Académique Documents

Professionnel Documents

Culture Documents

1817LL

Transféré par

Madhvi NemaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1817LL

Transféré par

Madhvi NemaDroits d'auteur :

Formats disponibles

Thermo Scientifc

Orion 1817LL

Low Level Chloride

Analyzer User Guide

test

values

mV

slope

E0

enter/

done

sample test program

error

cal.

cal

point 1

cal

point 2

three

pt. cal.

complete

cal

point 3

C

ppb

error

stable

ppm

sample

values

PURE WATER

TM

Monitors

Orion 1800 series

release latches to access

ROSS and the COIL trade dress are trademarks of Thermo Fisher Scientific Inc. U.S. patent 6,793,787.

AQUAfast, Cahn, ionplus, KNIpHE, No Cal, ORION, perpHect, PerpHecT, PerpHecTion, pHISA, pHuture, Pure Water, Sage, Sensing the Future, SensorLink,

ROSS, ROSS Ultra, Sure-Flow, Titrator PLUS and TURBO2 are registered trademarks of Thermo Fisher.

1-888-pHAX-ION, A+, All in One, Aplus, AQUAsnap, AssuredAccuracy, AUTO-BAR, AUTO-CAL, AUTO DISPENSER, Auto-ID, AUTO-LOG, AUTO-READ,

AUTO-STIR, Auto-Test, BOD AutoEZ, Cable-Free, CERTI-CAL, CISA, DataCOLLECT, DataPLUS, digital LogR, DirectCal, DuraProbe, Environmental Product

Authority, Extra Easy/Extra Value, FAST QC, GAP, GLPcal, GLPcheck, GLPdoc, ISEasy, KAP, LabConnect, LogR, Low Maintenance Triode, Minimum Stir

Requirement, MSR, NISS, One-Touch, One-Touch Calibration, One-Touch Measurement, Optimum Results, Orion Star, Pentrode, pHuture MMS, pHuture

Pentrode, pHuture Quatrode, pHuture Triode, Quatrode, QuiKcheK, rf link, ROSS Resolution, SAOB, SMART AVERAGING, Smart CheK, SMART STABILITY,

Stacked, Star Navigator 21, Stat Face, The Enhanced Lab, ThermaSense, Triode, TRIUMpH, Unbreakable pH, Universal Access are trademarks of

Thermo Fisher.

Guaranteed Success and The Technical Edge are service marks of Thermo Fisher.

PerpHecT meters are protected by U.S. patent 6,168,707.

PerpHecT ROSS electrodes are protected by U.S. patent 6,168,707.

ORION Series A meters and 900A printer are protected by U.S. patents 5,198,093, D334,208 and D346,753.

ionplus electrodes and Optimum Results solutions are protected by U.S. patent 5,830,338.

ROSS Ultra electrodes are protected by U.S. patent 6,793,787.

ORP standard is protected by U.S. patent 6,350,367.

No Cal electrodes are protected by U.S. patent 7,276,142.

2009 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries.

The specifications, descriptions, drawings, ordering information and part numbers within this document are subject to change without notice.

This publication supersedes all previous publications on this subject.

Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Table of Content

ntroduction 1

General Information 1

Principles of Operation 2

Principles of Calibration 3

Low Level Chloride Electrode Response 3

Of-line Calibration 4

Tree Point Calibration 4

One Point Calibration 4

Sample Requirements 5

Description of 1817LL Analyzer Components 6

Analyzer Preparation 9

Unpacking the 1817LL Analyzer 9

Unpacking the Refrigeration Unit 9

Mounting and Plumbing Instructions 10

Electrical Connection Instructions 11

Refrigeration Unit Connection Instructions 12

Installation of Reagent and Difusion Tubing 14

Installation of Chloride Electrode 15

Installation of Reference Electrode 16

Installation of ATC Probe 17

Flow Regulation 17

Analyzer Operation 19

Description of Basic Analyzer Controls 19

Start Up and Normal Analyzer Operation 20

Initial Analyzer Setup 21

Test Mode 22

Error Mode 22

Shutdown and Start Up Procedure 24

Shutdown 24

Start Up 25

Flow Of 25

Chapter 1

Chapter 2

Chapter 3

Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

nstallation and Operation of Modules 27

Signal Conditioner Module (Cat No 180001) 27

Removing the Installed Signal Conditioner Module 27

Replacing the Installed Signal Conditioner Module 27

Setting the Signal Conditioner Module Output 28

Electrical Connections for the Signal Conditioner Module 29

Description of the Signal Conditioner Module Controls 30

Programming the Signal Conditioner Module Measuring Range 31

Optional Alarm Module (Cat No 180011) 32

Installation of the Alarm Module 32

Setting the Alarm Module Output 33

Electrical Connections for the Alarm Module 34

Description of the Alarm Module Controls 35

Alarm During Calibration 35

Alarm After Power Failure 35

Setting Alarms 1 and 2 36

Calibration 37

Tree Point Calibration Procedure 37

Of-line Calibration Procedure 39

Analyzer Maintenance 41

Maintenance Schedule 41

Weekly Maintenance 42

Monthly Maintenance 42

Bimonthly Maintenance 43

Yearly Preventative Maintenance 44

Customer Services 45

Troubleshooting 45

Resetting the Analyzer 48

Assistance 49

Warranty 49

Notice of Compliance 50

Declaration of Conformity 51

Ordering Information 52

Mounting Dimensions 54

QC Sampler Installation and Operation 56

1817LL Analyzer Specifcations 58

QC Sampler Specifcations 58

Chapter 4

Chapter 7

Chapter 6

Chapter 5

Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide 1

chapter 1 ntroduction

This user guide covers the operation, maintenance and troubleshooting for

the Thermo Scientific Orion 1817LL low level chloride analyzer, which

incorporates the software features of a three point and off-line calibration

The 1817LL analyzer has a limit of detection of 10 ppb 5 ppb Used to

monitor boiler water and boiler blow down, the 1817LL analyzer is an

indicator that could detect costly condenser leaks A refrigeration unit cools

the sample down below 12 C, which enables the sensor to detect chloride

at extremely low levels without additional manipulation of the sample This

system includes a reference electrode with a double junction ceramic frit

designed that provides outstanding long term performance and a chloride-

sensing electrode known for its superior accuracy at low levels

Figure 1 shows a block diagram of sample flow through the analyzer

General nformation

Figure 1

Block Diagram of Sample Flow

temperature

probe

reference

probe

sensing

probe

calibration

level

measuring

level

reagent

addition

system

refrigerated

bath

drain

bypass

valve

calibration

injection

port

restrictor

owmeter

ow

valve

pressure

regulator

bypass

lter

inlet

valve

2 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Figure 2 illustrates the sample flow during normal operation

As shown in Figure 2, the sample (temperatures up to 45 C) enters the

1817LL analyzer and passes through the inlet valve, 1, bypass filter, 2,

pressure regulator, 3, flow valve, 4, flow meter, 5, and restrictor tubing,

6, and then flows through the fluid connector block, 7, into a reagent

diffusion bottle, 8, where the sample is acidified Once acidified, the

sample flows to a refrigeration unit, 9, that cools the sample to between 5

and 15 C 1 C and the sample is then transferred to the flow cell, 10,

through insulated tubing Within the flow cell the cooled sample passes

the chloride-sensing electrode, 11, and reference electrode, 12, in the top

portion of the flow cell The sample then flows past the temperature probe,

13, into an atmospheric drain, 14

1 Inlet Valve 9 Refrigerated Bath

2 Bypass Filter 10 Flow Cell

3 Pressure Regulator 11 Sensing Electrode

4 Flow Valve 12 Reference Electrode

5 Flowmeter 13 Temperature Probe

6 Flow Restrictor Tubing Bottle 14 Drain

7 Fluids Block 15 Electrolyte Reservoir

8 Reagent Diffusion Bottle 16 Bypass Valve

Principles of

Operation

Figure 2

Flow During Normal Operation

5

15

11

12

13 4

3

2

6

16

1

14

test values

mV

slope

E0

enter/ done

sample test program

error

cal.

