Académique Documents

Professionnel Documents

Culture Documents

Scope of Work For Mining Contractor & Coal Production Schedule - Rev.1

Transféré par

setiawannmDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Scope of Work For Mining Contractor & Coal Production Schedule - Rev.1

Transféré par

setiawannmDroits d'auteur :

Formats disponibles

201 1

COAL PRODUCTION SCHEDULE AND SCOPE OF WORK FOR MINING CONTRACTOR

PT. KUTAI ENERGI

Coal Mining Company

[Type the company name] | Confidential

PT. Kutai Energi Coal

Project

CONTENS

I.

II. III.

MINING DEVELOPMENT FOR A MINING PERIOD OF 5 YEARS COAL PRODUCTIONSCHEDULE SCOPE OF WORKS

III.1. Mining Operational III.1.1. Clearing III.1.2. Mining Overburden III.1.3. Waste Dump Location III.1.4. Coal Extraction III.1.4.1. Extraction III.1.4.3. Coal Delivery (Delivery point)

III.1.5. Haul Road III.1.5.1. Pit Areas III.1.5.2. Coal Haul Road maintenance III.1.6. Drainage III.1.7. Reclamation III.1.8. Safety and Occupational Health

III.2. General III.2.1. Office and Workshop facilities III.2.2. Camp for mining contractor staff and operators.

PT Kutai Energi | Confidential

PT. Kutai Energi Coal

Project

I.

MINING DEVELOPMENT FOR A MINING PERIOD OF 5 YEARS, AFTER INITIAL SETUP

PT. Kutai Energi coal project covers an area of 6,932 Hectares in the Kutai Kartanegara Regency, East Kalimantan Province. PT. Kutai Energi is focused on its core business of coal mining, and the mine operation was commenced production in 2010. We are continually doing extensive drilling exploration program to improve our coal resources and reserves. Throughout 2010 PT Kutai Energi continued an extensive exploration program and in 2011 exploration involved up to 21 drill rigs.

By the end of year 2010, PT. Kutai Energi commence improving mine infrastructure on with the plan of further integration and on track to achieve a better Kutai Energi.

All projects are designed to further create value through increased production and improved efficiency

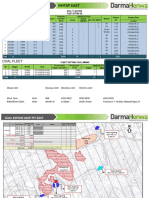

The following table is a mining development program from 2011 to 2015

PT. Kutai Energi | Confidential

PT. Kutai Energi Coal

Project

Mining D ve e lopm nt P ra P K i E rg e rog m T uta ne i P riod 2 1 - 2 1 e 01 05 No Ds e cription

Y r1 Y r2 Y r3 Y r4 Y r5 ea ea ea ea ea 21 01 21 02 21 03 21 04 21 05

1 C haul road construction pit to port : 10 KM oal 2 Port - L oadingconveyor cap. 1200t/hour 3 4 5 C S oal tockpile C rusher constr. 2 x 300 t/hour C onveyor use tripper travel/tripper car

6 KEMine office, and m ess 7 D rillingeksploration Block B, 2 and 3 8 D rillingeksploration Block 1,4 and F 9 D rillingeksploration Block C Dand E , 10 D rillingeksploration Block 5 and J 11 D rillingeksploration Block Gand H 12 Upg rade C rusher, barg loadingconvy. e

II.

COAL PRODUCTION SCHEDULE - MINING PERIOD OF 5 YEARS

PT. Kutai Energis target is to increase production in 2012, by conducting mine infrastructure completed in 2011.

