Académique Documents

Professionnel Documents

Culture Documents

Technical - Tables Siemens Cables

Transféré par

Ion Logofătu AlbertTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Technical - Tables Siemens Cables

Transféré par

Ion Logofătu AlbertDroits d'auteur :

Formats disponibles

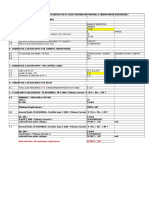

TECHNICAL TABLES AND FORMULAE

Motor Currents

Approximate current per phase for AC Motors at full load, assuming

average efciency and Power Factor.

Three Phase Formulae

kW

= Line Amps x Line Volts x 1.732 x P.F

1000

kVA

= Line Amps x Line Volts x 1.732

1000

kW

= kVA x P.F

THREE PHASE AC MOTORS (415V AC)

Power

kW

0.75

1.1

1.5

2.2

3.0

4.0

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

110

132

150

160

185

200

220

250

315

355

400

450

500

Horse Power

HP

1.0

1.5

2.0

3.0

4.0

5.5

7.5

10

15

20

25

30

40

50

60

75

100

120

150

180

200

220

250

270

300

340

430

480

545

610

680

Full Load Current

A

1.9

2.5

3.5

5.0

6.5

8.0

11

14

21

28

35

40

55

66

80

102

135

165

200

230

260

280

325

350

385

450

545

580

650

740

820

Electric Motors

Power Output

kW Output

= Power Input x Efciency

= kW Input x Efciency

kW Output

= 1.732 x Line Volts x Line Amps x P.F x Efciency

1000

kVA Input

= 1.732 x Line Volts x Line Amps

1000

Line Current

(Input)

Line Current

(Input)

= 1000 x kVA Input

Line Volts x 1.732

1000 x kW Output

Line Volts x 1.732 x P.F x Efciency

Table 6.1

156

Technical Support Phone 03) 9721 7281

Sales Phone 131 773

Sales Phone 131 773

Technical Support Phone 03) 9721 7281

157

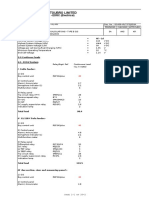

PERMISSIBLE SHORT CIRCUIT TEMPERATURE

AND THE PROSPECTIVE FAULT LEVEL FOR

CABLES AND THEIR INSULATION

Based on the nal (permissible) short circuit temperature of a

fault duration of 1 sec, the values for calculating the prospective

fault are listed below.

Insulation

Permissible Rated

Operating

Temperature

Permissible Short

Circuit

Temperature

Conductor temperature at the beginning of the short

circuit in C

Silicone

180

350

PVC

75

150

Untinned

Conductor

90

250

Tinned

Conductor

90

200

EVA

125

250

126 135 143 148 154 159 165 170 176

Tinned

Conductor

200

49

65

79

91

102 112 122 128 136 141 147 153 159

Soldered

Joint

160

36

58

74

180 165 150 135 120 105

90

80

70

60

50

40

30

J thr for 1 sec in A/mm

132 139 146 153 160 166 173 178 182 187 191 196 201

-

- 109 117 124 131 138

EPR

143 148 154 159 165 170 176

122 128 135 141 147 153 159

87

100 107 115 122 129 136 143

Table 6.2

158

Technical Support Phone 03) 9721 7281

Sales Phone 131 773

Sales Phone 131 773

Technical Support Phone 03) 9721 7281

159

Support for Vertically Suspended Cables

Formula for calculating the

fault level I thr of a cable

I thr

Example:

J thr x conductor size in mm2

A 4 x 25mm2 EPR/CSP fully loaded and

therefore having a continuous conductor

operating temperature of 90oC

I thr

=

143 x 25

=

3.58 kA for 1 second

For fault durations up to 5 sec or below 1 sec the following equation

is applicable (example is for 0.2 sec fault).

=

I(1

1 sec

=

I(1s) x

I thz

0.2 sec

The anchoring of cables is best achieved with a stress relief drum. The

open ended construction facilitates installation and replacement while

affording better stress relief and jacket protection than cable grips. At

least 2 1/2 cable turns should be wound around the drum. Refer to the

minimum Bending Radii data for each cable type to determine the

stress relief drum diameter.

Suggested stress relief drum design

Connection Point

Cable Suspension

The maximum free suspension height in metres for

reeling cables that must be vertically suspended shall be

calculated utilising the following.This formula protects the

copper conductors from deformation past their elastic limit.

Conductor deformation leads to cork screws and possible core

breakages.

