Académique Documents

Professionnel Documents

Culture Documents

Hoa Thang Genset Installation Guideline

Transféré par

Usman FaarooquiDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Hoa Thang Genset Installation Guideline

Transféré par

Usman FaarooquiDroits d'auteur :

Formats disponibles

HOA THANG

DIESEL POWER GENERATION

Diesel generator set installation recommendation INTRODUCTION

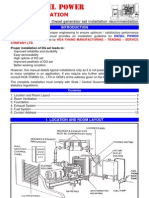

Genset Installation requires proper engineering to ensure optimum / satisfactory performance from the DG set. This manual provides an installation guideline for DIESEL POWER GENERATOR SETS supplied by HOA THANG MANUFACTURING TRADING SERVICE COMPANY LTD. Proper installation of DG set leads to: Improved reliability and durability Easy serviceability High uptime of DG set Improved aesthetic of DG set Better working condition However, this manual details typical installations only as it is not possible to give specific details to many variables in an application. If you require any further advice or information, please consult HOA THANG Co., LTD or OEMs at the address given on the back cover. The complete installation must comply with State / Central Government and other applicable statutory regulations. Contents 1. Location and Room Layout -------------------------------------------------------------------------------------- 3 2. Room Ventilation --------------------------------------------------------------------------------------------------- 4 3. Foundation ----------------------------------------------------------------------------------------------------------- 5 4. Exhaust System ---------------------------------------------------------------------------------------------------- 7 5. Fuel System---------------------------------------------------------------------------------------------------------- 9 6. Contact Address ---------------------------------------------------------------------------------------------------10

1. LOCATION AND ROOM LAYOUT

1 HOA THANG MANUFACTURING TRADING SERVICE COMPANY LTD

HOA THANG

DIESEL POWER GENERATION

Diesel generator set installation recommendation

2 HOA THANG MANUFACTURING TRADING SERVICE COMPANY LTD

HOA THANG

DIESEL POWER GENERATION

Diesel generator set installation recommendation

1.1 D.G. room should be located considering wind direction and there should be no obstruction to natural wind flow. 1.2 Position the generator set so that the prevailing wind do not enter into the radiator / exhaust outlet. If this is not possible, install a wind barrier. Distance of the wind barrier from the room should be atleast three times radiator core height. 1.3 Genset should be located away from polluted atmosphere like acidic fumes, cement dust, stone dust cotton fibres, furnace chemicals etc. wherever possible. 1.4 In case location is dusty or polluted, contact OEM/HOA THANG Co., LTD. Heavy duty air cleaner is must for such installations. Heat exchanger cooled system is recommended for such installations as radiator gets clogged in dusty atmosphere. 1.5 For humid / coastal atmospheric applications, anti condensation heaters are mandatory for alternator. 1.6 Genset should be nearer to the load centre. 1.7 Typical 2-meters free space around genset is recommended for proper heat dissipation and ease of service. However, to avoid hot air recirculation radiator cooled engines should have minimum possible space in the front. Minimum 1.5 meter free space is a must for 100 KVA and bigger gensets, for smaller gensets it should be 1 meter. Room layout is important for - Serviceability - Ventilation - Ease in operation - Genset room aesthetics 3 HOA THANG MANUFACTURING TRADING SERVICE COMPANY LTD

HOA THANG

DIESEL POWER GENERATION

Diesel generator set installation recommendation

1.8 In case of multiple sets provide minimum 2 meters clearance between gensets. 1.9 While making room layout provision should be made for : - Cables - Fuel lines - Breather vent - Coolant / lub oil drain - Raw water lines - Oil / spares storage 1.10 Future expansion plans should be considered while deciding room size.

