Académique Documents

Professionnel Documents

Culture Documents

Chemical Injection Skid

Transféré par

Aszrol PonimanDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chemical Injection Skid

Transféré par

Aszrol PonimanDroits d'auteur :

Formats disponibles

Title: Chemical Injection System Company: BC Petrochemical Sdn Bhd

OVERVIEW

Generally, Chemical Injection Skid is a chemical dosing system which is mainly used for oil & gas production, water injection and reduction of corrosion problem. The system consists of reciprocating pump, tote tank, mechanical & instrumentation items and etc. The system will be fabricate and design by manufacturer accordingly to the project requirement which been approved by client and design consultant. Typical chemical injection services as below:

System A. Oil Process Chemical Demulsifier Reverse emulsion breaker/deoiler Anti-foam Purpose Breaks down oil emulsions to aid oil/water separation. Will coalesce oil droplets in produced water systems. Prevents or minimises build-up of foam in production/test separators (prevents possible carry-over, improves separation efficiency). Reduces crude pour point to improve/maintain crude fluid characteristics. Modifies wax crystal structure and minimises wax build-up in oil systems. To prevent scale build-up in oil lines/equipment. To prevent/minimise corrosion in oil systems. To reduce H2S content. To treat/prevent asphaltenes To reduce flowing back pressure Inhibits formation of hydrates. Inhibits formation of hydrates. Eliminates potential of hydrates. To prevent/minimise corrosion in gas and oil system. To prevent foaming in deaerator (thereby maintaining efficient operation). To reduce oxygen content of water to be injected to zero. To assist in final filtration of water prior to injection. To complete biological treatment of water prior to injection. To minimise formation of scale in reservoir.

Pour point depressant Wax formation inhibitor Anti-scale Corrosion inhibitor H2S scavenger Asphaltene dispersant Drag Reducer Hydrate formation inhibitor B. Gas Process Hydrate formation inhibitor Glycol Corrosion inhibitor C. Water Process Anti-foam Oxygen scavenger Filter aid (e.g. ferric chloride) Biocide Scale inhibitor

Prepared by: MRS

Title: Chemical Injection System Company: BC Petrochemical Sdn Bhd

Some skids been design with IRCD unit. IRCD is an abbreviation of Injection Rate Control Device. Since introduction of IRCD, it allowed accurate dosing into a large number of injection points without need for separate dosing pumps. The control systems are designed to compensate for variations in the downstream system pressure at each point and maintain a constant chemical flow rate. The system will be cost-effective with as few as four injection points. The concept also has a potential application for NNM platforms where chemical transfer is by umbilical from the main platform.

Prepared by: MRS

Title: Chemical Injection System Company: BC Petrochemical Sdn Bhd

PRODUCT APPLICATION

APPLICATION OIL INDUSTRY OFFSHORE * Corrosion Inhibitor * Biocides * Methanol and Glycol * Pour Point Depressants * Wax Inhibitor GAS INDUSTRY * Boiler feed treatment * Methanol Injection CHEMICAL PLANT INDUSTRY * Boiler treatment * Water Treatment * Handling of liquefied gases REFINING * Water Treatment chemicals * The injection of inhibitor and gasoline to fuel oils

Prepared by: MRS

Title: Chemical Injection System Company: BC Petrochemical Sdn Bhd

TRACK RECORD

YEAR-2007 SCOPE OF SUPPLY: DESIGN, FABRICATE & SUPPLY 4 (FOUR) SKID CHEMICAL INJECTION SYSTEM (SMP-A/B/B & SMG-A) PROJECT: SAMARANG PROJECT LOCATION: SAMARANG PLATFORM, LABUAN CLIENT: SHAPADU ENERGY & ENGENEERING END USER: PETRONAS CARIGALI SDN BHD DELIVERY DATE: MAY, 2007 YEAR- 2008 SCOPE OF SUPPLY: DESIGN, FABRICATE & SUPPLY ONE (1) UNIT OF CHEMICAL INJECTION SKID (AQ-6800) PROJECT: EPCC J4 DEVELOPMENT LOCATION: J4 PLATFORM, BINTULU SARAWAK. CLIENT: KENCANA HL SDN BHD END USER: PETRONAS CARIGALI SDN BHD DELIVERY DATE: MARCH, 2008