PT Kutai Energi | Confidential

PT. Kutai Energi Coal

Project

C A P O U T NS H D L - P K T I E E G O L R D C IO C E U E T U A N R I P R D2 1 - 2 1 E IO 0 2 0 6

Pit SCHEDULE Waste Coal Exposed

Ash CV S ulphur TM IM adb adb gar adb ar adb

Base Quality

Units bcm tonne % Kcal/kg Kcal/kg % % %

2012

14,490,000 1,575,000

2013

18,768,000 2,040,000

2014

24,840,000 2,700,000

2015

28,069,402 3,051,022

27

4.95 5,744 5,152 1.25 24.74 16.09 9.2

4.95 5,744 5,152 1.25 24.74 16.09 9.2

5.05 5,776 5,242 1.41 23.57 15.78 9.2

5.04 5,764 5,228 1.40 23.71 15.89 9.2

Strip Ratio A-C Seam

Coal Exposed Ash CV Sulphur TM IM D-E Seam Coal Exposed Ash CV Sulphur TM IM adb adb adb ar adb

tonne % Kcal/kg % % % tonne

576,300 6.73 6,530 2.23 14.65 9.43 998,700 3.93 5,290 0.69 30.57 19.94

adb adb adb ar adb

% Kcal/kg % % %

746,500 6.73 6,530 2.23 14.65 9.43 1,293,500 3.93 5,290 0.69 30.57 19.94

1,395,250 6.01 6,447 1.98 15.38 9.89 1,304,750 4.03 5,059 0.80 32.32 22.08

1,550,300 6.01 6,447 1.98 15.38 9.89 1,500,722 4.03 5,059 0.80 32.32 22.08

III.

SCOPE OF WORKS

PT. Kutai Energi | Confidential

PT. Kutai Energi Coal

Project

III.1. Mining Operational

III.1.1. Clearing

No land clearing shall commence before written approval is given by the Company and shall be surveyed and supervised to ensure that only the approved area is cleared.

The Contractor will phase his land clearing activities in order to minimize the amount of runoff and sediment as a consequence of this activity. The Contractor shall provide an effective sediment control system (i.e. build sediment traps) for TSS (Total Suspended Solids) control as approved by the Company.

The Contractor shall clear all pit, dump, drainage and road areas of trees and vegetation. The cleared area should not extend beyond 10m from the Pit and dump limits.

III.1.2. Removal of Top Soil

The Contractor shall maximize recovery of top and sub soils. Topsoil or subsoil must be stockpiled in an area approved by the Company.

Topsoil and subsoil will be removed, hauled, and stockpiled properly according to the environmental standard at the designated area. An access to/from the stockpile shall be available at any time for re-handling purposes. Typical average thickness of topsoil is 0.5m and subsoil is 1.0m thick underneath the topsoil horizon.

PT Kutai Energi | Confidential

PT. Kutai Energi Coal

Project

III.1.2. Overburden Removal

The Contractor shall remove overburden from the Pit, and dump the overburden at locations and within dump limits approved by the Company. The overburden material shall be dumped and spread in a manner approved by the Company.

The working places on mining benches, on haul roads and at the dumps shall be maintained in a safe and tidy condition at all times, including adequate watering for dust suppression.

The Contractor will immediately notify the Company of any indications of which the Contractor is aware of pending instability in the mining pits or the dumps such as settlement and cracks. The Contractor will construct and maintain contour drains to minimize the amount of runoff water entering the mining pits and dumps.

The Company is required to maximize coal resource recovery and hence the Contractor is to take care in the uncovering and cleaning overburden from the top of any coal seam.

Safety berms are to be constructed along all bench crests and drop offs where vehicles could possibly access.

III.1.4. Coal Mining III.1.4.1. Extraction Coal shall be mined in a proper way so as, to the extent reasonably and economically practicable as approved by the Company to minimize any contamination by non-Coal

PT. Kutai Energi | Confidential

PT. Kutai Energi Coal

Project

material, coal loss, or flooding. The Contractor shall set in place procedures to prevent contamination of the coal by foreign objects; in particular ground engaging tools, steel, nuts and bolts, and waste (plastics etc) bottles.

III.1.4.2. Coal Delivery (Delivery point) The Contractor is required to manage the size of its coal truck fleet and schedule its operation in order to provide continuous, consistent feed to the ROM Crusher. The Coal delivery from pit to stockpile, distance about 10 Km.

