Académique Documents

Professionnel Documents

Culture Documents

Assembling Your Own Stripped AR - 1

Transféré par

bigwhiteguyDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Assembling Your Own Stripped AR - 1

Transféré par

bigwhiteguyDroits d'auteur :

Formats disponibles

Assembling Your Own Stripped AR-15 Lower Receiver

Assembling an AR-15 lower receiver is extremely easy and there's simply no reason why an AR owner shouldn't put their own rifle together. It saves you a few bucks, it's fun, and it'll give you an intimate knowledge of your weapon. The assembly requires less than an hour's worth of time even if you've never done it before, and no special tools are required beyond what's already in your toolbox. Some will recommend a set of brass punches, but I've never ruined any AR-15 parts with steel punches, so make your own choice. I assembled this lower receiver sitting at my computer desk to prove that one doesn't need a gunsmithing bench and tool set to do this job. I used ONLY the following tools: * A 1/16" x 4" punch (a small gauge nail with the sharp tip cut or filed off will suffice just fine) * A 3/16" x 5" Allen wrench * A 2mm x 40mm jeweler's flat-end screwdriver (these can also be found in an eyeglasses repair kit) * A set of miniature needle nose pliers (regular needle nose pliers work fine too) * A light hammer * A RRA stock wrench * A roll of electrical tape * A roll of masking tape The only things you'll truly need is a small punch or nail, something solid to tap it with, and the stock wrench that comes with pretty much every stock kit you buy these days. Any other tool simply makes the job a bit easier. Let's begin! Let's get familiar with the lower parts kit (LPK). This is a Rock River Arms LPK:

Spread out, the LPK looks like this (they're packed in machine oil, so you may want to lay them on a paper towel):

Here's close-ups of the parts, including the names of the individual parts:

Step One -- Take your stripped lower and insert the magazine catch into the mag catch hole left side of the receiver:

Step Two -- Insert the magazine catch spring over the magazine catch from the right side of the receiver:

Step Three -- Place the magazine catch button over the magazine catch spring:

Step Four -- Push the magazine catch button and spring down and thread the button onto the magazine catch. You will only be able to thread the button onto the very tip of the catch:

Step Five -- Install magazine catch. Obtain a long 3/16" Allen wrench (this will be used later too), and put tape on the tip so you don't scratch the finish of your receiver and parts. Apply Allen wrench to magazine catch button. Lift receiver up and push magazine catch button with Allen wrench. This will move the magazine catch outwards. Turn magazine catch clockwise to thread it into the button. Thread magazine catch into button until the tip of the catch is flush with the bottom inside of the button.

Step Six -- Place tape on the left side of the receiver and obtain the bolt catch roll pin. The tape will protect the finish of the receiver as you tap the roll pin down.

Step Seven -- Gently tap the bolt catch roll pin into the hole. Do not tap the bolt catch roll pin all the way through! The end of the pin should not protrude into the slot at all!

Step Eight -- Slip the bolt catch spring over the end of the bolt catch plunger:

Step Nine -- Drop the bolt catch spring and bolt catch plunger into the hole:

Step Ten -- Put the bolt catch into the slot. You will need to apply pressure on the plunger and spring, and line the holes up.

Step Eleven -- Tap the roll pin through and use a 1/16" punch or a small nail with the tip cut off to set it in the hole:

Step Twelve -- Insert pivot detent spring in the front and right side of the receiver at the top of the magazine well:

Step Thirteen -- This is the most difficult step by far, so be careful and take your time. Push the pivot detent into the spring while simultaneously pushing the pivot pin down into the pivot ear. You may find it useful to press the detent into the spring with a pair of needle nose pliers and use a very small, thin flat-end screwdriver to hold the detent in place while you slide the pivot pin into the ear. Whatever you do, take care not to launch the detent across the room. This is nearly inevitable, so it's prudent to block the detent's path through the air with an object or a helper should it decide to fly away on you. As this is very much a two-handed operation, I was unable to get pictures of the exact assembly process and can only currently provide pictures taken after each step:

Step Fourteen -- Take the trigger guard and insert it into place. The trigger guard has a built-in spring loaded detent of it's own, and there is a little hole for it right at the bottom of the magazine well. Mate the pin with the hole, and it will just snap right in:

Step Fifteen -- Line the holes in the end of the trigger guard up with the roll pin holes in the receiver. While supporting the bottom ear with something solid, gently tap the trigger guard roll pin in and set it with a small punch or cut-off nail. It is very important that you support the bottom ear while tapping the roll pin in, otherwise you risk breaking it off!:

Step Sixteen -- Assemble the trigger and trigger spring:

Please note: the small coil spring in the next picture is upside down! The fatter end should go into the trigger, opposite of what is shown. My apologies. When I built this lower for this how-to, I was apparently paying more attention to getting pictures than that little detail.