2. ROOM VENTILATION

4 HOA THANG MANUFACTURING TRADING SERVICE COMPANY LTD

HOA THANG

DIESEL POWER GENERATION

Diesel generator set installation recommendation

2.1 Ventilation of the generator room is necessary to remove heat and fumes dissipated by the engine, alternator and its accessories and to provide clean and fresh combustion air. Ventilation requirement is mandatory for all engines. Improper ventilation can lead to : - Poor fuel efficiency - Poor performance of genset - Failures of rubber components - High exhaust temperature and related failures - Unbearable working conditions due to higher room temperatures - High temperature rise in generator windings and possible failures / insulation properties deterioration 2.2 Cross ventilation and free flow of cool, clean and fresh air is must for satisfactory operation of DG set. Air should flow from alternator end to engine 2.3 For radiator cooled engines opening in front of radiator should be 1.5 times radiator core and at back 2.25 to 3 times radiator core. Ducting in front of radiator is recommended, however it is not mandatory.If exact opening in front of the radiator is not possible then ducting should be done to take out hot air. If opening in the back side of genset is not possible then opening on both sides of genset at the rear of the alternator may be acceptable. In this case total openings in two side walls should be atleast 3 times radiator core 2.4 Additional ventilation arrangement may be required forradiator cooled engines installed in acoustic rooms/enclosures. 2.5 Maximum allowed temperature rise above ambient in genset room / enclosure is : Max. Ambient 40 oC Allowable temp 10 oC o Above 40 C Allowable temp 5 oC Please note that appropriate deration may be applicable considering altitude and temperature for a particular engine/ alternator model. For higher ambient temperature, it is suggested to use ambieter (air handling system with cooler) to reduce genset room temperature and ventilation air requirement. 2.6 Field Check for Proper Ventilation 2.6.1. Run the engine on full load / typical load for about 1 hour so that temperature in the enset room gets stabilised. 2.6.2. Measure the ambient air temperature (ambient temperature should be measured outside the genset room in shade). 2.6.3. Measure the temperature inside the genset room. Genset room temperature should be measured near air cleaner inlet of engine. 2.6.4. Calculate temperature difference between genset room temperature and ambient i.e. delta T. Sometimes to ensure proper ventilation, it may be necessary to measure actual airflow by anemometer. 2.7 Suitable deration is required in case of ducting of alternator air inlet and outlet. For details please refer to OEM.

3 FOUNDATION

5 HOA THANG MANUFACTURING TRADING SERVICE COMPANY LTD

HOA THANG

DIESEL POWER GENERATION

Diesel generator set installation recommendation

3.1 Do not install genset on loose sand or clay. 3.2 Foundation should be designed considering safe bearing capacity of soil. Vibration isolators (AVMs) reduce generator set vibration and noise transmission to the surrounding structure. Hence they are recommended, however they are not mandatory. 3.3 If foundation is with anchor bolts, higher depths of foundation is required as compared to mounting on AVMs. Please refer attached table for depths of PCC (Plain Cement Concrete) for typical soil condition, however structural engineer should be consulted to verify the data depending upon soil condition. If RCC (Reinforced Cement Concrete) is used the depth of foundation can be reduced as per recommendation of structural / civil engineer. Pockets (150 mm x 150 mm) are required if foundation bolts are to be used. For AVMs plain foundation is adequate. Static and dynamic load data for foundation design can be furnished on request. Typical Depth Foundation 200KVA 200-550kVA 550-750 750-1250 1250-2000 250mm 350mm 450mm 550mm 650mm

4. EXHAUST SYSTEM

6 HOA THANG MANUFACTURING TRADING SERVICE COMPANY LTD

HOA THANG

DIESEL POWER GENERATION

Diesel generator set installation recommendation

4.1 Exhaust system should create minimum back pressure. Higher back pressure leads to : - Lower fuel economy - High exhaust temperatures and related failures - Poor performance of the engine - Less durability of the engine 4.2 Exhaust piping inside the genset room should be lagged along with aluminum sheet ladding to avoid heat input to the room. Typical thickness of lagging is 50 mm. 4.3 Exhaust flexible shall have its free length when it is installed. Recommended piping arrangement with support locations

5. FUEL SYSTEM

7 HOA THANG MANUFACTURING TRADING SERVICE COMPANY LTD

HOA THANG

DIESEL POWER GENERATION

Diesel generator set installation recommendation

5.1 Fuel supply and return line restriction for PT fuel system is max. 100 mm Hg. Higher restriction leads to : - Lower power - Late stopping - Engine die down 5.2 Typically fuel tank should be placed on the level as that of engine i.e. floor mounted. Locate fuel tank such that fuel outlet point (at bottom of fuel tank) is maximum 1.8 m (6 feet) below the fuel pump inlet or for top mounted fuel tank, top side of fuel tank is max 1.5 m (5 feet) above fuel return line. In case of Top Mounted tanks non return valves are must in fuel supply and return lines of specified value. Please contact OEMs /Hoa Thanh Co., LTD for necessary details.