III.1.5. Haul Road

III.1.5. Pit Areas The Contractor shall design and construct and maintain haul roads to connect the working Pit to the dump areas, coal haul connecting roads and general Pit and dump roads as required by the Contractor. All main haul roads shall be constructed in line with the Contractors road construction standards as approved by the Company. The Contractor shall design and construct any additional access roads required to complete the Services.

The Contractor is responsible for supply of sufficient water truck capacity required to suppress dust in the Pit and haulage areas.

III.1.5. Coal Hauling Road Maintenance

Maintain coal haul roads to connect the Pit to the coal port areas. III.1.6. Drainage

PT Kutai Energi | Confidential

PT. Kutai Energi Coal

Project

The Contractor is responsible for all water management within the Sites and Port link haul road. This includes the provision of Pit dewatering, diversions, flood mitigation around the Pit, road culverts as required, sediment control structures and environmental catchments drains. Pumped water is to be discharged into water channels as approved by the Company. Dirty mine water outside the approved limits shall not be discharged.

III.1.7. Reclamation III.1.8. Safety and Occupational Health

In performing the Services the Contractor shall comply with the Companys safety requirements as notified to the Contractor.

The safety requirements include, but are not limited to, providing: a. Road and general safety signage; b. Road traffic control structures and berms; c. Radio communication on all light vehicles

All the Contractor personnel on the Sites must have completed the Contractors induction (as approved by the Company), the Contractors representatives performing the inductions must obtain certification from the Company in regards to being suitably qualified to induct personnel prior to inducting any personnel. All the Contractor personnel on the Sites must conform to the Contractors safety management plan and any other safety requirements as notified to the Contractor and wear Contractor identification badges at all times.

PT. Kutai Energi | Confidential

10

PT. Kutai Energi Coal

Project

The Contractor shall perform a full risk assessment of the Services to be performed and present a report of such risk assessment to the Company before the Contractor will be permitted access to the Sites to perform the Services.

The Contractor will provide an appropriate level of supervision of the Services at all times. The supervision will be accountable for achieving all safety and production outcomes and follow the Contractors standards, rules, and procedures as approved by the Company.

The Contractor shall provide to the Company a report that details the following: (i) Number of employees in the previous month employed at the Sites; (ii) Aggregate number of hours of employment in the previous month of such employees; (iii) Number of accidents which caused lost time during the previous calendar month at the Sites; (iv) Frequency rate of lost time accidents at the Sites for the month and a description of these including days lost; (v) Frequency of equipment damage accidents at the Sites for the month and a description of these including cost; (vi) Number of accidents at the Sites requiring a referral to a doctor for the previous calendar month; (vii) Frequency rate of accidents at the Sites requiring a referral to a doctor for the month; (viii) Number of minor injuries at the Sites for the month;

(ix) Frequency rate of minor injuries at the Sites for the month; (x) Number of days lost from continuing injuries at the Sites carried over from the previous month(s);

PT Kutai Energi | Confidential

PT. Kutai Energi Coal

Project

11

(xi) Number of near misses or significant incidents at the Sites for the month; and

III.2. General

III.2.1. Office and Workshop facilities.

The Contractor shall construct their own office and workshop facilities for the performance of the Services. The Company shall provide land for the Contractors Facilities without cost to the Contractor.

III.2.2. Camp for mining contractor for staff and operators.

The Contractor shall construct their own accommodation facilities for the performance of the Services. The Company shall provide land for the Contractors Camp and Housing Accommodation without cost to the Contractor.

PT. Kutai Energi | Confidential

12

PT. Kutai Energi Coal

Project

APPENDIX 1

PIT BLOCK A

PT Kutai Energi | Confidential

PT. Kutai Energi Coal

Project

13

Out pit Dump

Out pit Dump

PT. Kutai Energi | Confidential

14

PT. Kutai Energi Coal

Project

APPENDIX 2

FACE POSITION PIT AND DUMP PERIOD YEAR 2012 - 2016

Face Position End of 2012

Face Position End of 2013

Face Position End Of 2014

Face Position End Of 2015

PT Kutai Energi | Confidential

PT. Kutai Energi Coal

Project

15

Face Position End Of 2016

APPENDIX 3

COAL DELIVERY POINT

PT. Kutai Energi | Confidential

Vous aimerez peut-être aussi

- Valuation Report of Coal MiningDocument71 pagesValuation Report of Coal MiningBudiman Sutanto100% (1)

