Académique Documents

Professionnel Documents

Culture Documents

RINA 2009 Bulk Carriers - Allowable Hold Mass Curves - Bureau Veritas - FINAL

Transféré par

Konstantis_chDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

RINA 2009 Bulk Carriers - Allowable Hold Mass Curves - Bureau Veritas - FINAL

Transféré par

Konstantis_chDroits d'auteur :

Formats disponibles

A PRACTICAL ASSESSMENT OF EXISTING BULK CARRIER LOCAL STRUCTURAL

STRENGTH IN RELATION TO THE ALLOWABLE HOLD MASS CURVES

K Chatzitolios, Bureau Veritas, Greece

G de Jong, Bureau Veritas, France

Dr JE Kokarakis, Bureau Veritas, Greece

SUMMARY

The allowable hold mass curves for vessels built after 1998 are mandatory in the loading manual & the loading

instrument as per IACS Unified Requirements S1A. The majority of the bulk carriers in service have been constructed

before 1998 and generally do not have allowable hold mass curves.

Pre-1998 bulk carriers engaged in multi-port operations need to have allowable hold mass curves to control the local

strength of the cargo hold structure for the envisaged loading conditions. The curves are produced according to the

loading conditions of the approved loading manual as a function of the draught. For the case of an individual hold they

are determined by examining bending and shear stresses in floors and girders, as well as buckling stresses in the

associated plating. For the case of two adjacent holds the strength of the transverse bulkhead and cross deck is

considered as well. The curves can be checked with finite element analysis or other methods to obtain the applicable

safety margin. The paper presents a theoretical derivation of the hold mass curves as function of the draught and

provides some comparisons with formulations by other class societies and IACS requirements. A practical methodology

to determine the hold mass curves when not available is proposed.

An interesting application, presented in a case study in the paper, is the determination of the maximum draught as a

function of the static still water bending moment at the empty holds. The combination of a hogging hull girder bending

moment and hydrostatic pressure at 60 to 70% of the scantling draught may cause severe buckling of the bottom plating

and exceed its ultimate strength. A methodology on how to assess this loading condition for holds which are not usually

empty is proposed.

1. INTRODUCTION

In 1998 IACS adopted Unified Requirement (UR) S1A,

effectively introducing additional requirements for

loading conditions, loading manuals and loading

instruments of both new and existing bulk carriers

1

.

UR S1A requires existing bulk carriers (that is, bulk

carriers contracted for construction before 1 July 1998)

with a length of 150 m and above to be provided with a

class approved loading instrument in order to enable the

ships master to check the envisaged loading conditions

(whether at sea or in port) against permissible

longitudinal strength criteria (hull girder bending

moments and shear forces). In this context a loading

instrument is considered as an effective means to

preventing overstressing of the hull girder, which could

potentially result in global structural collapse. In

addition, UR S1A requires single side skin bulk carriers

of 150 m length and above to be provided with a class

approved loading manual with typical loading sequences

where the vessel is loaded from commencement of cargo

loading to reaching the full deadweight capacity, and

1

UR S1A was introduced as an addition to UR S1, which

provides more general requirements for loading

conditions, loading manuals and loading instruments. UR

S1 is considered to be an implementation of the

requirements of Regulation 10(1) of the

International Convention on Load Lines,

1966.

vice versa. The reasoning behind this requirement is to

ensure that the vessel is not overstressed during loading

and discharging in port, which can happen due to faulty

loading sequences or (de)ballasting operations. The

sequence of loading the cargo holds, as well as the

amount of cargo which is loaded in each hold in one time

greatly influences the induced hull girder loads. This

issue is still very actual, in particular due to high speed

cargo loading at iron ore terminals (up to 16,000 tonnes

per hour) [1].

For new bulk carriers (contracted for construction on or

after 1 July 1998) of 150 m length and above, UR S1A

requires the class approved loading manual to

additionally include the following data:

Maximum allowable and minimum required mass of

cargo and double bottom contents of each hold as a

function of the draught at mid-hold position;

Maximum allowable and minimum required mass of

cargo and double bottom contents of any two

adjacent holds each hold as a function of mean

draught in way of these holds.

The values of maximum allowable and minimum

required mass of cargo can be plotted as a function of the

draught and are generally referred to as hold mass

curves. The loading instrument is required to display

whether the cargo hold mass is within permissible limits

and therefore needs to incorporate the hold mass curves.

This requirement for new ships effectively regulates

that, for any given loading condition, the local strength

capacity of the hull structure (strength of double bottom,

transverse bulkheads, etc.) is not exceeded and therefore

is to be considered as a complementary safety criterion to

the longitudinal strength criteria applicable to both new

and existing bulk carriers.

As pre 1998 bulk carriers are not required to have hold

mass curves, from an operational viewpoint they are

inherently less flexible than there newer counterparts, as

in practice they can only sail in the loading conditions

which have been approved in the loading manual. This

becomes a handicap if they are engaged in multi-port

operations, where the vessel will experience a wide

variety of loading conditions which may not be included

in the loading manual. Therefore, pre 1998 bulk carriers

effectively need hold mass curves in order to operate

safely on multi-port trades. As about 60% of the

approximately 7,000 bulk carriers in service today have

been built before 2000 (assuming a time delay of 18

months between contract signing and ship delivery), this

is by no means an academic issue [2].

For an individual hold the hold mass curves are

determined by examining shear stresses in floors and

double bottom girders, while for adjacent holds the

strength of cross deck and transverse bulkheads are of

main concern. The adjacent holds model is further

studied by evaluation of cross deck stresses stemming

from bending of the transverse bulkhead and hull girder

torsion. The curves can be checked with Finite Element

Analysis (FEA) or other methods to obtain the safety

margin.

This paper presents a comparison between various

formulations of hold mass curves amongst classification

societies and proposes ways to determine the curves for

existing ships when not available (pre 1998 bulk

carriers), as such creating a safe and easy way to expand

the trading flexibility of older bulk carriers.

In section 2 the technical background of the hold mass

curves is presented, considering formulations by different

class societies as well as IACS. Section 3 explains the

importance of hold mass curves for bulk carriers engaged

in multi-port operations; the focus is on the maximum

permissible draught in way of the empty holds as a

function of the hogging SWBM (Still Water Bending

Moment). Section 4 proposes a methodology for deriving

the hold mass curves on the basis of the theoretical

considerations presented in the previous sections and

presents an interesting application of hold mass curves:

the determination of the maximum draught as a function

of the static bending moment at the empty holds. The

combination of a hogging hull girder bending moment

and hydrostatic pressure at 60 to 70% of the scantling

draft is considered, which may cause severe buckling of

the bottom plating and exceed its ultimate strength

capacity. A methodology on how to assess this loading

condition for holds which are not usually empty is

proposed. Finally, in section 5 the main conclusions are

drawn and further recommendations are made.

TECHNICAL BACKGROUND

2.1 HOLD MASS CURVES FOR SEAGOING

CONDITIONS

As explained above, the hold mass curves are a means

for the master to decide obtain the maximum allowable

or minimum required cargo mass for an envisaged

loading condition which is not included in the loading

manual. The goal is to prevent overloading of the local

structure, such as the double bottom structure (plating,

floors and girders), the transverse bulkheads and the

cross deck structures. For example, if for an individual

cargo hold a cargo mass P has been approved for a

loading condition with a draught T1 at mid-length of the

considered hold, the double bottom structure might

experience excessive flexural deformation if the same

cargo mass is loaded for a loading condition with a

corresponding draught less than T1 (e.g. 0.5T1), as

depicted in Figure 1.