Step Seventeen -- Install trigger assembly:

Step Eighteen -- Install disconnector on top of trigger assembly. The notch in the bottom of the disconnector must be placed over the spring in the top of the trigger:

Step Nineteen -- Insert the trigger pin. This isn't difficult, but you'll have to push the whole assembly down with your finger, then wiggle the trigger and disconnector around a little bit to get it to fit. There's no science here...Just move stuff around until the pin goes through:

Step Twenty -- Assemble the hammer and hammer spring:

Step Twenty-One -- Install hammer assembly. The two legs of the spring must be resting on top of the trigger pin. You will have to forcefuly push the hammer into the receiver and fight the spring tension to line all the holes up so you may insert the hammer pin. However, like installing the trigger, this is not a difficult step either. Just keep wiggling things around until the hammer pin pushes through.

Step Twenty-Two -- Cock the hammer:

Step Twenty-Three -- Install the selector into the left side of the receiver:

Step Twenty-Four -- Insert selector detent and spring. The detent goes pointed end first into the little hole under the selector on the right side of the receiver. The spring follows it:

Step Twenty-Five -- Screw the grip on. There is a hole in the top of the grip on the right side. The selector detent spring must go inside this hole! Once the spring is inside the hole in the grip, push the grip all the way up into place. Insert the screw and locking washer in from the bottom and tighten:

Step Twenty-Six -- Install the rear takedown pin. First, insert the takedown pin detent, pointed end first into the hole in the rear of the receiver. Then insert the spring, but don't push the spring all the way in yet. Insert the takedown pin first, then push the spring and detent all the way in until they meet the pin. The spring will hang out until the stock is installed in the next step:

Step Twenty-Seven -- Prepare the stock for installation:

Step Twenty-Eight -- Thread the stock onto the receiver. When doing this, be very mindful of the takedown detent spring sticking out. Stop screwing the stock in before you reach the buffer pin hole:

Step Twenty-Nine -- Assemble and install the buffer pin and spring assembly:

Step Thirty -- Finish threading stock onto receiver. Push the buffer pin down with your finger while you give the stock a few more turns. Screw the stock in as far as you can so that it holds the buffer pin down, but does not prevent it's movement. You will know you've gone far enough when the stock is in the correct position (not twisted to one side or another), and the buffer pin can still move up and down freely:

Step Thirty-One -- Tighten the stock in place. Push the lock plate forward towards the receiver, taking care to make sure the takedown detent spring goes into the hole properly. While holding the stock lock plate down, tighten the castle nut down until it holds the lock plate in place. Take a stock wrench and tighten the castle nut down. You may use Loc-Tite on the castle nut, but it's not necessary:

Step Thirty-Two -- Install the buffer spring and buffer. Slide the spring into the buffer tube (inside the stock). Slip the buffer into the end of the spring and push it back. Rotate the buffer so that one of the flat edges is down so that it may pass over the buffer pin. Once you have pushed the buffer past the buffer pin, rotate the buffer so that one of the round sides is down. Release the buffer and it should stay put, held by the buffer pin.

Congrats! You've finished! The completed lower receiver:

Now it's time to assemble your AR-15: Step Thirty-Three -- Place your upper on top of the lower. Press the front pivot pin in, followed by the takedown pin. It's not unusual for new rifles to be tight and somewhat difficult to push the pins in on. So, these pins may require some light tapping with a hammer. As the weapon is used and disassembled for cleaning and maintenance, the process of inserting and extracting the takedown and pivot pins will become much easier:

The complete rifle:

Be sure to perform a function check prior to firing the rifle! Function checks should be performed at various stages of the assembly process. This is done by simply verifying that things work as they should. As long as you assemble the lower properly, you wont have any trouble. The important items to check are the selector switch, trigger assembly, and hammer assembly; everything else should be fine as long as you put everything together properly. To function check the selector switch: * Simply make sure selector rotates without binding. To function check the trigger assembly: * Be sure the trigger pivots smoothly when you pull it back. * Make sure the disconector pivots when pushed. To function check the hammer assembly: * Verify that hammer locks to the rear when pushed back (cocked position). * Verify that hammer pivots forward when trigger is pressed (if the upper is off, be sure to pad the lower where the hammer will strike or drop the hammer on your hand or else you risk cracking your receiver). * Without releasing the trigger, push the hammer back again and verify that it locks (caught by disconnector). * Releasing the trigger should not cause the hammer to pivot fully forward (caught by trigger). * Hammer will fall when trigger is pressed. To function check the rifle's correct operation: * Pull the charging handle to the rear and release. Place the selector on SAFE. Pull the trigger, and the hammer should not fall. * For semi-automatics, place the selector on FIRE. Pull the trigger and hold to the rear. The hammer should fall. Continue to hold the trigger to the rear, pull the charging handle to the rear, and release it. Release the trigger with a slow, smooth motion until the trigger is fully forward. The hammer should not fall. Pull the trigger. The hammer should fall. If your weapon passes all these function checks, it's time to fire it. * Load one round into a magazine. Insert the magazine. With the rifle pointed in a safe direction, pull the charging handle and release it, loading the round into the chamber. * Switch the selector to FIRE, take aim on a safe target, depress the trigger until it fires. * If the rifle fires, verify extraction of the brass case and that the bolt has been held open by the magazine.

* If the rifle successfully fires, perform this operation two more times. * Once you have completed three cycles of loading and firing a single round from the magazine, load three rounds into the magazine and fire the rifle. Verify that semi-automatic operation is functioning properly, and that all cases are feeding and extracting. * Complete two more cycles of firing three rounds from the magazine. * If the rifle passes all of these stages, load an entire magazine and slowly and deliberately fire each round, making sure everything is functioning properly. * After you have emptied an entire 20 or 30 round magazine successfully without issue, you are safe to use the rifle freely.

Vous aimerez peut-être aussi

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsD'EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsPas encore d'évaluation

- AR15 Build GuideDocument37 pagesAR15 Build GuideJohnSimmons123100% (6)

- Gun Digest's Customize Your Revolver Concealed Carry Collection eShort: From regular pistol maintenance to sights, action, barrel and finish upgrades for your custom revolver.D'EverandGun Digest's Customize Your Revolver Concealed Carry Collection eShort: From regular pistol maintenance to sights, action, barrel and finish upgrades for your custom revolver.Pas encore d'évaluation

- AR-15 Lower Assembly InstructionsDocument7 pagesAR-15 Lower Assembly Instructionsv00d00blues100% (1)

- Brooks Trigger Kit 1st Set If InstructionsDocument9 pagesBrooks Trigger Kit 1st Set If Instructionsjimmywiggles100% (3)

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesD'EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesPas encore d'évaluation

- AR-15 Builders Resource - Version 1 (Rev. 1)Document48 pagesAR-15 Builders Resource - Version 1 (Rev. 1)blowmeasshole1911100% (1)

- 级触发自动武器 PDFDocument15 pages级触发自动武器 PDFJin SongPas encore d'évaluation

- Colt AR-15 Rifle Lightning LinkDocument5 pagesColt AR-15 Rifle Lightning Linkelvergonzalez1100% (2)

- Practical Guide to the Operational Use of the PPS-43 Submachine GunD'EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunPas encore d'évaluation

- Trigger Slap and Doubling Trouble ShootingDocument8 pagesTrigger Slap and Doubling Trouble ShootingAdam Hemsley100% (2)

- A1 To A2Document45 pagesA1 To A2leeyangseopPas encore d'évaluation

- Bolt Together AR15 Lower ReceiverDocument0 pageBolt Together AR15 Lower ReceiverLogicIndustriesLLC100% (1)

- Datum Gear Inc Ar-15 Kevlar 80% Lower PresentationDocument20 pagesDatum Gear Inc Ar-15 Kevlar 80% Lower PresentationSam Cadle100% (3)

- The AK Short Throw TriggerDocument6 pagesThe AK Short Throw TriggerAdam Hemsley100% (1)

- Ar-10 Rifles PDFDocument12 pagesAr-10 Rifles PDFstonefirearmsPas encore d'évaluation

- SuppressorsD'EverandSuppressorsEditors of RECOIL MagazinePas encore d'évaluation

