Académique Documents

Professionnel Documents

Culture Documents

z3T - Stainless Steel 15-5 PH (EOS SS PH1)

Transféré par

Martin McMahonDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

z3T - Stainless Steel 15-5 PH (EOS SS PH1)

Transféré par

Martin McMahonDroits d'auteur :

Formats disponibles

3T RPD Ltd

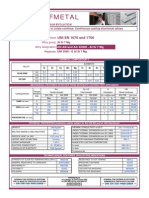

Application: EOS StainlessSteel PH1 is a pre-alloyed

Stainless Steel 15-5PH

(EOS SS PH1)

Material Specification

stainless steel in fine powder form. Its composition corresponds to US classification 15-5PH and European 1.4540 and fulfils the requirements of AMS 5659 for Mn, Mo, Ni, Si, C, Cr and Cu. This kind of steel is characterized by having very good corrosion resistance and mechanical properties, especially in the precipitation hardened state. It is widely used in a variety of medical, aerospace and other engineering applications requiring high hardness, strength and corrosion resistance. This material is ideal for many part-building applications (DirectPart) such as functional metal prototypes, small series products, individualised products or spare parts. Standard processing parameters use full melting of the entire geometry with 20m layer thickness, but it is also possible to use 40m layer thickness to increase the build speed. Using standard parameters the mechanical properties are fairly uniform in all directions. Parts made from EOS StainlessSteel PH1 can be machined, spark-eroded, welded, micro shot-peened, polished and coated if required. Unexposed powder can be re-used.

Typical applications: Engineering applications including functional prototypes, small series products, individualised products or spare parts.

Parts requiring high corrosion resistance, sterilisability, etc. Parts requiring particularly high hardness and strength.

Technical Data:

Minimum recommended Layer Thickness: Minimum Wall Thickness: Volume Rate: 20 m 0.4 mm between 1.8-3.2 mm3/s approx. 100% (7.8 g/cm3) Fe 71.5-80 wt% Cr 14-15.5 wt% Ni 3.5-5.5 wt% As built Ultimate Tensile Strength (MPIF 10) Yield strength (Rp 0.2%) Elongation at break Hardness Surface roughness - after shot-peening - after polishing - horizontal direction (XY) - vertical direction (Z) - horizontal direction (XY) - vertical direction (Z) - horizontal direction (XY) - vertical direction (Z) 1150 MPa 50 MPa 1050 MPa 50 MPa 1050 MPa 50 MPa 1050 MPa 50 MPa 16% + 4% 17% + 2% 30-35 HRC Ra 4.5 m Rz up to < 0.5 m 12.5 m/moC 13.8 + 0.8 W/moC 13.7 + 0.8 W/moC 460 + 20 J/kgoC 550oC 15.7 + 0.8 W/moC 15.8 + 0.8 W/moC 470 + 20 J/kgoC 550oC Cu 2.5-4.5 wt% Mn max 1 wt% Si max 1 wt% Mo max 0.5 wt% Nb 0.15-0.45 wt% C max 0.07 wt%

Physical and Chemical Properties:

Relative Density with Standard Parameters Material composition

Mechanical Properties at 20oC:

After age-hardening* 1450 MPa 100 MPa 1450 MPa 100 MPa 1300 MPa 100 MPa 1300 MPa 100 MPa 12% + 2% 12% + 2% min 40 HRC

Thermal Properties:

Coefficient of Thermal Expansion (20-500oC) Thermal conductivity (at 20oC) Specific heat capacity Maximum operating temperature

* Age hardening modified H900: 482 C / 4h / air cooling

- horizontal direction (XY) - vertical direction (Z) - as laser sintered

Source: EOS

To obtain a quotation, simply email your 3D CAD data to post@3trpd.co.uk or call us for free advice on +44 (0)1635 580284

www.3trpd.co.uk/dmls

ISO 9001:2000 & ISO 13485:2003 Medical Devices certifications

Vous aimerez peut-être aussi

- Applied Welding Engineering: Processes, Codes, and StandardsD'EverandApplied Welding Engineering: Processes, Codes, and StandardsPas encore d'évaluation

- S-13MN.B: ApplicationsDocument1 pageS-13MN.B: ApplicationsOcta IrawanPas encore d'évaluation

