Académique Documents

Professionnel Documents

Culture Documents

Emoto Speed Control Report

Transféré par

ericelijahDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Emoto Speed Control Report

Transféré par

ericelijahDroits d'auteur :

Formats disponibles

Simulating and Implementing Speed Control for an Electric Motorcycle

Lennon Rodgers, Eric Gilbertson, Kavya Manyapu

Massachusetts Institute of Technology

Department of Mechanical Engineering

2.140 Analysis and Design of Feedback Control

Final Project for Spring 2009

1. IntroductionandOverview

This study simulates and implements closed-loop PID speed control on an electric motorcycle.

Firstly, a theoretical model of the plant (motorcycle) was formulated using the derived equations of

motion and the Single Input Single Output (SISO) techniques learn in this course. A PID controller was

chosen because the Proportional controller (P) has good disturbance rejection properties, the Integral

controller (I) provides zero steady state error to a step input and the Derivative controller (D) leads to a

faster response. The SISO tool in Matlab was initially used to obtain estimates for the gains of the

controller required to meet a rise time of ~4 seconds, and zero steady state error requirements. The plant

and controller model were then simulated using Simulink and the gains were tuned appropriately to obtain

precise specifications. Furthermore, performing driving experiments with the electric motorcycle

validated the model. The simulation and experiments were performed under various disturbances, such as

hills and wind.

2. SystemModel

A model of the Plant (motorcycle) was first determined. To accomplish this, the equations of

motion were derived.

2.1. EquationsofMotionforthePlant

The motorcycle can be simplified as a mass on an incline with externally applied forces acting on

it (Figure 2-1). The motorcycle is propelled forward by a force on the wheel, F

w

, but slowed down by the

aerodynamic drag, F

drag

, the rolling resistance, F

rolling

, and the horizontal component of weight. Thus

summing the forces in the x-direction yields:

m x = F

w

C( x + w)

2

mg mgSin 1

Where m is the total mass of the motorcycle and rider, w is the wind speed, is the rolling resistance

coefficient, and C is the aerodynamic drag coefficient, which can be written as:

C =

1

2

AC

d

2

where is the density of air, A is the combined cross-sectional area of the motorcycle and driver and C

d

is

the drag coefficient of the motorcycle and driver. For this study, a linear form of Equation 1 will be used:

m x = F

w

C( x + 2 x w + w

2

) ( + Sin)mg 3

The force on the wheel is generated by a DC permanent magnet motor, which is connected to the

rear wheel of the motorcycle via two sprockets and a chain (Figure 2-2). Mechanical advantage is

achieved by using a sprocket ratio (z), which is defined as:

z = r

sw

/ r

s

4

The sprocket ratio amplifies the torque by a factor of z:

w

= z 5

where is the motor torque, and

w

is the torque on the wheel through the rear sprocket. Summing the

torques from the center point of the rear wheel yields:

J

= z F

w

r

w

6

Where J is the equivalent moment of inertia of both wheels and r

w

is the outer radius of the wheel. The

velocity of the motorcycle is related to the angular velocity of the wheel by the equation:

x =

r

w

7

Thus:

= x / r

w

8

Combining Equations 3, 6 and 8 yields:

J x

r

w

+ m x + C( x + 2 x w + w

2

) + ( + Sin)mg

( )

r

w

= z

9

Which has the Laplace transform of:

mr

w

+

J

r

w

s + Cr

w

(1+ 2w)

X + Cw

2

r

w

+ ( + Sin)mgr

w

= Tz 10

Where L(a) is the Laplace Transform of the variable a:

X = L( x )

T = L()

11

Figure 2-1: Free Body Diagram of the motorcycle. Figure 2-2: Free Body Diagram of the rear

wheel.

The remaining unknown is the torque from the motor, which is set by the user via the throttle

input. Thus, it is desired to relate the input voltage of the motor, V

in

, to the output torque of the motor, .

The motorcycles DC permanent magnet motor can be modeled using resistance, inductance, and back

emf elements as shown in Figure 2-3 [1]. Summing the voltage drops across each element gives the

following relationship:

V

in

= iR +V

emf

+ L

di

dt

12

Where V

in

is the input voltage, i is the current, V

emf

is the back emf voltage, and L is the motor inductance.

The motor will provide a back emf voltage proportional to its angular velocity, which by using Equation 7

can be written as:

V

emf

= K

emf

m

=

K

emf

z

r

w

x

13

The motor torque, , is related to the input current by the torque constant K

t

:

= K

t

i 14

If it is assumed that the motor acts as a perfect force transducer, the torque and back emf constants are

equal:

K

t

= K

emf

15

Now rewriting Equation 12 using Equations 13, 14, and 15:

V

in

=

R

K

t

+

K

t

z

r

w

x +

L

K

t

16

By taking the Laplace transform of Equation 16, the torque can be determined:

T =

K

t

Ls + R

V

in

K

t

z

r

w

X

17

Combining Equations 10 and 17 yields:

X =

V

in

Ls + R

K

t

z

J

r

w

+ mr

w

(

\

|

\

!

|

s + Cr

w

(1+ 2w)

(

\

|

\

!

| +

K

t

z

r

w

|

|

|

|

|

|

|

|

( + sin)mgr

w

+ Cw

2

r

w

J

r

w

+ mr

w

(

\

|

\

!

|

s + C(1+ 2w)r

w

+

K

t

2

z

2

Ls + R ( )r

w

|

|

|

|

|

|

18

Thus the velocity can be written as the sum of two components:

X = G

1

V

in

G

2

19

Where:

G

1

=

1

Ls + R

K

t

z

J

r

w

+ mr

w

(

\

|

\

!

|

s + Cr

w

(1+ 2w)

(

\

|

\

!

| +

K

t

z

r

w

|

|

|

|

|

|

|

|

G

2

=

( + sin)mgr

w

+ Cw

2

r

w

J

r

w

+ mr

w

(

\

|

\

!

|

s + C(1+ 2w)r

w

+

K

t

2

z

2

Ls + R ( )r

w

|

|

|

|

|

|

20

2.2. DeterminingtheSystemConstants

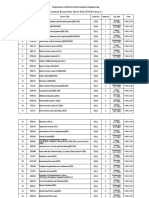

Table B-1 provides a summary of the constants in Equation 20. The aerodynamic coefficients

(Equation 2) were determined by comparing theoretical and experimental estimates of the power required

to maintain a constant speed of 20 m/s on a flat road with a 2 m/s wind. By assuming a more realistic non-

linear aerodynamic drag, the force balance under these conditions is (Equation 1):

F

w

=

1

2

AC

d

(20 + 2)

2

+ mg 21

And the mechanical power required is:

P

w

= F

w

x =

1

2

AC

d

(20 + 2)

2

+ mg

20 22

A power meter was installed on the motorcycle (Figure 2-4), which measured the actual total electrical

power, P

e

, being consumed under these conditions (20 m/s cruising speed with a light wind). Since the

manufacturer states that the motor has an efficiency of 0.88, the mechanical power can be estimated

using:

P

w

= (P

e

P

p

) 0.88

23

Where P

p

is the power required to run the motorcycle lights (approximately 200 Watts). Initial values for

C

d

, A and were obtained from a published reference [2]. Using these published estimates, Equations 22

and 23 agreed with each other by 10%. The values of C

d

and A were adjusted until the results from

Equations 22 and 23 were equal.

Open loop speed versus time plot (Figure 3-1) was plotted for both the simulation and experiment,

and the estimated constants from Table 1 were adjusted within the uncertainty, so the two plots closely

matched. The throttle input was given a generic unit that ranged from 0 (off) to 1000 (full throttle). This

was done to simplify the conversion between motor voltage and speed. Thus a conversion is required to

convert the 0->1000 value to a motor voltage. Since the motor has a maximum voltage of 72 Volts, the

conversion factor is 72/1000. This is the gain in the step to voltage block. The throttle was set to

approximately 630, which corresponded to a steady state speed of roughly 13 m/s. Thus the conversion

between speed (m/s) and 0->1000 is 630/13. This is the gain used in the feedback loop of the closed loop

system to convert velocity to reference velocity.

Figure 2-3: DC motor model. Figure 2-4: The Cycle Analyst power meter.

3. ControllerDesign

The SISO tool in Matlab was initially used to obtain estimates for the gains of the controller required

to meet a rise time of ~4 seconds, and zero steady state error requirements. The plant and controller model

were then simulated using Simulink and the gains were tuned appropriately to obtain precise

specifications. The final gain values were K

p

=3, K

i

=1/2, and K

d

=1/5.

The open loop system is composed of transfer function blocks for the plant and the three

disturbances: rolling resistance, wind, and hills. The plant transfer function is G

1

and the three

disturbances are the components of G

2

(Equation 19). The closed loop system uses a PID controller with a

saturation block to ensure the controller output voltage does not exceed the maximum motor voltage

output of 72 volts (corresponding to a number of 1000). In the closed loop system the output velocity is

converted to a velocity number between 0 (0m/s) and 1000 (20m/s) and the error between this number

and the desired velocity number is fed back into the PID controller. The output of the system is a velocity

in m/s.

A root locus was plotted for the loop transmission of the closed loop system including disturbances,

controller, and plant to determine system stability. Gains were assumed to be at a constant ratio of K

p

=6K

i

and K

p

=15K

d

, which were the same ratios used in the experiments and simulations. The gain K

p

was

varied in this analysis. The root locus plot above is zoomed-in on the dominant poles of the system and

shows that the system is stable for all gains K

p

except for K

p

=0, where the system is marginally stable.

Our system uses K

p

=3 and is thus stable.

Figure 3-1: Open Loop comparison between the

simulation and experiment.

Figure 3-2: Pole-Zero plot of the plant transfer

function.

Table 3-1: Open loop Simulink model.

Table 3-2: Open loop Simulink model.

SimulationResults

The open loop and closed loop systems were simulated using a step input of 630, which

corresponds to 13 m/s. Wind speed was assumed to be zero and the terrain was assumed to be flat. The

90% rise time is 4 seconds as specified in the system requirements and the steady state error is zero. The

motor command is at saturation for the first few seconds, and then decreases as the error decreases. The

command then reaches a nearly steady value, as the error becomes zero.

In the presence of a hill and wind, the open loop response should have a non-zero steady state

error but the closed-loop response to have zero steady state error. This is shown in the simulation with

wind of 1 m/s and hill of 10 degrees (Figure 3-4).

4. ExperimentalSetupandResults

4.1. DescriptionoftheElectricVehicle

The tests were performed on an electric motorcycle built by one of the team members. The

specifications of the motorcycle are listed in Table B-2. A wiring schematic of the power electronics is

shown in Figure B-2. Without closed loop control, the motorcycle is controlled using a 0-5 Volt twist

throttle, which is operated by the driver. The throttle command is sent to a motor controller, which

regulates the power between the batteries and motor.