Prepared by: MRS

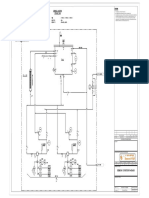

BC PETROCHEMICAL SDN BHD APPENDIX 1

Project Client End User Delivery date : SAMARANG PROJECT : SHAPADU ENERGY & ENG. (SEEN) : PETRONAS CARIGALI SDN BHD : MAY, 2007 Project Client End User Delivery Date : EPCC J4 DEVELOPMENT : KENCANA HL SDN BHD : PETRONAS CARIGALI SDN BHD : MARCH, 2008

SMG-A SKID : CORROSION INHIBITOR

CI skid with 5 air driven pumps and 13 IRCD unit

SMP-A/B/C SKIDS : CI & BIOCIDE

During Installation at fabrication yard

IN HOUSE FACTORY ACCEPTANCE TEST

Skid consist of CI, PPD & WAX DISSOLVER

Vous aimerez peut-être aussi

- Chemical Injection PDFDocument4 pagesChemical Injection PDFermusat100% (1)

- Production ImprovementsDocument8 pagesProduction ImprovementsAlberto darianPas encore d'évaluation

- Chemical Injection SkidDocument6 pagesChemical Injection SkidRaheel SultanPas encore d'évaluation

- SOW - Chemical Injection Skids (Solar) Rev0Document13 pagesSOW - Chemical Injection Skids (Solar) Rev0Aamir Sayeed100% (2)

- Chemical Injection Package SpecificationDocument21 pagesChemical Injection Package SpecificationAnonymous ygQUvDK100% (2)

- P&ID Additive Injection SkidDocument4 pagesP&ID Additive Injection SkidOctavianus Harahap100% (3)

- ONGC - Mehsana P&ID For Chemical Dosing Skid-1Document1 pageONGC - Mehsana P&ID For Chemical Dosing Skid-1bmanojkumarPas encore d'évaluation

- Hen 0000 Me SP 0012 - B4Document29 pagesHen 0000 Me SP 0012 - B4sherviny100% (2)

- Dye Injection Skid Process DatasheetDocument7 pagesDye Injection Skid Process Datasheetjibran42Pas encore d'évaluation

- Pig Trap Interlock SpecificationDocument5 pagesPig Trap Interlock SpecificationUzezi OkePas encore d'évaluation

- 10 Gas Conditioning SystemDocument24 pages10 Gas Conditioning SystemRavi Sankar VenkatesanPas encore d'évaluation

- Basics of Wellhead Control Panel (WHCP) Instrumentation ToolsDocument21 pagesBasics of Wellhead Control Panel (WHCP) Instrumentation ToolsJOHNSON SANYAPas encore d'évaluation

- 01 T121-HA-02005 Specification For Metering Skid PDFDocument13 pages01 T121-HA-02005 Specification For Metering Skid PDFMayur Patel100% (2)

- BL 1649 US Chemical Injection For Oil and Gas Tcm11-7888Document12 pagesBL 1649 US Chemical Injection For Oil and Gas Tcm11-7888Veera ManiPas encore d'évaluation

- Scope of Work For New Chemical Skid On PQP-HT Draft Copy For InformationDocument13 pagesScope of Work For New Chemical Skid On PQP-HT Draft Copy For InformationBui Khoi Nguyen100% (3)

- Chemical Injection MethodsDocument13 pagesChemical Injection MethodsIndra NainggolanPas encore d'évaluation

- Peco Filter CaseDocument11 pagesPeco Filter CaseLuis MaureraPas encore d'évaluation

- L&T GateGlobe&CheckValves-API 600Document31 pagesL&T GateGlobe&CheckValves-API 600vsvineesh100% (1)