add

std 1

add

std. 2

three

pt. cal.

complete

add

std. 3

C

ppb

error

stable

ppm

sample values

10

9

8

7

PURE WATER

TM

Monitors

Orion 1800 series

release latches to access

Figure 2 Legend

3 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Calibration procedures for analytical instruments are important and must

be performed carefully The 1817LL analyzer employs a two-segment

calibration method to cover a wide range of concentrations, the first

segment versus the concentration and the second segment versus logarithm

of the concentration The calibration is carried out at three chloride levels,

concentration being in the ranges of 0 to 20 ppb, 75 to 125 ppb and 100

to 10000 ppb from low to high The first chloride level can be the zero

chloride solution, the second and the third levels can be generated by

introducing known chloride concentration using the dynamic calibrator

through the injection port Calibration parameters of both segments are

computed by the microprocessor, and effects from temperature fluctuation

are constantly corrected Based on the potential measured in the sample

solution, the microprocessor is makes a judgment of which segment of

calibration is to be used to read the chloride concentration

The chloride electrode responds to changes in chloride ion concentration

The sensing surface of the electrode consists of the mixture of a metal

amalgam and a sparingly should be chloride salt of the metal In samples

free of mercury ions, the potential of the electrode is determined by the

solubility of the salt, which depends on the temperature and the chloride

concentration of the sample

At low levels of chloride (< 125 ppb), the electrode responds approximately

linearly to the changes of chloride concentration at high levels of chloride

(> 75 ppb), the electrode responds logarithmically to the changes of

chloride concentration in a Nernstian manner The response can be

characterized by the following equations:

Low Levels: E = E

0

(T) + S

1

(T)* (C -

C2

)

High Levels: E = E

0

(T) + S

2

(T)* log (C/C

2

)

E = measured electrode potential

E

0

(T) = temperature dependent potential value

S

1

(T), S

2

(T) = temperature dependent slope values

C = concentration (activity) of chloride ion

C

2

= concentration (activity) of chloride ion of the

second standard

The analyzer calls for a three point calibration to determine the actual

values of all the parameters and then enables measurements of chloride at

all low and high levels

In order to achieve the low detection limit, the analyzer incorporates a

cooling system to reduce the sample temperature The analyzer also uses

its microprocessor to constantly update temperature corrections from data

supplied by the ATC probe

Principles of

Calibration

Low Level Chloride

Electrode Response

4 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

The off-line calibration feature of 1817LL analyzer allows the operator

to adjust the analyzer to values determined by alternate methods used in

their laboratory, such as ion chromatography and colorimetric method It

is essentially a one point calibration To perform an off-line calibration, a

sample is taken from the bypass of the analyzer; the sample value is stored

in memory; the sample is analyzed by an alternate method of choice;

the previously stored reading is adjusted to the lab method result and

the analyzer is then returned to the analysis mode The term off-line

calibration refers only to the fact that a sample from 1817LL analyzer

bypass is taken off-line for laboratory analysis; in fact, no downtime

is experienced during the procedure and the analyzer remains online

throughout the procedure

This procedure provides maximum calibration accuracy and requires

the use of a dynamic calibrator (Cat No 15DC15 for 115 V or

Cat No 15DC20 for 220 V) In addition to calculation of electrode E

0

,

as is done in off-line calibration procedure, this procedure determines the

electrode slope

To perform a dynamic three point calibration, the 1817LL analyzer is

first connected to a chloride-free sample stream This can be taken as

the first standard of zero chloride An appropriately diluted standard is

then prepared The supplied syringe is filled with the diluted standard

and mounted on the dynamic calibrator The dynamic calibrator is then

mounted near the analyzer and the syringe tubing connected to the

standard injection port By adjusting the dynamic calibrator pump settings,

two different flow rates produce two known standards diluted into the

sample background By pressing the appropriate keys on the analyzer when

prompted, the analyzer completes the calibration

If a mistake is made or problems occur during calibration, an error light

will turn on and alert the operator By pressing the error key, the operator

can access information on the display to help determine the problem

A quick one point calibration may be run using the QC sampler

(Cat No 18GRAB) See the QC Sampler Installation and Operation

section for details

Off-line Calibration

Three Point Calibration

One Point Calibration

5 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Sample inlet connection 1/4 NPTF If particulate matter is present in

the sample, pre-filtration is necessary Moderate amounts of particulates

will be removed by the 60 micron stainless steel filter located after the

inlet valve

Flow rate 40 mL/minute, nominal

Pressure 8 to 100 psig Contact Technical Support for details on sample

handling if the pressure is outside of this range See the Assistance section

Temperature Temperature must be between 5 and 45 C

Chloride level Chloride levels are read directly in ppb or ppm, when

calibrated with Thermo Scientific Orion chloride calibration standard

(Cat No 941707)

Sample alkalinity Sample alkalinity should not be more than 50 ppm

CaCO

3

equivalent For higher sample alkalinity, contact Technical Support

See the Assistance section

Sample Requirements

6 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Note: Numbers in the description refer to Figure 3

Sample Inlet Valve (1) Accepts the sample stream via a 1/4 inch NPTF

connector The operator must supply the sample with a pressure of 8 to 100

psig and a sample flow rate to the analyzer of 50 mL/minute minimum

Bypass Filter Assembly (2) A 60 micron stainless steel filter traps

particulate matter in the sample stream

Pressure Regulator (3) Adjusts flow on the incoming sample stream

Flow Valve (4) Used to turn off the flow to the flow cell

Flow Meter (5) Measures the sample flow rate, a 40 mL/minute nominal

flow is required through the analyzer

Flow Restrictor Tubing (6) Maintains a steady sample flow rate in

conjunction with the pressure regulator

Fluid Connector Block (7) Connects the reagent diffusion bottle to the

sample stream and flow cell assembly

Reagent Diffusion Bottle (8) Acidifies and adds iodine to the sample by

means of passive diffusion

Refrigerated Bath (9) Cools the sample stream to below 10 C

Flow Cell (10) Contains the reference electrode, sensing electrode, ATC

probe and sample measurement reservoir

Chloride Electrode (11) Senses chloride ions in the sample stream and

produces an electrical potential dependent on sample concentration Must

be placed on the left hand side of the flow cell

Reference Electrode (12) Provides a constant reference potential and

completes the measurement circuit Must be placed on the right hand side

of the flow cell

ATC Probe (13) Measures the sample temperature and inputs the data to

the microprocessor for automatic temperature compensation (ATC)

Drain (14) Atmospheric drain prevents back pressure on the reference

electrode located behind the reagent bottle

Electrolyte Reservoir (15) - Provides a constant flow of electrolyte solution

through the reference electrode for maximum stability

Description of 1817LL

Analyzer Components

7 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Bypass Valve (16) Used to throttle the flow in the bypass system located

behind the reagent bottle

LED Display (17) Provides digital readouts of concentration,

temperature, millivolts and error codes

Keypad (18) Consists of five mode keys, four prompt indicator lights,

two scroll keys and one key for entering data Mode and error indicators are

also incorporated on the keypad

On/Off Switch (19) Controls all power to the electronics

Standard Injection Port (20) Allows connection of dynamic calibrator

tubing to the fluid connector block during a three point calibration

Thumbscrew (21) Supports the reagent diffusion bottle

Compression Fitting (22) Connects the flow restrictor tubing to the

flow meter

Figure 3

Major Components of Low

Level Chloride Analyzer

WHVW

YDOXHV

mV

slope

E0

enter/

done

sample test program

error

cal.