Height

C x CSA x N

W x 9.8

C

CSA

N

W

=

=

=

=

Number of Conductors in the cable

Conductor Cross Section in mm2

Max. Tensile limit in N/mm2 of the cable

Cable Weight in kg/mtr

Example: Cordaex (K) 5 x 1.5 mm2

= 5 x 1.5 x 20

= 150

0.26 x 9.8

2.54

160

Technical Support Phone 03) 9721 7281

Single

Clamp

Fixed

Mounting

59 mtrs

maximum

suspension

height

Sales Phone 131 773

Stress Relief

Drum

Cable

Sales Phone 131 773

Technical Support Phone 03) 9721 7281

161

CHEMICAL RESISTANCE OF DIFFERENT

Chemical

PCP

3.3kV Flex

Neoprene 1

Acetic acid

Benzene

Bitumous tar

Bleach (NaCLO2)

Coke oven gas

Diesel oil

Ethylene glycol

Gasoline

Hydraulic oil

Hydrochloric acid (21%)

Hydrogen sulphide

Kerosene

Methanol

Methyl ethyl keton

Nitric acid (10%)

Phosphoric acid (60%)

Picric acid (10%)

Potassium chloride

Sodium hydroxide (25%)

Sulphuric acid (50%)

Transformer oil

Trichlorethylene

Vegetable oils & fats

UV resistance

Ozone resistance

Water resistance

Tear & notch resistance

Low temp. exibility

Abrasion resistance

P

F

G

VG

VG

F

VG

G

VG

E

E

G

E

G

G

VG

E

E

E

E

G

P

VG

E

VG

E

VG

E

VG

PCP

CSP

Planoex

Ozoex

Protolon (SM)

Cordaex (SMK)

Protomont

Rondoex

Neoprene 2

Hypalon

P

F

G

VG

VG

F

VG

G

VG

E

E

G

E

G

G

VG

E

E

E

E

VG

P

VG

E

VG

E

E

VG

VG-E

Table 6.3

E = Excellent

VG = Very Good

The results tabled are generic for each particular sheath compound and

attack, temperature and contact contamination

CABLE SHEATH MATERIALS

F

F

G

VG

VG

VG

VG

G

VG

E

VG

G

E

G

E

E

E

E

E

E

G

P

VG

E

VG

E

G

VG

VG

CPE

PU

EPR

EVA

SI

PVCPU EPR

Mining MSR

Spreaderex

Hydrorm

EVA125

Sinotherm

Protoex

Pendantex

Chlorinated

Polyethylene

F

F

G

VG

VG

VG

VG

G

VG

E

E

G

E

G

E

E

E

E

E

E

VG

P

VG

E

VG

VG

VG

G

G-VG

Polyurethane

Ethylene

Propylene

P

P

P

E

VG

F

E

F

P

P

E

F

E

E

E

E

VG

E

E

E

F

P

VG

E

E

E

F-G

E

G

Ethylvinyl

Acetate

F

P

P

P

G

G

F

G

VG

F

G

G

P

P

P

P

F

E

P

P

G

P

G

VG

E

G

F

G

VG

Silicone

Polyvinyl

Chloride

P

F

G

VG

VG

VG

G

F

VG

VG

VG

F

G

P

VG

E

E

E

G

VG

VG

P

VG

G

E

G

VG

G

VG

G = Good

PCP Polychloroprene (Neoprene) CSP Chlorosulphonated Polyethylene (Hypalon) CPE Chlorinated

162

Technical Support Phone 03) 9721 7281

Sales Phone 131 773

F

P

G-VG

F

VG

VG

F

E

E

F

P

VG

F

G

F

G

F

E

P

P

E

F-P

E

E

E

F

E

E

E

VG

P

F

VG

F

P

E

P

E

P

P

P

E

P

P

E

P

E

P

P

P

P

E

VG

VG

E

P

E

P

F = Fair

P = Poor

should be used as such. For a more exact evaluation, the chemical concentration, duration of

should be known.

Polyethylene EPR Ethylene Propylene Rubber EVA Ethyl vinyl Acetate PVC Polyvinyl Chloride

Sales Phone 131 773

Technical Support Phone 03) 9721 7281

163

VOLT DROP

Formula 1 Actual Volts

Vd =

where

Vd =

L=

I=

mV/Am =

In accordance with AS 3000 the permissible volt drop from the point

of the connection is 5% of the supply voltage. The following tables

and formula should be used to satisfy volt drop limitations.

L x I x mV/Am

1000

volt drop in volts

route length of cable in metres

current to be carried in Amps

millivolt per ampere metre

value from Tables 6.4 and 6.5.

*With this method the drop in voltage (in volts) is given

and shall not exceed 5% of the supply voltage, i.e.,

5% of 415V = 20.75V.

Formula 2

mV/A.m value Vc

where

=

Vc =

Vd =

L=

I=

1000 x Vd

LxI

millivolts per Ampere metre

volt drop in volts

route length of cable in metres

current to be carried in Amps

* With this method the millivolts per ampere metre is given

and the appropriate conductor size shall be selected from

Tables 6.5 and 6.6. The conductor size selected shall be

nearest to, but not exceed the formula result,

e.g.,

415V, 3 phase installation,

load demand is 55A,

100m length: OZOFLEX

Result: 3.77mV/A.m 4 x 10mm2

164

Technical Support Phone 03) 9721 7281

Sales Phone 131 773

Three Phase Voltage Drop - Single Core Cables in Trefoil

Conductor

Three Phase Voltage Drop at 50Hz, mV/Am

Size

Conductor Temperature C

45C

mm2

Max.

60C

0.8pf

Max.

75C

0.8pf

Max.