- TC1625 - Catalog - pgs41-43 Cameron Wills PDFDocument3 pagesTC1625 - Catalog - pgs41-43 Cameron Wills PDFFelix Julio Céspedes SotoPas encore d'évaluation

- Final MSR Rev (1) - CDocument104 pagesFinal MSR Rev (1) - CDeepak Goyal100% (1)

- Comparing API and ASME-ANSI Flanges Dimensions and Pressure RatingsDocument2 pagesComparing API and ASME-ANSI Flanges Dimensions and Pressure Ratingsjorge1952100% (1)

- Chemical Injection SkidDocument1 pageChemical Injection SkidKalyankumar KrishnamoorthyPas encore d'évaluation

- Pig Launcher & ReceiverDocument4 pagesPig Launcher & ReceiverMEHDI100% (1)

- El Merk Project Contract No.: SC 4012100 Petrofac Job No.: JI - 195Document5 pagesEl Merk Project Contract No.: SC 4012100 Petrofac Job No.: JI - 195Marwa KoubaiesPas encore d'évaluation

- (Chemical Injection System) - Operation and Maintenance ManualDocument19 pages(Chemical Injection System) - Operation and Maintenance Manualasri elektronikPas encore d'évaluation

- Data Sheet Sight GlassDocument5 pagesData Sheet Sight GlassAdhya RazanPas encore d'évaluation

- SK-A-YCC-021 Sales Gas Filtration System FSDDocument30 pagesSK-A-YCC-021 Sales Gas Filtration System FSDtouseef88Pas encore d'évaluation

- Transient Study of Trip on Associated Gas CompressorDocument16 pagesTransient Study of Trip on Associated Gas Compressorjagiprem123Pas encore d'évaluation

- Matrix solutions bangalore pipe sizingDocument2 pagesMatrix solutions bangalore pipe sizingNaveen PetePas encore d'évaluation

- Oil & gas chemical injection systemsDocument2 pagesOil & gas chemical injection systemsharry_chemPas encore d'évaluation

- Vessel Data SheetDocument1 pageVessel Data SheetMichael HaisePas encore d'évaluation

- Hydraulic Report - 23th MarchDocument51 pagesHydraulic Report - 23th MarchGoutam GiriPas encore d'évaluation

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinPas encore d'évaluation

- Peq001-03-Dcom-0000-Pl-T601-3001-2 - General Drawing Tlt-La-3170Document1 pagePeq001-03-Dcom-0000-Pl-T601-3001-2 - General Drawing Tlt-La-3170Carlin BabuchasPas encore d'évaluation

- Mokveld-Product Sheet Angle ChokeDocument2 pagesMokveld-Product Sheet Angle Chokeyulianus_sr100% (1)

- Operating Manual Sec 12 - Chemical Injection - Rev0Document6 pagesOperating Manual Sec 12 - Chemical Injection - Rev0Anonymous aIuHKoKZjPas encore d'évaluation

- Zirco Ltd. Pressure/Vacuum Relief Valve: ClientDocument1 pageZirco Ltd. Pressure/Vacuum Relief Valve: Clientsusanto100% (1)

- ONGC P&ID For W+SDocument1 pageONGC P&ID For W+SbmanojkumarPas encore d'évaluation

- Heavy Oil Drag Reducing Agent PDFDocument12 pagesHeavy Oil Drag Reducing Agent PDFMichael MedinaPas encore d'évaluation

- Wellhead control panel solutionDocument2 pagesWellhead control panel solutionkmsrini@yahoo.com100% (1)

- Dual Pot Sand Filter PsDocument2 pagesDual Pot Sand Filter PskanchanabalajiPas encore d'évaluation

- 3-Phase Test Separators VVFDocument2 pages3-Phase Test Separators VVFPetroFisicPas encore d'évaluation

- 13049-03-MIS-003 - Well Head Control PanelsDocument12 pages13049-03-MIS-003 - Well Head Control PanelsJuan Pablo Sanchez MelgarejoPas encore d'évaluation