- EOS Material-Datasheet Stainless-Steel-PH1 M290 en PDFDocument5 pagesEOS Material-Datasheet Stainless-Steel-PH1 M290 en PDFMiguel A. ChávezPas encore d'évaluation

- A07-297 OD Expanded Small PartsDocument12 pagesA07-297 OD Expanded Small PartsKyle DriscollPas encore d'évaluation

- 17 4 PHDocument2 pages17 4 PHzaranrajputPas encore d'évaluation

- Supply Range of AISI M42 Tool Steel High SpeedDocument4 pagesSupply Range of AISI M42 Tool Steel High SpeedSama UmatePas encore d'évaluation

- Material Data Sheet: Eos Stainlesssteel Gp1 For Eosint M 270Document5 pagesMaterial Data Sheet: Eos Stainlesssteel Gp1 For Eosint M 270Charles SedilloPas encore d'évaluation

- Material Data Sheet: Eos Stainlesssteel Ph1 For Eosint M 270Document5 pagesMaterial Data Sheet: Eos Stainlesssteel Ph1 For Eosint M 270Charles SedilloPas encore d'évaluation

- Mild Steel SpecificationDocument1 pageMild Steel SpecificationSteinol SolutionsPas encore d'évaluation

- Tipos de Acero InoxidableDocument4 pagesTipos de Acero Inoxidablechorch123Pas encore d'évaluation

- Stainless Steel AISI Grades For PM ApplicationsDocument16 pagesStainless Steel AISI Grades For PM ApplicationsAxtronPas encore d'évaluation

- SMAW high-alloy electrode applicationsDocument1 pageSMAW high-alloy electrode applications2003vinayPas encore d'évaluation

- UNS R30006 Steel GradesDocument3 pagesUNS R30006 Steel GradesRatnakar PatilPas encore d'évaluation

- Korloy2005 CatalogueDocument44 pagesKorloy2005 CataloguezahirkamilPas encore d'évaluation

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-4 EN 10084 EN 10297-1Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-4 EN 10084 EN 10297-1farshid KarpasandPas encore d'évaluation

- AISI Type 403 Stainless Steel Properties and ApplicationsDocument7 pagesAISI Type 403 Stainless Steel Properties and ApplicationsMiguelPacheecoAgamezPas encore d'évaluation

- HCS GuidebookDocument44 pagesHCS GuidebookKorong KapampanganPas encore d'évaluation

- RFQ of C45 SteelDocument3 pagesRFQ of C45 Steelnhirpara1Pas encore d'évaluation

- Stainless Steel Grade AISI 430/430FDocument2 pagesStainless Steel Grade AISI 430/430Fabhijit.ghotane100% (1)

- Sadique Pro If SteelDocument12 pagesSadique Pro If Steelsatish_trivediPas encore d'évaluation

- Datenblatt 4105 UKDocument2 pagesDatenblatt 4105 UKVahid SarfarazPas encore d'évaluation

- Specification: EN9 - 070M55: Hollowbar - Co.zaDocument3 pagesSpecification: EN9 - 070M55: Hollowbar - Co.zaAnantha RamanPas encore d'évaluation

- Material Cross Reference TableDocument3 pagesMaterial Cross Reference TableLuis Pol SistiPas encore d'évaluation

- Brass Material Property Data Sheet for Custom FastenersDocument2 pagesBrass Material Property Data Sheet for Custom FastenersMuzammil Ali KhanPas encore d'évaluation

- Chemical CompositionDocument6 pagesChemical CompositionAkbar DarmawansyahPas encore d'évaluation

- CR StandardsDocument6 pagesCR Standardsalpha_beta48Pas encore d'évaluation

- Ferite CatalogDocument195 pagesFerite CatalogBorcan Cristi100% (3)

- Stainless Steels Guide - Properties, Applications & GradesDocument16 pagesStainless Steels Guide - Properties, Applications & GradesAndika RizalPas encore d'évaluation

- Aspac Royalloy enDocument7 pagesAspac Royalloy enNugroho Faris SudrajatPas encore d'évaluation

- 17 4 PHDocument2 pages17 4 PHParag NaikPas encore d'évaluation

- Part 4 - Selection of Mater - FBR (MS8 - Saroja Saibaba)Document23 pagesPart 4 - Selection of Mater - FBR (MS8 - Saroja Saibaba)Arnav ChakrabortyPas encore d'évaluation