90C

0.8pf

Max. 0.8pf

1.0

33.9

35.9

37.6

39.5

1.5

22.9

24.1

25.3

26.7

2.5

13.7

14.4

15.2

15.9

8.68

9.14

9.62

10.1

5.80

6.11

6.42

6.74

10

3.43

3.64

3.83

4.00

16

2.18

2.30

2.41

2.53

25

1.28

1.35

1.42

1.48

35

1.00

1.06

1.11

1.16

50

0.748

0.788

0.824

0.863

70

0.532

0.558

0.584

0.627

95

0.411

0.430

0.447

0.464

120

0.331

0.345

0.357

0.371

150

0.286

0.303

0.307

185

0.244

0.244

0.251

0.251

0.260

0.259

0.269 0.267

240

0.213

0.210

0.218

0.215

0.223

0.221

0.229 0.227

300

0.192

0.186

0.197

0.191

0.201

0.196

0.206 0.201

400

0.178

0.167

0.182

0.171

0.184

0.174

0.187 0.178

500

0.168

0.153

0.170

0.156

0.171

0.159

0.173 0.161

630

0.159

0.141

0.160

0.142

0.161

0.144

0.164 0.150

0.319

Table 6.4

Sales Phone 131 773

Technical Support Phone 03) 9721 7281

165

WIRING SYSTEMS IN HAZARDOUS AREAS

(Not applicable to coal mining areas)

Three Phase Voltage Drop - Multicore Cables

Conductor

Size

Class I

Three Phase Voltage Drop at 50Hz, mV/Am

Conductor Temperature C

45C

mm2

Max.

1.0

1.5

2.5

4

6

10

16

25

35

50

70

95

120

150

185

240

300

400

500

630

33.4

23.2

14.0

8.85

5.91

3.52

2.22

1.30

1.01

0.759

0.533

0.438

0.324

0.274

0.234

0.196

0.175

0.161

0.145

0.138

0.8pf

0.196

0.175

0.154

0.136

0.124

60C

Max

0.8pf

36.5

24.4

14.7

9.32

6.24

3.69

2.32

1.37

1.07

0.797

0.559

0.424

0.339

0.284

0.242

0.201

0.180

0.164

0.147

0.139

0.201

0.178

0.158

0.139

0.126

75C

Max.

0.8pf

38.6

25.6

15.5

9.82

6.56

3.90

2.46

1.44

1.12

0.837

0.589

0.445

0.353

0.298

0.253

0.208

0.184

0.173

0.149

0.140

0.207

0.183

0.162

0.142

0.128

90C

Max. 0.8pf

40.4

29.0

16.2

10.3

6.88

4.07

2.58

1.51

1.18

0.875

0.613

0.464

0.367

0.308

0.260

0.213

0.197

0.189

0.151

0.142

Intrisically safe systems in

accordance with AS 2381.7

Cable in metallic conduit

Served MIMS

PVC, elastomer or silicone sheathed;

circular unarmoured

PVC, elastomer or silicone sheathed;

armoured

Cables in rigid and exible,

non-metallic conduit

0.213

0.188

0.165

0.145

0.131

Metal sheathed, served and armoured

Flexible cords and cables in

accordance with Clause 3.16.1 AS 2381.1 - 1991

Cables in corrugated non-metallic

conduit

Metal sheathed, served and

unarmoured

X

Table 6.6

X denotes acceptable use

Table 6.5

NOTE: The values in the tables are taken from AS 3008.1 and

based on cables operating at maximum conductor temperature. For

lightly loaded cables the standard also permits determination of the

appropriate Vd in such cases and therefore the tables list reduced

conductor temperatures.

166

Class II

Zone 0 Zone 1 Zone 2

Technical Support Phone 03) 9721 7281

Sales Phone 131 773

Clause 3.16.1 - AS2381.1-1991 states that the maximum length of

the exible cable shall be 600mm in Class 1 Zone 0 and Zone 1.

This table, extracted from the hazardous location standard AS2381.1,

nominates the allowable cable types for each Class and Zone

classication.

Fibre optic cables can be used in all areas without further protection.

Sales Phone 131 773

Technical Support Phone 03) 9721 7281

167

DE-RATING FOR PARALLEL CONNECTION

The following factors should be applied to conductors

connected in parallel for the various methods of installation.

Table taken from AS 3008.1.

Arrangement of Cables

1

De-rating Factors

No. of Circuits/Cables in parallel

8

9

10

12

14

16

18

-

1.

Bunched in air

1.00

0.87

0.75

0.72

0.70

0.67

2.

Bunched on a surface or

enclosed in conduit or

ducting

1.00

0.80

0.70

0.65

0.60

0.57

0.54

0.52

0.50

0.48

0.45

0.43

0.41

3.

Single

layer on

wall or oor

Touching

1.00

0.85

0.79

0.75

0.73

0.72

0.72

0.71

0.70

Spaced*

1.00

0.94

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

Touching

0.95

0.81

0.72

0.68

0.64

0.63

0.62

0.61

Spaced*

0.95

0.85

0.85

0.85

0.85

0.85

0.85

0.85

0.85

0.85

0.85

0.85

0.85

4.

5.

Single

layer under

ceiling

6.

20 or

more

-

0.39 0.38

-

0.90 0.90

-

0.85 0.85

Table 6.7

NOTE: De-rating is necessary for the purpose of thermal

dissipation.

