Académique Documents

Professionnel Documents

Culture Documents

Types of Lubricants: Lubrication

Transféré par

050370Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Types of Lubricants: Lubrication

Transféré par

050370Droits d'auteur :

Formats disponibles

501E

Lubrication

Accessories for Lubrication

When using an LM system, it is necessary to provide effective lubrication. Without lubrication, the rolling elements or the raceway may be worn faster and the service life may be shortened. A lubricant has effects such as the following. (1) Minimizes friction in moving elements to prevent seizure and reduce wear. (2) Forms an oil lm on the raceway to decrease stress acting on the surface and extend rolling fatigue life. (3) Covers the metal surface to prevent rust formation. To fully bring out an LM systems functions, it is necessary to provide lubrication according to the conditions. It is necessary to study the mounting positions of the grease nipple and piping joint according to the installation direction. (If the mounting orientation of the LM Guide is other than horizontal installation, the lubricant may not reach the raceway completely. Be sure to let THK know the installation direction and the exact position in each LM block where the grease nipple or the piping joint should be attached. For the mounting position of the LM Guide, see A1-12.) Even with an LM system with seals, the internal lubricant gradually seeps out during operation. Therefore, the system needs to be lubricated at an appropriate interval according to the conditions.

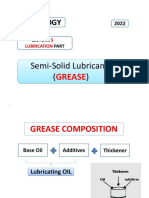

Types of Lubricants

LM systems mainly use grease or sliding surface oil for their lubricants. The requirements that lubricants need to satisfy generally consist of the following. (1) High oil lm strength (2) Low friction (3) High wear resistance (4) High thermal stability (5) Non-corrosive (6) Highly anti-corrosive (7) Minimal dust/water content (8) Consistency of grease must not be altered to a significant extent even after it is repeatedly stirred. For lubricants that meet these requirements, see A24-3.

A24-2

501E

Lubrication

Types of Lubricants

Grease Lubrication

Greasing intervals vary depending on the conditions and environments. For normal use, we recommend greasing the system approximately every 100 km of travel distance. Normally, replenish grease of the same group from the grease nipple or greasing hole provided on the LM system. Mixing different types of grease may deteriorate the systems performance, such as increased consistency.

Lubricant Type Brand name AFA Grease (THK) see A24-7 AFB-LF Grease (THK) see A24-8 AFC Grease (THK) see A24-10 AFE-CA Grease (THK) see A24-12 AFF Grease (THK) see A24-14 AFG Grease (THK) see A24-18 AFJ Grease (THK) see A24-20 Albania Grease No.2 (Showa Shell Sekiyu) Daphne Exponex Grease No.2 (Idemitsu) or equivalent

*Recommended greases vary according to the conditions and environment. See A24-6 to A24-23 for details.

Grease

Lithium-based grease (JIS No. 2) Urea-based grease (JIS No. 2)

Oil Lubrication

LM systems that require oil lubrication are shipped with only anti-rust oil applied. When placing an order, specify the required lubricant oil. (If the installation direction of the LM Guide is other than horizontal installation, the lubricant may not reach the raceway completely. Be sure to let THK know the installation direction of the LM Guide. For the mounting position of the LM Guide, see A1-12.) The amount of oil to be supplied varies with stroke length. For a long stroke, increase the lubrication frequency or the amount of oil so that an oil lm reaches the stroke end of the raceway. In environments where a liquid coolant is spattered, the lubricant will be mixed with the coolant, and this can result in the lubricant being emulsified or washed away, causing significantly degraded lubrication performance. In such settings, apply a lubricant with high viscosity (kinematic viscosity: approx. 68 cst) and high emulsication-resistant, and adjust the lubrication frequency or the amount of the feed lubricant. For machine tools and similar devices that are subject to heavy loads and require high rigidity and operate at high speed, it is advisable to apply oil lubrication. Make sure that lubrication oil normally discharges from the ends of your lubrication piping, i.e., the oiling ports that connect to your LM system.