- Quick Opening ClosuresDocument4 pagesQuick Opening ClosureseduinPas encore d'évaluation

- Chemical Injection MethodsDocument13 pagesChemical Injection MethodsCakTomPas encore d'évaluation

- Operating & Control PhilosophyDocument16 pagesOperating & Control PhilosophyPrasadPas encore d'évaluation

- Operating ManualDocument58 pagesOperating ManualMaamer Zayd100% (1)

- Pig Launching & Receiving Procedures ExplainedDocument11 pagesPig Launching & Receiving Procedures ExplainedBalasubramanianPas encore d'évaluation

- PB02-LPS-001 Low Pressure Steam System: Saudi Arabian Oil CompanyDocument1 pagePB02-LPS-001 Low Pressure Steam System: Saudi Arabian Oil CompanyzhangPas encore d'évaluation

- LAUNCH & RETRIEVAL METHODSDocument7 pagesLAUNCH & RETRIEVAL METHODSGerman Felipe Torres100% (4)

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariPas encore d'évaluation

- Snamprogetti: Gaskets For Flanged PipingDocument10 pagesSnamprogetti: Gaskets For Flanged PipingTerrance Badree100% (3)

- Manual Valves Datasheet. Rev 1Document7 pagesManual Valves Datasheet. Rev 1eke23Pas encore d'évaluation

- GP 43-50 31 January 2009Document52 pagesGP 43-50 31 January 2009Orlando RojasPas encore d'évaluation

- Pig Launcher and Receiver TrapDocument1 pagePig Launcher and Receiver TrapJaroslaw KoniecznyPas encore d'évaluation

- Dosing SystemDocument27 pagesDosing Systemmanoj nirgude100% (3)

- Chemical Dosing Package P&IDDocument1 pageChemical Dosing Package P&IDbmanojkumarPas encore d'évaluation

- Design Engineering Services BrochureDocument40 pagesDesign Engineering Services BrochureAiddie GhazlanPas encore d'évaluation

- Saes A 014 PDFDocument20 pagesSaes A 014 PDFSuman TamilselvanPas encore d'évaluation

- SAES-A-014 Design of Hydrate Inhibition and Dehydration Systems PDFDocument21 pagesSAES-A-014 Design of Hydrate Inhibition and Dehydration Systems PDFFlorante NoblezaPas encore d'évaluation

- MA 4wrkshp Sept ZDocument4 pagesMA 4wrkshp Sept ZAszrol PonimanPas encore d'évaluation

- Electrical Service & Wiring Installation Handbook: (806) 775-7732 Lubbock (806) 271-3311 Spur (940) 937-2565 ChildressDocument36 pagesElectrical Service & Wiring Installation Handbook: (806) 775-7732 Lubbock (806) 271-3311 Spur (940) 937-2565 Childressamrsah61083Pas encore d'évaluation

- Model RSF66 Dual Position Series: Technical Specifications RSF66 Electrical SpecificationsDocument5 pagesModel RSF66 Dual Position Series: Technical Specifications RSF66 Electrical SpecificationsAszrol PonimanPas encore d'évaluation

- Alco 2vr SeriesDocument1 pageAlco 2vr SeriesAszrol PonimanPas encore d'évaluation

- PCB ManufacturingDocument60 pagesPCB ManufacturingRichard PuthotaPas encore d'évaluation

- Freeze Dryer Lyophilisation FishDocument4 pagesFreeze Dryer Lyophilisation FishcouvrefeuPas encore d'évaluation

- Zinky-13 Inorganic Zinc Rich Primer Technical Data SheetDocument4 pagesZinky-13 Inorganic Zinc Rich Primer Technical Data SheetppglPas encore d'évaluation

- CH 1 Construction Materials Notes.Document7 pagesCH 1 Construction Materials Notes.Naif AbdulfetahPas encore d'évaluation

- Testing For Biological MoleculesDocument3 pagesTesting For Biological MoleculessariniPas encore d'évaluation