If sufcient clearance from adjacent conductors/cables is

allowed for then no de-rating is necessary. To avoid de-rating

a minimum clearance of 2 x cable O.D for horizontal, and

4 x cable O.D for vertical installation in air are given

in AS 3008.1

* Spaced in the above table indicates a clearance of 1 x cable

O.D between adjacent cables.

168

Technical Support Phone 03) 9721 7281

Sales Phone 131 773

Sales Phone 131 773

Technical Support Phone 03) 9721 7281

169

ATTENUATION DATA FOR CORDAFLEX AND

Attenuation Data

for Individually

Individually Screened Conductors

Screened

Frequency

Line Attenuation Impedance

Conductors

Hz

dB/1000ft

dB/km

Z

300

0.26

0.85

200

600

0.37

1.2

150

1200

0.52

1.7

110

2400

0.70

2.3

90

4800

0.98

3.2

60

9600

1.28

4.2

50

19200

1.52

5.0

40

38400

1.83

6.0

38

48000

1.92

6.3

35

57600

1.38

6.5

35

115200

2.44

8.0

35

153600

2.59

8.5

35

PLANOFLEX SCREENED CORES

Capacitance

pF/ft

nF/km

61.0

200.2

61.0

200.0

61.0

200.0

60.9

199.9

60.8

199.6

60.7

199.0

60.5

198.6

60.4

198.0

60.3

197.9

60.3

197.8

60.2

197.4

60.1

197.2

Inductance

mH/1000ft mH/km

0.08

0.256

0.08

0.256

0.08

0.256

0.08

0.256

0.08

0.256

0.08

0.256

0.08

0.256

0.08

0.251

0.08

0.249

0.08

0.248

0.07

0.238

0.07

0.235

Resistance

/1000ft

/km

15.2

50

15.2

50

15.2

50

15.2

50

15.2

50

15.2

50

15.2

50

15.8

52

16.5

54

16.8

55

19.2

63

20.4

67

Capacitance

pF/ft

nF/km

31.3

102.6

30.9

101.4

30.5

100.2

30.2

99.2

30.1

98.6

29.9

98.1

29.8

97.6

29.6

97.2

29.6

97.0

29.5

96.9

29.4

96.4

29.3

95.9

Inductance

mH/1000ft mH/km

0.21

0.69

0.21

0.69

0.21

0.69

0.20

0.67

0.20

0.66

0.20

0.65

0.19

0.61

0.17

0.56

0.16

0.54

0.16

0.52

0.14

0.47

0.14

0.46

Resistance

/1000ft

/km

7.9

26

7.9

26

7.9

26

7.9

26

7.9

26

9.1

30

11.0

36

14.6

48

15.8

52

17.1

56

23.8

78

26.8

88

Table 6.8

Attenuation Data

for Twisted

Twisted Screened Pairs

Screened Pair

Frequency

Line Attenuation Impedance

Conductors

Hz

dB/1000ft

dB/km

Z

300

0.13

0.42

250

600

0.18

0.60

200

1200

0.24

0.80

150

2400

0.30

1.0

130

4800

0.40

1.3

100

9600

0.46

1.5

90

19200

0.61

2.0

85

38400

0.85

2.8

80

48000

1.01

3.3

78

57600

1.07

3.5

75

115200

1.68

5.5

70

153600

1.74

5.7

70

Table 6.9

170

Technical Support Phone 03) 9721 7281

Sales Phone 131 773

Sales Phone 131 773

Technical Support Phone 03) 9721 7281

171

DC AND AC RESISTANCE OF FLEXIBLE CABLES

Conductor

Size

mm2

0.5

0.75

1.0

1.5

2.5

4

6

10

16

25

35

50

70

95

120

150

185

240

300

400

500

Single Core

Conductor Temperature C

DC resistance

/km

20C

38.2

25.4

19.1

13.0

7.82

4.85

3.32

1.93

1.18

0.710

0.521

0.391

0.258

0.202

0.156

0.123

0.101

0.0835

0.0613

0.0452

0.0373

AND CORDS WITH COPPER CONDUCTORS

Conductor

Size

AC resistance at 50 Hz, /km

60C

29.4

22.1

15.0

9.05

5.61

3.74

2.23

1.37

0.822

0.603

0.453

0.299

0.235

0.182

0.144

0.119

0.0928

0.0740

0.0565

0.0483

75C

30.9

23.2

15.8

9.51

5.90

3.93

2.35

1.44

0.864

0.634

0.476

0.314

0.246

0.191

0.151

0.125

0.0972

0.0775

0.0590

0.0503

90C

32.4

24.4

16.6

10.0

6.18

4.12

2.46

1.50

0.906

0.665

0.499

0.330

0.258

0.200

0.158

0.131

0.102

0.081

0.0615

0.0523

mm2

0.5

0.75

1.0

1.5

2.5

4

6

10

16

25

35

50

70

95

120

150

185

240

300

400

500

Multicore

Conductor Temperature C

DC resistance

/km

20C

40.1

26.7

20.0

13.7

8.21

5.09

3.39

2.02

1.24

0.746

0.547

0.410

0.271

0.212

0.164

0.129

0.106

0.0877

0.0644

0.0475

0.0392

AC resistance at 50 Hz, /km

60C

45.1

30.9

23.1

15.9

9.50

5.89

3.92

2.34

1.44

0.864

0.633

0.475

0.315

0.247

0.191

0.151

0.125

0.0981

0.0787

0.0606