Lubricant Type Sliding surface oil or turbine oil ISOVG32 to 68 Brand name Super Multi 32 to 68 (Idemitsu) Vactra No.2SLC (Exxon Mobil) DTE Oil (Exxon Mobil) Tonner Oil (Showa Shell Sekiyu) or equivalent

Accessories for Lubrication

Oil

A24-3

Vous aimerez peut-être aussi

- Lubrication of GearsDocument6 pagesLubrication of GearsCesar VasquesPas encore d'évaluation

- 638050Document3 pages638050Alex CentenoPas encore d'évaluation

- LubricationDocument8 pagesLubricationSick LovePas encore d'évaluation

- Types of Lubricants: LubricationDocument2 pagesTypes of Lubricants: Lubricationengineer bilalPas encore d'évaluation

- Types of Lubricants: LubricationDocument2 pagesTypes of Lubricants: LubricationShubham sonalePas encore d'évaluation

- MCE321 - Lubrication and LubricantsDocument9 pagesMCE321 - Lubrication and LubricantsVanina VaniniPas encore d'évaluation

- Guide To Electric Motor Bearing LubricationDocument7 pagesGuide To Electric Motor Bearing LubricationUber_Konstruktor100% (2)

- Lubrication Types and GradesDocument6 pagesLubrication Types and Gradesroopa mPas encore d'évaluation

- Lubrication For Journal BearingDocument25 pagesLubrication For Journal BearingNguyễn Thanh SơnPas encore d'évaluation

- Guide To EM Bearing LubricationDocument12 pagesGuide To EM Bearing LubricationAnonymous alQXB11EgQ100% (1)

- Jet Aircraft Engine Lubrication Systems: Learning ObjectivesDocument24 pagesJet Aircraft Engine Lubrication Systems: Learning ObjectivesArun AkPas encore d'évaluation

- Bearing 072-079Document8 pagesBearing 072-079Volety_Sarma_1703Pas encore d'évaluation

- Guide To Electric Motor Lubrication ExxonDocument0 pageGuide To Electric Motor Lubrication Exxont_syamprasad100% (1)

- Lubrication GuideDocument28 pagesLubrication GuideVarun PineamaneniPas encore d'évaluation

- Best Practices For Lubing API Centrifugal Pump Bearing HousingsDocument7 pagesBest Practices For Lubing API Centrifugal Pump Bearing HousingsguluuPas encore d'évaluation

- Gear Lubrication 3Document9 pagesGear Lubrication 3rashm006ranjan100% (1)

- ENB 04 0555 Rev B Bearing Lubrication PDFDocument5 pagesENB 04 0555 Rev B Bearing Lubrication PDFIrwan SyahPas encore d'évaluation

- 115 Rock Drill Oil ApplicationsDocument2 pages115 Rock Drill Oil ApplicationsRandi Riki AdtiaPas encore d'évaluation

- Practices For Lurbricating Bearing in APIDocument6 pagesPractices For Lurbricating Bearing in APINguyen ChuyenPas encore d'évaluation

- Constant Level Oiler - Vented or NonventedDocument7 pagesConstant Level Oiler - Vented or Nonventedpeach5Pas encore d'évaluation

- TT Components and Characteristics of GreaseDocument2 pagesTT Components and Characteristics of GreaseAnonymous alQXB11EgQPas encore d'évaluation

- What You Need To Know When Selecting Gear OilsDocument5 pagesWhat You Need To Know When Selecting Gear OilsmarciofelipessantosPas encore d'évaluation

- Engine Lubricating SystemsDocument21 pagesEngine Lubricating SystemsDeepak Dileep100% (1)

- Lubrication of Spline ShaftsDocument2 pagesLubrication of Spline ShaftsdispublishPas encore d'évaluation

- ReducerDocument37 pagesReducerSubhaanPas encore d'évaluation

- Cyl LubricationDocument7 pagesCyl LubricationThuria TunPas encore d'évaluation

- Lubrication ProjectDocument23 pagesLubrication ProjectAaron Palm100% (1)

- Bearing Importance of LubricationDocument5 pagesBearing Importance of LubricationgeppaPas encore d'évaluation

- Gearbox LubricationDocument5 pagesGearbox LubricationTaranpreet Singh100% (1)

- TT Electric Motor Bearing Lubrication GuideDocument7 pagesTT Electric Motor Bearing Lubrication GuidepatipanpanitanPas encore d'évaluation