5. CONTACT ADDRESS

NGUYEN VAN THANH Director HP: 0903 760 787 HOA THANG MANUFACTURING-TRADING-SERVICE CO., LTD Add: 13/12, No. 8 Str., Linh Tay W., Thu Duc Dist., HCMC, VN Tel/Fax: (84-8) 4432507 E-mail: hoathangco@saigonnet.vn Supply: * Generator Set, Transformer Station, M & E Contractor * ATS, Synchronized Panel, Distributor Panel * Construction Machine, Industrial Equipment * Office Equipment, Fire Extinguished Equipment * Spare-parts, Installation, Reparation & Maintenance 8 HOA THANG MANUFACTURING TRADING SERVICE COMPANY LTD

Vous aimerez peut-être aussi

- Genset Installation Recommendation: A LocationDocument27 pagesGenset Installation Recommendation: A LocationShiv Kumar VermaPas encore d'évaluation

- Data Sheet FOR High Mast Lighting System: Indian Oil Corporation LimitedDocument8 pagesData Sheet FOR High Mast Lighting System: Indian Oil Corporation Limitedbiswajit biswasPas encore d'évaluation

- Turbine ErectionDocument131 pagesTurbine ErectionSam92% (12)

- Hyundai Dash 9 Posi - Nega SytemDocument70 pagesHyundai Dash 9 Posi - Nega SytemRobert Zehender99% (76)

- LSC Bus Industrial EsDocument54 pagesLSC Bus Industrial EsYonatan MayVePas encore d'évaluation

- Hyundai Electric BrochureDocument36 pagesHyundai Electric BrochurebadbenzationPas encore d'évaluation

- Bosch/Electro-Voice Ceiling Speaker Placement CalculatorDocument6 pagesBosch/Electro-Voice Ceiling Speaker Placement CalculatorKp SatishPas encore d'évaluation

- Knowledge is "Real Power": Introduction to Power QualityD'EverandKnowledge is "Real Power": Introduction to Power QualityPas encore d'évaluation

- HLE5 Series Totally Enclosed Fan-Cooled Induction MotorsDocument112 pagesHLE5 Series Totally Enclosed Fan-Cooled Induction MotorsJuanFuentesBecerra100% (3)

- Temperature Winding CorrectionDocument4 pagesTemperature Winding CorrectionedgardPas encore d'évaluation

- Motor Pump Protection RelaysDocument6 pagesMotor Pump Protection RelaysAnand ShuklaPas encore d'évaluation

- Lts-Cvg-P01-16-0005-A4 Daar PDFDocument32 pagesLts-Cvg-P01-16-0005-A4 Daar PDFSanjoy SanyalPas encore d'évaluation

- 13.MCB For Motor ProtectionDocument48 pages13.MCB For Motor Protectionrajinipre-1Pas encore d'évaluation

- HT SWITCHGEAR specification summaryDocument7 pagesHT SWITCHGEAR specification summaryIwan TristiawanPas encore d'évaluation

- Service Manual Goodman GPH16MDocument63 pagesService Manual Goodman GPH16MMitchell BaileyPas encore d'évaluation

- Technical Specification of 1MW Diesel Generator Power Plant Set From ChinaDocument21 pagesTechnical Specification of 1MW Diesel Generator Power Plant Set From ChinaAndrew Jeyakumar100% (1)

- Energy Efficient Motor Efficiency ClassDocument36 pagesEnergy Efficient Motor Efficiency ClassGAGANPas encore d'évaluation

- DMA AD Lighting Handbook 1sted Elec - Ver Part 2Document244 pagesDMA AD Lighting Handbook 1sted Elec - Ver Part 2zelitePas encore d'évaluation