Figure 1: Excessive flexural deformation of double

bottom structure [3]

The basic idea behind the derivation of the hold mass

curves is to use the approved loading conditions from the

loading manual as a starting point for an inverse analysis

in order to obtain acceptable new conditions. As the net

resultant load on the double bottom is the governing

parameter for the variation in the local structural

response, the objective of the exercise is to control this

load, which is defined as the difference between the

downward force exerted by the mass of the cargo in the

hold & ballast water in the double bottom tanks and the

upward force resulting from the sea pressure. Both forces

are composed of a static and a dynamic component. The

downward force consists of the own weight of the mass

of the cargo and ballast water (static part) plus the inertia

loads caused by the ship motion induced accelerations

acting on this mass (dynamic part)

2

. The upward force

consists of the hydrostatic load (static part) plus the

hydrodynamic loads caused by ship motions in waves

(dynamic part). In linear rigid body dynamics the

hydrodynamic load is considered to be the sum of the

hydromechanical (reaction) loads caused by the ship

2

The own mass of the ship structure is neglected as it is

small compared to the mass of the cargo.

moving (oscillating) in the undisturbed fluid surface and

the forces exerted by the waves on the restrained body

(wave exciting loads). An example of the net resultant

load on the double bottom is presented in Figure 1, in

which only the static parts are considered.

For the purpose of structural analysis it is sufficiently

accurate to approximate the hydrodynamic load by a

Froude-Krylov type of wave load using the ship relative

motion as wave amplitude (as opposed to the wave

elevation relative to the undisturbed free surface) [4]. As

the variation of the net resultant load on the double

bottom is the highest for the upright ship condition

(usually the head sea condition is considered) the

analysis focuses on this condition, see Figure 2.

Figure 2: Wave load distribution on the basis of the

relative ship motion hU in upright ship condition [4]

In a generic form, the net resultant load on the double

bottom of a single cargo hold, in terms of the average

pressure

DB

p , can be expressed as follows:

,

`

.

|

+

+ +

L

T 2

U 1

H

ZU DB C

DB

1

e h T g

B

) a g )( M M (

p

(1)

where MC is the mass of the cargo, MDB the mass of the

ballast water in the double bottom tanks, g the gravity

acceleration, aZU the vertical acceleration at mid-length of

the cargo hold, H the length of the considered hold, B

the moulded breadth, the density of seawater, T1 the

draught at mid-length of the considered hold, hU the

relative motion at mid-length of the considered hold

corresponding to the vertical acceleration aZU and L the

ship length (as defined in the Rules)

3

. The factor

L

T 2

1

e

is a correction on the relative wave motion (or

elevation), taking into account the rapid decrease in

orbital motion and velocity of the fluid particles with

increasing distance from the free surface, effectively

reducing the hydrodynamic pressure on the bottom with

increasing draught and vice versa. The corrected wave

elevation is usually called the effective wave elevation

[5]. In hydrodynamic literature this effect is sometimes

referred to as the Smith Effect. It is to be noted that for

reasons of simplicity the presence of the hopper tanks

and lower stool of the (corrugated) transverse bulkheads

3

It is assumed that the ship is moving in deep water with

wavelength equal to the ship length.

is ignored; an issue which needs to be accounted for later

on in the analysis

4

.

The vertical acceleration aZU and relative motion hU need

to be evaluated simultaneously (at the same time instant)

to satisfy Newtons Second Law. This can be done on the

basis of ship motion calculations (2D or 3D radiation-

diffraction analysis) and or by applying reference values

of the load cases defined in the Rules (which have been

obtained from a statistical analysis of a large amount of

ship motion calculations) [6].

The goal is to obtain the maximum values of the net

resulting upward and downward loads, which can then be

compared to the net loads of the corresponding approved

loading conditions. By plotting the known approved

combinations of cargo mass and draught in a graph, the

hold mass curves are obtained, as schematically shown in

Figure 3. Curve (a) connects the approved loading

conditions 1 (maximum cargo mass P at scantling

draught T) and 2 (part load condition), denoting the

maximum permissible cargo mass. Curve (b) connects

the approved loading conditions 3 (loading condition at

the maximum permissible draught Tmax at which the

considered hold may be empty) and 4 (minimum

required cargo mass at scantling draught). The enclosed

(shaded) area is considered to be the safe loading area in

which the net resulting load on the double bottom is

within acceptable limits.

Figure 3: Example of hold mass curves

It is to be noted that the approach is rather conservative,

as curve (a) suggests that the maximum permissible

cargo mass which can be taken in the hold can only be

loaded when sailing at the scantling draught. Most

designs, however, have sufficient margin to sail with the

maximum cargo mass at a draught less than the scantling

draught. In that case curve (a) is replaced by the two

segmented curve (c), thus enlarging the loading

flexibility of the ship

5

. It is also to be noted that the hold

mass curves are not necessarily straight lines.

4

It is also assumed that the cargo upper surface is

horizontal, but this assumption is also made in the base

case (loading condition in the approved loading manual).

5

This is explicitly taken into account by UR S25 and the

CSR.

The hold mass curves can be computed by demanding

that the net resultant double bottom pressure in the

envisaged loading condition is to be equal to the net

resultant pressure in the approved reference loading

condition. Considering that the variation in vertical

acceleration and relative motion is small over the range

of operational draughts [7], the maximum permissible

cargo mass Pmax at draught T T

1

< , where there is no

ballast water in the double bottom tanks, can be written

as follows (curve (a) in Figure 3):

]

]

]

]

,

`

.

|

+

+

L

T 2

L

T 2

U 1

ZU

H

max

1

e e h ) T T (

a g

Bg

P P

(2)

where P is the maximum cargo mass at scantling draught

T (see above).

The worst load case for the downward net resulting

double bottom pressure, which is relevant for the

maximum permissible cargo mass, is the case where the

vertical downward acceleration aZU reaches the maximum

value. In BV Rules this is represented in load case b,

for which the relative wave motion is half of the

maximum value. The maximum value is attained in load

case a, which is essentially a Froude-Krylov case as the

vertical acceleration for this load case is zero (ship fixed

in the undisturbed wave) [6].

Expression (2) can be simplified by considering that, for

practical loading conditions, the absolute value of the

term

,

`

.

|

L

T 2

L

T 2

U

1

e e h

is much smaller than

) T T (

1

and also has a negative value which

increases Pmax. Therefore, if this term is neglected for

reasons of simplicity this is on the safe side. Applying

this simplification, expression (2) reduces to:

) T T (

a g

g

B P P

1

ZU

H max

+

(3)

which is still dependent on the vertical acceleration aZU.

Computation of the value of aZU utilising the formulae

from the Rules is straightforward and can today easily be

incorporated in the on-board loading computer. For older

ships with less modern on-board tools, however, this may

be more difficult. In order to achieve fast and practical

results, suitable for on-board calculation, the term

ZU

a g

g

+

may be set to unity (essentially neglecting

aZU). This is again a simplification on the safe side, as in

reality the term is always less than unity

6

. Applying this

second simplification, expression (2) further reduces to:

6

For a capesize bulk carrier the term typically varies

between 0.7 (midship region) and 0.85 (hold no 1),

where the accelerations are calculated for a probability

level of 10

-5

.

) T T ( B P P

1 H max

(4)

which is very easy to apply. On the basis of equation (4),

the slope of curve (a) in Figure 3, dPmax/dT, is constant

and equal to B

H

, which is in essence the hold

water-plane area multiplied by the water density.