0.0522

75C

47.4

32.5

24.3

16.7

10.0

6.19

4.12

2.46

1.51

0.908

0.666

0.499

0.331

0.259

0.201

0.159

0.131

0.103

0.0824

0.0632

0.0542

90C

49.7

34.0

25.5

17.5

10.5

6.49

4.32

2.58

1.58

0.952

0.698

0.523

0.346

0.271

0.211

0.166

0.138

0.107

0.0860

0.0658

0.0563

Table 6.10

Table 6.10 lists measured values that conform to AS 3008.1

for rope laid exible cables. For cables with an alternate core

length of lay (e.g., CORDAFLEX) the values will alter slightly.

172

Technical Support Phone 03) 9721 7281

Sales Phone 131 773

Sales Phone 131 773

Technical Support Phone 03) 9721 7281

173

Vous aimerez peut-être aussi

- 2240 162 Pve U 004 SHT 3 3 01Document13 pages2240 162 Pve U 004 SHT 3 3 01Anagha DebPas encore d'évaluation

- Knowledge is "Real Power": Introduction to Power QualityD'EverandKnowledge is "Real Power": Introduction to Power QualityPas encore d'évaluation

- Fault Level One PointDocument19 pagesFault Level One Pointkapil100% (1)

- Cu Lugs FerrulesDocument11 pagesCu Lugs FerrulesSreekanth RaveendranPas encore d'évaluation

- Power Cable Schedule and Sizing CalculationDocument3 pagesPower Cable Schedule and Sizing Calculationankit singlaPas encore d'évaluation

- S.No. Technical Parameters Specified 110Kv 1250A Electrically Motor (Cum) Manually Operated IsolatorDocument19 pagesS.No. Technical Parameters Specified 110Kv 1250A Electrically Motor (Cum) Manually Operated IsolatorneerajPas encore d'évaluation

- VR La Batterie Edited 15Document8 pagesVR La Batterie Edited 15SOMU_61Pas encore d'évaluation

- AAC American Sizes ASTM B231 / B231M Stranded Aluminum ConductorsDocument2 pagesAAC American Sizes ASTM B231 / B231M Stranded Aluminum ConductorsRejnald ZyfiPas encore d'évaluation

- Cable SizingDocument9 pagesCable Sizingmuhammad nazirPas encore d'évaluation

- H LV Switch Gear Functions and SelectionDocument28 pagesH LV Switch Gear Functions and SelectionRavindar ArumugamPas encore d'évaluation

- Cal-Mn Dastur T2117 Rev 2Document4 pagesCal-Mn Dastur T2117 Rev 2Shubham BaderiyaPas encore d'évaluation

- CT Sizing For MalawiDocument2 pagesCT Sizing For MalawiDharmenderSinghChoudharyPas encore d'évaluation

- Swing and Deflection CalculationsDocument28 pagesSwing and Deflection CalculationsanandpurushothamanPas encore d'évaluation

- Merlin Gerin Medium VoltageDocument10 pagesMerlin Gerin Medium VoltagekjfenPas encore d'évaluation

- AAAC ConductorDocument3 pagesAAAC ConductorRelief_EngineerPas encore d'évaluation

- Suspension Insulation String BuDocument11 pagesSuspension Insulation String BuM_D_MendisPas encore d'évaluation

- Sizing CalcDocument1 pageSizing Calckarthikraja21Pas encore d'évaluation

- Info Iec60038 (Ed6.2) en DDocument4 pagesInfo Iec60038 (Ed6.2) en DArief Muhammad LubisPas encore d'évaluation

- Case - 2.6 Ef (Star TCC)Document1 pageCase - 2.6 Ef (Star TCC)joshPas encore d'évaluation

- 13.MCB For Motor ProtectionDocument48 pages13.MCB For Motor Protectionrajinipre-1Pas encore d'évaluation

- Selective Coordination Breaker Application ChartDocument5 pagesSelective Coordination Breaker Application Charthanner90Pas encore d'évaluation

- Bangladesh National Building Code 2012 Part6 Chapter 6Document111 pagesBangladesh National Building Code 2012 Part6 Chapter 6morphie_blackPas encore d'évaluation

- Calculate Size of ContactorDocument3 pagesCalculate Size of ContactordhruvPas encore d'évaluation

- PyrometerDocument6 pagesPyrometerCikgu KimpalanPas encore d'évaluation

- Caledoniana HT CableDocument100 pagesCaledoniana HT Cable1382acePas encore d'évaluation

- Sheild CalculationDocument9 pagesSheild CalculationPrayas SubediPas encore d'évaluation

- 03HYUNDAI Intelligent Preventative Diagnostic System (HiPDS)Document12 pages03HYUNDAI Intelligent Preventative Diagnostic System (HiPDS)juliancansenPas encore d'évaluation