- Spec 4140 & 4130Document7 pagesSpec 4140 & 4130Nisa_nishePas encore d'évaluation

- AB2 Aluminium Bronze Properties ApplicationsDocument1 pageAB2 Aluminium Bronze Properties ApplicationsTirta BudiawanPas encore d'évaluation

- Metrode 410NiMo B-11Document4 pagesMetrode 410NiMo B-11Claudia MmsPas encore d'évaluation

- Datasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Document6 pagesDatasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Mohammed Saleem Syed KhaderPas encore d'évaluation

- Corrosion Resistant 15%Cr 5%Ni Precipitation Hardening Stainless SteelDocument2 pagesCorrosion Resistant 15%Cr 5%Ni Precipitation Hardening Stainless SteelsilpawdmPas encore d'évaluation

- CHF101 CHW S16 PDFDocument1 pageCHF101 CHW S16 PDFImmalatulhusnaPas encore d'évaluation

- Nirosta 4104: Krupp EdelstahlprofileDocument2 pagesNirosta 4104: Krupp EdelstahlprofileLuis MayorgaPas encore d'évaluation

- Heat Treat 2Document5 pagesHeat Treat 2gawaPas encore d'évaluation

- Robofil M 700Document1 pageRobofil M 700Martin DunnePas encore d'évaluation

- Maraging Steel Material Spec for 3D PrintingDocument1 pageMaraging Steel Material Spec for 3D Printingmartinm3tPas encore d'évaluation

- Presentation1 (1)Document35 pagesPresentation1 (1)S RPas encore d'évaluation

- SS GP1 M270 - 04 09 - enDocument5 pagesSS GP1 M270 - 04 09 - enPiotr PawłowskiPas encore d'évaluation

- Data Sheet of Cobalt ChromiumDocument6 pagesData Sheet of Cobalt ChromiumDeva RajPas encore d'évaluation

- Aluminum Alloy EvolutionDocument2 pagesAluminum Alloy Evolutionc4pp3ll410_m4tt0Pas encore d'évaluation

- Sandvik 7C27Mo2 Strip Steel DatasheetDocument2 pagesSandvik 7C27Mo2 Strip Steel Datasheetearth metallurgical services pvt.ltd.Pas encore d'évaluation

- 15 5PH Bars Sheets Plates SpecificationsDocument2 pages15 5PH Bars Sheets Plates SpecificationsSachin RoutPas encore d'évaluation

- 15-7 Mo Data BulletinDocument16 pages15-7 Mo Data BulletinmsdoharPas encore d'évaluation

- RFQ of C45 SteelDocument3 pagesRFQ of C45 Steelnhirpara1Pas encore d'évaluation

- Datasheet-Sandvik-3r60-En-V2020-12-10 07 - 47 Version 1Document7 pagesDatasheet-Sandvik-3r60-En-V2020-12-10 07 - 47 Version 1Bruno AlfanoPas encore d'évaluation

- PTE LTD: Dimensional Specification (Inch) For Stud Bolts As Per Asme B18.2.1Document4 pagesPTE LTD: Dimensional Specification (Inch) For Stud Bolts As Per Asme B18.2.1Balderas Rosas WilibaldoPas encore d'évaluation

- Bronze LG2 2Document1 pageBronze LG2 2Ftg WwfdfPas encore d'évaluation

- CoCr MP1 M270 Material Data SheetDocument6 pagesCoCr MP1 M270 Material Data Sheetgpiprototype.comPas encore d'évaluation

- Austenitic Standard GradesDocument6 pagesAustenitic Standard Gradesfierro44Pas encore d'évaluation

- 19 - Kyocera Milling - Endmill - Radius - Ball-Nose 2010-2011 (ENG)Document24 pages19 - Kyocera Milling - Endmill - Radius - Ball-Nose 2010-2011 (ENG)karadimasPas encore d'évaluation

- Modern Handbook Electrode GuideDocument1 pageModern Handbook Electrode GuideTran van VuongPas encore d'évaluation

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesD'EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesPas encore d'évaluation

- Barcol ProcedureDocument1 pageBarcol ProcedureseetharamannPas encore d'évaluation

- Pangmalakasang Elements Sa MD Part3Document100 pagesPangmalakasang Elements Sa MD Part3Kezia Canonigo SalaPas encore d'évaluation