cal

point 1

cal

point 2

three

pt. cal.

complete

cal

point 3

C

ppb

error

stable

ppm

sampIe

vaIues

6

15

22

11

12

17

18

19

13

5

4

10

3

22

2

7

8

9

14

1

16

20

PURE WATER

TM

Monitors

Orion 1800 series

release latches to access

8 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide 9

chapter 2 Analyzer Preparation

Report any obvious damage to the shipping container to the carrier

and hold it for inspection The carrier (not Thermo Fisher Scientific) is

responsible for any damage incurred during shipment

1 Open the outer box Remove the foam corner support pieces

2 Open the inner box and remove the cardboard retaining shell Remove

the accessory boxes (four pieces) and user guide

3 Unbolt the analyzer from the mounting board Save all hardware for use

during installation

4 Carefully place the analyzer at a convenient location Do not pull or lift

the analyzer by its fluidic components

1 See the manufactures instructions before removing the refrigeration

unit from its box

2 Place the refrigeration unit within five feet of the 1817LL analyzer for

proper installation

Unpacking the

1817LL Analyzer

Unpacking the

Refrigeration Unit

Figure 4

Unpacking the 1817LL Analyzer

10 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

1 Select a site for the analyzer that allows it to be permanently bolted (in

an upright position) with ample height for atmospheric drain operation

and ready access to both electronic controls The analyzer location must

permit connection to a plumbed in sample line, a drain, an AC power

supply and any connections for output devices

2 The analyzer should be mounted as close to the sampling point as

possible This ensures the fastest possible response to changing

sample conditions

3 Prepare the mounting holes Carefully lift the analyzer and bolt it into

place Do not lift the analyzer by holding on to any of the plumbing

or fluid handling components.

4 Connect a waste line to a drain of sufficient capacity, 05 inch

(127 cm) OD is recommended

5 Connect the sample line to the 025 inch (0635 cm) NPTF stainless

steel inlet It is recommended that a shut off valve be installed at the

sampling point

Mounting and

Plumbing nstructions

11 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

1 Remove the protective plastic, front panel inside the cabinet, by

unscrewing the four holding screws Remove the protective plastic

plug at the bottom of the cabinet and feed the AC power line through

the hole

2 Set the voltage (from the underside of analyzer) to either 115 V or 230

V (factory default setting is 115 V)

3 Connect the AC power according to the wiring diagram in Figure 5

4 All electrical wiring feeding through the chassis of the cabinet must pass

through appropriate electrical fittings in order to maintain the design

integrity of the splash proof cabinet housing the analyzer electronics As

different types of fittings may be required at various installations, this

feed through is to be supplied by the user

Warning: A grounded metal conduit is required for FCC compliance

5 Replace the protective plastic front panel when complete

Warning: Failure to replace the protective plastic front panel will result

in a potential shock hazard

Electrical Connection

nstructions

(Brown) Hot Line in

Ground

Green/Yellow

Line In

AC Power

Inlet

(Blue) Common Line in

Voltage Selector (115V/230V)

(Switched from Underside

of Instrument)

Power ON/OFF

(Switched from Underside

of Instrument)

Figure 5

Electrical Wiring of

1817LL Analyzer

12 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

1 Open the bag that contains the tubing components The bag should

contain ten feet of 1/4 plastic tubing, five feet of foam tubing

insulation and two 1/4-3/8 union compression fittings

2 Cut the plastic tubing into two five-foot lengths Ensure that the cut is

straight, and the tubing end is smooth and undamaged

3 Remove the nut from the unused compression fitting on the back of

the fluids block, and slide it over the end of one of the pieces of plastic

tubing Leave about one inch of tubing protruding from the end of the

nut, as shown in Figure 6

4 Insert the tubing into the hole of the compression fitting until it cannot

be pushed any further Then, slide the nut back over the threads of the

fitting and tighten while holding the tubing in place

5 Remove the nut from the unused compression fitting on the back of the

flow cell, and slide it over the end of the other piece of plastic tubing

Leave about one inch of tubing protruding from the end of the nut, as

shown in Figure 6

6 Insert the tubing into the hole of the compression fitting until it cannot

be pushed any further Then, slide the nut back over the threads of the

fitting and tighten while holding the tubing in place

7 Remove the larger nut from one of the union compression fitting, and

slide it over the end of one of the rigid tubing outlets on the lid of the

refrigerated bath Leave about one inch of tubing protruding from the

end of the nut, as shown in Figure 6

8 Slide the compression fitting over the rigid tubing until it cannot be

pushed any further Then, slide the nut back over the threads of the

fitting and tighten while holding the compression fitting in place

9 Repeat steps 7 and 8 for the other compression fitting

10 Slide the free end of the plastic tubing connected to the flow cell into

the insulation tubing Push the insulation tubing down the length of

the plastic tubing until it cannot be pushed any further

11 Push the free end of the foam insulation back, exposing about two

inches of plastic tubing Remove the smaller nut from one of the union

compression fitting on the lid, and slide it over the end of the exposed

plastic tubing Leave about one inch of tubing protruding from the end

of the nut, as shown in Figure 6

Refrigeration

Unit Connection

nstructions

13 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

12 Insert the tubing into the hole of the compression fitting on the lid

until it cannot be pushed any further Then, slide the nut back over the

threads of the fitting and tighten while holding the tubing in place

13 Remove the smaller nut from the unused compression fitting on the lid,

and slide it over the free end of the other length of plastic tubing Leave

about one inch of tubing protruding from the end of the nut, as shown

in Figure 6

14 Insert the tubing into the hole of the compression fitting on the lid

until it cannot be pushed any further Then, slide the nut back over the

threads of the fitting and tighten while holding the tubing in place

Figure 6

Tubing Protruding from the Nut

14 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Warning: Formic acid is hazardous Use protective glasses and gloves Refer

to bottle label for precautions

1 Support the bottom of the reagent bottle Turn the thumbscrew

counterclockwise to release diffusion bottle Unscrew the white bottle

cap and gray tubing connector assembly Keep the bottle supplied with

the analyzer as a spare

2 Take a new bottle of reagent to a well-ventilated area such as a

laboratory fume hood Unscrew and remove the white cap

3 Connect the diffusion tubing (Cat No 181060) to the tubing

connector assembly, as shown in Figure 7 Place the tubing assembly

and cap into the bottle

4 Replace the gray cap and screw the white cap on tightly

5 Insert the five nipples on the top of the reagent diffusion bottle into the

fluid connector block, as shown in Figure 7

6 Support the bottom of the reagent bottle with one hand and tighten the

thumbscrew clockwise

nstallation of

Reagent and

Diffusion Tubing

tubing

barbed fittings

reagent

diffusion

bottle

white cap

nipples with small O-rings

gray cap with large O-ring

tubing should be connected to

right-hand barbed fittings only

(as seen from the front)

fluid connector block

Front

injection port

Figure 7

Reagent Diffusion

Bottle Assembly

View from front left side of the analyzer

15 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

1 Unpack the chloride electrode (Cat No 100025) and carefully remove

the protective cap Save the cap for future storage of the electrode

2 Insert the chloride electrode into the sensing hole of the flow cell cap

See Figure 3 The sensing electrode is placed in the hole to the left

of the divider in the flow cell

3 Connect the electrode to the cable marked Sens Elect

4 Wait at least one hour before calibrating the analyzer

nstallation of

Chloride Electrode

16 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Note: Numbers in the description refer to Figure 8