- HV CablesDocument74 pagesHV CablesRague MiueiPas encore d'évaluation

- Specification For Variable Speed DrivesDocument18 pagesSpecification For Variable Speed DrivesBalasubramani100% (1)

- Guide For Electrical Design Engineers - Chapter 5: Mitigation of Voltage UnbalanceDocument16 pagesGuide For Electrical Design Engineers - Chapter 5: Mitigation of Voltage UnbalanceHans De Keulenaer100% (5)

- Marine BoilersDocument16 pagesMarine BoilersPawan Beniwal100% (1)

- Datasheet For Induction MotorDocument5 pagesDatasheet For Induction MotorRohan GuravPas encore d'évaluation

- WAPDA Circuit Breaker SpecificationDocument33 pagesWAPDA Circuit Breaker SpecificationSami Ulhaq100% (1)

- Parameter: Data Sheet For 3 Phase TransformerDocument1 pageParameter: Data Sheet For 3 Phase Transformermkbhat17kPas encore d'évaluation

- Concrete ON MALDIVESDocument55 pagesConcrete ON MALDIVESKãrthìçk JkrPas encore d'évaluation

- Chemrite - 540Document2 pagesChemrite - 540ghazanfarPas encore d'évaluation

- Generators & UPSDocument15 pagesGenerators & UPSgopalraojiPas encore d'évaluation

- Fig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyDocument3 pagesFig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyAmer GonzalesPas encore d'évaluation

- Guidecesmm3 Sa v1Document96 pagesGuidecesmm3 Sa v1Hafizuddin HanafiPas encore d'évaluation

- Caterpillar XQ1000 Containerized Diesel Generator SetDocument10 pagesCaterpillar XQ1000 Containerized Diesel Generator SetMacAllister MachineryPas encore d'évaluation

- EN50272 enDocument1 pageEN50272 enRadu JunePas encore d'évaluation

- Annexure-1 - IE Transformer EarthingDocument1 pageAnnexure-1 - IE Transformer Earthingniltanishq143Pas encore d'évaluation

- Electrical Regulations IndexDocument61 pagesElectrical Regulations IndexRabi Sankar BanerjeePas encore d'évaluation

- ABB TransformatoriDocument1 pageABB TransformatoridgngPas encore d'évaluation

- YKK Series High-Voltage Three-phase Induction Motors CatalogDocument17 pagesYKK Series High-Voltage Three-phase Induction Motors CatalogAgustinus Bayu Dewanto100% (1)

- NEC cable tray sizing guideDocument5 pagesNEC cable tray sizing guideVishnu Vardhan Reddy BaitintiPas encore d'évaluation

- Networking Working BOQ PDFDocument9 pagesNetworking Working BOQ PDFMuneeb Ur rehmanPas encore d'évaluation

- Oman Wastewater electrical standardDocument18 pagesOman Wastewater electrical standardbakien-canPas encore d'évaluation

- Cambodia Catalog Passenger Lift PDFDocument28 pagesCambodia Catalog Passenger Lift PDFaliPas encore d'évaluation

- 20 - Technical Data & FormulationsDocument11 pages20 - Technical Data & FormulationsSnzy DelPas encore d'évaluation

- Transformers Troubleshooting GuideDocument1 pageTransformers Troubleshooting GuidemahmoudPas encore d'évaluation

- Medium Voltage Metal Clad Switchgear CatalogDocument24 pagesMedium Voltage Metal Clad Switchgear CatalogRobert John ToledoPas encore d'évaluation

- Air Core Reactor Design ReviewDocument4 pagesAir Core Reactor Design Reviewwaqas_a_shaikh4348Pas encore d'évaluation

- Rowan University Design Guide - PanelboardsDocument1 pageRowan University Design Guide - PanelboardszelitePas encore d'évaluation

- Electrical Cable Sizing Calculation for 80KW LoadDocument5 pagesElectrical Cable Sizing Calculation for 80KW LoadacecPas encore d'évaluation

- Cable LoadDocument1 pageCable LoadSenthil KumarPas encore d'évaluation

- CBIP PublicationDocument6 pagesCBIP PublicationVamsi ManojPas encore d'évaluation