4.2. ExperimentalPlanandHardware

The driving experiments included both open and closed loop control of the motorcycle. The control

block diagrams for both cases are shown in Figure 4-3 and Figure 4-4.

The algorithm for open loop is as follows:

Figure 3-3: Open and closed loop simulated without

additional disturbances.

Figure 3-4: Open and closed loop simulated for a hill

disturbance.

1. The driver sets the reference (or desired) speed via the twist throttle.

2. This throttle signal is sent directly to the motor controller.

3. The motorcycle accelerates to reach the desired speed.

4. In real time the microcontroller senses the throttle signal and measures the vehicle speed.

This information is time stamped and logged in memory for post-analysis.

The algorithm for closed loop is as follows:

1. The driver sets reference (or desired) speed via the twist throttle.

2. The microcontroller measures the reference speed via the throttle signal.

3. The microcontroller measures the vehicle speed.

4. The microcontroller performs PID algorithm.

5. The microcontroller sends appropriate command to motor controller.

6. In real time the microcontroller senses the reference and command signals and measures the

vehicle speed. This information is time stamped and logged in memory for post-analysis.

Below is a description of how each of the three signals is read or generated, and how the PID algorithm

was formulated.

ReferenceSpeed

The throttle generates an analog signal that varies from 1 Volt (off) to 4 Volts (full on). There is a

linear relationship between the throttle position and the desired speed (e.g. half throttle implies the driver

wants to travel at half of the maximum speed). The Arduino microcontrollers analog to digital converter

(A/D) reads in this signal and assigns values ranging from 0 (0 Volts) to 1018 (5 Volts).

MeasuringSpeed

The speed is measured using a magnetic reed switch and two small magnets (Figure 4-1). The signal

from the switch goes from high (5 Volts) to low (0 Volts) when one of the magnets passes over the

switch. Thus the switch generates a high-low pulse for each half revolution of the front wheel. This pulse

signal is connected to a digital input of the Arduino microcontroller ( Figure 4-6) and the time between

each pulse, t, is determined by measuring the time between the front edge of two consecutive pulses.

Since this time corresponds to the time it took for the wheel to rotate through a half revolution, the speed

can be determined using the following relationship:

x _ =

r

w

36 10

8

t s

24

Where r

w

is the radius of the wheel in meters, t is the time between pulses in milliseconds, and s is the

maximum speed of the motorcycle in meters/second (e.g. 20 m/s).

PIDAlgorithm

For the closed loop case, the speed is measured, and the error is determined as the difference

between the Reference Speed and the Actual Speed:

e _ =V

Th _

x _

25

Where V

Th_

and

x _ are the Reference Speed and Actual Speed, and they vary from zero (0 m/s speed) to

1000 (maximum speed, which is 20 m/s). In general the underscore designates a quantity that varies from

0 to 1000. This universal quantity was required since each of the signals has a different unit. The actual

Command to the motorcycle is determined by applying a PID algorithm to the error [1]:

V

Cmd _

= K

P

e _+ K

I

e _ dt + K

D

de _

dt

26

In practice a discrete approximation must be used:

V

Cmd _

k

= K

P

e

_

k

+ K

I

(e

_

n

t

n

)

n=1

k

+ K

D

e

_

k

e

_

k1

t

k

27

Where t is the change in time between the steps:

t

k

= t

k

t

k1

28

The superscripts are used to designate particular time steps, and should not be confused as exponent

powers.

Figure 4-1: The speed is measured using a reed

magnetic switch and two magnets attached to the

front brake disk.

Figure 4-2: A pulse is generated each time the

magnet passes over the Reed switch. The speed is

measured by measuring the time between pulses.

CommandSignal

The Command signal controls the motor power output via the motor controller. The PID controller

decides the value of this signal. The signal is generated by the microcontroller as a Pulse Width

Modulated (PWM) output, though an RC filter is required to convert the PWM signal to an analog signal.

The resulting analog signal, V

Cmd

,

varies from 0 Volts (zero power) 4 Volts (maximum power) and is sent

to the motor controller.

ExperimentalHardware

The entire loop runs at about 5 Hz. For each case, RC filters were required because of the significant

electromagnetic noise generated by the motor (Figure 4-5). The experimental hardware is shown in

Figure 4-6. A microcontroller was required to measure the input signals, perform calculations, and

command the motor controller. A data logger was used to capture the experimental data in real time. The

motorcycle was rewired to allow the microcontroller to read the throttle measurements and also send

commands to the motor controller. A toggle switch and a quick disconnect was also installed to allow for

rapid reconfiguration between the open and closed loop operations. All of the added hardware was

mounted on a wooden platform and attached to the motorcycle tank with a large magnet. Instead of using

the throttle, a constant reference voltage was achieved by using a small external battery source and a

voltage divider. This reference voltage was connected to an activation switch, so that repeatable step

inputs could be obtained during tests.

Figure 4-3: Open-loop control block diagram.

Figure 4-4: Closed-loop control block diagram.

It should be noted that safety was strongly considered when preparing and performing the driving

tests. Many hours of tests were performed in the lab, and with the motorcycle chain removed. A fake

speed was simulated for these lab tests by spinning a wheel with a magnet in front of the magnetic (reed)

switch. Multiple all-off safety switches were installed on the motorcycle. The computer code was

analyzed thoroughly and safety limits and checks were implemented when possible.

Figure 4-5: Schematic of the experimental hardware.

Figure 4-6: Actual experimental hardware added to

the electric motorcycle.