- Lubricacion de CadenasDocument3 pagesLubricacion de CadenasAlfredo MazziniPas encore d'évaluation

- Sleeve or Plain Bearing LubricationDocument3 pagesSleeve or Plain Bearing LubricationVolety_Sarma_1703100% (1)

- Report On Engine LubricationDocument9 pagesReport On Engine LubricationJitesh MhatrePas encore d'évaluation

- LEC5 Lubrication 2022Document37 pagesLEC5 Lubrication 2022mohamed hodiriPas encore d'évaluation

- Lecture 3Document52 pagesLecture 3saxadi4814Pas encore d'évaluation

- Instructions of Reducer Model FH1005.142.F1B-00: Shanghai Zhenhua Heavy Industry Co.,Ltd July, 2010Document12 pagesInstructions of Reducer Model FH1005.142.F1B-00: Shanghai Zhenhua Heavy Industry Co.,Ltd July, 2010Ivan MaltsevPas encore d'évaluation

- SHE73 LubricaciónDocument48 pagesSHE73 Lubricacióngonzalo valderramaPas encore d'évaluation

- Fkr555.109.d4a 00apmt ManualDocument12 pagesFkr555.109.d4a 00apmt ManualJavier FernándezPas encore d'évaluation

- Automatic and Manual GreasingDocument10 pagesAutomatic and Manual GreasingAhmed SalahPas encore d'évaluation

- Cylinder and Packing LubeDocument6 pagesCylinder and Packing LubemadhancairnPas encore d'évaluation

- Qip Ice 23 Lubrication SystemsDocument24 pagesQip Ice 23 Lubrication SystemsMohan Kumar SPas encore d'évaluation

- LubeCoach Volume and Frequency Recommendations PDFDocument13 pagesLubeCoach Volume and Frequency Recommendations PDFEstebanRiveraPas encore d'évaluation

- Elsvare Gas Turbine Lube OilDocument36 pagesElsvare Gas Turbine Lube OilshaonaaPas encore d'évaluation

- Most Common Cause of Bearing FailureDocument7 pagesMost Common Cause of Bearing FailureTim KuPas encore d'évaluation

- 2.5 Lubrication System - NotesDocument6 pages2.5 Lubrication System - NotesAustin ChechechePas encore d'évaluation

- Cooling and Lubrication of I.C. EngineDocument18 pagesCooling and Lubrication of I.C. EnginePrakhar ParetaPas encore d'évaluation

- Service Lubricating SystemDocument24 pagesService Lubricating SystemEDEN JIMENEZPas encore d'évaluation

- Ballscrew Lubrication Instructions: Linear Motion Products & TechnologyDocument1 pageBallscrew Lubrication Instructions: Linear Motion Products & TechnologyhollabackcockPas encore d'évaluation

- 05 - LubrifiereDocument14 pages05 - Lubrifieresandel123Pas encore d'évaluation

- Gleitlager enDocument32 pagesGleitlager enMarcelo Topon100% (1)

- Cylinder Lubrication SystemDocument8 pagesCylinder Lubrication SystemSilvio RodriguezPas encore d'évaluation

- CHAPTER 8 Engine Lubrication and CoolingDocument30 pagesCHAPTER 8 Engine Lubrication and CoolingRushabh PatelPas encore d'évaluation

- A Review On Grease Lubrication in Rolling BearingsDocument11 pagesA Review On Grease Lubrication in Rolling BearingsfahreezPas encore d'évaluation

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityD'EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityÉvaluation : 3 sur 5 étoiles3/5 (4)

- Essex Terraplane Six 1933 Owner's Manual of InformationD'EverandEssex Terraplane Six 1933 Owner's Manual of InformationPas encore d'évaluation

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualD'EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualD'EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualPas encore d'évaluation

- ICE Annex A Methodologies For RecyclingDocument17 pagesICE Annex A Methodologies For RecyclingChai Lin NyokPas encore d'évaluation

- CV Mayank Shekhar Dwivedi IITBDocument4 pagesCV Mayank Shekhar Dwivedi IITBGoutam GiriPas encore d'évaluation

- Control Panel STD Design PDFDocument71 pagesControl Panel STD Design PDFDuy ThaiPas encore d'évaluation