- Medium Velocity Water Spray (MVWS) System - Electrical4UDocument16 pagesMedium Velocity Water Spray (MVWS) System - Electrical4UkaustavPas encore d'évaluation

- Electrical Characteristics of CablesDocument32 pagesElectrical Characteristics of CablesSupakint Suteepichatpunt100% (1)

- Electrical-Engineering-Examination Syllabus PDFDocument7 pagesElectrical-Engineering-Examination Syllabus PDFJoseph JoePas encore d'évaluation

- Ductile Iron Gate Valve PN16. BS EN 1171:2002 PN16Document8 pagesDuctile Iron Gate Valve PN16. BS EN 1171:2002 PN16Emil AbdoPas encore d'évaluation

- Overcurrent Protection Relays PDFDocument3 pagesOvercurrent Protection Relays PDFruwangaroshalPas encore d'évaluation

- The Panama Canal: Third Set of Locks ProjectDocument33 pagesThe Panama Canal: Third Set of Locks Projectomar_cohen_1Pas encore d'évaluation

- Goel Power Engineers AMF Panel Price-ListDocument1 pageGoel Power Engineers AMF Panel Price-Listrdeepak99100% (1)

- Process Automation Factory Automation Terminal AutomationDocument4 pagesProcess Automation Factory Automation Terminal AutomationRitaban R. BanerjeePas encore d'évaluation

- How To Read A Motor NameplateDocument8 pagesHow To Read A Motor Nameplateabdulyunus_amirPas encore d'évaluation

- Turndown Ratio ExplainedDocument3 pagesTurndown Ratio ExplainedklashincoviskyPas encore d'évaluation

- Data Bulletin Transformer Key Features: Dry-Type, Cast-Resin, and Liquid-Filled Transformers Class 7300Document4 pagesData Bulletin Transformer Key Features: Dry-Type, Cast-Resin, and Liquid-Filled Transformers Class 7300Dinesh SelvakumarPas encore d'évaluation

- Annex A Requirement Specs - HVLS Fan 20 Feb FinalDocument3 pagesAnnex A Requirement Specs - HVLS Fan 20 Feb FinalJia WenjiePas encore d'évaluation

- 16280x Eaton MV Autovar PFC Capacitor Bank Specifications Oct112013Document16 pages16280x Eaton MV Autovar PFC Capacitor Bank Specifications Oct112013Ahmed Said GhonimyPas encore d'évaluation

- Trench SpecificationsDocument4 pagesTrench SpecificationsFatoni Gea AirlanggaPas encore d'évaluation

- Is 2026 1 2011 PDFDocument31 pagesIs 2026 1 2011 PDFAravind Sampath100% (2)

- Is 14494 1998Document37 pagesIs 14494 1998Anand Agrawal100% (1)

- Electromagnetic Flow MetersDocument11 pagesElectromagnetic Flow MeterssethuraghulPas encore d'évaluation

- Voltage DropDocument5 pagesVoltage DropZulkarnain DahalanPas encore d'évaluation

- NATF Dallas 20150604 JContoDocument16 pagesNATF Dallas 20150604 JContoUsman FaarooquiPas encore d'évaluation

- NATF Dallas 20150604 JContoDocument16 pagesNATF Dallas 20150604 JContoUsman FaarooquiPas encore d'évaluation

- OdzDocument62 pagesOdzTudor RatiuPas encore d'évaluation

- BlackBerry - PlayBook - Tablet User - Guide 1526983 0418113733 001 1.0 US PDFDocument48 pagesBlackBerry - PlayBook - Tablet User - Guide 1526983 0418113733 001 1.0 US PDFUsman FaarooquiPas encore d'évaluation

- Application Challenges GFMDocument12 pagesApplication Challenges GFMUsman Faarooqui100% (1)

- Reporting of M. Tech. Candidates For AdmissionDocument3 pagesReporting of M. Tech. Candidates For AdmissionDevender SharmaPas encore d'évaluation

- A Review of Optimization Techniques For Hybrid Renewable Energy SystemsDocument16 pagesA Review of Optimization Techniques For Hybrid Renewable Energy SystemsUsman FaarooquiPas encore d'évaluation