Following the same reasoning as above, the minimum

required cargo mass Pmin at draught

max 1

T T > , where

the amount of ballast water in the double bottom tanks is

the same for both loading conditions (may be empty or

full), can be written as follows (curve (b) in Figure 3):

]

]

]

]

,

`

.

|

+

+

L

T 2

L

T 2

U max 1

ZU

H

min

max 1

e e h ) T T (

a g

Bg

P

(5)

The worst load case for the upward net resulting double

bottom pressure, which is relevant for the minimum

required cargo mass, is the case where the positive

relative motion hU reaches the maximum value. In BV

Rules this is represented in load case a, for which the

vertical acceleration is zero (see above). Application

reduces (5) to:

]

]

]

]

,

`

.

|

+

L

T 2

L

T 2

U max 1 H min

max 1

e e h ) T T ( B P

(6)

Expression (6) can be simplified by considering that, for

practical loading conditions, the absolute value of the

term

,

`

.

|

L

T 2

L

T 2

U

max 1

e e h

is much smaller than

) T T (

max 1

and also has a negative value which

decreases Pmin. Therefore, if this term is neglected for

reasons of simplicity, this is on the safe side. Applying

this simplification, expression (6) reduces to:

) T T ( B P

max 1 H min

(7)

which is independent of the relative motion hU and the

vertical acceleration aZU and therefore very easy to apply.

Similarly to the development above, the slope of curve

(b) is equal to the one of curve (a). Consequently curves

(a) and (b) are parallel.

Further analysis of expressions (4) and (7) learns that,

due to the simplifications, the imposed conservation of

load (net resulting double bottom pressure) has in fact

been reduced to imposed conservation of mass, which is

easier to compute. For the case of the maximum cargo

mass the reduced hold displacement due to the reduction

in draught equals the reduction in permissible cargo

mass, while for the case of the minimum cargo mass the

increased hold displacement due to the increase in

draught equals the increase in required cargo mass.

As mentioned above the presence of the hopper tanks and

transverse bulkhead lower stool have been ignored. The

consequences of these simplifications are depending on

the height of the rated upper surface of the bulk cargo

above the tank top hm, see Figure 4.

Figure 4: Effect of cargo filling level on double bottom

cargo pressure

For the maximum permissible cargo mass we consider

case a, denoted by hm,a, where the rated upper surface is

above the hopper tank and can be considered as the

maximum filling level corresponding to the maximum

cargo mass P at the scantling draught T. If a new loading

condition with less draught is envisaged, application of

(4) yields a reduction in cargo mass of

) T T ( B

1 H

. This is achieved by reducing hm by

) T T (

1

B

, where B is the bulk cargo density.

This expression is valid only if the new rated upper

surface cargo level is above the top of the hopper tank; in

other words:

DB HT m

h h h . If the rated upper

surface would be less (case b), the amount of cargo mass

reduction to keep constant the net resultant pressure on

the double bottom (flat part) would be less due to the

presence of the hopper tank and transverse bulkhead

lower stool volumes. This means that the results are

slightly conservative but on the safe side.

For the minimum required cargo mass the draught is

increased above the maximum Tmax draught for which the

cargo hold has may be empty in accordance with the

approved loading manual. So the hold is filled from zero

to a certain value to compensate for the increase in sea

pressure exerted on the double bottom. Application of (7)

yields an increase in cargo mass (from zero) of

) T T ( B

max 1 H

. However, due to the presence of

the hopper tanks and transverse bulkhead lower stool less

cargo mass is required to achieve the necessary cargo

pressure increase on the double bottom (flat part) than is

computed by expression (7), where the full displacement

addition (acting on the total width of the ships bottom)

is compensated as cargo mass increase (gradually

increasing its influence from the width of the flat part of

the double bottom to the total ship breadth). Therefore,

the minimum required cargo mass is overestimated by

expression (7) and can be corrected for the presence of

the non cargo carrying volumes. For a rated upper

surface cargo level above the top of the hopper tank (

DB HT m

h h h ), the correction includes the complete

volume of the hopper tanks, which gives:

[ ]

LS DB HT HT H B max 1 H min

V ) h h ( b ) T T ( B P

(8)

where, bHT is the width of the hopper tank, hHT the height

of the hopper tank and hDB the height of the double

bottom.

For a rated upper surface cargo level below the top of the

hopper tank (

DB HT m

h h h < ), the correction is

dependent on the value of hm, which is not known a priori

but can be estimated by

) T T ( h

max 1

B

m

. As the

hopper tanks are neglected, this is a conservative

approach (hm is overestimated). The minimum cargo

mass can than easily be calculated by considering the

cargo volume up to filling level hm and the associated

bulk cargo density. As the transverse bulkhead lower

stool is low compared to the height of the cargo hold, hm

will usually be higher than the height of the lower stool.

This justifies a correction on Pmin by subtracting the term

LS B

V . Defining bm as follows, see Figure 5:

) T T (

h h

b

b

max 1

DB HT

HT

B

m

(9)

we can write for the minimum required cargo mass:

]

]

]

+

LS DB HT

HT

m HT m

H B min

V ) h h (

b

b ) b 2 B b (

P

(10)

Figure 5: Definition of bm

The verification of the maximum permissible and

minimum required cargo mass is to be performed for the

case of individual cargo holds, as described above, and

for the case of two adjacent cargo holds. In fact, the case

of individual cargo holds addresses the maximum

bending moment and shear force in the floors, the

maximum bending moment in the double bottom girders

at mid-length of the cargo hold and the maximum shear

force in the double bottom girders at the ends of the

cargo hold when considering alternate loading conditions

(angular deformation at hold ends due to asymmetrical

loading produces the maximum bending moment in the

double bottom girders at mid-length of hold). The case of

two adjacent cargo holds considers the maximum

bending moment and shear force in the double bottom

girders acting simultaneously at the transverse bulkhead

(the condition of zero angular deformation at the hold

ends due to symmetric loading produces the maximum

bending moment in the double bottom girders at the hold

ends) and the shear strength of the (corrugated)

transverse bulkhead.

Based on the derivations and considerations above, it is

easy to see that a straightforward application of the

conservation of mass principle provides quick and

conservative estimates of the maximum permissible and

minimum required cargo mass. The maximum

permissible cargo mass for two adjacent holds

max 2 1

) P P ( + at a draught T T

1

< can be written as

follows:

) T T ( B ) ( P P ) P P (

1 2 H 1 H 2 1 max 2 1

+ + +

(11)

where

2 1

P P + is the maximum mass of cargo in two

adjacent holds at the scantling draught, while H1 and H2

denote the length of the two adjacent cargo holds,

respectively.

Following the same reasoning, the minimum required

cargo mass for two adjacent holds

min 2 1

) P P ( + at a

draught

max 1

T T > can be written as follows:

) T T ( B ) ( ) P P (

max 1 2 H 1 H min 2 1

+ +

(12)

2.2 HOLD MASS CURVES FOR HARBOUR

CONDITIONS

During loading and unloading in port the maximum

allowable cargo mass is higher than at sea due to the

absence of waves generating large vertical accelerations

and relative motions. In a similar fashion the minimum

required cargo mass is less than at sea. Due to this

reduction of dynamic loads, the ship has more flexibility

in loading conditions during port operations, which is

regulated by providing specific hold mass curves for the

harbour conditions in addition to the seagoing conditions.

In the ideal port situation of no accelerations and no

relative motions expression (1) reduces to:

1

H

DB C

DB

gT

B

g ) M M (

p

+

(13)

The maximum permissible cargo mass for a single hold

in harbour condition Pmax is derived on the basis of the

known maximum permissible cargo mass from seagoing

condition at the scantling draught. Equating expression

(1) for seagoing condition with P M

C

, 0 M

DB

and T T

1

to expression (14), after some algebra,

gives:

DB 1

L

T 2

U H

ZU

max

M T e h T B

g

a g

P P

,

`

.

|

+

(14)

This expression requires computation of aZU and hU.

Simply ignoring them would yield extremely

conservative results, as expression (15) would be

effectively reduced to expression (4) for seagoing

conditions, with the exception of the double bottom

ballast water mass which is very small compared to the

maximum cargo mass. In other words, the loading

flexibility of the ship would be too much restricted.

Therefore, any attempt for simplification of (15) must

still include one of the two dynamic parameters.