- PKN Company ProfileDocument27 pagesPKN Company ProfileIntan Dewi Probowati100% (1)

- Simulasi CashflowDocument24 pagesSimulasi CashflowDeviSulistiaPas encore d'évaluation

- Daily Production ReportDocument3 pagesDaily Production ReportOna PetrusPas encore d'évaluation

- Mine SchedullingDocument58 pagesMine SchedullinggarawahyucPas encore d'évaluation

- Brosur - 9 April 2019Document8 pagesBrosur - 9 April 2019fernandoPas encore d'évaluation

- SOP Ore BargingDocument8 pagesSOP Ore BargingAgus BudiluhurPas encore d'évaluation

- Equipment Plan & BGT Calculation: Base Calculation Planned Calculation PC 200 PC 300 PC 300Document13 pagesEquipment Plan & BGT Calculation: Base Calculation Planned Calculation PC 200 PC 300 PC 300Iwan DermawanPas encore d'évaluation

- Mining Methods: PlotmakerDocument78 pagesMining Methods: PlotmakertamanimoPas encore d'évaluation

- Tabel 8.7 Sasaran Produksi Penambangan Batubara Dan Penggalian OverburdenDocument38 pagesTabel 8.7 Sasaran Produksi Penambangan Batubara Dan Penggalian OverburdenSean ChoiPas encore d'évaluation

- Reporting Coal Exploration FriederichMDocument73 pagesReporting Coal Exploration FriederichMDadan100% (1)

- Company Profile 090410r1Document27 pagesCompany Profile 090410r1Nipindo PrimatamaPas encore d'évaluation

- Kapasitas DumptruckDocument1 pageKapasitas Dumptruckadien_miningPas encore d'évaluation

- Company ProfileDocument25 pagesCompany ProfileKresna Bayu Imanieac Jr'sPas encore d'évaluation

- Mining Guide 2022Document166 pagesMining Guide 2022Bas KoroPas encore d'évaluation

- Cadangan Reklamasi PertambanganDocument18 pagesCadangan Reklamasi PertambanganAndrie ChandraPas encore d'évaluation

- Integra Open Cut - Mining Operations Plan Amendment 2Document129 pagesIntegra Open Cut - Mining Operations Plan Amendment 2beku_ggs_bekuPas encore d'évaluation

- Case Study - MineSched at SebukuDocument27 pagesCase Study - MineSched at SebukuBlank Kusuma100% (1)

- Mining Industry PresentationsDocument38 pagesMining Industry Presentationspoitan2Pas encore d'évaluation

- Project Summary ReklamasiDocument10 pagesProject Summary ReklamasiBagus TriwantoroPas encore d'évaluation

- Analisa Keuangan Tambang-2Document33 pagesAnalisa Keuangan Tambang-2rahadewiPas encore d'évaluation

- 026 MineSafeDocument28 pages026 MineSafeTri FebriyaniPas encore d'évaluation

- SIS Company Profile 2011Document28 pagesSIS Company Profile 2011RzAnzoel GlbaPas encore d'évaluation

- StandardProcedures Nickel LateriteDocument29 pagesStandardProcedures Nickel LateriteImam Taufiq FaqihPas encore d'évaluation

- Company Profile PT. Mathesis Global MineralDocument12 pagesCompany Profile PT. Mathesis Global MineralJeremy lovenPas encore d'évaluation

- Sukses Berkarir Di Industri TambangDocument32 pagesSukses Berkarir Di Industri TambangFaishol UmarPas encore d'évaluation

- 9-Early Magmatic & Nickel Laterite DepositDocument79 pages9-Early Magmatic & Nickel Laterite DepositotongjefriPas encore d'évaluation