1 Unpack the reference electrode, 7, (Cat No 100057) and tubing

from the shipping box Remove the protective caps from the bottom

and sidearm of the electrode Save the caps for future storage of the

electrode Inspect the electrodes internal components Verify that the

electrode is at least half filled with the internal fill solution If not,

replace the electrode

2 While passing the 1/8 inch tubing, 31, into the electrode through the

sidearm, slide the 1/4 inch tubing, 32, over the sidearm The outside

tubing should extend 3/8 to 1/2 inch over the sidearm

3 Remove the cap and fluid seal from the 900063 electrolyte bottle, 33

Hold the bottle in upright position Check that the rubber gasket, 34,

is properly aligned, and connect the cap end of the tubing assembly to

the bottle The 1/8 inch tubing should extend into the bottle

4 Hold the reservoir above the electrode with the bottle cap end down

The electrode should be horizontal with the sidearm pointing up

Gently shake the electrode to allow any trapped air bubbles to rise into

the bottle as the electrode fills with solution

5 Dry off the ceramic frit on the base of the electrode with tissue paper

Squeeze the electrolyte bottle for a few seconds A small amount of

solution should bead up on the frit surface, indicating good electrolyte

flow If no moisture is visible, the electrode is clogged and should be

cleaned or replaced

6 Invert the electrolyte bottle and snap it into the clip, 35 Use the

supplied push pin to puncture three air vents on the bottom of

the bottle

Caution: Failure to vent the electrolyte bottle will lead to noisy and

drifting readings

7 Connect the electrode to the electronic chassis using the keeper cable

labeled Ref Elect Insert the electrode into the reference hole in the

flow cell cap See Figure 3

nstallation of

Reference Electrode

17 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

The automatic temperature compensation (ATC) probe is already

connected to the electronics housing Insert it into the remaining hole in

the flow cell cap

When the 1817LL analyzer is first commissioned, it is advisable to flush

out the fluidics system overnight prior to the initial calibration and use

The electronics need not be turned on at this time Refer to Figure 3

1 Open sample inlet valve

2 Pull out the red locking ring of the pressure regulator, 3, and then

adjust the black knob so the ball of the flow meter reads 40 mL/min

Push in the red locking ring to secure the setting

3 Open the bypass valve Check for the appropriate sample flow Readjust

the pressure regulator if required

4 Wait at least one hour before calibrating the analyzer

Figure 8

Reference Electrode Assembly

35

33

34

31

32

30

7

nstallation of

ATC Probe

Flow Regulation

18 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide 19

chapter 3 Analyzer Operation

On/off switch Controls power to all electronics and air pump, located on

electronic chassis bottom and includes an integral circuit breaker

LCD display Displays four and a half digits plus polarity sign used to

read concentration, slope, E

0

millivolts, temperature, error messages and

diagnostic information

Mode indicating LED Located to left of LCD display Indicates range

(ppb or ppm), error codes and electrode stable in sample mode Displays

temperature (C), millivolts, electrode slope and E

0

on LCD in test mode

Prompt indicating LED Prompts the operator during calibration Four

LEDs located in keypad region are used: cal point 1, cal point 2, cal point 3

and three pt cal complete

and keys Increase or decrease displayed values that can be operator-

changed such as alarm level, analog output range, off-line calibration and

blank correction values

Enter/done key Enters value displayed on LCD into memory for later

use Also used to indicate to analyzer that a required calibration step has

been completed

Sample key Puts the 1817LL analyzer into the sample mode and

re-activates any optional modules This is also the default mode, the

analyzer automatically enters the sample mode when it is first turned on

and after calibration

Cal key Starts the 1817LL analyzer in the calibrate mode Operator is

then prompted through the steps necessary for calibration

Test key Places 1817LL analyzer into the test mode where the LCD

displays temperature, millivolts, E

0

and slope Each successive push of the

test key steps analyzer through this sequence and an LED on the left of

display indicates value displayed

Error key If the error LED is lit (soft error), pressing the error key causes

the LCD to display an error code In the case of a hard error, the LCD will

cease to display the normal output and instead display the error code only

Refer to the Error Mode section

Description of Basic

Analyzer Controls

20 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Program key Used to program expected calibration concentrations for

three point calibration and used in conjunction with the cal key for off-line

calibration Also used to display the low range calibration slope

1 Install the 1817LL analyzer according to the instructions in the

Analyzer Preparation section The power supply should be wired for

proper voltage and the analyzer should be suitably grounded

2 Turn on the flow at the sample inlet and flush for at least one hour

3 Power up the 1817LL analyzer using the toggle switch on the bottom

the of electronics case See Figure 3

4 Observe air bubbling through liquid in the flow cell The LCD will

display the following information sequence:

a + 18888

b 1817 while LEDs sequentially light (mode indicating LEDs and

test LED on modules are not tested during start up sequence)

c Revision number of software program (eg, -xy-)

5 After completion of steps 1 through 4, the analyzer enters the normal

sample mode

Figure 9

Front Panel Keypad

test

vaIues

mV

slope

E

0

enter/

done

sample test program

error

cal.

cal

point 1

cal

point 2

three

pt. cal.

complete

cal

point 3

C

ppb

error

stable

ppm

sampIe

vaIues

Start Up and Normal

Analyzer Operation

21 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

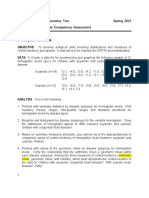

Before the first sample measurements on the 1817LL analyzer can be

performed, the calibration concentration increments must be programmed

into its memory See Table 1 The P2 and P3 values shown in Table 1 are

based on using the Thermo Scientific Orion 100 ppm chloride standard

(Cat No 941707)