- Waukesha Worldpump - ArticleDocument4 pagesWaukesha Worldpump - Articlepaulo cesar hernandez mijangosPas encore d'évaluation

- J Est 2018 11 027Document14 pagesJ Est 2018 11 027Hiraya HaeldrichPas encore d'évaluation

- Reactive Wetting, Evolution of Interfacial and Bulk IMCs and Their Effect On Mechanical PDFDocument32 pagesReactive Wetting, Evolution of Interfacial and Bulk IMCs and Their Effect On Mechanical PDFeid elsayedPas encore d'évaluation

- U-5 - 2022 - Tecnologías de Tratamientos - BDocument39 pagesU-5 - 2022 - Tecnologías de Tratamientos - BSimón OsésPas encore d'évaluation

- General ChemistryDocument44 pagesGeneral ChemistrySUSANA, NIÑA FELIZ C.100% (1)

- Geotehnics of SoftsoilDocument44 pagesGeotehnics of SoftsoilVinna RinayaniPas encore d'évaluation

- Bayer Process Diagram ExplainedDocument6 pagesBayer Process Diagram ExplainednatsmdPas encore d'évaluation

- Hazardous Substance Assessment Checklist Rev 3-1Document5 pagesHazardous Substance Assessment Checklist Rev 3-1Santo WardanaPas encore d'évaluation

- Fan - 2009 - 8 - ECTC 2009 - 2 RahimDocument5 pagesFan - 2009 - 8 - ECTC 2009 - 2 RahimkraidonPas encore d'évaluation

- Fire Watch Training PDFDocument41 pagesFire Watch Training PDFHamdi Rafiek83% (23)

- Parker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016Document370 pagesParker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016mds9185Pas encore d'évaluation

- SABIC® LLDPE - 118NM - Global - Technical - Data - SheetDocument1 pageSABIC® LLDPE - 118NM - Global - Technical - Data - SheetKenneth ShiPas encore d'évaluation

- Bronze Castings For Bridges and TurntablesDocument4 pagesBronze Castings For Bridges and TurntablesmatiullahPas encore d'évaluation

- Development of An Electrochemical Metal-Ion Biosensor Using Self-Assembled Peptide NanofibrilsDocument7 pagesDevelopment of An Electrochemical Metal-Ion Biosensor Using Self-Assembled Peptide NanofibrilsRenan Guilherme de Oliveira GuihPas encore d'évaluation

- Chlorine Dioxide PDFDocument4 pagesChlorine Dioxide PDFSudhakar Rao100% (1)

- Coal combustion calculationsDocument3 pagesCoal combustion calculationsShane PatulotPas encore d'évaluation

- Chapter 13 Rock Physics at Laboratory Scale, From Textbook: Rock Quality, Seismic Velocity, Attenuation and AnisotropyDocument47 pagesChapter 13 Rock Physics at Laboratory Scale, From Textbook: Rock Quality, Seismic Velocity, Attenuation and AnisotropyCamilo Cepeda UgaldePas encore d'évaluation

- ASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedDocument1 pageASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedAmanda Ariesta ApriliaPas encore d'évaluation

- 374382Document32 pages374382RertobiPas encore d'évaluation

- Critical Chloride Content in Reinforced ConcreteDocument7 pagesCritical Chloride Content in Reinforced ConcreteAshrafPas encore d'évaluation

- Determination of Alcohol Content in WineDocument5 pagesDetermination of Alcohol Content in WineAna María Vallejo TorresPas encore d'évaluation

- Textile Apparel Ecological Safety Quality V9 - 3Document21 pagesTextile Apparel Ecological Safety Quality V9 - 3mmbPas encore d'évaluation

- 3466Document8 pages3466sk m hassanPas encore d'évaluation

- FP TackifierDocument8 pagesFP TackifierNguyễn Viết LươngPas encore d'évaluation

- GTU BE Semester V Mass Transfer Operations I Exam Summer 2016Document2 pagesGTU BE Semester V Mass Transfer Operations I Exam Summer 2016Shivam PanchalPas encore d'évaluation