- Proyeksi Cash FlowDocument4 pagesProyeksi Cash FlowelviraPas encore d'évaluation

- Pt. Jayeon SejahteraDocument52 pagesPt. Jayeon SejahteraTrends Property100% (1)

- Pt. Dahlia Biru Coal Mining PDFDocument10 pagesPt. Dahlia Biru Coal Mining PDFRino ErmawanPas encore d'évaluation

- Silica Sand Purifiyng FacilityDocument15 pagesSilica Sand Purifiyng FacilityMohd Suhaimizi Mohd NorPas encore d'évaluation

- Mine Plan and Mine Schedule Flow ChartDocument5 pagesMine Plan and Mine Schedule Flow ChartFebriansyah Nurdin100% (6)

- 9-Coal Mining CompleteDocument60 pages9-Coal Mining CompleteAchmad Rasyidi89% (9)

- Coal Sourcing Handling and Transportation Report - Volume - VDocument497 pagesCoal Sourcing Handling and Transportation Report - Volume - Vদেওয়ানসাহেবPas encore d'évaluation

- Summary of Progress Transhipment On Vessel Mv. Manalagi TisyaDocument1 pageSummary of Progress Transhipment On Vessel Mv. Manalagi TisyaMuhammad Rabbil AlbadriPas encore d'évaluation

- Rencana Jam Kerja Tahun 2011: 2011 Cumm 1 2 3 4 5 6 7 8 9 10 11 12Document52 pagesRencana Jam Kerja Tahun 2011: 2011 Cumm 1 2 3 4 5 6 7 8 9 10 11 12MangAndrian100% (5)

- Madhani Tlatah NusantaraDocument5 pagesMadhani Tlatah Nusantarabugie1970Pas encore d'évaluation

- Cash Flow Mining Operation SamarindaDocument3 pagesCash Flow Mining Operation SamarindaRatmokoAdiNugrohoPas encore d'évaluation

- 01 Thiess Mining Plan - Tom CooneyDocument30 pages01 Thiess Mining Plan - Tom CooneyDwik Thesoulof VillianoPas encore d'évaluation

- Budget Operation Agm-Mje 1 Fleet 2 BargeDocument6 pagesBudget Operation Agm-Mje 1 Fleet 2 BargeAchmad DjunaidiPas encore d'évaluation

- Muarateweh Field TripDocument3 pagesMuarateweh Field TripAgus Budiluhur100% (1)

- Weekly Report 1-7-2013Document26 pagesWeekly Report 1-7-2013Dadan100% (1)

- Business PlanDocument9 pagesBusiness PlanAgus BudiluhurPas encore d'évaluation

- Kalimantan Coal Railway ProjectDocument23 pagesKalimantan Coal Railway ProjectmimandapiconePas encore d'évaluation

- Smelter AnalysisDocument8 pagesSmelter AnalysisDavid Budi Saputra100% (1)

- Compro PPA 2023Document20 pagesCompro PPA 2023imaharPas encore d'évaluation

- Case Study MineSched at SebukuDocument27 pagesCase Study MineSched at SebukuDadanPas encore d'évaluation

- Business Proposal For Bulk Material Handeling System 2022Document32 pagesBusiness Proposal For Bulk Material Handeling System 2022NORTECH TRINITYPas encore d'évaluation

- Lahat Mine - Typical Mining ProjectDocument46 pagesLahat Mine - Typical Mining ProjectAgus Budiluhur100% (3)

- Adoc - Pub PT Dahlia Biru Coal MiningDocument15 pagesAdoc - Pub PT Dahlia Biru Coal MiningyunediPas encore d'évaluation

- Silica Sand Mining FinalDocument43 pagesSilica Sand Mining FinalChusnadiPas encore d'évaluation

- DOID Delta Dunia Makmur TBK Presentation Material UBS November 2010Document19 pagesDOID Delta Dunia Makmur TBK Presentation Material UBS November 2010Arief PermanaPas encore d'évaluation

- Daily Plan 12 April 2022Document16 pagesDaily Plan 12 April 2022Alfrid ImanuelPas encore d'évaluation