Code Meaning

P0 1 point cal concentration

P1 Low arrange slope

P2 3 point cal standard 2 concentration

P3 3 point cal standard 3 concentration

P4 3 point cal standard 1 concentration

1 Press the program key until the LCD displays P2 The current value

for the second calibration concentration increment will be displayed

Default value is 100 ppb

2 Change this value using the and keys Press the enter/done key to

store the appropriate value in memory

3 Press the program key until the LCD displays P3 The current value for

the third calibration concentration increment will be displayed Default

value is 1 ppm

4 Change this value using the and keys Press the enter/done

key to store the appropriate value in memory and the analyzer will

automatically return to sample mode

5 Press the program key until the LCD displays P4 The current value for

the first calibration concentration increment will be displayed Default

value is 0 ppb

6 Change this value using the and keys Press the enter/done

key to store the appropriate value in memory and the analyzer will

automatically return to sample mode

7 The battery backup of memory will maintain programmed variables for

at least one month if the battery is fully charged

nitial Analyzer Setup

Table 1

Program Key Table

22 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

When the test key is pressed, the LCD displays temperature, millivolts,

high range, slope and E

0

Every time the test key is pressed, the analyzer

steps through the sequence An LED to the left of display indicates the

value displayed

If the test mode is entered from the sample mode, sample and test

LEDs will be lit If the test mode is entered from the calibration mode,

calibrate and test LEDs will be lit Note that while the LCD displays test

information, the analyzer still continues normal sampling or calibration

sequences Therefore, when sample and test modes are pressed, signal

conditioning and optional alarm modules are active When the calibrate

and test modes are entered, calibration prompt LEDs will light as usual

To exit the test mode, press the sample or calibrate key The LCD will

display instantaneous computed concentration

If the sample key is pressed while in the calibration mode, the current

calibration will abort with no data saved

The 1817LL analyzer diagnoses two types of errors that are termed

hard and soft In the event of hard error, the analyzer cannot compute

any meaningful concentration values, the error LED will be lit and the

LCD will display an error code The signal conditioner module will

indicate zero scale and alarms will be deactivated Hard errors must be

corrected prior to resumption of normal operation (E40 and E50) by

performing a complete calibration

If the error LED is active but the analyzer continues to display

concentration, it is a soft error Soft errors can affect accuracy and/or

precision of the displayed concentration but not interfere with analyzers

ability to compute the sample concentration To determine the cause of soft

errors, press the error key and the LCD will display the error code

Test Mode

Error Mode

23 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Error Code Meaning

E00 No error

E01 Default values are used, the analyzer has not been calibrated since

start up or the reset button was pushed

E02 Sample is outside the temperature range of 5 to 45 C or the cooled

sample is outside the temperature range of 0 to 15 C

E03 Combination of E01 and E02

E04 Faulty ATC probe, or related circuitry

E05 Combination of E01 and E04

E10 After calibration the new slope is outside expected range

E20 Calibration due, last calibration performed 30 days ago, reminder to

perform another calibration

E30 Calibration due and slope error, this indicates that the last calibration

was performed at least 30 days ago and the electrode slope was out

of specification at that time

E40 Calibration overdue, it was at least 6 weeks since the last calibration

and the analyzer beyond this point could be out of specification

This is a hard error, the only way to exit this error is to perform a

complete three point or off-line calibration, a blank correction will not

affect this error code

E50 Calibration overdue and slope error, it was at least 6 weeks since the

last calibration and the electrode slope was out of specification at

that time, the analyzer beyond this point could be out of specification

This is a hard error, the only way to exit this error is to perform a

complete three point or off-line calibration, a blank correction will not

affect this error code

The most common error codes are combinations of the above codes, but

other errors may be displayed:

E12 = E10 and E02

E14 = E10 and E04

E21 = E20 and E01

E22 = E20 and E02

Table 2

Error Codes and Meanings

24 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

The following steps should be taken if a loss of sample flow is expected

for more than one day These procedures will prevent possible build-up of

acidic reagent vapors in the analyzer

Note: At cycling power plants or on analyzers where sample flow to the

analyzer is frequently interrupted, the installation of a backup sample

is recommended Connect a suitable high purity water source (such as

condensate storage tank) into the sample line just upstream of the analyzers

sample inlet By putting shutoff valves in both sample and backup lines at

this point, backup or actual sample flow can be quickly valved in or out

as required In this way, continuous flow to the analyzer can be supplied

and the need for the following startup/shutdown, equilibration and

recalibration procedures is eliminated Note, however, that for sample flow

loss of only a few hours, analyzer recalibration should not be required

1 Shut off sample flow prior to the analyzer inlet

2 Turn off power

3 Drain the flow cell

Danger: Shut off the power switch at the base of the analyzer before

beginning the procedure; otherwise, the air pump will spatter acid

reagent outward as bottle is removed

Warning: Wear rubber gloves and safety goggles to avoid possible

injury from reagent residues in the system

4 Remove the reagent bottle and store it in a well ventilated area such as a

laboratory fume hood

5 Carefully pull the chloride and reference electrodes out of the top of the

flow cell and let them hang by their connectors Locate the protective

end cap from reference electrode kit and place it on the base of the

reference electrode This will prevent the reference electrode from

drying out

Shutdown and

Start Up Procedure

Shutdown

25 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

1 Replace the diffusion tubing if the sample flow has been off for more

than a few days Tubing becomes brittle with long term exposure to

reagent Use a fume hood and wear rubber gloves and safety goggles for

this procedure If age of reagent is not known, replace it and note in the

maintenance records Re-install the bottle on the analyzer

2 Polish the chloride electrode according to the instructions found

with the polishing strips that are included with the chloride electrode

(Cat No 100025)

3 Restore the sample flow to the analyzer If necessary, adjust the pressure

and flow rate through the analyzer to normal ranges

4 Remove the protective end cap from the reference electrode Re-install

the electrode on analyzer, being careful not to disconnect the reservoir

tubing from the sidearm

5 When the analyzer reading stabilizes (about one hour), recalibrate

according to the Calibration section

If the analyzer is expected not to have flow for time periods of less than

twenty-four (24) hours, leave the analyzer on and neglect its output

If the time is expected to be greater than twenty-four hours, follow the

procedures in the Shutdown section

Start Up

Flow Off

26 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide 27

chapter 4 nstallation and Operation

of Modules

The 1817LL analyzer is shipped with a signal conditioner module (Cat

No 180001) factory installed Review the Setting the Module Output

section and the Removing the Installed Module section if you need to

change the factory settings When factory settings are correct for your

analyzer, proceed to the Electrical Connections section

1 Ensure that the power to the 1817LL analyzer is turned off at the

power source

2 Unscrew the module keypad from the black brackets using the two

screws on the keypad

3 Make sure that the plungers are pulled back so the grommets are in a

closed position

4 Slide out the module far enough to access the DIP switches

1 Ensure that the power to the 1817LL analyzer is turned off at the

power source

2 Open the door of the electronic assembly Use a number 2 Phillips head

screwdriver to remove the four screws on the decorative panel

3 Remove the module keypad from the shipping box

4 Unscrew the module keypad from the black brackets using the two

screws on the keypad

5 Make sure that the plungers are pulled back so the grommets are in a

closed position

6 Proceed to the Setting the Module Output section

Signal Conditioner

Module

(Cat No 180001)

Removing the nstalled

Signal Conditioner Module

Replacing the nstalled

Signal Conditioner Module

28 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

The signal conditioner has two voltage outputs (0 to 5 or 0 to 10 volts) and

two current outputs (4 to 20 or 0 to 20 mA isolated) Switches are preset

by manufacturer at 0 to 5 volts and 4 to 20 mA, but can be reset using

the DIP switches (see Figure 10) on the signal conditioner printed circuit

board When required, alter preset output values before sliding the module

into the analyzer, as follows (refer to Table 3)

1 Current output, factory set at 4 to 20 mA 0 to 20 mA is obtained

when switching S1-2 to OFF position and S1-3 to ON position

2 Voltage output, factory set at 0 to 5 VDC 0 to 10 VDC is obtained

when switching S1-1 to ON position

3 Slide the PC board onto the analyzer guide rails The rear of the PC

board should touch the backplane and the plug should fit securely into

its socket Check that the module bracket is against both rails

4 Push the plungers in

5 Make sure that the flex cable is attached to the keypad and to the PC

board If not, carefully slide the header into the socket

S1-1 S1-2 S1-3 S1-4

0 to 5 V OFF X X X

0 to 10 V ON X X X

4-20 mA X ON OFF X

0-20 mA X OFF ON X

X = No effect

Figure 10

Dip Switches on Signal

Conditioner Board

Setting the Signal

Conditioner Module Output

Table 3

Signal Conditioner

Output Modes

1

2

3

4

29 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

1 If the module keypad is still attached, unscrew the module keypad from

the black brackets using the two screws on the keypad

2 Feed the wire through the hole in the chassis bottom labeled option

See Figure 11

3 Run the wire along the wire trough to the signal conditioner

4 Connect the wires to the voltage (0 to 5 V or 0 to 10 V) or current

(0 to 20 mA or 4 to 20 mA) output See Figure 11

5 Check the flex cable connections

6 Screw the keypad on the black metal brackets

7 Check the flex cable connections

8 Measure to ensure that the appropriate number of panels were removed

9 Align the decorative panel against the four stand-offs and reattach it

with Phillips head screws The decorative panel should not cover any of

the optional module

Warning: For safety reasons, the 1817LL analyzer should not be operated

without the decorative panel in place Failure to replace the panel could

expose the operator to dangerous voltages

Output Terminals

Voltage ( + ) 1

( ) 2

Current ( ) 7

( + ) 8

Electrical Connections

for the Signal

Conditioner Module

1 2 3 4 5 6 7 8

0 to 5V DC or

0 to 10v DC

Output

1K Load Min.