4.3. InitialExperimentalResults

Figure 4-7 compares Open and Closed Loop for the

driving experiments. It can be seen that the rise time was

reduced from about 10 seconds to roughly 4 seconds,

and there was zero steady state error. The next section

will discuss more of the experimental results in detail,

and compare them with the simulations.

5. ComparisonofSimulationand

ExperimentalResults

It can be seen from Figure 5-1 that the plant model

matches the experimental results within 5% through the

entire test. The closed loop simulation (Figure 5-2),

however, diverges by as much as 7%. It is likely that the

closed loop error is caused by the approximate integration method used (Equation 27). Figure 5-3 shows

how the Riemann sum method likely over estimated the integration in the experiment, and thus the

microcontroller sent an incorrect higher command. Figure 5-4 shows a comparison of closed loop when a

larger integration gain is used, which in effect simulates the overestimate from the Riemann sum. Also

part of the errors could have also been caused by the RC-filters, which were not modeled in the

simulation.

Figure 5-5 shows the voltage (command) signal being applied to the motor by the PID algorithm. As

expected, the controller is initially saturated at a maximum command of 72 Volts. The command then

tapers off to the steady state value of approximately 48 Volts. Figure 5-6 supports the previous prediction

that the error between the simulation and experimentation is caused by the Riemann sum integration.

The final test performed was a step input with a hill/disturbance. Beacon Hill was chosen due to its

steepness and proximity to campus. As before, the step input of 3 Volts (corresponding to 13 m/s) was

applied. As can be seen from Figure 5-7, the model matches the experiment very well at the beginning

and at the end, but there is a significant amount of error (~20%) in the middle. The increased Ohmic

resistance in the motor most likely causes this error. The Ohmic resistance would have likely been much

higher than previously measured in the laboratory because of the difference in motor temperature. The

motor was very hot because it was necessary to drive ~5 KM to the hill, and also drive up and around the

hills a few times before finding an appropriate testing site. Figure 5-8 confirms this theory. Future tests

should include a cool-down period for the motor before executing the tests.

Figure 4-7: Open versus Close Loop

experimental results.

Figure 5-1: Open loop simulation and experimental

results.

Figure 5-2: Closed loop simulation and

experimental results.

Figure 5-3: The Riemann sum integration (blue

dashed lines) overestimates the integral for a

decreasing function.

Figure 5-4: Closed loop simulation and

experimental results with a larger K

I

= 0.7 used for

the simulation. A K

I

= 0.5 was used in the

experiments.

Figure 5-5: Command signal for closed loop

simulation and experimental results.

Figure 5-6: Command signal for closed loop

simulation and experimental results with a larger

K

I

= 0.7 used for the simulation. A K

I

= 0.5 was

used in the experiments.

Figure 5-7: Closed loop speed control going up

Beacon Hill.

Figure 5-8: Closed loop speed control going up

Beacon Hill using a higher R = 0.16 Ohms for the

simulation.

6. Conclusions

A low cost microcontroller, data logger, and RC-filters were used to provide closed loop speed

control of an electric motorcycle. A theoretical plant model was derived, and Matlab/Simulink was used

to determine the appropriate controller gains. Both the simulations and experiments showed that a PID

controller provided the required rise time of 4 seconds and zero steady state error for a step input. There

was ~5% agreement between the model and experiments when factors such as integration error, and

increased thermal resistance in the motor were considered. Thus, it is likely that the motorcycle model

could accurately be used to predict other performance metrics such as power consumption and

acceleration. Our results show that a linear model is adequate at the speeds tested, though it is unlikely to

be appropriate at higher speeds (>13 m/s) due to increased (non-linear) aerodynamic drag.

7. RolesofGroupMembers

Lennon Rodgers built the motorcycle, designed and executed the experimental tests, helped with

the modeling and simulations, and wrote the corresponding sections in the report.

Eric Gilbertson lead the modeling and simulation effort, assisted in the experimental tests, and

wrote the corresponding sections in the report.

Kavya Kamal Manyapu helped in the initial planning of the experimentation and modeling, and

wrote the Introduction and Appendix F.

AppendixA: References

[1] Gene F. Franklin, 2006, Feedback Control of Dynamic Systems, 5th Edition, Prentice Hall

[2] Vittore Cossalter, Motorcycle Dynamics, 2nd Edition

AppendixB: ElectricMotorcycleDetails

Figure B-1: The Electric Vehicle (EV) for this project.

Table B-1: A summary of the constants used in the simulation.

Table B-2: Electric Motorcycle Specifications.

Range: 25-30 miles

Top Speed: 45 MPH

Transmission: Direct drive

Braking: Regenerative and friction

Charging Time: ~6 hours

Energy Requirement: 70 to 75 Watt-hrs/mile

Batteries: 6 x 12 Volt Lead Acid (Sealed, AGM)

Battery Life: 10,000 miles

Voltage: 72 Volts

Motor Power: 9 kWatts Continuous

Electricity Cost: 1.5 cents/mile

Construction Cost: $3000 (total)

Constant Description Method Value

L Inductance of the motor

Measured with inductance

meter

50*10

-6

Hen.

R Resistance of motor Measured with Ohm meter 0.12 Ohm

K

t

Torque constant

Determined from

manufacturers data

0.187 N-m/Amp and

Volt/rad

m

Total mass of motorcycle and

driver

Calculated/Estimated 310 kg

J

Combined Moment of Inertia

for both front and rear wheels

Calculated/Estimated 1.4 kg-m

2

z Sprocket Ratio Fixed 6

r

w

Radius of the wheel Measured/Estimated 0.32 m

C

d

Drag Coefficient Estimated 0.6

A Frontal Area of motorcycle Estimated 0.41 m

2

Figure B-2: Wiring schematic of the power electronics on the electric motorcycle for the Open Loop

configuration.

