Académique Documents

Professionnel Documents

Culture Documents

What Is A Document?: Tips On ISO 9001 Quality Management System Documentation

Transféré par

Mohammad Jaid AlamDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

What Is A Document?: Tips On ISO 9001 Quality Management System Documentation

Transféré par

Mohammad Jaid AlamDroits d'auteur :

Formats disponibles

Tips on ISO 9001 Quality Management System Documentation What is a document? Lets begin with some definitions.

A document is information that is written or recorded on some medium such as paper or computer. A document may specify requirements (e.g. a drawing or technical specification); provide direction (e.g. quality plan); or show results or evidence of activities performed (e.g. records). What is a procedure? A procedure is a specific way to perform an activity or process (methods or practice used by an organization) and it may or may not be written. If it is written, it is called a documented procedure. The same reasoning applies to work instructions (which are ways to perform a discrete task) which may or not be documented. What purpose does QMS documentation serve? QMS documentation provide the following benefits and objectives: 1. Communication of Information - needed by the organization to plan, operate and control its processes. The type and extent of the documentation will depend on the criteria listed above, as well as the degree of formality of communication systems and the level of communication skills within the organization, and the organizational culture. 2. Evidence of conformity - provides evidence that what was planned and what has actually been done. 3. Knowledge reservoir and sharing - to preserve and disseminate the organizations experiences; business and technical know-how. A typical example would be a technical specification, which can be used as a base for design and development of a new product. 4. Training tool - to train personnel in performing their responsibilities 5. Consistency of performance - by having all personnel perform to the same method, practice or procedure 6. Promote best practice - document the best way of performing activity using internal and external knowledge What are the ISO 9001 requirements for QMS documentation? Clause 4.2.1 specifies all the different types of documentation needed for your QMS. You must have documented statements of your quality policy and objectives. Specific requirements for these documents are stated elsewhere in clause 5 of the standard. You must have a documented Quality Manual. There are many ways to document your Quality Manual; and this would be determined by the size,

structure and complexity of your organization. Clause 4.2.2 specifies more requirements for the contents of the quality manual. This standard is not heavy on documented (written) procedures as was the case with previous standards. Clause 4.2.1d requires you to have documents needed to ensure the effective planning, operation and control for QMS processes. The nature and extent of such documentation will vary from organization to organization, based on factors listed below. What criteria should an organization use to determine how much QMS documentation it should have? The need to have additional documentation beyond those specified in this standard may depend upon - customer, regulatory and your own organizational requirements. Other factors to consider may include complexity of products and processes; effect on quality; risk of customer dissatisfaction; economic risk; effectiveness and efficiency; competence of personnel; workforce stability and past quality problems and nonconformities. For example, the complex your products or processes are, the greater the risk of problems occurring. The use of documentation and other controls serve to prevent or reduce these risks. If you have a highly educated and stable workforce, then the amount of documentation needed may be significantly less than an organization that has a high workforce turnover and lower educational requirements. Regardless of how and to what extent you document your QMS, you must demonstrate the effective implementation of your QMS in terms of conformity to ISO 9001, customer, regulatory and your own organizational requirements. In what medium should QMS documents be communicated? Any combination of media is acceptable for documents and records provided they conform to requirements specified in clause 4.2.3 control of documents and clause 4.2.4 control of records. These may include, but not limited to: paper, magnetic. electronic or optical computer disc, photograph, audiovisual, etc. What are the mandatory documented procedures required by ISO 9001:2000? Under ISO 9001, you must have documented procedures for - clause 4.2.3 - Control of documents; clause 4.2.4 - Control of records; clause 8.2.2 Internal audit; clause 8.3 - control of nonconforming product; clause 8.5.2 Corrective action and clause 8.5.3 - Preventive action. These documented procedures have to be controlled in accordance with the requirements of clause 4.2.3