+ +

0 mA to 20 mA or

4 mA to 20 mA Current Output

1K Load Min.

Figure 11

Wiring Diagram of

Signal Conditioner

Table 4

Outputs Of Signal

Conditioner Terminals

30 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Set zero Sets the lower level concentration output In this mode, the

LED above the set zero key is active To set the output to either linear or

logarithmic, hold the key down to toggle between these two output forms

Set full scale Sets the upper level concentration output In this mode, the

LED above the set full scale key is active

Test Generates the zero or full scale output to set up an external recording

device The test key deactivates the signal conditioner module and either

the set zero or full scale LED will be active After pressing the test key, there

will be an output delay of up to three seconds Press the sample key to

reactivate the module

Mode indicating LED Located on the left of the module keypad

Indicates the linear or logarithmic signal output When the set zero key is

held, the mode toggles between these output forms

Description of the

Signal Conditioner

Module Controls

Figure 12

Signal Conditioner Keypad

Figure 13

Wiring Diagram of Signal

Conditioner Module

Iog output

Iinear output

test

set

zero

set fuII

scaIe

signaI output

31 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

1 Press the set zero key The LED above the set zero key will activate and

the LCD will display the current programmed value The preset default

value is 01 ppb for log range and 01 ppb for linear range

2 Set the value by pressing the and keys The lowest possible value

is 01 ppb

3 Press the enter/done key when the correct value is displayed

4 Set the upper range by pressing the set full scale key and repeat steps

2 and 3 The preset default value is 100 ppm It is not possible to set

the zero value higher than full scale, and a range of at least two decades

should be used

5 To send zero percent and 100 percent of the full scale signal to an

external recording device, press the test key on the signal conditioner

module The first time the test key is pressed, the zero percent signal

will be sent and the second time the test key is pressed, the full scale

signal will be sent Remember, there may be up to a three second delay

when the test key is pressed

6 To alternate from log to linear mode:

Press the set zero key The output mode will toggle between log and

linear, indicated by the LED The log and linear zero and full scale are

independent and should be set separately Press the enter/done key

when in the desired mode

P0 Off-line Calibration Value 000

P1 Low Range Slope - 0.57

P2 Standard 2 100 ppb

P3 Standard 3 1 ppm

P4 Standard 1 0 ppb

Set Zero (log) 0.1 ppb

Set Zero (linear) 0.1 ppb

Set Full Scale (log) 100 ppm

Set Full Scale (linear) 100 ppm

Set Alarm 1 100 ppb

Set Alarm 2 1.00 ppm

Slope - 57 mV

E

0

118 mV

Programming the Signal

Conditioner Module

Measuring Range

Table 5

1817LL Default Values

32 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

The 1817LL analyzer alarm circuit is unique If the analyzer detects that

the chloride concentration is increasing at such a rate that the high alarm

value will be reached within an hour, a warning signal is activated This

signal is a one second alarm every four seconds that increases in frequency

as the concentration approaches the alarm level Also, if the absolute

chloride concentration is 90% of the high level alarm, an intermittent

warning signal is activated to alert the operator that the high concentration

limit is being approached If this feature is not desired, the low alarm can

be used to set external alarm Alarms are rated at 10 A, 250 V

The optional module is mounted in the analyzer in the following manner:

1 Ensure that the power to the 1817LL analyzer is turned off at the

power source

2 Open the door of the electronic assembly Use a number 2 Phillips head

screwdriver to remove the four screws on the decorative panel

3 Remove the optional module keypad assembly from the shipping box

4 Unscrew the module keypad from the black brackets using the two

screws on the keypad

5 Make sure that the plungers on the black metal frame are pulled back

so that the grommets are in a closed position

Optional Alarm

Module

(Cat No 180011)

nstallation of the

Alarm Module

Figure 14

Alarm Module

33 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

For both alarms 1 and 2, NO and NC conditions are available

simultaneously For the alarms disabled condition, either NO (factory set)

or NC is available To change a factory setting, perform the following steps:

1 Soldered the appropriate jumper, to change between the NO and NC

mode for an alarms disabled remote indication (terminals 7 and 8)

See Figure 15

2 Place the PC board (see Figure 14) onto the analyzer guide rails

The rear of the PC board should touch the backplane and the plug

should fit securely into its socket Check that the module bracket is

against both rails Press the two plastic plungers down to lock the

module in place

3 Make sure that the flex cable is attached to the keypad and to the PC

board If not, carefully slide the header into the socket

Mode Jumper

NO E7 to E8 (factory set)

NC E6 to E8

Setting the Alarm

Module Output

Table 6

Terminals 7 and 8

Alarms Disabled

Figure 15

Jumper Connections on

Alarm Module PC Board

7 8

E6 E7

E8

34 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

1 Feed the wire through the hole in the chassis bottom

2 Run the wire along the wire trough to the alarm module

3 Connect the output wires as required See Table 7

4 Check the flex cable connections

5 Screw the keypad on the black metal brackets

6 Check the flex cable connections

7 Measure to ensure that the appropriate number of panels have been

removed from the protective cover

8 Align the protective cover decorative panel against the four stand-offs

and re-attach it with Phillips head screws The protective cover should

not obscure any optional module

Warning: For safety reasons, the 1817LL analyzer should not operate

without the protective cover in place Failure to replace the cover could

expose the operator to dangerous voltages

Outputs Terminals

Alarm 1 Comm 1

NC 2

NO 3

Alarm 2 Comm 4

NC 5

NO 6

Disable Comm 7

NO/NC 8

Electrical Connections

for the Alarm Module

Table 7

Outputs Of Alarm

Module Terminals

Figure 16

Wiring Diagram of

Alarm Module

1 2 3 4 5 6 7 8

NC

ALARM 1

Alarm contacts

10A 250VAC max

NO

NC

NO

NC

E6

E8

E7

ALARM 2

Alarm contacts

10A 250VAC max

Disable output contacts

Choose either NC or NO

contacts 10A 250VAC max

35 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Set alarm 1 Sets the alarm 1 parameter When the alarm 1 key is pressed,

the LED on the key is active See Table 5 for default values

Set alarm 2 Sets the alarm 2 parameter When the alarm 2 key is pressed,

the LED on the key is active See Table 5 for default values

Test Activates and deactivates alarm 1 and alarm 2 and deactivates relays

The test LED will be lit along with corresponding mode key To reactivate

the module, press the sample key on the front panel keypad

Mode indicating LED Located to the left of the keypad Indicates

if either alarm goes off If the alarms are not active, the deactivated

LED blinks; for example, during calibration For both alarms, the LED

indicating activation is on whenever the concentration is above the set

point Since each alarm output has a normally open and normally closed

position, any external alarm can be set to go off when the concentration is

either above or below the set point

Note: The corresponding LED for either alarms turns on when the

concentration exceeds the set point Simultaneously, the relay closes and the

NO position closes

During calibration the alarm module is automatically deactivated After

the completion of calibration the 1817LL analyzer automatically enters

the sample mode; however, the alarm module remains deactivated To

reactivate, press the sample key The alarm module is deactivated to avoid

the high concentration alarm that would result from the standards used

to calibrate

After a power failure, the alarm module remains deactivated until the

sample key on the front panel keypad (see Figure 9) is pressed The alarm

settings are not affected by power provided for remote indication

Description of the Alarm

Module Controls

Figure 17

Alarm Module Keypad

aIarm one

aIarm two

deactivated

test

aIarm

one

aIarm

two

aIarm moduIe

Alarm During Calibration

Alarm After Power Failure

36 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Note: Alarm limits work on five decade ranges only For example if an