- Basis MATLABDocument4 pagesBasis MATLABUsman FaarooquiPas encore d'évaluation

- Pohnpei Hospital Preliminary Engineering ReportDocument2 pagesPohnpei Hospital Preliminary Engineering ReportUsman FaarooquiPas encore d'évaluation

- Apr Jun12 PetrofedDocument92 pagesApr Jun12 PetrofedUsman FaarooquiPas encore d'évaluation

- Hoa Thang Genset Installation GuidelineDocument8 pagesHoa Thang Genset Installation GuidelineUsman FaarooquiPas encore d'évaluation

- GeneratorDocument1 pageGeneratorelectricalconsultantPas encore d'évaluation

- Input EchoDocument62 pagesInput EchoAkhil JosePas encore d'évaluation

- Basalt FRP Reinforcing Bars For Concrete StructuresDocument6 pagesBasalt FRP Reinforcing Bars For Concrete StructuresSuresh ShanmugavelPas encore d'évaluation

- Polycarbonate Glazing SystemDocument16 pagesPolycarbonate Glazing SystemGirish DhawanPas encore d'évaluation

- ECOBA Statistic 2004Document1 pageECOBA Statistic 2004dungnv2733Pas encore d'évaluation

- Fuzhou Tianyu Electric Co., LTD.: KYN31-24 Armored Metal-Enclosed SwitchgearDocument22 pagesFuzhou Tianyu Electric Co., LTD.: KYN31-24 Armored Metal-Enclosed SwitchgearRusman LumbantoruanPas encore d'évaluation

- Attachment 07.1 - ARGAL - Vertical PumpsDocument28 pagesAttachment 07.1 - ARGAL - Vertical PumpsJefferson GilPas encore d'évaluation

- SD SD1Document1 pageSD SD1Mohammed AldajaPas encore d'évaluation

- Commissioning Documentation For Final Inspection and Certificate of Occupancy 2Document1 pageCommissioning Documentation For Final Inspection and Certificate of Occupancy 2Humaid ShaikhPas encore d'évaluation

- Valuation Report ExampleDocument25 pagesValuation Report ExampleKenan TemboPas encore d'évaluation

- Structural Coils (SS) : International StandardsDocument2 pagesStructural Coils (SS) : International StandardsVengatesh HariPas encore d'évaluation

- IIT Fracture and Fatigue Short CourseDocument248 pagesIIT Fracture and Fatigue Short CourseSumit BasuPas encore d'évaluation

- Design of ring foundation for 18m diameter tankDocument6 pagesDesign of ring foundation for 18m diameter tankSher AfganPas encore d'évaluation

- DNV RU YACHT Pt3Ch5Document68 pagesDNV RU YACHT Pt3Ch5Ante KezicPas encore d'évaluation

- Tender Process AND DocumentationDocument35 pagesTender Process AND DocumentationHardik GandhiPas encore d'évaluation

- Assignment Road Constuction IIDocument6 pagesAssignment Road Constuction IIKry ThanakPas encore d'évaluation

- Operator's Manual for 662420-B Air Motor Oil PumpDocument11 pagesOperator's Manual for 662420-B Air Motor Oil PumpgnunezisventecPas encore d'évaluation

- Stress and Strain - Axial Loading2Document33 pagesStress and Strain - Axial Loading2Clackfuik12Pas encore d'évaluation

- Form 1 - Architect's CertificationDocument4 pagesForm 1 - Architect's CertificationAkshata Patil ParvatikarPas encore d'évaluation

- Polymers 13 03480 v2Document13 pagesPolymers 13 03480 v2SEBASDAZACPas encore d'évaluation

- Concrete Mix Design Methods, Verification StudyDocument26 pagesConcrete Mix Design Methods, Verification StudyAhmed M AminPas encore d'évaluation

- Auris Ilaria Tower ADocument9 pagesAuris Ilaria Tower AvPas encore d'évaluation

- ENG 3731 Materials and Methods Construction Course OverviewDocument21 pagesENG 3731 Materials and Methods Construction Course OverviewJanina Frances RuideraPas encore d'évaluation