- Proposal Bisnis Coal Mining Jgi Tanung Mangkaliat VilageDocument13 pagesProposal Bisnis Coal Mining Jgi Tanung Mangkaliat VilageRIDWANPas encore d'évaluation

- Capability Profile Open Cut Coal Brochure - English - Flat PDFDocument4 pagesCapability Profile Open Cut Coal Brochure - English - Flat PDFJohn KalvinPas encore d'évaluation

- Efective Working Hours Y Q Date Days: EGI Unit UADocument8 pagesEfective Working Hours Y Q Date Days: EGI Unit UAprimaPas encore d'évaluation

- Brief Site Visit ReportDocument19 pagesBrief Site Visit Reportjulianusginting00Pas encore d'évaluation

- CORR-5057 TOR Pipeline PiggingDocument11 pagesCORR-5057 TOR Pipeline PiggingAbdelaaliPas encore d'évaluation

- Mine ManagementDocument7 pagesMine ManagementBranden OxfordPas encore d'évaluation

- Final Review of EC, IEE & EIA Regulation 2021 (LAW DEPARTMENT AMENDMENT)Document18 pagesFinal Review of EC, IEE & EIA Regulation 2021 (LAW DEPARTMENT AMENDMENT)munaizza100% (1)

- Concept PaperDocument7 pagesConcept PaperGerard DomingoPas encore d'évaluation

- 12-18-12 EditionDocument28 pages12-18-12 EditionSan Mateo Daily JournalPas encore d'évaluation

- Aplicaciones Bomba de LodosDocument6 pagesAplicaciones Bomba de LodosJosuePas encore d'évaluation

- Analisis Kinerja Crushing Plant Pada Tambang Andesit Berdasarkan Target Produksi Di PT Buana Nur Barokah Desa Batujajar Timur, Kecamatan Batujajar, Kabupaten Bandung Barat, Provinsi Jawa BaratDocument8 pagesAnalisis Kinerja Crushing Plant Pada Tambang Andesit Berdasarkan Target Produksi Di PT Buana Nur Barokah Desa Batujajar Timur, Kecamatan Batujajar, Kabupaten Bandung Barat, Provinsi Jawa BaratOkky Raymond CorneliusPas encore d'évaluation

- Prep Plant/tipple PermitsDocument3 pagesPrep Plant/tipple PermitsRishiraj SahooPas encore d'évaluation

- PWC Investment Appraisal of Mining-Capital-projects Jul12Document16 pagesPWC Investment Appraisal of Mining-Capital-projects Jul12Nicholas AngPas encore d'évaluation

- Lodigiani Gjcpi 2020 2Document21 pagesLodigiani Gjcpi 2020 2Kwok AvishaPas encore d'évaluation

- Environmental Management (Effluents and Solid Waste Disposal) Regulations 2006Document30 pagesEnvironmental Management (Effluents and Solid Waste Disposal) Regulations 2006Teererai KaguraPas encore d'évaluation

- Investor Presentation MARCH 2021Document42 pagesInvestor Presentation MARCH 2021dnikosdPas encore d'évaluation

- Design Minerall Processing PlantDocument20 pagesDesign Minerall Processing Plantdarioharloc2272Pas encore d'évaluation

- JORC Online Learning Brochure DigitalDocument4 pagesJORC Online Learning Brochure Digitalwidadi.apPas encore d'évaluation

- Denr Mo 98-03Document10 pagesDenr Mo 98-03AJS NATUMULANPas encore d'évaluation

- Cold and Dark - Better WorldsDocument93 pagesCold and Dark - Better WorldsJill Biden100% (1)

- Training and RecruitmentDocument42 pagesTraining and RecruitmentTechno EntertainerPas encore d'évaluation

- 05 Wms Green Fields RenaissanceDocument5 pages05 Wms Green Fields RenaissanceAllan DouglasPas encore d'évaluation

- Simulation Modelling of Mining Systems Massmin 2000Document13 pagesSimulation Modelling of Mining Systems Massmin 2000Camila Contreras CarrascoPas encore d'évaluation