Rewriting (14) into a static and a dynamic part gives:

( )

DB 1 H static max,

M T T B P P

(15)

L

T 2

U H

ZU

dynamic max,

e Bh

g

a

P P

(16)

The key point for simplification is to evaluate the two

terms of (17) against each other. Making use of practical

data on typical bulk carriers and considering the worst

load case for the downward net resulting double bottom

load (maximum downward vertical acceleration), it can

be shown that approximately

L

T 2

U H

ZU

e Bh 3

g

a

P

. Therefore, (17) can be

approximated by:

L

T 2

U H dynamic max,

e Bh 2 P

(17)

It can further be shown that the L/T ratio for typical bulk

carriers from 10k DWT is between 12.5 and 19.

Therefore, the term

L

T 2

e

will be between 0.60 and

0.70. By setting

L

T 2

e

to a conservative value of 0.5

(the corresponding L/T ratio is 9), expression (18) can be

conservatively further reduced to:

U H dynamic max,

Bh P

(18)

This is conservative, as the value of the dynamic part,

giving a positive contribution to the maximum

permissible cargo mass, is underestimated. As such,

expression (14) can be safely simplified as follows:

( )

DB 1 U H max

M T h T B P P

(19)

where hU corresponds to the relative motion for the load

case where the vertical acceleration is maximum, which

is easy to calculate (BV Rules load case b).

The minimum required cargo mass for a single hold in

harbour condition Pmin is derived on the basis of the

known minimum required permissible cargo mass from

seagoing condition at the scantling draught. Equating

expression (1) for seagoing condition with 0 M

C

,

0 M

DB

and

max 1

T T to expression (14) results in

the following expression

DB max

L

T 2

U 1 H min

M T e h T B P

max

,

`

.

|

(20)

which is independent of the vertical acceleration aZU.

Following the reasoning above,

L

T 2

e

can be taken as

0.5. This underestimation is on the safe, side as it

increases the minimum required cargo mass. In doing so,

expression (21) can be reduced to:

DB max U 1 H min

M ) T h 5 . 0 T ( B P

(21)

where hU corresponds to the relative motion for the load

case where the relative motion is maximum, which is

easy to calculate (BV Rules load case a).

In a similar fashion as above, applying the conservation

of mass principle, expressions for the maximum

permissible and minimum required cargo mass for two

adjacent holds can be derived. The maximum permissible

cargo mass for two adjacent holds

max 2 1

) P P ( + at a

draught T T

1

< can be written as follows:

2 DB 1 DB 1 U 2 H 1 H

2 1 max 2 1

M M ) T h T ( B ) (

P P ) P P (

+

+ +

(22)

where

2 1

P P + is the maximum mass of cargo in two

adjacent holds at the scantling draught, H1 and H2

denote the length of the two adjacent cargo holds,

respectively, hU corresponds to the relative motion for the

load case where the vertical acceleration is maximum

(BV Rules load case b), while MDB1 and MDB1 represent

the mass of the double bottom ballast water of the two

adjacent cargo holds, respectively.

Applying the same reasoning, the minimum required

cargo mass for two adjacent holds

min 2 1

) P P ( + at a

draught

max 1

T T > can be written as follows:

2 DB 1 DB

max U 1 2 H 1 H min 2 1

M M

) T h T ( B ) ( ) P P (

+ +

(23)

where hU corresponds to the relative motion for the load

case where the relative motion is maximum (BV Rules

load case a).

2.3 CONSIDERATIONS FOR IMPROVEMENT

In order to make the process of evaluating hold mass

curves as practical and efficient as possible, the formulae

derived in this section have been simplified as far as

possible. This enables easy calculation on-board which

does not require complicated mathematics. In order to

stay on the safe side, the simplifications give a rather

conservative result, which inherently means that there is

room for optimisation of loading flexibility when the

more complex formulae are used instead of the

simplified ones. The obvious conservative assumption in

all formulations for the generation of the mass hold

curves is that it is assumed that the shear strength at full

draft is marginal and it is necessary to preserve shear

force at different drafts.

With the availability of good on-board computation

tools, in particular the loading instrument, this has

become relatively easy to implement. In fact,

improvements in the Rules after the introduction of UR

S1A are mandating the implementation of the hold mass

curves in the loading instrument, as will be described in

the following section.

2.4 DEVELOPMENTS OF IACS UNIFIED

REQUIREMENTS FOR HOLDS MASS

CURVES FOR NEW RULES AFTER UR S1A

As described in the introduction, UR S1A makes the

inclusion of the hold mass curves in the approved loading

instrument mandatory for new ships

7

. UR S20 has

introduced the development of the hold mass curves have

taking into account cargo hold flooding, UR S20 is

applicable to new single and double side skin bulk

carriers of 150 m length and over with cargo density

equal to or higher than 1.0 m

3

(applicable for single side

skin bulk carriers contracted for construction on or after

1 July 1998 and double side skin bulk carrier contracted

for construction on or after 1 July 1999 or 1 January

2000, depending on the width of the double side skin)

and considers the allowable hold loading in the case of

flooding of any (individual) cargo hold on the basis of

the cargo carried (volume, density and permeability),

effectively increasing bulk carrier safety. Due to the

change in the maximum permissible cargo mass at the

maximum draft, the hold mass curves for the maximum

permissible cargo mass for a reduced draught are

changed as well. In a similar fashion UR S22 has

changed the allowable hold loading of the foremost cargo

hold of bulk carriers bulk carriers contracted for

construction before 1 July 1998, with length of 150 m or

more and cargo density of equal to or higher than 1.78

t/m

3

.

With the introduction of UR S25 the hold mass curves

have been further developed. UR S25 is applicable to

bulk carriers of 150 m in length and over, which are

7

In the context of UR S1A new ships are ships

contracted for construction on or after 1 July 1998.

contracted for construction on or after 1 July 2003. With

UR S25, harmonised notations and associated design

loading conditions have been introduced. This has

created a uniform way to assess bulk carrier designs with

regard to their cargo carrying capacity and loading

flexibility. This in turn has generated a high degree of

transparency for ship owners and operators, as well as a

technical level playing field for designers and class

societies, and as such further enhanced bulk carrier

safety.

The three basic notations are as follows [8]:

BC-A: for bulk carriers designed to carry dry bulk

cargoes of cargo density 1.0 t/m

3

and above with

specific holds empty at maximum draught in

addition to BC-B conditions

BC-B: for bulk carriers designed to carry dry bulk

cargoes of cargo density 1.0 t/m

3

and above with

all cargo holds loaded in addition to BC-C

conditions

BC-C: for bulk carriers designed to carry dry bulk

cargoes of cargo density less than 1.0 t/m

3

For each of the three notations UR S25 provides a list of

design loading conditions to be checked. These loading

conditions are chosen in such a way that the design

incorporates multi-port operations which affect the local

strength and therefore directly define the hold mass

curves.

Key seagoing loading conditions in this respect are the

following [8]:

Any cargo hold is to be able to of carrying full cargo

mass with fuel oil tanks in double bottom in way of

the cargo hold, if any, being 100% full and ballast

water tanks in the double bottom in way of the cargo

hold being empty, at 67% of the maximum draught

8

;

Any cargo hold is to be capable of being empty with

all double bottom tanks in the way of the cargo hold

being empty, at 83% of the maximum draught;

Similar conditions apply for the case of two adjacent

cargo holds, with the empty cargo holds condition at

75% of the maximum draught. In addition, loading

conditions while in harbour are addressed.

In applying these seagoing conditions, the loading

conditions 5 and 3 presented in Figure 3 are fixed. In

fact, curve (a) is replaced by curve (c), as shown in

Figure 6. Only if the ship is assigned the additional

notation {no MP} these conditions can be waived.

Figure 6: Hold mass curves based on UR S25, including

multi-port operations

For BC-A bulk carriers, which are capable of sailing in

alternate conditions, specific additional loading

conditions are specified, including a margin in cargo

loading for the carriage of high density cargo (equal to

10% of full cargo mass).