Table B-3: Hardware added for the PID experiments.

Name Description

Arduino Duemilanove Microcontroller Low cost ($30) commercially available

microcontroller.

Logomatic v2 Serial SD Datalogger Writes serial/UART signals to text files on a

micro-SD card ($60).

AppendixC: MicrocontrollerExperimentalCode

Below is the code for the Arduino microcontroller.

Open Loop:

/*

cruise control for eMoto, the electric motorcycle

*/

int throttle_pin = 2; // select the input pin for the analog input from the throttle

int speed_pin = 7; // pin used to measure the speed signal

long throttle;

//speed specific variables

int speed;

long time1;

long time2;

long time_enter;

long time_current;

int delta_time;

int current_value;

int previous_value;

int flag;

int check;

long speed_time;

long previous_speed_=0;

long temp_speed=0;

long reference_speed_;

long actual_speed_;

long time_stamp;

long velocity_change_squared_;

void setup() {

pinMode(speed_pin, INPUT); // declare the command_pin as an OUTPUT

Serial.begin(9600); // open the serial port at 9600 bps:

}

void loop() {

while (1)

{

//determine desired / reference speed and then convert units to standard 0->1000

throttle = analogRead(throttle_pin); // read the value from the throttle. 0V = 0, 5V = 1018 (187 for zero

throttle to 860 for full throttle from throttle)

reference_speed_ = (throttle-187)*1000/666; //takes the throttle (user input) and converts it to units of 0-

>1000

//determine speed and then convert units from time to standard 0->1000

speed_time = determine_speed(); //returns time between pulses in msec. //it will return 3000ms if the

pause is greater than 1 second.

if (speed_time==3000) //this zeros out the velocity if the pause was greater than 1 second between pulses.

{

actual_speed_ = 0;

}

else

{

actual_speed_ = 54670/speed_time; //the speed put it units of 0->1000

//this checks to make sure the speed didn't suddenly change. This is physically impossible, and is caused

by a faulty speed sensor reading

//this is saying that the difference between the error^2 can never be greater than 90000 (which means that

the abs. value of the diff. in error can never be greater than 300).

velocity_change_squared_ = (actual_speed_ - previous_speed_)*(actual_speed_ - previous_speed_);

if (velocity_change_squared_>90000)

{

actual_speed_ = previous_speed_; //if the new speed measurement "actual_speed" is way off, then just

use the previous measurement

}

previous_speed_ = actual_speed_; //set it for next time around

}

//determine current time

time_stamp = millis();

Serial.print(time_stamp);

Serial.print(", ");

Serial.print(throttle);

Serial.print(", ");

Serial.print(reference_speed_);

Serial.print(", ");

Serial.print(speed_time);

Serial.print(", ");

Serial.println(actual_speed_);

} // outer most while loop

}

//**********************************************

//This function determines the speed of the motorcycle

//**********************************************

int determine_speed() {

int first_run = 1; //a switch used to determine the first time through

time_enter = millis(); //determine the time you enter this loop

flag = 0;

while (1) //loops until two pulses are found. Then continue_loop is set to 0, and kicks out

{ //while loop

if (first_run == 1) //for the first time through we need to measure a value only - since we're doing a

previous / derivative kind of measure

{

current_value = digitalRead(speed_pin);

first_run = 0; //this is used as a switch - to determine the first run through the program.

}

else //this chunk is done all other times besides the first run through

{

previous_value = current_value;

current_value = digitalRead(speed_pin);

check = (current_value+previous_value)*previous_value; //check = 1 means that it went from a 1 to a 0.

A check = 0 means two zeros in a row, and check = 2 means two ones in a row

//Serial.println(check, DEC);

if (check==1 && flag ==0)

{

time1 = millis(); //measure current time

flag = 1;

check = 0; //makese sure it doesn't run into the next if statemnt

}

if (check==1 && flag ==1)

{

time2 = millis(); //measure current time

delta_time = time2-time1;

//Serial.println(delta_time, DEC);

return delta_time;

} //end of if (check==1 && flag ==1)

} //else used for first time through

time_current = millis();

if((time_current-time_enter)>1000) //if it's taking longer than 1 second to determine speed, the speed is

essentially zero, so return a large time value

{

delta_time = 3000;

return delta_time;

}

} //end outer while loop

} //end determine_speed function

Closed Loop:

/*

cruise control for eMoto, the electric motorcycle

*/

int throttle_pin = 2; // select the input pin for the analog input from the throttle

int command_pin = 10; // select the pin that will send commands to the controller

int speed_pin = 7; // pin used to measure the speed signal

long throttle;

int throttle_volts;

long command_value;

long signal_out;

//speed specific variables

int speed;

long time1;

long time2;

long time_enter;

long time_current;

int delta_time;

int current_value;

int previous_value;

int flag;

int check;

long speed_time;

long reference_speed_;

long actual_speed_;

long velocity_change_squared_;

long previous_speed_=0;

long command_;

long command;

long error_;

long error_previous_;

//PID Controller parameters

long proportional_term = 0;

long integral_term = 0;

long derivative_term = 0;

long current_time = 0;

long previous_time = 0;

void setup() {

pinMode(command_pin, OUTPUT); // declare the command_pin as an OUTPUT

pinMode(speed_pin, INPUT); // declare the command_pin as an OUTPUT

Serial.begin(9600); // open the serial port at 9600 bps:

}

void loop() {

previous_time = millis(); //this needs to be done to setup the clock.

while (1)

{

//determine desired / reference speed and then convert units to standard 0->1000

throttle = analogRead(throttle_pin); // read the value from the throttle. 0V = 0, 5V = 1018 (187 for zero

throttle to 860 for full throttle from throttle)

reference_speed_ = (throttle-187)*1000/666; //takes the throttle (user input) and converts it to units of 0-

>1000

if (reference_speed_<20) //this is to turn things off if the user lets go of the throttle. The following is

only done if the throttle is in a go position

{

analogWrite(command_pin, 0); //sets output to zero if user takes hands of throttle

//the following resets the PID values when the user lets off throttle. This prevents windup

integral_term = 0; //reset value otherwise there's windup

error_previous_ = 0; //reset value

error_ = 0; //reset value

previous_time = millis(); //this needs to be done to setup the clock.

}

else //only do the rest of the program if the user has a + input (if the throttle is being twisted) otherwise

just continue to loop and skip most of the program

{

//determine speed and then convert units from time to standard 0->1000

speed_time = determine_speed(); //returns time between pulses in msec. //it will return 3000ms if the

pause is greater than 1 second.

if (speed_time==3000) //this zeros out the velocity if the pause was greater than 1 second between pulses.

{

actual_speed_ = 0;

}

else

{

actual_speed_ = 54670/speed_time; //the speed put it units of 0->1000

//this checks to make sure the speed didn't suddenly change. This is physically impossible, and is caused

by a faulty speed sensor reading

//this is saying that the difference between the error^2 can never be greater than 90000 (which means that

the abs. value of the diff. in error can never be greater than 300).

velocity_change_squared_ = (actual_speed_ - previous_speed_)*(actual_speed_ - previous_speed_);

if (velocity_change_squared_>90000)

{

actual_speed_ = previous_speed_; //if the new speed measurement "actual_speed" is way off, then just

use the previous measurement

}

previous_speed_ = actual_speed_; //set it for next time around

}

//********************************

//need to trim off values, since sometimes they shoot under or over from noise in throttle

if (reference_speed_<=10)

{

reference_speed_ = 0;

}

if (reference_speed_>=990)

{

reference_speed_ = 1000;

}

//********************************

//determine the error: difference between reference and desired. Error here as units from 0->1000

error_previous_ = error_; //used in the PID calculations below for the integral term. We need to know

previous error;

error_ = reference_speed_-actual_speed_;

//this is to prevent oscillations due to small errors in the velocity measurement, etc.

//if(((error_-error_previous_)*(error_-error_previous_))<

/*

Serial.print(error_);

Serial.print(", ");

Serial.print( reference_speed_);

Serial.print(", ");

Serial.println(actual_speed_);

*/

//calls the PID routine, using the error as an input. Error here as units from 0->1000

pid_controller();

//Serial.println(integral_term, DEC);

//converts the 0->1000 units to PWM understanding units: between 0 (always off) and 255 (always on)

command = command_*200/1000 + 55;

//send command signal through PWM

analogWrite(command_pin, command); // value: the duty cycle: between 0 (always off) and 255 (always

on). value: the duty cycle: between 0 (always off) and 255 (always on).

/*

Serial.print("Actual Speed: ");

Serial.print(actual_speed_, DEC);

Serial.print(", ");

Serial.print("Ref Speed: ");

Serial.print(reference_speed_, DEC);

Serial.print(", ");

Serial.print("Error: ");

Serial.print(error_, DEC);

Serial.print(", ");

Serial.print("Command: ");

Serial.println(command_, DEC);

*/

} //If statement right before the while //this is to turn things off if the user lets go of the throttle. The

following is only done if the throttle is in a go position

} // outer most while loop

}

//**********************************************

//This function determines the speed of the motorcycle

//**********************************************

int determine_speed() {

int first_run = 1; //a switch used to determine the first time through

time_enter = millis(); //determine the time you enter this loop

flag = 0;

while (1) //loops until two pulses are found. Then continue_loop is set to 0, and kicks out

{ //while loop

if (first_run == 1) //for the first time through we need to measure a value only - since we're doing a

previous / derivative kind of measure

{

current_value = digitalRead(speed_pin);

first_run = 0; //this is used as a switch - to determine the first run through the program.

}

else //this chunk is done all other times besides the first run through

{

previous_value = current_value;

current_value = digitalRead(speed_pin);

check = (current_value+previous_value)*previous_value; //check = 1 means that it went from a 1 to a 0.

A check = 0 means two zeros in a row, and check = 2 means two ones in a row

//Serial.println(check, DEC);

if (check==1 && flag ==0)

{

time1 = millis(); //measure current time

flag = 1;

check = 0; //makese sure it doesn't run into the next if statemnt

}

if (check==1 && flag ==1)

{

time2 = millis(); //measure current time

delta_time = time2-time1;

//Serial.println(delta_time, DEC);

return delta_time;

} //end of if (check==1 && flag ==1)

} //else used for first time through

time_current = millis();

if((time_current-time_enter)>1000) //if it's taking longer than 1 second to determine speed, the speed is

essentially zero, so return a large time value

{

delta_time = 3000;

return delta_time;

}

} //end outer while loop

} //end determine_speed function

//**********************************************

//PID Routine

//**********************************************

long pid_controller() {

//determining the time step;

current_time = millis();

delta_time = (current_time-previous_time);

previous_time = current_time;

//Serial.println(delta_time, DEC);

//determine the different PID terms

proportional_term = error_*3;

integral_term = error_*delta_time/1000*3/10 + integral_term; //divide by 1000 because time is in msec.