- DRC OecdDocument74 pagesDRC Oecdfaraci.lucaPas encore d'évaluation

- MassMin 2004 PDFDocument740 pagesMassMin 2004 PDFFelipe Espinoza Cortés100% (2)

- Flora and Fauna Literature 1Document66 pagesFlora and Fauna Literature 1doriePas encore d'évaluation

- Ams 201301 enDocument200 pagesAms 201301 enLucas LobãoPas encore d'évaluation

- Minerals: Geometallurgical Characterisation With Portable FTIR: Application To Sediment-Hosted Cu-Co OresDocument20 pagesMinerals: Geometallurgical Characterisation With Portable FTIR: Application To Sediment-Hosted Cu-Co OresCESAR FUENTES VERAPas encore d'évaluation

- Mineral Property ValuationDocument9 pagesMineral Property Valuationinv_gradePas encore d'évaluation

- Global ResourcesDocument23 pagesGlobal Resourcescooldude99344Pas encore d'évaluation

- Nielson & Co., Inc. Vs Lepanto Consolidated Mining Co. CASE NUMBER: L-21601DATE: December 28, 1968PONENTE: Zaldivar, J.FACTSDocument2 pagesNielson & Co., Inc. Vs Lepanto Consolidated Mining Co. CASE NUMBER: L-21601DATE: December 28, 1968PONENTE: Zaldivar, J.FACTSMonaliza LiztsPas encore d'évaluation

- TDF - Assignment Week 12Document4 pagesTDF - Assignment Week 12Ayu Sekar TunjungPas encore d'évaluation

- Minerals by @captainsdugoutDocument68 pagesMinerals by @captainsdugoutAdinath RohamarePas encore d'évaluation

- Standard Operating Procedures For Sugar Industry PDFDocument60 pagesStandard Operating Procedures For Sugar Industry PDFzalabi100% (5)

- Special Report On Silicosis & Other Forms of Occupational Lung DiseasesDocument8 pagesSpecial Report On Silicosis & Other Forms of Occupational Lung DiseasesSamit CarrPas encore d'évaluation

- Dmre Information BookletDocument15 pagesDmre Information BookletFabian JaduePas encore d'évaluation

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansD'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansPas encore d'évaluation

- To Engineer Is Human: The Role of Failure in Successful DesignD'EverandTo Engineer Is Human: The Role of Failure in Successful DesignÉvaluation : 4 sur 5 étoiles4/5 (138)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetD'EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsD'EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsPas encore d'évaluation

- Well Integrity for Workovers and RecompletionsD'EverandWell Integrity for Workovers and RecompletionsÉvaluation : 5 sur 5 étoiles5/5 (3)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansD'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Troubleshooting and Repair of Diesel EnginesD'EverandTroubleshooting and Repair of Diesel EnginesÉvaluation : 1.5 sur 5 étoiles1.5/5 (2)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeD'EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeÉvaluation : 4.5 sur 5 étoiles4.5/5 (59)

- Summary of Neil Postman's Amusing Ourselves to DeathD'EverandSummary of Neil Postman's Amusing Ourselves to DeathÉvaluation : 4 sur 5 étoiles4/5 (2)

- Geotechnical Engineering Calculations and Rules of ThumbD'EverandGeotechnical Engineering Calculations and Rules of ThumbÉvaluation : 4 sur 5 étoiles4/5 (17)

- Structural Cross Sections: Analysis and DesignD'EverandStructural Cross Sections: Analysis and DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)

- Flow Analysis for Hydrocarbon Pipeline EngineeringD'EverandFlow Analysis for Hydrocarbon Pipeline EngineeringPas encore d'évaluation

- Practical Reservoir Engineering and CharacterizationD'EverandPractical Reservoir Engineering and CharacterizationÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesD'EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesÉvaluation : 4 sur 5 étoiles4/5 (2)

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisD'EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisÉvaluation : 5 sur 5 étoiles5/5 (3)