UR S25 specifically addresses the issue of the hold mass

curves as based on the design loading conditions. For

other draughts than those specified in the design loading

conditions, the maximum allowable and minimum

required mass is to be adjusted for the change in

buoyancy acting on the bottom (to be calculated using

the water plan area at each draught). This is, in fact, an

implementation of the principle of the conservation of

mass as derived and justified in section 2.1.

8

The full cargo mass is defined as the cargo mass in a

hold corresponding to cargo with a virtual density

(homogeneous mass/hold cubic capacity, minimum 1.0

t/m3) filled to the top of the hatch coaming and is not to

be less than the actual cargo mass in a cargo hold

corresponding to a homogeneously loaded condition at

maximum draught [8].

2.5 OTHER CLASS SOCIETIES

Similarly to the developments described above, other

class societies apply the same basic concept in order to

estimate the mass hold curves. Examples of other pre-

CSR methods utilised by other classes are depicted on

Figure 7 for the seagoing case only.

The upper curve in essence preserves the net load, i.e.

the difference between the cargo weight and the

buoyancy of the cargo hold on the basis of purely static

considerations. The maximum cargo is deduced adding

the net load to the buoyancy force. Of course the

maximum cargo has been determined beforehand for

each hold by structural analysis. The minimum cargo at

design draft is determined by subtracting the net load

from the buoyancy. The abscissa for the minimum cargo

curve is determined from similar triangles, being parallel

to the maximum cargo curve.

Figure 7: Hold mass hold curves, pre-CSR, seagoing

The lower curve is based on the same philosophy, but it

accounts for dynamic effects as shown in the derivation

above. Parameter k ranges from 0.67 to 1 depending on

the load cases studied at the design stage. It is known that

IACS UR S25 dictates that the case of 67% of full draft

with the maximum cargo hold load be studied in the

design stage, with respect to local and global strength.

The minimum cargo curve, although not shown in the

lower part of Figure 6, is determined by the following

relationship:

,

`

.

|

4

T

T

5 P 11 . 0 P

max

max min

(24)

Equation (24) provides the interesting relation between

the minimum and the maximum cargo in the hold. This

relation is based on statistical evaluation of many bulk

carriers instead of computations. According to (24), the

minimum cargo load is 11% of the maximum one.

2.6 DEVELOPMENT OF HOLDS MASS

CURVES FOR THE COMMON

STRUCTURAL RULES

Hold mass curves generation is necessary for all bulk

carriers above 90 meters according to the CSR. The

approach follows the logic introduced in UR S25, see

section 2.4. According to the formulation, the maximum

cargo mass for a draught less than 67% of the maximum

is given by:

( )

h

T T 67 . 0

V 025 . 1 M 1 . 0 M ) T ( P

max

H H HD max

+

(25)

where h is the vertical distance from the top of the inner

bottom to the main deck at centre-line, VH is the volume

of the hold excluding the volume enclosed by the hatch

coaming, MH is the actual cargo mass corresponding to a

homogeneously loaded condition at maximum draught,

MHD is the maximum cargo mass allowed to be carried in

a cargo hold according to the design loading conditions

with specified holds empty at maximum draught, Tmax is

the maximum draught and T is the actual draught under

consideration.

Similarly for the minimum load:

( )

h

T 83 . 0 T

V 025 . 1 ) T ( P

max

H min

(26)

Equation (26) is valid for a draught above 83% of the

maximum as dictated by UR S25. The two relations

above which are depicted pictorially on Figure 8, are

valid for holds designed to be always full, like the ore

holds. For holds which can be empty at maximum draft,

there is no meaning for minimum cargo, whereas the

maximum cargo for draught less than 67% of the

maximum is given by:

( )

h

T T 67 . 0

V 025 . 1 M ) T ( P

max

H Full max

(27)

where MFull is the cargo mass corresponding to cargo

with virtual density filled up to the top of hatch coaming.

The density is the maximum between one and MH/VH.

Figure 8: Mass hold curves according to CSR (ore hold)

The curves are simplified greatly at the expense of

operational flexibility when the limitation {No MP} is

added to the vessel notation (see also section 2.4), as this

notation removes the need to evaluate additional loading

conditions dictated by UR S25, such as the carriage of

the maximum cargo at 67% of the maximum draught and

empty ore hold at a draught as high as 83% of the

maximum.

INFLUENCE OF STILL WATER BENDING

MOMENT

Bulk carriers are sometimes engaged in multi-port

loading operations, although the great majority are not

designed for such. It is possible in such a multi-port

operation that the designated ore holds may be unloaded

at one port with the vessel proceeding to another port for

further unloading. In such a case, the combination of

hogging hull girder bending moment and external

pressure corresponding to a reduced draught of the order

of 60 to 70% of the maximum one may result in buckling

of the bottom plating. Importantly, this is a case which is

not routinely checked. A simple procedure is derived

below which aims to calculate the maximum permissible

draught in way of the empty ore hold (designed to carry

heavy cargo but operating empty) as a function of the

hogging SWBM (Still Water Bending Moment). This

procedure does not require performing a finite element

analysis. Typically the calculations are performed for the

midship ore hold and are applicable to all ore holds when

operating empty. In case the draught is severely limiting,

local reinforcement of the bottom may be necessary to

resolve the buckling problem. It is thus proposed to

develop a graph of the maximum permissible graph as a

function of the SWBM on the basis of satisfying the

buckling strength criterion:

0 . 1 BF

9 . 1

y , crit

y R m

9 . 1

x , crit

x R m

]

]

]

]

+

]

]

]

]

(28)

Where

R m

, are the material and the load factors,

both equal to 1.02, BF is the buckling factor defined by

equation (28), crit,x and crit,y are the critical buckling

stresses for the panel under consideration, while x and

y are the stresses exerted on the bottom panels in the

longitudinal and transverse directions, respectively.

Transverse stress y results from the hydrostatic and

hydrodynamic pressures on the bottom, computed from

analysis of the elementary bottom panel. This stress is

determined from a grillage analysis through the BV

program STEEL described in the next section. It can also

be estimated by simple panel response relations with the

handicap that the fixity of the plate boundaries needs to

be assumed as either fixed or clamped. Longitudinal

stress y stems from the contribution of hull girder static

and dynamic bending moments and the bottom pressure.

The former can be determined by :

wave static girder hull , x

05 . 1 +

(29)

where the factor 1.05 is a safety margin type factor due

to the higher uncertainty of the wave induced stress. The

wave induced and the static stress are computed on the

basis of simple beam theory. The wave induced stress is

multiplied by a factor equal to 0.625 which represents the

maximum in 10

5

wave encounters. Satisfaction of

equation (28) above needs to be ensured at all

combinations of draught and SWBM (which can be

controlled). An application of the procedure described

will be presented in the examples section.

A limitation for the SWBM for a given draught should be

obtained as well from the buckling requirements of the

upper sloping bulkhead and side shell in the upper wing

tank (due to sagging bending moment). This limitation

could be critical for the bulk carriers with transversely

framed side shell in upper tank and thin sloping

bulkheads. The shear strength of the side shell between

the loaded and empty holds (in block loading) should

also be checked for the allowable cargo mass. The

sagging SWBM at any seagoing condition is not to

exceed:

WIBM

y

I

SWBM

crit sag max

(30)

where I is the hull girder net moment of inertia at the

mid-hold section, y is the distance between the hull

girder neutral axis and the structural member under

consideration (plate panel or longitudinal stiffeners), crit

is the critical buckling stress of the structural member

under consideration and WIBM is the Wave Induced

Bending Moment as prescribed in the Rules.