alarm is set to 10 ppb, the alarm will go off at 10 ppb and will continue

to remain on until the 10 ppm value is reached Anything above the five

decade range will turn the alarm off

1 Press the alarm 1 key The LED above the alarm 1 key will activate and

the LCD will display the current alarm 1 value

2 Change the displayed value by pressing the and keys

3 Press the enter/done key when the correct value is displayed The alarm

1 value is set

4 Press the alarm 2 key The LED above the alarm 2 key will activate and

the LCD will display the current alarm 2 value

5 Change the displayed value by pressing the and keys

6 Press the enter/done key when the correct value is displayed The alarm

2 value is set

7 If an external alarm circuit is to be tested, press the test key The first

press of the test key deactivates both alarms, the second press activates

alarm 1 and the third press activates alarm 2 Press the sample key to

exit the test mode

Setting Alarms 1 and 2

Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide 37

chapter 5 Calibration

Note: The sample flow rate must be maintained at 40 mL/minute

during calibration

1 Switch the sample line to a zero chloride solution

2 Place or mount the dynamic calibrator at a proper position near

the analyzer

3 Load the 100 ppm chloride standard (Cat No 941707) into a 20 mL

syringe and expel any air

4 Connect the calibration tubing to the syringe and prepare the dynamic

calibrator as instructed in the dynamic calibrator user guide

5 Set up the standard concentrations to be used for calibration:

a Press the program key The analyzer will display the P0, P1, P2, P3,

and P4 values, in this order, each time the program key is pressed

The meanings of the values are described in the table below

Meaning Value

P0 1 point calibration

concentration

Default value 0 ppb

Range from 0 to 1000 ppb

P1 Low range slope Default value -0.57 mV/ppb

Range from -0.30 to -1.1 mV/ppb

P2 3 point calibration

standard 2 concentration

Default value 100 ppb

Range from 75 to 125 ppb

P3 3 point calibration

standard 3 concentration

Default value 1.0 ppm

Range from 500 ppb to 10 ppm

P4 3 point calibration

standard 1 concentration

Default value 0 ppb

Range from 0 to 20 ppb

This value is always in the unit of ppb, even

though no unit is shown on the analyzer

b When the analyzer displays the value of P2, press the and

keys, if required, to change the value to the desired standard 2

concentration value and then press the enter/done key to accept

the new value A P2 value around 100 ppb is recommended

Three Point

Calibration Procedure

38 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

c Press the program key until the value of P3 is displayed Press

the and keys, if required, to change the value to the desired

standard 3 concentration value and then press the enter/done

key to accept the new value A P3 value around 1000 ppb is

recommended

d Press the program key until the value of P4 is displayed Press

the and keys, if required, to change the value to the desired

standard 1 concentration value and then press the enter/done key

to accept the new value A P4 value around 0 ppb is recommended

6 Press the cal key The cal point 1 LED will light If standard 1 has been

set to 0 ppb, pass only the zero chloride solution to the analyzer Allow

15 minutes for the analyzer to stabilize, or press the test key to show

the potential reading When a stable value is shown, press the enter/

done key The cal point 1 LED will turn off Wait for the analyzer to

determine a stable reading

7 When a stable reading has been determined, the cal point 2 LED

will light If standard 2 has been set to 100 ppb, turn the dynamic

calibrator to the X1/100 position and set the percentage dial to read

101% Turn on the dynamic calibrator and turn the injection valve at

the flow cell to standard Allow 10 minutes for the analyzer to respond

and stabilize When a relatively stable potential value is shown, press

the enter/done key The cal point 2 LED will turn off Wait for the

analyzer to determine a stable reading

8 When a stable reading has been determined, the cal point 3 LED

will light If standard 3 has been set up to 100 ppm, change the

dynamic calibrator to the X1/10 position and set the percentage dial to

read 102% Allow 10 minutes for the analyzer to respond and stabilize

When a relatively stable potential value is shown, press the enter/

done key The cal point 3 LED will turn off Wait for the analyzer to

determine a reading

9 When a stable reading has been determined, the three pt cal complete

LED will light Press the enter/done key to accept the new calibration

10 Turn off the dynamic calibrator and close the standard injection valve at

the flow cell

11 The new calibration parameter values can be viewed by pressing the

program key to view P1 as the low range slope and by pressing the test

key to view high range slope and E

0

39 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

The off-line calibration feature is simply a one point calibration, using an

alternate method value for P0 The term off-line calibration refers only to

the fact that a sample from the 1817LL analyzer bypass is taken off-line

for laboratory analysis; in fact, no downtime is experienced and the analyzer

remains online throughout the procedure Also, the zero chloride solution

can be used for convenience A known chloride concentration can also be

generated by using the calibrator and the zero chloride solution Therefore

off-line chloride analysis may not be necessary, but can be done if desired

Action 1817LL Analyzer Response

1 Take a grab sample from the

bypass of the 1817LL analyzer

(Figure 3, number 16) Make

sure that the analyzer is in the

sample mode

2 Press the calibrate key

Wait for the cal point 1 LED

to light

The cal point 1 LED will light

Within three seconds, the fill/flow

off LED will light

3 Press the program key The program LED will light

Pressing the program key allows

the current mV values and

concentration to be simultaneously

stored in P0 For the purposes of off-

line calibration, only P0 is used The

analyzer returns automatically to the

sample mode The program LED

remains lit, indicating an off-line

calibration has been initiated

4 Operator returns with a grab

sample analysis value

There is no time limit on this step

and the program LED remains lit

5 Press the program key Allows the operator to view the

previously stored P0 value

6 Press the and keys, if

required, to adjust reading to

the grab sample analysis value

There are no set limits for the off-

line calibration value

7 Press the enter/done key The analyzer will remain in the

program mode with the adjusted P0

value from step 6 displayed, while

internally the E

0

is calculated When

calculations are completed, the

analyzer will return to sample mode

Off-Line Calibration

Procedure

40 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide 41

chapter 6 Analyzer Maintenance

The 1817LL analyzer is designed for simple maintenance Follow the

instructions in this section to ensure proper operation of your analyzer

Table 8 outlines our recommended maintenance schedule

mportant: To ensure proper maintenance and good analyzer performance,

a service log book should be kept Record date and type of maintenance

done Mark and date fluid levels of reagent and reference reservoir and

date when replaced Tag each electrode cable with installation date of

electrode This system has proven to be successful by the Thermo Fisher

Scientific Service Department, and is especially useful to plants who rotate

analyzer operators

The Thermo Fisher Scientific Service Department provides a periodic

checkout, calibration and operator training service on site to certify analyzer

performance to published specifications This service can be tailored to fit

individual customer needs If interested, please contact the Thermo Fisher

Scientific Service Department at 1-800-225-1480

Frequency Operation

Weekly Check flow rate

Visual inspection

Monthly Calibrate

Check reference electrode filling solution and refill if necessary

Clean or replace filter element

2 Months Replace reagent, diffusion tubing and O-rings

12 Months Replace reference electrode

Replace chloride electrode

Replace O-rings

Replace restrictor tubing

Maintenance

Schedule

Table 8

Recommended

Maintenance Schedule

42 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

1 Check that the sample flow rate is between 35 and 45 mL/min To alter

the flow rate, pull out the black locking knob of the pressure regulator,

and then rotate the black knob to increase (clockwise) or decrease

(counterclockwise) sample flow Push in the knob to set the rate

2 Inspect the analyzer for leakage Diffusion tubing leakage is indicated

by a rise in level of reagent

3 Check that there are no error indications and the displayed

concentration is reasonable

4 Check that reference electrolyte solution is adequate One bottle lasts

up to several months

Polish the Chloride Electrode

The chloride electrode should be polished according to the instructions

with the polishing strips (Cat No 151713)