- Notice - Odd Sem End Semester Examinations 2022-23 - Phase 2 - Procedure - 020223Document1 pageNotice - Odd Sem End Semester Examinations 2022-23 - Phase 2 - Procedure - 020223pritamchandra007Pas encore d'évaluation

- Depth of InvestigationDocument8 pagesDepth of InvestigationGogot Pantja ParijogoPas encore d'évaluation

- Soccer Field Lighting DesignDocument22 pagesSoccer Field Lighting DesigndevakaPas encore d'évaluation

- ReadmeDocument9 pagesReadmewatzzupPas encore d'évaluation

- Structural Concept - Helix StructureDocument6 pagesStructural Concept - Helix StructurebistsushantPas encore d'évaluation

- Continuous Thread Stud Double End Stud ADocument11 pagesContinuous Thread Stud Double End Stud AMarius Mihai Buzduga0% (1)

- Sumanta Chowdhury - CLS Aipmt-15-16 XIII Phy Study-Package-7 Set-1 Chapter-27Document32 pagesSumanta Chowdhury - CLS Aipmt-15-16 XIII Phy Study-Package-7 Set-1 Chapter-27Rohit Raj0% (1)

- Bearing Detail PDFDocument1 152 pagesBearing Detail PDFJayesh MachhiPas encore d'évaluation

- Supriya 113418799Document4 pagesSupriya 113418799Kewl JstPas encore d'évaluation

- 04 Rociador Tyco K11.2 SRDocument6 pages04 Rociador Tyco K11.2 SRRuben Saucedo JacomePas encore d'évaluation

- Muhammad Akif Naeem Open Ended Lab Signals and SystemDocument20 pagesMuhammad Akif Naeem Open Ended Lab Signals and SystemMuhammad Akif NaeemPas encore d'évaluation

- D91 PDFDocument3 pagesD91 PDFJuan Diego ArizabalPas encore d'évaluation

- Astm D3212.380331 1Document3 pagesAstm D3212.380331 1anish_am2005Pas encore d'évaluation

- Plastic Coatings: Advanced Polymer Technologies ForDocument13 pagesPlastic Coatings: Advanced Polymer Technologies ForFazlul HoquePas encore d'évaluation

- Implementing Routing Facilities For Branch Offices and Mobile WorkersDocument180 pagesImplementing Routing Facilities For Branch Offices and Mobile WorkersAlejandro Cordero OrdoñezPas encore d'évaluation

- Unit 16Document35 pagesUnit 16api-334267616Pas encore d'évaluation

- Reason Key CommandsDocument6 pagesReason Key CommandsVijay KumarPas encore d'évaluation

- Risk Assess T-17 - Using Portable Hand ToolsDocument4 pagesRisk Assess T-17 - Using Portable Hand ToolsMAB AliPas encore d'évaluation

- ASTM Data and ControlDocument141 pagesASTM Data and ControlYohanes Ronny100% (1)

- Yousif Alotaibi 01 CVDocument3 pagesYousif Alotaibi 01 CVyousefx20Pas encore d'évaluation

- DW-143 - Leakage Factor As Per Calculation FormulaDocument2 pagesDW-143 - Leakage Factor As Per Calculation Formulasandeep7426Pas encore d'évaluation

- Guinness Case StudyDocument3 pagesGuinness Case StudyMunyaradzi T HotoPas encore d'évaluation

- IEC Systems Manual - SCRDocument102 pagesIEC Systems Manual - SCRgabriel100% (3)

- 2007 Volkswagen Jetta Fuse Box Diagram (Inside and Outside) Needed PDFDocument7 pages2007 Volkswagen Jetta Fuse Box Diagram (Inside and Outside) Needed PDFGuillermo Nájera MolinaPas encore d'évaluation

- Seafrost BD50F Refrigerator SystemDocument7 pagesSeafrost BD50F Refrigerator SystemMathiyazhagan SPas encore d'évaluation

- Quest CCS ProjectDocument10 pagesQuest CCS ProjecttruehemingwayPas encore d'évaluation

- Contra Dam, SwissDocument31 pagesContra Dam, SwissSudheekar ReddyPas encore d'évaluation