- Data Sheet 151uk Hardox 400 Plate 2017-04-19 313 371857150 en PDFDocument2 pagesData Sheet 151uk Hardox 400 Plate 2017-04-19 313 371857150 en PDFLuis GuevaraPas encore d'évaluation

- Syllabus For B.Tech Manufacturing TechnologyDocument74 pagesSyllabus For B.Tech Manufacturing TechnologyJuhi SinghPas encore d'évaluation

- Materials Selection ProcessDocument9 pagesMaterials Selection ProcessMarskal EdiPas encore d'évaluation

- AssignDocument4 pagesAssignnicolePas encore d'évaluation

- Astm D4060 10 PDFDocument5 pagesAstm D4060 10 PDFHsiao Yoyo0% (1)

- PlasticsDocument163 pagesPlasticsLincoln ZhaoXi100% (1)

- Astm Vol 02 01 Copper and Copper AlloysDocument816 pagesAstm Vol 02 01 Copper and Copper AlloysMetal dept100% (1)

- Methods of Mechanical Testing: Standard Terminology Relating ToDocument11 pagesMethods of Mechanical Testing: Standard Terminology Relating ToadelPas encore d'évaluation

- Universal UH250 WilsonHardnessDocument2 pagesUniversal UH250 WilsonHardnessKhoa Bui AnhPas encore d'évaluation

- Qualification of Non-Metallic Sealing Materials and ManufacturersDocument21 pagesQualification of Non-Metallic Sealing Materials and ManufacturerstankPas encore d'évaluation

- No 1Document10 pagesNo 1jeovanPas encore d'évaluation

- BS en Iso 11124-2-1997 (2000) BS 7079-E2-1994Document14 pagesBS en Iso 11124-2-1997 (2000) BS 7079-E2-1994Shankar GurusamyPas encore d'évaluation

- 1 s2.0 S0079670018303265 MainDocument44 pages1 s2.0 S0079670018303265 Mainxu.dachong59Pas encore d'évaluation

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFtiele_barcelosPas encore d'évaluation

- Problem Knowledge Materials " Ceramic ": Name: Diogo Rinaldi Freitas NIM: 1701010110068 Dep: Civil EnginerringDocument4 pagesProblem Knowledge Materials " Ceramic ": Name: Diogo Rinaldi Freitas NIM: 1701010110068 Dep: Civil EnginerringDiogo RinaldiPas encore d'évaluation

- Incombustible Materials QuizDocument32 pagesIncombustible Materials Quizcallielizza100% (5)

- Failure Analysis of Cooling Fan GearboxDocument7 pagesFailure Analysis of Cooling Fan GearboxJoão Paulo VissottoPas encore d'évaluation

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocument38 pagesRockwell Hardness of Metallic Materials: Standard Test Methods ForochablePas encore d'évaluation

- MonotubeDocument56 pagesMonotubeleovenuPas encore d'évaluation

- Rockwell Hardness TestDocument6 pagesRockwell Hardness TestChinmay DeoPas encore d'évaluation

- 2012 MTK3A11 Failure Analysis AssignmentDocument12 pages2012 MTK3A11 Failure Analysis AssignmentAbdullah KaymakcıPas encore d'évaluation

- 1 s2.0 S2665917421001963 MainDocument3 pages1 s2.0 S2665917421001963 MainBhanuka ThennakoonPas encore d'évaluation

- Hubungan Kekerasan Dan Kekuatan Tarik Bahan 27-2011Document5 pagesHubungan Kekerasan Dan Kekuatan Tarik Bahan 27-2011Ibnu FajarPas encore d'évaluation

- Hardness Conversion TableDocument2 pagesHardness Conversion TableUmesh SakhareliyaPas encore d'évaluation

- Hapter: MetalsDocument55 pagesHapter: Metalsbedo39Pas encore d'évaluation

- GPPF - 2017 - Paper - 26 Stg10T-steel PDFDocument6 pagesGPPF - 2017 - Paper - 26 Stg10T-steel PDFDavorin IvićPas encore d'évaluation

- Scheme of Examination for B.Tech MME ProgramDocument29 pagesScheme of Examination for B.Tech MME ProgramSahil RajPas encore d'évaluation

- Astm E6Document12 pagesAstm E6Nacer KisyPas encore d'évaluation