- BHP Trigger JobDocument8 pagesBHP Trigger Jobssnvet100% (3)

- AR15 Barrel Nut IndexingDocument1 pageAR15 Barrel Nut IndexingMike Nichlos100% (3)

- The SWD Lightning LinkDocument2 pagesThe SWD Lightning LinkRay Bailey100% (3)

- Lightning Link Printable Template V1.0Document5 pagesLightning Link Printable Template V1.0Luis Carlos Martinez100% (1)

- Ruger MkII Ejector Dimension Ed FlatDocument1 pageRuger MkII Ejector Dimension Ed FlatMike NichlosPas encore d'évaluation

- Blueprints To Build A Mark II Sten GunDocument25 pagesBlueprints To Build A Mark II Sten GunKawchhar AhammedPas encore d'évaluation

- Io Inc January 2016 News Press ReleaseDocument4 pagesIo Inc January 2016 News Press Releaseapi-242710584Pas encore d'évaluation

- AR15 Trigger ComparisonDocument16 pagesAR15 Trigger ComparisonIM_JohnnyV100% (1)

- ListDocument40 pagesListCarlos Ramos100% (1)

- Mujahadeen AR-15Document13 pagesMujahadeen AR-15Chris Leahy100% (2)

- AK Accurizing TipsDocument27 pagesAK Accurizing TipsEmilio Torres EsguerraPas encore d'évaluation

- Bolt Action 9Document10 pagesBolt Action 9spartywrx100% (1)

- Build AR15 LowersDocument4 pagesBuild AR15 LowersBuildAR15Lowers67% (3)

- Us 3722358Document9 pagesUs 3722358awe234Pas encore d'évaluation

- Carl Gustav SMGDocument18 pagesCarl Gustav SMGJorihood100% (1)

- Homebuilt - HPDE AR15 LowerDocument15 pagesHomebuilt - HPDE AR15 LowerMike Bell100% (3)

- Grasshopper Ak-47 Jig GuncoDocument5 pagesGrasshopper Ak-47 Jig Guncoterrencebelles100% (2)

- Cetme FlatDocument15 pagesCetme Flatjohnoneal0% (2)

- Dremeling A GLOCKDocument18 pagesDremeling A GLOCKBillyGlock100% (1)

- Instrucions 50Document5 pagesInstrucions 50blazerman3Pas encore d'évaluation

- KMR QRF MCMR: Bravo Company MFG®Document3 pagesKMR QRF MCMR: Bravo Company MFG®Matt KienertPas encore d'évaluation

- 1911 Frame TutorialDocument22 pages1911 Frame Tutorialblackta6100% (6)

- Handi Instr OneDocument9 pagesHandi Instr OnenotjustsomeonePas encore d'évaluation

- Mod Firearm Beretta - US Patent 5596162Document9 pagesMod Firearm Beretta - US Patent 5596162luanfunari100% (1)

- MPA 22 ManualDocument16 pagesMPA 22 ManualChris Choat100% (1)

- Modulus Arms Heavy-Duty AR-15 Jig Instructions V1Document21 pagesModulus Arms Heavy-Duty AR-15 Jig Instructions V1Justin HeadPas encore d'évaluation

- Making The Extractor Cut On A Virgin Barrel - The AK Files ForumsDocument4 pagesMaking The Extractor Cut On A Virgin Barrel - The AK Files Forumsscout50Pas encore d'évaluation

- Ruger 10 22 Rifle Full Auto ConversionDocument22 pagesRuger 10 22 Rifle Full Auto Conversionspanky6276100% (2)

- Polymer80: Phoenix Version - G150 80% Lower Receiver InstructionsDocument13 pagesPolymer80: Phoenix Version - G150 80% Lower Receiver InstructionsTimothy ScottPas encore d'évaluation

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongPas encore d'évaluation

- АК туториалDocument63 pagesАК туториалLucas Gabriel100% (2)

- AR15 ExtractorDocument1 pageAR15 ExtractorfuriousgaulPas encore d'évaluation

- America's Rifle - The ARDocument15 pagesAmerica's Rifle - The ARlsilva171Pas encore d'évaluation

- Manish Kumar: Desire To Work and Grow in The Field of MechanicalDocument4 pagesManish Kumar: Desire To Work and Grow in The Field of MechanicalMANISHPas encore d'évaluation