//Since it's an integral, it sums w/ previous value of integral_term

derivative_term = (error_-error_previous_)*1000/delta_time*1/5; //multiply by 1000 because time is in

msec.

//add them together for total PID control

command_ = (proportional_term+integral_term+derivative_term); //devide by 1000 to undo integer math

used in this section

if (command_ >= 1000) //limit check and also to make sure that values don't go over 1000 - this will

cause runover.

{

command_ = 1000; //limit check. Values can only be between 0 and 1000 though the sum above could

provide values outside of the bound

}

if (command_<=10) //limit check. Values can only be between 0 and 1000 though the sum above could

provide values outside of the bound. //there is no physical meaning to a negative command. Though

negative numbers cause overflows and causes a false signal.

{

command_ = 0;

}

Serial.print(current_time);

Serial.print(", ");

Serial.print(throttle);

Serial.print(", ");

Serial.print(reference_speed_);

Serial.print(", ");

Serial.print(speed_time);

Serial.print(", ");

Serial.print(actual_speed_);

Serial.print(", ");

Serial.print(error_, DEC);

Serial.print(", ");

Serial.print(command_, DEC);

Serial.print(", ");

Serial.print(proportional_term, DEC);

Serial.print(", ");

Serial.print(integral_term, DEC);

Serial.print(", ");

Serial.println(derivative_term, DEC);

}

AppendixD: MatlabandSimulinkSimulationCode

%2.140 motorcycle project

%All units are SI

clear all

J=1.4; %combined inertia of both wheels (kg m^2)

L=50*10^-6; %motor inductance (H) at 1kHz

R=0.12; %motor resistance (ohms) at 1kHz

Kt=0.187; %torque constant (and back emf constant) (Nm/A and

Vs/rad)

b=0; %motor damping

rw=0.32; %wheel radius (m)

mu=0.02; %rolling resistance coefficient

m=305; %mass of motorcycle plus rider (kg)

CdA=0.25; %Drag coefficient times approximate frontal area (m^2)

rho=1.2; % air density (kg/m^3)

C=1/2*rho*CdA; %aerodynamic drag coefficient

g=9.8; %gravity (m/s^2)

z=6; %gear ratio'

wind=3; %wind velocity (m/s)

theta=0; %hill angle relative to horizontal in degrees up hill is

positive

%Controller Parameters

Kp=3; %proportional gain

Ki=5/10; %integral gain

Kd=1/5; %derivative gain

% Kp=31.9; %proportional gain

% Ki=5; %integral gain

% Kd=2.8; %derivative gain

numc=[Kp*Kd 0 Kp*Ki];

denc=[1 0];

s=tf([1 0],[1]);

G1=1/((L*s+R)/(Kt*z)*((J/rw+m*rw)*s+C*(1+2*wind)*rw)+Kt*z/rw);

[num,den]=tfdata(G1,'v');

G2=rw/((J/rw+m*rw)*s+C*(1+2*wind)*rw+Kt^2*z^2/((L*s+R)*rw));

[numr,denr]=tfdata(G2,'v');

RollResist=mu*m*g;

WindForce=C*wind^2;

HillForce=m*g*sind(theta);

%for the SISO tool - not really needed...

G2_siso =

(mu*m*g+C*wind^2+m*g*sind(theta))*rw/((J/rw+m*rw)*s+C*(1+2*wind)*rw+Kt

^2*z^2/((L*s+R)*rw));

G1_siso = G1*72/20;

load ExpData_Open.txt

load ExpData_Closed.txt

load ExpData_Hill.txt

sim('motorcycle_closed_loop.mdl')

sim('motorcycle_open_loop.mdl')

AppendixE: OtherMethodsofControllerdesignforElectricVehicles:

By Kavya Manyapu

In order to track longitudinal velocity of an electric motorcycle, one other technique to

design a controller is to employ a feedback linearization strategy. Although our project involves

linear dynamic model for the motorcycle, the advantage of using feedback linearization

technique helps to transform a nonlinear model into a linear closed-loop system via appropriate

control feedback. This allows the use of the linear system theorem to analyze this linear closed

loop system. The values of the design constants can be adjusted appropriately to obtain better

system performance

1

.

Figure E-1: Block Diagram of an electric motorcycle. (Shan Lin, 1999)

Yet other methods that can be used in order to have control of the plant subject to uncertainty

and exogenous disturbance is to make use of some of the advanced analysis and design tools

such as Optimal LQR/Kalman filtering, Adaptive control or robust H

/H

2

controller which

provide a significant improvement in dealing model uncertainty and disturbance attenuation in

comparison to classical linear designs.

Another interesting cruise controller design was done in a study by Lee et.al on electric vehicles

where an intelligent control system was proposed that not only could control the speed of the

electric vehicle, but also provide information about the residual power in the battery system by

monitoring its power consumption. The system consists of both motor driver control and energy

management systems. The driver control subsystem was implemented as a closed-loop speed

control system by using a muscle-like control law with compliant properties

3

. The concept of the

proposed control system that was proposed in the study is shown in figure 2., where DCS is the

drive control subsystem.

Figure E-2: An illustration of the proposed intelligent control system by Lee et.al

The design of the DCS was inspired by the compliant capabilities of the biological limb. The

illustration of the DCS control blocks is shown in figure 3 , which is an excerpt from the paper.