2. CASE STUDIES

4.1 DERIVATION OF HOLD MASS CURVES

As has been described previously, the hold mass curves

may provide the pre-1998 bulk carriers with the ability to

safely operate a variety of loading conditions apart from

the ones checked in the design stage. It is very common,

from an operational point of view, for a vessel to be

needed to load cargoes at reduced draughts and in

loading patterns different from the ones shown in the

loading manual. These loading conditions, apart from the

stability and longitudinal strength aspect which are

examined on-board with the aid of the loading

instrument, have also to be checked from local strength

point of view in the plan approval office. The aim of this

examination is to verify the structural integrity of the

plating, the ordinary stiffeners and the primary

supporting members for each hold under the given

loading condition. The plating and the stiffeners are

checked at various sections of the ships length with the

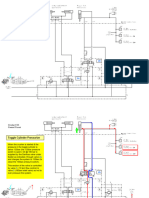

MARS program (a typical section in MARS is shown

in Figure 9). MARS is a panel-to-panel 2D analysis tool

based on the requirements of the BV Rules. The primary

supporting members (girders and floors) are assessed

using the STEEL program. STEEL is a 3D beam

analysis program which calculates all deformations, local

moments, forces and stresses in structures modelled by

beams subjected to static loads (in Figure 10 a STEEL

model is shown extending from the middle of one hold to

the middle of the next hold is depicted). Depending on

the loading condition at hand, the review may also

include the examination of the transverse bulkheads and

the cross deck areas. All this process is time consuming

and is also specific for each loading condition, which

means that it has to be repeated every time the proposed

condition deviates from the loading manual.

In order to bypass the process described above, the hold

mass curves can be formulated based on the vessels

existing loading manual. By the time these curves have

been created and implemented on board (as a supplement

to the loading manual), the vessel gains the flexibility to

be loaded in ways, otherwise restrictive, without further

examination.

Figure 9: Typical MARS section for the assessment of

the plating and ordinary stiffeners

Figure 10: Two-hold model in STEEL for the assessment

of the primary supporting members of the bottom

Application of the mathematical equations presented in

section 2 on a capesize bulk carrier yields the hold mass

curves for each hold and for the pairs of adjacent holds.

These are depicted in Figures 11 and 12 for No 5 and No

6 cargo holds, respectively, and in Figure 13 for the

adjacent No 5 and No 6 cargo holds. The main

particulars of the vessel are given in Table 1.

Table 1: Main particulars of the case study vessel

Length over all (Loa) 253.92 m

Length between perpendiculars 241.00 m

Moulded breadth 40.00 m

Moulded depth 21.00 m

Scantling draught 14.60 m

Block coefficient 0.822

Deadweight (approx.) 100,000 t

Figure 11: Hold mass curves for No 5 cargo hold

Figure 12: Hold mass curves for No 6 cargo hold

The loading manual can provide directly points 3 and 5

(see Figure 11), that produce the Pmax curve (a) and the

Pmin curve (b) for seagoing conditions. More specifically,

point 5 corresponds to a loading condition at which the

hold is fully loaded at the minimum possible draught

Tactual calculated at mid length of the hold. The critical

condition for the even holds that fulfils this requirement

is usually the full load homogeneous condition (in

particular the arrival condition, which has a smaller

draught than the departure condition) or the full load

alternate (arrival) condition for the ore holds. Since Tactual

(as depicted by the actual full load condition) is usually

smaller than the scantling draught T, the Pmax curve

obtains the flat section between points 5 and 1 by

applying T T

actual

in expression (4). It is important

to note at this point that when calculating the minimum

and maximum mass for each hold from the actual

loading conditions, the mass of double bottom contents

MDB (if any) should be added to the mass of cargo in the

hold, as this weight also counteracts to the upward acting

sea pressure. This MDB should not be confused as being

only ballast water, since it represents any liquid weight in

the double bottom situated underneath the flat inner

bottom of the cargo hold. It is common to have fuel and

diesel oil tanks underneath the aft holds of bulk carriers

and this weight is bound to be present in the full load

condition, while ballast water is not.

By following the same approach as above, point 3

corresponds to a loading condition at which the hold may

be empty, at the maximum possible draught Tmax

(calculated at mid-length of the hold). For an (uneven)

ore hold this is typically the heavy ballast condition (and

especially the departure condition, which has a greater

draught than the arrival condition), whereas for an even

hold this is, in most cases, the alternate condition at full

draught (departure condition). Due to these different

draughts, the Pmin curve of the even holds (curve (b) of

Figure 12) is usually a flat line which coincides with the

axis of the draughts (horizontal axis). The relevant curve

for the ore hold (curve (b) of Figure 11) starts at Tmax and

ends at T, being at the same time parallel to the Pmax

curve.

Following the procedure described above for No 5 cargo

hold, with a length of 26.6 m, points 5 and 3 would be

the following for the vessel under consideration (draught

in m, cargo mass in t):

) 26949 , 15 . 14 ( ) P , T ( P

max actual 5

(associated bulk cargo density: 1.67 t/m

3

)

) 0 , 07 . 10 ( ) 0 , T ( P

max 3

The Pmin and Pmax curves for seagoing conditions can now

be derived from expressions (4) and (7), respectively. In

order to produce the relevant curves for harbour

conditions, we need to calculate the relative motion hU..

According to BV Rules, the reference value of the

relative motion, at any hull transverse section, can be

obtained from the formulas in Table 2 [9].

Table 2: Maximum relative motion h1 in the upright ship

condition [9]

T1 shown in Table 2 (for a location between 0,3L and

0,7L) may be taken equal to Tactual (for the Pmax curve) and

Tmax (for the Pmin curve). The wave parameter is

calculated on the basis of the wave parameter C (see

Table 3) and the navigation coefficient n (see Table 4).

Based on the above, for No 5 cargo hold (mid-length

situated at x = 0.43L), the relative motion hU is equal to

m

h

h

U

291 . 3

2

1

for the Pmax curve (load case b)

and hU = h1 = 6.582m for the Pmin curve (load case a).

The relevant curves for harbour conditions (curves (c)

and (d)) can now be produced by substituting the data of

points 3 and 5 and hU to expressions (19) and (21). In

case that Pmax (seagoing) is calculated from a loading

condition with a liquid weight MDB underneath the hold,

then this weight has to be deducted in (19) and (21).

Table 3: Wave parameter C [9]

Table 4: Navigation coefficient n [9]

Figure 13: Hold mass curves for No 5 and No 6 adjacent

cargo holds

The same procedure should be followed for producing

the hold mass curves for two adjacent holds. The loading

conditions in the loading manual will provide points 3

and 5 of Figure 13. Point 5 represents the loading

condition at which the sum of the cargo mass in the two

adjacent holds and the related double bottom contents

) M M (

2 DB 1 DB

+ (if any) is maximum, at the

minimum possible draught Tactual (calculated at mid-

length of the holds). This could be a full load

homogeneous condition at the maximum draught (arrival

condition). Again by applying T T

actual

in (11), the

max 2 1

) P P ( + curve (a) shows the flat section between

points 5 and 1.

In a similar manner, point 3 now corresponds to a

loading condition at which the sum of cargo in two

adjacent holds and their relative double bottom contents

) M M (

2 DB 1 DB

+ (if any) is minimum, at the

maximum possible draught Tmax (calculated at mid-length

of the holds). An expected loading condition for this

point would be the heavy ballast condition in which the

adjacent holds are empty. This condition will not apply

to the heavy ballast hold and its adjacent holds because

of the weight of ballast water in the cargo hold. For this

pair of holds, the light ballast condition could be a

possible determinant for point 3. For the vessel under

consideration, points 5 and 3 are the following (draught

in m, cargo mass in t):

) 29407 , 46 . 14 ( ) ) P P ( , T ( P

max 2 1 actual 5

+

) 0 , 09 . 10 ( ) 0 , T ( P

max 3

The

min 2 1

) P P ( + and

max 2 1

) P P ( + curves for

seagoing conditions can now be derived by substituting

the data of points 3 and 5 to the expressions (11) and

(12), respectively (with length of No 6 cargo hold 26.6

m). Similarly expressions (22) and (23) will yield the

relevant

max 2 1

) P P ( + and

max 2 1

) P P ( + curves for

the harbour conditions. In case that

max 2 1

) P P ( +

(seagoing) is calculated from a loading condition with a

liquid weight ) M M (

2 DB 1 DB

+

underneath the

hold(s), then this weight has to be deducted in

expressions (22) and (23).

