Académique Documents

Professionnel Documents

Culture Documents

Dos Donts BMCG2

Transféré par

Neeru GohlanDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Dos Donts BMCG2

Transféré par

Neeru GohlanDroits d'auteur :

Formats disponibles

BHARAT METAL CUTTING GAS ---DOS & DONTS Dos Only trained/experienced staff should carry out the

f should carry out the cutting job Visually examine all equipment and fittings before use Always use braided flexible hose (BIS MARK) Check hoses for cuts, cracks and other defects before use Wear the necessary personal protective equipment Check that there are no flammable substances nearby Use only flint guns or spark lighters to light the gas torch Lay out hoses properly to prevent coming into contact with heat sources Before starting work, check cylinder/hose for fitness and leakage In case of leakage, the regulator to be immediately shut off and to be started again only after certification by a competent person Secure all gas cylinders to prevent them from being knocked down and keep them at a safe distance from heat sources Ensure fire-fighting equipment is readily available for immediate use Bharat Metal Cutting Gas (BMCG) cylinder should always be kept in vertical upright with the valves uppermost position BMCG cylinders should always be fixed with safety cap when not in use BMCG cylinders should always be closed from the regulator when not in use BMCG cylinders should always be kept in ground level with proper cross ventilation In order to prevent the hazardous collection of gas, cylinders shall be placed away from culverts, depressions, entrances or openings leading to below ground level compartment and drains Always use standard industrial regulator Braided flexible hose length to be kept as short as possible and to be pressure tested / leak tested with soap solution every month Always light the cutting torch immediately after adjustment of oxygen & fuel ratio by crack opening the torch valves Always use right size of nozzle for a particular thickness of metal Always place the cylinders at a safe distance of at least 3 M from an electrical source

Donts Do not keep BMCG cylinder in a closed or confined space Do not place BMCG cylinders near heat source. Maintain a minimum distance of 15 mtrs from the heat source Do not place BMCG cylinders below ground level compartment or pit

Cylinders shall not be installed at a place where they are likely to cause an obstruction Cylinders shall not be installed at a place where they may be overheated for example, close to steam pipes, boilers, furnaces etc Do not keep hoses in twisted looped or kinked condition Do not expose hoses to any kind of external pressures Braided flexible hose shall not have any joints in between BMCG cylinders shall not be placed in such a position where conditions (such as falling of objects) likely to affect their safety Do not roll the cylinders on the ground, always move the cylinders on foot ring The cylinders shall not be rolled or dropped from a height Naked flames shall never be used for checking gas-tightness of the installations Do not remove the valve of your own Do not be a mechanic of your own, call mechanic/maintenance person if any problem arises BMCG CYLINDERS RECEIPT & STORAGE OF CYLINDERS

Dos All cylinders to be checked for leakage prior to receipt. The cylinders should be checked for weight to avoid over filled cylinders The cylinders should be stored vertically. The cylinders should always be kept in capped condition

Donts The cylinders should not be rolled on the ground The cylinders should not be kept near heat source The cylinder should not be kept very near power lines The cylinders should not be dropped while handling. Do not store more than 100 KG of BMCG together in unlicensed premises

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Flow Chart Fixed Column BasesDocument4 pagesFlow Chart Fixed Column BasesstycnikPas encore d'évaluation

- Jobs For Software Testers in Siemens Teamcenter Software Through Industry Experience ProgramDocument4 pagesJobs For Software Testers in Siemens Teamcenter Software Through Industry Experience ProgramKumar SPas encore d'évaluation

- Hydraulic Excavator GuideDocument9 pagesHydraulic Excavator Guidewritetojs100% (1)

- Approved List of Manufacturers: Line Pipes (Carbon/Alloy Steel)Document4 pagesApproved List of Manufacturers: Line Pipes (Carbon/Alloy Steel)Sourav Kumar GuptaPas encore d'évaluation

- Pid Handbook 1002-02 PDFDocument94 pagesPid Handbook 1002-02 PDFMUHAMMAD TAUFEEQPas encore d'évaluation