- Short Circuit CalculationsDocument1 pageShort Circuit CalculationsBibin JoyPas encore d'évaluation

- Application Guide: General PointsDocument71 pagesApplication Guide: General PointsWaseem MohammedPas encore d'évaluation

- Conduit Sizing CalculationDocument17 pagesConduit Sizing CalculationAbdelKarim BaariniPas encore d'évaluation

- Available Fault Current Calculation: 0 I kVA X 1000 Trans. FLADocument8 pagesAvailable Fault Current Calculation: 0 I kVA X 1000 Trans. FLAconsultnadeem70Pas encore d'évaluation

- Voltage Drop CalculatorDocument24 pagesVoltage Drop CalculatorShahjehanSajidPas encore d'évaluation

- Heat Load Calculation of CabinetDocument4 pagesHeat Load Calculation of Cabinethemant kumar0% (1)

- Operating Temperature Within LV Switchgear - EEPDocument6 pagesOperating Temperature Within LV Switchgear - EEPSundaresan SabanayagamPas encore d'évaluation

- Current Carrying Capacities & Other Technical TablesDocument7 pagesCurrent Carrying Capacities & Other Technical TablesImran_firdousiPas encore d'évaluation

- Short Circuit Rating Selection Criteria For Circuit Breaker in PV PlantsDocument12 pagesShort Circuit Rating Selection Criteria For Circuit Breaker in PV PlantsMohamed KhayerallaPas encore d'évaluation

- ! - 1979 - Drouet, M., & Nadeau, F. - Pressure Waves Due To Arcing Faults in A SubstationDocument4 pages! - 1979 - Drouet, M., & Nadeau, F. - Pressure Waves Due To Arcing Faults in A SubstationMikePas encore d'évaluation

- 3ph Isc at LV InstallationDocument7 pages3ph Isc at LV InstallationbambangPas encore d'évaluation

- PV System Load Estimation WorksheetDocument10 pagesPV System Load Estimation WorksheetAndrei HorhoianuPas encore d'évaluation

- Battery Sizing 3 Trafo (Latest)Document20 pagesBattery Sizing 3 Trafo (Latest)jm.mankavil6230Pas encore d'évaluation

- 3-Phase Short-Circuit Current (Isc) at Any Point Within A LV Installation - Electrical Installation GuideDocument5 pages3-Phase Short-Circuit Current (Isc) at Any Point Within A LV Installation - Electrical Installation Guidesiddiq shahPas encore d'évaluation

- 110kV Power Electric TransformerDocument4 pages110kV Power Electric TransformerCristian Camilo Silva GuevaraPas encore d'évaluation

- Sizing Calculations For 20/3.3 KV, 12.5 MVA Transformer Feeder CableDocument9 pagesSizing Calculations For 20/3.3 KV, 12.5 MVA Transformer Feeder CableNeomax BuildersPas encore d'évaluation

- D2.07 Non Segregated Phase Bus DuctsDocument3 pagesD2.07 Non Segregated Phase Bus DuctsSaraswatapalitPas encore d'évaluation

- KSH International Enamelled Copper Conductors/Strips BrochureDocument2 pagesKSH International Enamelled Copper Conductors/Strips Brochurekshintl100% (1)

- F87L 7SL82 rv2Document7 pagesF87L 7SL82 rv2PằngPằngChiuChiuPas encore d'évaluation

- Working Clearance For Outdoor Installation Ref IEC 61936 Fig 3 Safety Clearance Sectional Clearance Safety ClearanceDocument1 pageWorking Clearance For Outdoor Installation Ref IEC 61936 Fig 3 Safety Clearance Sectional Clearance Safety ClearanceMeghavahinaPas encore d'évaluation

- N2XYDocument2 pagesN2XYCharles SteblinaPas encore d'évaluation

- A View On Internal Arc Testing of LV SwitchgearDocument8 pagesA View On Internal Arc Testing of LV Switchgeardes1982Pas encore d'évaluation

- ACP Revit MEP Electrical Exam Objectives PDFDocument1 pageACP Revit MEP Electrical Exam Objectives PDFPavan Kumar AJPas encore d'évaluation

- Voltage Drop CalcDocument4 pagesVoltage Drop CalcnashapkPas encore d'évaluation

- REF Fuse Sizing GuideDocument11 pagesREF Fuse Sizing GuideRa ArPas encore d'évaluation

- Bus Bar Voltage Drop Calculation: Bus Bar No SR - No Location Sub Panel No Power Line Length (MT) Line Current (Amp)Document6 pagesBus Bar Voltage Drop Calculation: Bus Bar No SR - No Location Sub Panel No Power Line Length (MT) Line Current (Amp)MeghavahinaPas encore d'évaluation

- Miniature Circuit Breaker-DetailsDocument7 pagesMiniature Circuit Breaker-Detailssrabon1059Pas encore d'évaluation

- "Gas Insulated Substation: An Overview": Powergrid Corporation of India LimitedDocument35 pages"Gas Insulated Substation: An Overview": Powergrid Corporation of India LimitedSaurabh KumarPas encore d'évaluation