In the description given above for the creation of the hold

mass curves from the actual conditions of the loading

manual, points 5 and 3 have been correlated to typical

conditions found in all loading manuals. While this is

true most of the times, it is not always the case.

Sometimes these points correspond to different loading

conditions which involve combination of slack holds and

ballasted double bottom tanks. This is due to the fact that

bulk carriers built prior to the UR S25 requirements

would include in their loading manuals each condition

pattern (i.e. slack holds) that the vessel was designed for

to sail. The UR S25 solved this issue by applying generic

loading conditions during the design stage depending on

the type of the vessel.

4.2 MAXIMUM DRAFT AS A FUNCTION OF

STATIC BENDING MOMENT (ORE HOLDS)

The capesize bulk carrier utilised in the previous section

to demonstrate the derivation of the hold mass curves

will also be used to apply the method described in

Section 3 to study the influence of draught and static

bending moment on the bottom strength of the ore holds

(loaded in the alternate condition). The vessel does not

have BC-A, BC-B or BC-C notation in compliance with

URS 25. If it did, then it is known that (excluding the

case where {No MP} is assigned) the maximum draft

which can be tolerated for the ore holds with 100%

hogging SWBM is 83% of the scantling draught. The

question for the vessel under study, which is a pre-

URS25 ship, is to determine the maximum draught for

which the ore holds can be left empty. We choose to

study No 5 cargo hold, which is located in the middle of

the vessel and therefore subjected to the highest hull

girder stresses. Conclusions drawn for this hold can be

conservatively extended to the other ore holds as well.

The hogging SWBM is 2,538,000 KN

.

m and the wave

induced (vertical) bending moment WIBM equal to

3,650,000 KN

.

m. The moment of inertia of the cross

section in No 5 cargo hold and the position of neutral

axis are 330 m

4

and 9.5 m, respectively. On the basis of

these data, the buckling factors (defined by equation

(28)) are computed as a function of the draught

(percentage of scantling draught Ts) and the hogging

SWBM. The results are depicted in Figure 14.

Figure 14: Buckling factor versus draft and static

bending moment

It is evident that No 5 cargo hold cannot be empty close

and below the scantling draught. Calculations for the

maximum draught, assuming 100% of the SWBM is

acting, are depicted in Figure 15 as a function of the

buckling factor. It is found that the buckling factor BF is

lower than one below (approximately) 78% of the

scantling draught.

Figure 15: Buckling factor versus draught (at 100%

SWBM)

The sensitivity of the bottom plating buckling strength to

the static bending moment is depicted in Figure 16,

which is a multi-modal version of the previous one.

Figure 16 depicts the maximum permissible draught as a

function of the hogging SWBM. The sensitivity of the

buckling strength to the bottom thickness is shown in

Figure 17. As expected, there is a parabolic relation

between the buckling strength (BF) and the bottom

thickness.

Figure 16: Sensitivity to the hogging SWBM

Figure 17: Sensitivity to the bottom thickness

CONCLUSIONS

In order for bulk carriers to safely sail a certain loading

condition, three key points need to be checked. First, the

longitudinal strength characteristics, in terms of still

water bending moment and shear force, need to be

verified against the permissible values. Second, the

ships intact and damage stability particulars need to be

checked in accordance with the applicable criteria. Third,

the local strength of the cargo hold structure, loaded by

the cargo mass forces and external sea pressures, is to be

checked against applicable yielding, buckling and fatigue

criteria.

The first two points can be readily dealt with on-board by

entering the loading condition into the loading instrument

(or loading computer), which is mandatory for all bulk

carriers of 150 m in length and over. The loading

instrument of modern bulk carriers, contracted for

construction on of after 1 July 1998, IACS UR S1A

requires the hold mass curves, making verification of the

third point straightforward for the master. For pre-UR

S1A bulk carriers the hold mass curves are not

mandatory. Therefore, if loading conditions other than

the conditions of the approved loading manual are

envisaged, the hold mass curves need to be specifically

derived to check the local strength of the cargo hold

structure. This is particularly important when the vessel

will be engaged in multi-port operations with strong

variation of cargo mass against draught for the different

cargo holds. As the majority of the in-service of bulk

carriers consists of pre-UR S1A ships, a practical method

for establishing the hold mass curves is needed.

On the theoretical level (section 2), the basic requirement

for the derivation of the hold mass curves is the

conservation of the net vertical load on the double

bottom structure. These curves have been derived in this

paper and it was shown that, by conservatively

simplifying the derived expressions, the conservation of

load requirement reduces to the conservation of mass

requirement generally adopted in UR S25. With this

method simple expressions are obtained for calculating

the hold mass curves for individual cargo holds and two

adjacent cargo holds, in seagoing as well as harbour

conditions.

With the introduction of UR S25, later followed by the

CSR, the minimum envelope of the hold mass curves has

been clearly defined and the hold mass curves follow

directly from the application of the rule strength

requirements to the prescribed loading conditions. For

pre-UR S25 bulk carriers the situation is more

complicated. Generally speaking, the set of approved

loading conditions from the loading manual serves to

define the hold mass curves on the basis of the

expressions derived in this paper, which provides the

ship owner with more loading flexibility. In case the

envisaged loading condition is outside the hold mass

curves obtained in this manner, additional strength

checks are to be performed in order to accept the new

loading condition. It is obvious that the loading

flexibility obtained from the hold mass curves is

somewhat limited due to the conservative simplifications

which have been made in order to ensure an easy and

quick process. When the more general expressions

(before application of the simplifications) are applied,

more loading flexibility can be obtained in result.

In section 3 the importance of the combination of draught

and hogging still water bending moment for the case of

empty holds in multi-port conditions was emphasised, as

there is a significant risk of buckling of the bottom

plating due to the combination of local and global

compression stresses. This issue needs to be specifically

addressed when deriving the hold mass curves for multi-

port operations.

A practical application of the derived hold mass curves is

presented in the case studies on a 100k DWT capesize

bulk carrier. Hold mass curves have been derived for No

5 cargo hold, No 6 cargo hold and the adjacent No 5 and

No 6 cargo holds. In addition, the maximum draught at

which No 5 cargo hold can be empty, while the

maximum hogging still water bending moment is acting,

has been derived from a buckling analysis of the bottom

plating. Finally, a sensitivity study into the effect of the

value of the still water bending moment and bottom

plating thickness was carried out.

In conclusion, a practical methodology for the derivation

of the hold mass curves has been presented, which is

easy to apply to existing bulk carrier and can be used to

extend the operating profile of bulk carriers in a safe

way, taking into account the relevant strength limits of

the cargo hold local structure. This is particularly

relevant for existing ships which need to engage in multi-

port operations.