- Experiment 1 Phy 360Document14 pagesExperiment 1 Phy 360Mohd Khairul0% (2)

- Engineering Technical Report of The v12 Engine and Related Assignments at Tipco IncDocument36 pagesEngineering Technical Report of The v12 Engine and Related Assignments at Tipco Incapi-244817040Pas encore d'évaluation

- 0751 VICTAULIC in Mechanical PipingDocument17 pages0751 VICTAULIC in Mechanical PipingsyafiqPas encore d'évaluation

- Butter Smooth Slomo Slow Motion Sony Vegas EugeniaDocument5 pagesButter Smooth Slomo Slow Motion Sony Vegas EugeniaJack BakerPas encore d'évaluation

- Oracle PLSQL Best Practices and Tuning PDFDocument270 pagesOracle PLSQL Best Practices and Tuning PDFKeyur Pandya100% (1)

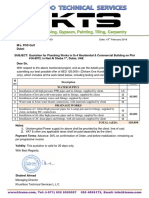

- KTS Quotation Meidan Building Plumbing Works PDFDocument1 pageKTS Quotation Meidan Building Plumbing Works PDFShakeel Ahmad100% (1)

- Tensile TestDocument15 pagesTensile Testdwimukh360Pas encore d'évaluation

- 32961part Genie Z-45-22Document138 pages32961part Genie Z-45-22johanaPas encore d'évaluation

- DA 65we EnglishDocument2 pagesDA 65we EnglishAlvin NguyenPas encore d'évaluation

- Boeco Mantas de CalentamientoDocument2 pagesBoeco Mantas de CalentamientoJhon VallejoPas encore d'évaluation

- ACAS II Operations in The European RVSM EnvironmentDocument45 pagesACAS II Operations in The European RVSM Environmentali4957270Pas encore d'évaluation

- Guide to Manual J Load Calculations in 40 CharactersDocument27 pagesGuide to Manual J Load Calculations in 40 Characters123john123100% (3)

- Sda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Document1 pageSda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Himani PatelPas encore d'évaluation

- GT Kompetitor parts list comparisonDocument4 pagesGT Kompetitor parts list comparisonrachmad syahputraPas encore d'évaluation

- Möller Valve Spherical Closing Segment Universal ValveDocument2 pagesMöller Valve Spherical Closing Segment Universal ValveYhanePas encore d'évaluation

- Rajib Mall Lecture NotesDocument97 pagesRajib Mall Lecture NotesAnuj Nagpal100% (1)

- BIT3251 BIT3251 BIT3251 BIT3251 應用指南 應用指南 應用指南 應用指南: Beyond Innovation TechnologyDocument10 pagesBIT3251 BIT3251 BIT3251 BIT3251 應用指南 應用指南 應用指南 應用指南: Beyond Innovation TechnologyHamza AbbasiPas encore d'évaluation

- Palm Tower 3 Coverage ReportDocument61 pagesPalm Tower 3 Coverage ReportHassan DaudPas encore d'évaluation

- CE 308 Lec 7 Mixing, Handling and Placing of ConcreteDocument29 pagesCE 308 Lec 7 Mixing, Handling and Placing of ConcretewasimkhaliqPas encore d'évaluation

- What is a Gear Motor? - An In-Depth GuideDocument15 pagesWhat is a Gear Motor? - An In-Depth GuidePuneet KumarPas encore d'évaluation

- L-990 Sensor Tap: Codes Power Supply Temperature Control WeightDocument3 pagesL-990 Sensor Tap: Codes Power Supply Temperature Control WeightNguyên Trịnh CaoPas encore d'évaluation

- MS 1472-2017Document65 pagesMS 1472-2017Thinagaran100% (2)

- H61H2 A ManualDocument88 pagesH61H2 A ManualkuriganoPas encore d'évaluation

- 199408Document93 pages199408denis alvarezPas encore d'évaluation

- Download Descargar libro de geometria analitica de ricardo figueroa bookDocument3 pagesDownload Descargar libro de geometria analitica de ricardo figueroa bookJuniorPas encore d'évaluation