You may choose to include your procedures and lower level documentation in your quality manual or organize them in some other fashion. The practicality of this would depend on the size of your organization, complexity of products and processes; competency of personnel, media used for documentation (hard copy versus computerized); ease of use and understanding by personnel; maintainability; etc. Depending on these same criteria, you may decide to have additional procedures (beyond the mandatory six) or carry over some or all the procedures you had under previous QMS systems. Some of the mandatory procedures can be combined, e.g., correction and preventive action may be combined as long as you address the specific requirements of each clause 8.5.2 and 8.5.3. You could also have more than one procedure for any of the mandatory clauses listed above. Note there are several ways to write procedures, other than the conventional narrative form. In fact, narrative documentation has been found to be the least effective way to promote user comprehension and ease of use. Procedures may be documented graphically (e.g. flowchart; video; series of pictures or photographs, etc.). Can you provide examples of documents, other than policies, quality manual and procedures, that an organization may need for its QMS? In addition to the documents specifically called out in ISO 9001, clause 4.2.1d calls for documents deemed necessary for effective management and control of your processes. These could include - process maps, process flow charts and/or process descriptions; organization charts; quality plan, material specifications; competence criteria, product specifications, packaging specifications, manufacturing specifications, work and test instructions; forms; schedules; set-up specifications, etc. ISO 9001 calls for many records to provide evidence of effective planning, operation and control of processes. Examples include - management review records; calibration records, internal audit records; corrective action records, etc. Again, your processes may call for additional records beyond those expected by ISO 9001. Many clauses do not specifically call for documents and records, but there is a strong implication in the wording of the need to have them. This is where you must be guided by clauses 4.2.1d and 7.1b for documents and 4.2.1e; 4.2.4 and 7.1d for records. Use these clauses to determine what documents and records are needed to provide evidence of effective planning, operation and control. Remember to use the requirements of clause 4.2.3 to control all documents you choose to include in your QMS; and the requirements of clause 4.2.4 to control all QMS records.

What should be documented in my Quality Manual? The quality manual (QM) is a special type of document that describes your QMS. Your QMS is comprised of a number of business processes needed to satisfy customer and other stakeholder requirements. For your QMS manual to be meaningful, provide a brief description of each of these processes and the key ISO 9001 control requirements that apply to them. Do not follow the common practice of writing back the clauses of the standard. This serves no useful purpose to anyone. Your quality manual must also include a description of the interaction of your QMS processes. This can be done in any number of ways including - process maps; flowcharts; process diagrams; spreadsheets; etc. You QM must define the scope of your QMS. Your QMS scope should include - facilities (manufacturing and support locations), products, processes, your policies for Quality Management and other standards, etc. Customers will want to know the extent of your product, QMS and manufacturing capabilities and the Certification Body (Registrar) will want to determine the time and effort needed to audit your organization. Provide details of any clause exclusions from your scope, e.g. 7.3 Product Design and Development, and your justification for it. You must justify all exclusions and remember, exclusions can only be made from clause 7. Besides describing your QMS, your quality manual could provide information on organizational background and capabilities. It may be used by customers, regulatory bodies, suppliers and company personnel for a variety of purposes. There are many other acceptable ways to document your quality manual. You have flexibility in whether or not to include your procedures and lower level documentation with your quality manual or organize them in some other fashion. You may include all or some of your procedures in your Quality Manual or reference them to your Quality Manual. Keep a listing or index at the front or back of your Manual showing the complete list of your procedures whether included or referenced. The practicality of all this would depend, of course, on the size of your organization; complexity of products and processes; competency of personnel; media used for documentation (hard copy versus computerized); ease of use and understanding by personnel; etc. So go ahead and organize your documentation to facilitate ease of use; understandability, availability and maintainability. As a part of your QMS (see 4.2.1) documentation, the quality manual is subject to all of the controls in clause 4.2.3. How does an organization demonstrate conformance to ISO 9001, if

it has minimal documentation? In order to claim conformity with ISO 9001:2000, the organization must be able to provide objective evidence of the effectiveness of its processes and its quality management system. Clause 3.8.1 of ISO 9000:2000 defines "objective evidence" as "data supporting the existence or verity of something" and notes that "objective evidence may be obtained through observation, measurement, test, or other means." Note that organizations may be able to demonstrate conformity without the need for extensive documentation. Objective evidence does not necessarily depend on the existence of documented procedures, records or other documents, except where specifically mentioned in ISO 9001:2000. In some cases, (for example, in clause 7.1(d) Planning of product realization, and clause 8.2.4 Monitoring and measurement of product), it is up to the organization to determine what records are necessary in order to provide this objective evidence. Where the organization has no specific internal procedure for a particular activity, and this is not required by the standard, (for example, clause 5.6 Management Review), it is acceptable for this activity to be conducted using as a basis the requirements of clause 5.6 and it can also be used for both internal and external conformity audit purposes.