REFERENCES

1. Intercargo, Intercargo Briefing: Loading Rates,

Rev.0.1, 21 November 2008

2. Lloyds MIU, SeaWay, May 2009

3. IACS, Bulk Carriers - Guidance and Information on

Bulk Cargo Loading and Discharging to Reduce the

Likelihood of Over-stressing the Hull Structure,

Rec. 46, 1997

4. Bureau Veritas, Rules for the Classification of Steel

Ships, Pt B, Ch 5, Sec 5, [2], April 2009

5. Journe JMJ, Massie WW, Offshore

Hydrodynamics, First Edition, Delft University of

Technology, January 2001

6. Bureau Veritas, Rules for the Classification of Steel

Ships, Pt B, Ch 5, Sec 4, April 2009

7. Bureau Veritas, Rules for the Classification of Steel

Ships, Pt B, Ch 5, Sec 3, [2], April 2009

8. IACS, Harmonised Notations and Corresponding

Design Loading Conditions for Bulk Carriers, UR

S25, Rev. 2, July 2004

9. Bureau Veritas, Rules for the Classification of Steel

Ships, Pt B, Ch 5, April 2009

AUTHORS BIOGRAPHIES

Kostantinos Chatzitolios currently works in Bureau

Veritas as a hull surveyor in the plan approval office

(HPO) of Piraeus, Greece. He joined Bureau Veritas in

2005 after obtaining a Diploma in Naval Architecture

and Marine Engineering from the National Technical

University of Athens. In the four years that he has

worked in HPO he has dealt with stability and hull

matters of bulk carriers, oil tankers and passenger ships.

In the last two years he is specialized in the hull structure

of bulk carriers (existing and CSR) and oil tankers.

Konstantinos is currently undertaking a Masters degree

in Business Administration (International MBA) in the

Athens University of Economics and Business.

Gijsbert de Jong holds the current position of product

manager at Bureau Veritas and is based in the Head

Office in Paris. He is responsible for the international

business development in the field of container ships and

dry bulk carriers, as well as a number of specialised ship

types.

Gijsbert joined Bureau Veritas in 2001 after obtaining an

MSc in Naval Architecture & Marine Engineering from

Delft University of Technology. Before moving to Sales

& Marketing Management in 2007, he has worked as

hull surveyor and department manager for the Bureau

Veritas plan approval office in Rotterdam. During this

period Gijsbert has built up extensive experience with

dry cargo & container ships, dredgers, asphalt carriers,

product tankers, reefers & tugs. In his present position he

is working closely together with BVs technical

specialists and extensive international network to

develop new products and services meeting with the

maritime industrys specific needs.

Gijsbert has published technical papers on container

ships, bulk carriers, arctic shipping and fuel cell power

systems and regularly writes articles for marine industry

magazines.

Dr John Emmanuel Kokarakis, a 1979 graduate of

National Technical University of Athens, he holds PhD

(1986) and Masters degrees in Naval Architecture (1983)

and Masters in Mechanical Engineering (1984) from the

University of Michigan. He worked for over ten years as

a consultant undertaking technical problems worldwide.

His specialization was in the area of technical

investigation of marine accidents. In his capacity as a

forensic engineer he participated in the technical

investigation of the Exxon Valdez grounding, Sea-crest

Capsize, Piper Alpha fire and explosion, Aleutian

Enterprise foundering in Alaska as well as many other

accidents of less notoriety.

The last eleven years he works in Greece, in the area of

classification. Having served in the plan approval office

of American Bureau of Shipping in Piraeus, he then

joined Germanischer Lloyd heading their tanker and bulk

carrier team in Greece. He is currently the Technical

Director of Bureau Veritas in the Hellenic and Black Sea

Region. In his duties Dr. Kokarakis is responsible for the

smooth technical operation in the region as well as in the

harmonic cooperation with the BV offices worldwide to

the benefit of the BV clients in Greece. He was a

member of the team which developed the Common

Structural Rules.

Vous aimerez peut-être aussi

- Mukhopadhyay Question-Answer: 1. Latest Regulations For Bulk CarrierDocument88 pagesMukhopadhyay Question-Answer: 1. Latest Regulations For Bulk CarrierMariyath Muraleedharan KiranPas encore d'évaluation

- Longitudinal Strength SectionDocument19 pagesLongitudinal Strength SectionmaaathanPas encore d'évaluation

- Stability Precious NoteDocument48 pagesStability Precious NoteAung Htet KyawPas encore d'évaluation

- Barge 180Ft Deck Load Capacity & Strength-Rev1Document52 pagesBarge 180Ft Deck Load Capacity & Strength-Rev1Wahyu Codyr86% (7)

- Lifting Analysis Preview)Document4 pagesLifting Analysis Preview)Faisal AjaPas encore d'évaluation

- Assessing Stability of a Barge Crane for Cargo LiftingDocument44 pagesAssessing Stability of a Barge Crane for Cargo Liftingsethhoffman85Pas encore d'évaluation

- Stability Theory IIDocument36 pagesStability Theory IIFazl GhoriPas encore d'évaluation

- Fender Selection For STS Ops YokohamaDocument0 pageFender Selection For STS Ops YokohamabranikPas encore d'évaluation

- Stability Talkie TalkieDocument46 pagesStability Talkie TalkieSakthi Javelin100% (1)

- Container Lashing WebDocument16 pagesContainer Lashing WebSined SinedPas encore d'évaluation

- Critical KG Curves for Stability AssessmentDocument3 pagesCritical KG Curves for Stability AssessmentNAUTASPas encore d'évaluation

- Stability Talkie Talkie LJMUDocument46 pagesStability Talkie Talkie LJMURahul SainiPas encore d'évaluation

- Stability Talkie TalkieDocument43 pagesStability Talkie TalkieAhtashamuddin NizamudinPas encore d'évaluation

- Marpol 25A: Is It Safety or Absurdity?: Escuela Técnica Superior de Ingenieros NavalesDocument16 pagesMarpol 25A: Is It Safety or Absurdity?: Escuela Técnica Superior de Ingenieros NavalesJorge SilvaPas encore d'évaluation

- Executive Summary:: International Maritime OrganizationDocument11 pagesExecutive Summary:: International Maritime OrganizationelmauioPas encore d'évaluation

- Types and Power of Harbour Tugs - The Latest Trends: Prace Naukowe Politechniki WarszawskiejDocument12 pagesTypes and Power of Harbour Tugs - The Latest Trends: Prace Naukowe Politechniki WarszawskiejYudi DarmawanPas encore d'évaluation

- Stability Information Manual - FormatoDocument42 pagesStability Information Manual - FormatoelavayenPas encore d'évaluation

- Rabu Control Trim, Stability and StressDocument9 pagesRabu Control Trim, Stability and StressFaisal MakarimPas encore d'évaluation

- PIANC-World Congress Panama City, Panama 2018 Bollard LoadsDocument12 pagesPIANC-World Congress Panama City, Panama 2018 Bollard LoadsAnonymous ZMLlQvBop75% (4)

- 202 The Principles of Naval Architecture Series: 6.2.1 Classification Societies RulesDocument33 pages202 The Principles of Naval Architecture Series: 6.2.1 Classification Societies RulesJuan SilvaPas encore d'évaluation

- S1A.PDF - DefaultDocument2 pagesS1A.PDF - DefaultJony DarkoPas encore d'évaluation

- Motion Criteria For The Efficient Unloading of Container Vessels Hans MoesDocument14 pagesMotion Criteria For The Efficient Unloading of Container Vessels Hans MoesNaval2014DNPas encore d'évaluation

- Container Terminal Operation - Current Trends and Future ChallengesDocument32 pagesContainer Terminal Operation - Current Trends and Future ChallengesAkram Faisal100% (2)

- Safe Working LoadDocument16 pagesSafe Working LoadHugo Vco RvaPas encore d'évaluation

- OTC 15313 Development of Load-Out Methodology For On-Ground-Build FSODocument5 pagesOTC 15313 Development of Load-Out Methodology For On-Ground-Build FSOhiyeonPas encore d'évaluation

- Recent Developments in Loading ComputersDocument3 pagesRecent Developments in Loading ComputersanandreevPas encore d'évaluation

- (25452843 - New Trends in Production Engineering) Impact of Dock Tanks Pumping Plan On Structural Loads of A Dock and A ShipDocument7 pages(25452843 - New Trends in Production Engineering) Impact of Dock Tanks Pumping Plan On Structural Loads of A Dock and A ShipСергей ДедовPas encore d'évaluation