- IEEE STD C57.19.00-2004 (CN - EN)Document18 pagesIEEE STD C57.19.00-2004 (CN - EN)pdrich8Pas encore d'évaluation

- 33 KV Cable Sizing CalculationDocument3 pages33 KV Cable Sizing CalculationmohanadsamaraPas encore d'évaluation

- Sieyuan Electric Co., LTD: ClientDocument19 pagesSieyuan Electric Co., LTD: ClientRami The OnePas encore d'évaluation

- Calculation of Looses in Electric Power Cables As The Base For Cable Temperature AnalysisDocument9 pagesCalculation of Looses in Electric Power Cables As The Base For Cable Temperature AnalysisAzam Dan AzimPas encore d'évaluation

- Bonfignioli EWP Wheel Drives PDFDocument8 pagesBonfignioli EWP Wheel Drives PDFIon Logofătu AlbertPas encore d'évaluation

- CH2H - Hydrodynamic Drive InfoDocument2 pagesCH2H - Hydrodynamic Drive InfoIon Logofătu AlbertPas encore d'évaluation

- Using Water As A MedicineDocument4 pagesUsing Water As A MedicineIon Logofătu AlbertPas encore d'évaluation

- General Specification For Radial Type Motorised Cable ReelersDocument5 pagesGeneral Specification For Radial Type Motorised Cable ReelersIon Logofătu AlbertPas encore d'évaluation

- Vickers DCV With Manual LatchDocument12 pagesVickers DCV With Manual LatchIon Logofătu AlbertPas encore d'évaluation

- CH1H - Introduction To Specimas SystemDocument4 pagesCH1H - Introduction To Specimas SystemIon Logofătu AlbertPas encore d'évaluation

- Rubber BandsDocument11 pagesRubber BandsIon Logofătu AlbertPas encore d'évaluation

- Hogan Copy of New Price List Updted (As at 4 5 2011)Document16 pagesHogan Copy of New Price List Updted (As at 4 5 2011)Ion Logofătu AlbertPas encore d'évaluation

- Technical Specification For Road Rail Equipment FSS550Document70 pagesTechnical Specification For Road Rail Equipment FSS550Ion Logofătu AlbertPas encore d'évaluation

- 300 Signs and Symptoms of Celiac DiseaseDocument7 pages300 Signs and Symptoms of Celiac DiseaseIon Logofătu AlbertPas encore d'évaluation

- 7 Ways To Reduce Man Boobs & Decrease Estrogen LevelsDocument9 pages7 Ways To Reduce Man Boobs & Decrease Estrogen LevelsIon Logofătu AlbertPas encore d'évaluation

- Info BroucherDocument2 pagesInfo BroucherIon Logofătu AlbertPas encore d'évaluation

- Rail Wheel DrawingsDocument27 pagesRail Wheel DrawingsIon Logofătu AlbertPas encore d'évaluation

- Know Your Honey. Different Types of Honey and Their Health BenefitsDocument11 pagesKnow Your Honey. Different Types of Honey and Their Health BenefitsIon Logofătu AlbertPas encore d'évaluation

- Tips For Growing TomatoesDocument30 pagesTips For Growing TomatoesIon Logofătu Albert100% (1)

- Steel ChartDocument5 pagesSteel ChartTommie PrinslooPas encore d'évaluation

- List of Standards On File: Noise ManagementDocument2 pagesList of Standards On File: Noise ManagementIon Logofătu AlbertPas encore d'évaluation

- The Grape CulturistDocument5 pagesThe Grape CulturistIon Logofătu AlbertPas encore d'évaluation

- Amygdala: For Other Uses, See Amygdala (Disambiguation)Document16 pagesAmygdala: For Other Uses, See Amygdala (Disambiguation)Ion Logofătu AlbertPas encore d'évaluation

- John Yudkin .The Man Who Tried To Warn Us About SugarDocument5 pagesJohn Yudkin .The Man Who Tried To Warn Us About SugarIon Logofătu Albert100% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Pruning Grapevines: Young VinesDocument1 pagePruning Grapevines: Young VinesIon Logofătu AlbertPas encore d'évaluation

- Risk ManagementDocument12 pagesRisk ManagementIon Logofătu AlbertPas encore d'évaluation

- Using Water As A MedicineDocument4 pagesUsing Water As A MedicineIon Logofătu AlbertPas encore d'évaluation

- Daniel Hanna Complete List of Roses I Have Grown in SydneyDocument79 pagesDaniel Hanna Complete List of Roses I Have Grown in SydneyIon Logofătu AlbertPas encore d'évaluation

- Banana and Vanilla Tea CakeDocument10 pagesBanana and Vanilla Tea CakeIon Logofătu AlbertPas encore d'évaluation

- Demerits GeneralDocument13 pagesDemerits GeneralIon Logofătu AlbertPas encore d'évaluation

- Case Study 10 Treatment ProgramDocument5 pagesCase Study 10 Treatment ProgramIon Logofătu AlbertPas encore d'évaluation

- Case Study 12 Treatment Program1Document3 pagesCase Study 12 Treatment Program1Ion Logofătu AlbertPas encore d'évaluation