Figure E-3: Drive Control subsystem

The muscle control characteristics were analogs of the DC motor control and the control law for

the electric vehicle was derived relating equations of muscle control to DC motor control, where

for example the muscle force used in the figure above was defined as the DC motor control

voltage Vm

3

. Also the testing of this controller on an electric scooter proved the validity of the

design.

1. Jung-Shan Lin; Li-Chen Fu; Model Analysis and Controller Design of Electric

Motorcycles; Proceedings of the American Control Conference, California June 1999

2. Fenge Yuan, Stabilizing Control Design of a Motorcycle,Thesis,RMIT University 2007

3. Lee,D.T, Dhiah.S.J, Lee,C.M, Wee.C.H; Intelligent Control of Electric Scooters, (366)

Intelligent Systems and Control - 2002

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Lecture VIII: Fourier Series: Maxim RaginskyDocument20 pagesLecture VIII: Fourier Series: Maxim RaginskyShakil Safin OrthoPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Terminal Exams Date Sheet-Fall 2020 (Version-1) : Department of Electrical and Computer EngineeringDocument6 pagesTerminal Exams Date Sheet-Fall 2020 (Version-1) : Department of Electrical and Computer EngineeringMuhammad Zaeem AkmalPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Creep Testing Kappa SSDocument2 pagesCreep Testing Kappa SSGustavo LealPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- 05 - Beams and FramesDocument10 pages05 - Beams and FramesOn Fan ChowPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- TUTORIAL Settling - 20172018 PDFDocument15 pagesTUTORIAL Settling - 20172018 PDFHomesick TutorsPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Design and Construction of A Gallium Fixed-Point Blackbody at CENAMDocument3 pagesDesign and Construction of A Gallium Fixed-Point Blackbody at CENAMjrlr65Pas encore d'évaluation

- M2x2 2179enDocument8 pagesM2x2 2179enSerge RinaudoPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- SEMIKRON DataSheet SKKE 15 07170871 PDFDocument4 pagesSEMIKRON DataSheet SKKE 15 07170871 PDFVinicius Veiverberg DillPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Slope Deflection Method Lecture 6Document97 pagesSlope Deflection Method Lecture 6Santosh PatilPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Mathematical Modelling of GTAW and GMAWDocument240 pagesMathematical Modelling of GTAW and GMAWferayPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Tutorial: 2D Simulation of A 300 KW BERL Combustor Using The Magnussen ModelDocument17 pagesTutorial: 2D Simulation of A 300 KW BERL Combustor Using The Magnussen ModelQurat ul ainPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Theory of PlasticityDocument110 pagesTheory of Plasticitytayyeb803Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Applied Physics Lab Report 3 (Group A4)Document7 pagesApplied Physics Lab Report 3 (Group A4)T RexPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- 1st Year Chemistry All MCQS Short Questions For Federal Board Punjab BoardDocument8 pages1st Year Chemistry All MCQS Short Questions For Federal Board Punjab BoardDaniyal yousaf100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- FIITJEE Kinematics Practice Sheet for Class 11 PhysicsDocument2 pagesFIITJEE Kinematics Practice Sheet for Class 11 PhysicsVinod AgrawalPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- TPCurveExplainsOutflowPerformanceDocument2 pagesTPCurveExplainsOutflowPerformanceMuhammad MujahidPas encore d'évaluation

- Bernard P. Binks, Tommy S. Horozov Colloidal Particles at Liquid Interfaces PDFDocument519 pagesBernard P. Binks, Tommy S. Horozov Colloidal Particles at Liquid Interfaces PDFTanvir Hossain100% (1)

- Some Applications of Quantum Mechanics PDFDocument436 pagesSome Applications of Quantum Mechanics PDFArif MamonPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- MIT22 312F15 Note L4Document65 pagesMIT22 312F15 Note L4udaykumar8995Pas encore d'évaluation

- Heiser - Temperature Charts For Induction and Constant Temperature HeatingDocument10 pagesHeiser - Temperature Charts For Induction and Constant Temperature Heatingsharkdude1134Pas encore d'évaluation

- Chemical Reaction EngineeringDocument93 pagesChemical Reaction EngineeringGuru Raj BhattPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Heating Mechanism Analysis. General OverviewDocument4 pagesHeating Mechanism Analysis. General OverviewVlad TampizaPas encore d'évaluation

- Ec2305 Transmission Lines & Wave Guides Question BankDocument6 pagesEc2305 Transmission Lines & Wave Guides Question BankharvishPas encore d'évaluation

- en Atex Vegamet 624 625 Ex Vegascan 693 Ex (Index 02)Document8 pagesen Atex Vegamet 624 625 Ex Vegascan 693 Ex (Index 02)IME Salvador Zurita HernandezPas encore d'évaluation

- Particle Image VelocimetryDocument16 pagesParticle Image VelocimetrySiamakPas encore d'évaluation

- ME 218 - Spring 2018 - Week05 HandoutDocument7 pagesME 218 - Spring 2018 - Week05 HandoutNitin BhatiPas encore d'évaluation

- Matter and Atomic Structure: Jirim Dan Struktur AtomDocument1 pageMatter and Atomic Structure: Jirim Dan Struktur AtomLatchena JayashankarPas encore d'évaluation

- Physics Project On ThermoelectricityDocument10 pagesPhysics Project On ThermoelectricityAbdul SamiPas encore d'évaluation

- Chemistry 14Document3 pagesChemistry 14BALA GANESHPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Beyond Form - Http-Dahamvila-Blogspot-ComDocument21 pagesBeyond Form - Http-Dahamvila-Blogspot-ComDaham Vila BlogspotPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)