- I.A.-1 Question Bank EM-3 (Answers)Document11 pagesI.A.-1 Question Bank EM-3 (Answers)UmmPas encore d'évaluation

- Schmidt Hammer TestDocument5 pagesSchmidt Hammer Testchrtrom100% (1)

- Powerplant QuestionsDocument19 pagesPowerplant QuestionsAshok KumarPas encore d'évaluation

- Philips HD 9 User ManualDocument3 pagesPhilips HD 9 User ManualNdangoh DerekPas encore d'évaluation

- Credit Card Authorization Form WoffordDocument1 pageCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaPas encore d'évaluation

- World Trends in Municipal Solid Waste ManagementDocument11 pagesWorld Trends in Municipal Solid Waste ManagementNeima EndrisPas encore d'évaluation

- Chomsky's Universal GrammarDocument4 pagesChomsky's Universal GrammarFina Felisa L. AlcudiaPas encore d'évaluation

- 1st Unseen Passage For Class 5 in EnglishDocument7 pages1st Unseen Passage For Class 5 in EnglishVibhav SinghPas encore d'évaluation

- Unit 7 ActivitiesDocument8 pagesUnit 7 ActivitiesleongeladoPas encore d'évaluation

- Shift Registers NotesDocument146 pagesShift Registers NotesRajat KumarPas encore d'évaluation

- 19 Uco 578Document20 pages19 Uco 578roshan jainPas encore d'évaluation

- Conflict Management A Practical Guide To Developing Negotiation Strategies Barbara A Budjac Corvette Full ChapterDocument67 pagesConflict Management A Practical Guide To Developing Negotiation Strategies Barbara A Budjac Corvette Full Chapternatalie.schoonmaker930100% (5)

- Emerson Mentor MP ManualDocument182 pagesEmerson Mentor MP ManualiampedrooPas encore d'évaluation

- International Supply Chain ManagementDocument2 pagesInternational Supply Chain ManagementPRASANT KUMAR SAMALPas encore d'évaluation

- Fiedler1950 - A Comparison of Therapeutic Relationships in PsychoanalyticDocument10 pagesFiedler1950 - A Comparison of Therapeutic Relationships in PsychoanalyticAnca-Maria CovaciPas encore d'évaluation

- LQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQDocument5 pagesLQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQSAJAL KOIRALAPas encore d'évaluation

- College of Engineering Cagayan State UniversityDocument16 pagesCollege of Engineering Cagayan State UniversityErika Antonio GutierrezPas encore d'évaluation

- Afa Coursework ExamplesDocument6 pagesAfa Coursework Examplesiuhvgsvcf100% (2)

- Why We Need A Flying Amphibious Car 1. CarsDocument20 pagesWhy We Need A Flying Amphibious Car 1. CarsAsim AhmedPas encore d'évaluation

- Noth PicturesDocument17 pagesNoth PicturesJana AssaPas encore d'évaluation

- Be and Words From The List.: 6B Judging by Appearance Listening and ReadingDocument3 pagesBe and Words From The List.: 6B Judging by Appearance Listening and ReadingVale MontoyaPas encore d'évaluation

- The Technology Procurement HandbookDocument329 pagesThe Technology Procurement HandbookAlexander Jose Chacin NavarroPas encore d'évaluation

- Cross Border Data Transfer Consent Form - DecemberDocument3 pagesCross Border Data Transfer Consent Form - DecemberFIDELIS MUSEMBIPas encore d'évaluation

- Kunst 1600 Case AnalysisDocument3 pagesKunst 1600 Case AnalysisrakeshPas encore d'évaluation

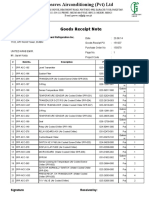

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocument4 pagesGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanPas encore d'évaluation

- Manitou 1350RDocument4 pagesManitou 1350RcandlaganPas encore d'évaluation

- KSP Solutibilty Practice ProblemsDocument22 pagesKSP Solutibilty Practice ProblemsRohan BhatiaPas encore d'évaluation

- ERP Solution in Hospital: Yangyang Shao TTU 2013Document25 pagesERP Solution in Hospital: Yangyang Shao TTU 2013Vishakh SubbayyanPas encore d'évaluation

- Mathematics4 q4 Week4 v4Document11 pagesMathematics4 q4 Week4 v4Morales JinxPas encore d'évaluation