- Case Study 10 Treatment ProgramDocument5 pagesCase Study 10 Treatment ProgramIon Logofătu AlbertPas encore d'évaluation

- LIB (Lithium Ion Battery)Document27 pagesLIB (Lithium Ion Battery)Ericke Nandita MaharaniPas encore d'évaluation

- CPP & Cqa PDFDocument71 pagesCPP & Cqa PDFanon_695264516100% (1)

- Gas Laws Practice Test - Ans. KeyDocument4 pagesGas Laws Practice Test - Ans. Keycabbiemartinez100% (1)

- USP-NF Atorvastatin CalciumDocument8 pagesUSP-NF Atorvastatin CalciumPhạm Đức LộcPas encore d'évaluation

- STI - SP001-00 - Standard For Inspection of In-Service Shop Fabricated Aboveground Tanks For Storage of Combustible and Flammable LiquidsDocument20 pagesSTI - SP001-00 - Standard For Inspection of In-Service Shop Fabricated Aboveground Tanks For Storage of Combustible and Flammable LiquidsJoe BetkerPas encore d'évaluation

- Enhancement in Biogas Production From Press MudDocument5 pagesEnhancement in Biogas Production From Press MudHarsha Vardhan ReddyPas encore d'évaluation

- Graphene Quantum Dot, S: Presented by Fiza Aziz Roll No 151226 Department of PhysicsDocument25 pagesGraphene Quantum Dot, S: Presented by Fiza Aziz Roll No 151226 Department of PhysicsFiza AzizPas encore d'évaluation

- Space WeatherDocument36 pagesSpace WeatherMat MinPas encore d'évaluation

- Safety Analysis For The Production of MethanolDocument14 pagesSafety Analysis For The Production of MethanolTauseef Aamere RosePas encore d'évaluation

- Marine Adhesives Product CatalogueDocument35 pagesMarine Adhesives Product CatalogueDaniela TomovaPas encore d'évaluation

- Shell Gadus S3 Wirerope: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S3 Wirerope: Performance, Features & Benefits Main ApplicationsptscmscPas encore d'évaluation

- Fire Fighting Foam Principles and Ethanol-Blended FuelDocument38 pagesFire Fighting Foam Principles and Ethanol-Blended FuelFrancois HamiauxPas encore d'évaluation

- PoseidonDocument2 pagesPoseidonAlan CordobaPas encore d'évaluation

- Physics Today: Quantum CriticalityDocument8 pagesPhysics Today: Quantum CriticalityAndré RojasPas encore d'évaluation

- Bilal ThesisDocument63 pagesBilal ThesisKashif Ur RehmanPas encore d'évaluation

- Elec6063 Optoelectronics and Lightwave Technology: Part 2: Leds and Lasers - 1 (Leds)Document43 pagesElec6063 Optoelectronics and Lightwave Technology: Part 2: Leds and Lasers - 1 (Leds)wanxin zhouPas encore d'évaluation

- Sop of UV HPLCDocument5 pagesSop of UV HPLCSachin S RanePas encore d'évaluation

- Double Effect Absorption Water Chillers 100 To 1500 Tons: Product ManualDocument100 pagesDouble Effect Absorption Water Chillers 100 To 1500 Tons: Product ManualPraveesh ThomasPas encore d'évaluation

- Flare Header Purge Rate DataDocument3 pagesFlare Header Purge Rate DatappsutorPas encore d'évaluation

- Raghavendra Bhat. GPUC High School Section, MegaravalliDocument8 pagesRaghavendra Bhat. GPUC High School Section, Megaravallisyedyaseen39375Pas encore d'évaluation

- Process For The Preparation of Amorphous Atorvastatin Calcium From Crystalline Atorvastatin CalciumDocument7 pagesProcess For The Preparation of Amorphous Atorvastatin Calcium From Crystalline Atorvastatin CalciumDrkrishnasarma pathyPas encore d'évaluation

- Material GroupsDocument36 pagesMaterial Groupsatish chandra GautamPas encore d'évaluation

- Example Chemical and Biological CompositionDocument8 pagesExample Chemical and Biological CompositioniskandarPas encore d'évaluation

- Rate Law and The Eyring EquationDocument11 pagesRate Law and The Eyring EquationManjunath.RPas encore d'évaluation

- Carbon Enrichment in Mo SteelDocument50 pagesCarbon Enrichment in Mo SteelDhananjay ShimpiPas encore d'évaluation

- تقرير تأكل (Anodic Protection)Document10 pagesتقرير تأكل (Anodic Protection)ياسر نوفل ورد100% (1)

- Mathematics Arithmetic and Number Sense Algebra Geometry: (Answer Many Word Problems As Possible)Document5 pagesMathematics Arithmetic and Number Sense Algebra Geometry: (Answer Many Word Problems As Possible)DarlenePas encore d'évaluation

- Astm f2129Document9 pagesAstm f2129edgmundarayPas encore d'évaluation

- Chem 315 - Lab 5 - Gas Chromatography - AcetatesDocument13 pagesChem 315 - Lab 5 - Gas Chromatography - AcetateskPas encore d'évaluation

- Furnace SoftwareDocument7 pagesFurnace SoftwareolaPas encore d'évaluation