 pagesOperation and Service 69UG15: Diesel Generator Setluis aguileraPas encore d'évaluation

- Hume 100 ReviewerDocument7 pagesHume 100 ReviewerShai GaviñoPas encore d'évaluation

- The Confucian Transformation of Korea: Harvard-Yen Ching Institute Monograph SeriesDocument456 pagesThe Confucian Transformation of Korea: Harvard-Yen Ching Institute Monograph SeriesAnna D.Pas encore d'évaluation

- Mobility StrategyDocument38 pagesMobility StrategySoubhagya PPas encore d'évaluation

- Angle ModulationDocument26 pagesAngle ModulationAtish RanjanPas encore d'évaluation