Calibrate the Analyzer

Refer to the Calibration section for the step-by-step calibration procedure

Replace the Reference Electrode Filling Solution

Discard the 181073 filling solution that is packaged with the 100057

reference electrode The 181073 filling solution contains chloride ions and

cannot be used with 1817LL analyzer The 900063 filling solution must be

used with 1817LL analyzer

Filling solution is meant to be a two month supply Therefore, if reservoir is

less than half full, replace solution as follows:

1 Remove the spent electrolyte bottle from the clip Unscrew the cap and

discard the bottle

2 Remove the cap and seal from the new electrolyte filling solution

Check that the rubber gasket is properly aligned, and then connect the

cap/tubing assembly to the bottle The 1/8 tubing should extend into

the bottle

3 Invert the electrolyte bottle and snap it into the clip

4 Use the push pin to puncture three air vents in the bottom of the filling

solution bottle

Weekly Maintenance

Monthly Maintenance

43 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Replacement/Cleaning of Sample Inlet Filter

1 Turn off the sample flow

2 Remove the filter hex cap using a 1 inch open-ended wrench

3 Separate the filter cap with bypass valve assembly from the filter body

4 Remove the filter element and soft gasket (if necessary)

5 Replace the gasket and press a new sintered element into the filter body

6 Replace the hex cap and bypass valve assembly and reposition the

bypass drain line into the drain assembly

7 Retighten the hex cap to approximately 75 oz in torque

8 Turn on the sample flow and check for leaks

9 Readjust the bypass flow

10 To clean the sintered filter element, clean it with agitated dilute

sulfuric acid

Replace the Reagent, Tubing and O-rings

1 Replace the acid reagent and diffusion tubing Shut off the analyzer

prior to the inlet Remove the reagent diffusion bottle by unscrewing

the black thumbscrew at the top of the fluid connector block Support

the bottle at its base, unsnap the clip around middle and remove the

bottle from the analyzer

Caution: Wear protective goggles and gloves Refer to the bottle label

for precautions and water in well ventilated area

2 Remove the cap, lift out the gray insert and remove the old diffusion

tubing from the nipples Rinse the cap with deionized water Replace

the five small O-rings on the tubing connector barbs and one large O-

ring on the reagent bottle Install the new reagent and tubing Re-install

the reagent bottle on the analyzer and mark the level and date Restore

sample flow to the analyzer Wait at least one hour to allow the analyzer

to equilibrate prior to recalibration

Bimonthly

Maintenance

44 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Replace the Reference Electrode (Cat. No. 100057)

1 See the Analyzer Preparation section for step-by-step instructions

Replace the Sensing Electrode (Cat. No. 100025)

1 See the Analyzer Preparation section for step-by-step instructions

Replace the Reagent Bottle Assembly O-ring

1 When the reagent bottle is removed, replace the O-ring between the

bottle and adaptor

Replace the Restrictor Tubing

1 Close the sample inlet valve

2 Loosen the fitting connector cap (5/8 white nut) on top of the flow

meter assembly and pull out the restrictor adaptor and the restrictor

tube assembly

3 Unscrew the restrictor from the fluid connector block by turning the

5/8 white fitting counterclockwise

4 Replace the old restrictor assembly with a new assembly, being careful

not to cross the thread flow cell manifold inlet Tighten the Phillips

head screws holding the flow cell to the rear panel

5 Push the adaptor into the fitting connector on top of the flow meter

assembly and to the inlet of the fluid connector block Hand tighten

both white 5/8 nuts

6 Turn on the sample inlet valve and check for leaks Hand tighten

where necessary

Yearly Preventive

Maintenance

restrictor

adapter

restrictor

tube assembly

clamp

fitting

flow

meter

O-ring

to flow cell

manifold

Figure 18

Restrictor Tubing Assembly

Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide 45

chapter 7 Customer Services

The following covers troubleshooting that can be performed without special

tools or skills Note that in most installations, the temperature in the flow cell

should read between 0 to 15 C and a millivolt reading between +400 and

+100 should be observed High range slopes between -48 and -2 mV/decade

and low range slopes between -047 and -067 mV/ppb should be obtained

Malfunction Possible Cause Remedy

Low Slope Improper calibration

technique

Recalibrate

Sensing electrode defective Replace and recalibrate

Calibration standards

contaminated

Recalibrate with fresh

standards

Electronics failure Contact Technical Support

Zero chloride solution

contaminated

Replace and recalibrate

Pipet failure Refer to pipet user guide

Standards 1, 2 and 3

interchanged

Recalibrate

Electronics failure Try resetting the analyzer or

contact Technical Support

Defective dynamic calibrator Check dynamic calibrator

flow rate

Positive Slope Reference and sensing

cables interchanged

Swap cables

High Slope Improper calibration

technique

Recalibrate

Sensing electrode defective Replace and recalibrate

Standards contaminated Recalibrate with fresh

standards

Electronics failure Try resetting computer, or

contact Technical Support

Background concentration

too high for standards used

Use higher standards

Slow responding sensing

electrode

Polish sensing electrode and

recalibrate

Defective dynamic calibrator Check dynamic calibrator

flow rate

Troubleshooting

46 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Malfunction Possible Cause Remedy

Noisy Reference electrolyte

not flowing

Make sure that the

electrolyte bottle is flowing

properly and that the bottle

has been vented

Electrode failure Replace electrode

Loose ground wire Check ground wire at

flow cell

Analyzer okay,

recorder defective

Change recorder

Signal conditioner error Compare the LCD output

with the module output, if

the LCD output is quiet while

the recorder is noisy contact

Technical Support

Temperature probe failure Press the test key to check

temperature stability, if noisy

replace probe

Electronics failure Try resetting computer, or

contact Technical Support

Excessive Drift Loose ground Check ground wire

connection at flow cell,

tighten if necessary

Reference electrolyte not

draining properly

Make sure that the

electrolyte bottle is vented

check tubing to electrode

for obstruction

Reference electrode Failure Replace reference electrode

Chloride electrode failure Replace sensing electrode

Temperature probe failure Press the test key to check

temperature stability, if noisy

replace probe

Burst diffusion tubing Monitor the liquid level in

the reagent bottle if the

liquid level rises, replace the

reagent and diffusion tubing

Tubing connector may need

replacement if leaking

Electronics failure Try resetting computer, or

contact Technical Support

Low Flow Rate Sample pressure below 8 psi Check sample pressure,

increase if less than 8 psi

Pressure regulator set

too low

Increase pressure by pulling

on red locking ring and

turning black knob clockwise

Bypass filter clogged Replace or clean filter

Restrictor tubing crimped

or clogged

Replace restrictor tubing

47 Thermo Scientifc Orion 1817LL Low Level Chloride Analyzer User Guide

Malfunction Possible Cause Remedy

Does Not Calibrate

Properly

Contaminated standards Use new standard solutions

Reagent spent Replace reagent

Flow cell contaminated Rinse flow cell with

deionized water, flush flow

cell overnight with flow on at

calibration liquid level

Electrode failure Replace one or

both electrodes

Temperature probe failure Press the test key to check