Vous aimerez peut-être aussi

- Clause 8 - ExplanationDocument33 pagesClause 8 - Explanations_agali2413Pas encore d'évaluation

- Audit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19D'EverandAudit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19Pas encore d'évaluation

- Understanding Document Control by Adanma Kadiri.Document12 pagesUnderstanding Document Control by Adanma Kadiri.Kelechi OchuloPas encore d'évaluation

- Workpaper GuidelinesDocument4 pagesWorkpaper GuidelinesAltynay IlyassovaPas encore d'évaluation

- Conformity Assessment (Management System Certification)Document5 pagesConformity Assessment (Management System Certification)Talal AhmedPas encore d'évaluation

- Summary of Iso 90091Document3 pagesSummary of Iso 90091Ihuhwa Marta TauPas encore d'évaluation

- 015 GMP Documentation1Document40 pages015 GMP Documentation1ipatoffPas encore d'évaluation

- Pub100373 PDFDocument12 pagesPub100373 PDFedgelcer100% (1)

- Revision Record Sheet: TitleDocument4 pagesRevision Record Sheet: TitleSanjay MalhotraPas encore d'évaluation

- Manual-Procedures-Forms-Matrix - P-XXX NumbersDocument1 pageManual-Procedures-Forms-Matrix - P-XXX NumbersAngelo SantiagoPas encore d'évaluation

- All Processes ChecklistDocument9 pagesAll Processes ChecklistAndy Le GrangePas encore d'évaluation

- Internal Audit - SOPDocument18 pagesInternal Audit - SOPmgPas encore d'évaluation

- Management Review Meeting Report - 03Document2 pagesManagement Review Meeting Report - 03Claire TanPas encore d'évaluation

- The Program of QmsDocument16 pagesThe Program of QmsHamza Sharif AdamPas encore d'évaluation

- Qms 505 Lecture 4 Checklist For Developing An Appropriate Quality Management SystemDocument4 pagesQms 505 Lecture 4 Checklist For Developing An Appropriate Quality Management SystemJACKSON OSUHPas encore d'évaluation

- 2.06 SIPOC DiagramDocument4 pages2.06 SIPOC DiagramJulioRomeroPas encore d'évaluation

- Why ISO 9001Document19 pagesWhy ISO 9001Arun K SharmaPas encore d'évaluation

- How Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementDocument3 pagesHow Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementPavan MujawdiyaPas encore d'évaluation

- CPA Compliance ChecklistDocument25 pagesCPA Compliance ChecklistFizz FirdausPas encore d'évaluation

- Guide For Quality System Manual Internal Audit: ApprovedDocument9 pagesGuide For Quality System Manual Internal Audit: ApprovedMan Peatman ManpeatmanPas encore d'évaluation

- ISO 9001 Transition GuideDocument12 pagesISO 9001 Transition GuideJon DesferPas encore d'évaluation

- Iso9001 2015 Quality Manual Template 1 1024Document1 pageIso9001 2015 Quality Manual Template 1 1024Adhi GunantoPas encore d'évaluation

- ISO 9001 - 2015 Audit Check ListDocument10 pagesISO 9001 - 2015 Audit Check Listsandeep KumarPas encore d'évaluation

- Internal Quality Management System Audit Checklist (ISO9001:2015)Document24 pagesInternal Quality Management System Audit Checklist (ISO9001:2015)Fatimaezzahraa BouaalamPas encore d'évaluation

- 112 - QMS - Internal Auditor Training Program 9001 - 2105 Version - 2 DaysDocument2 pages112 - QMS - Internal Auditor Training Program 9001 - 2105 Version - 2 DaysKKSATPas encore d'évaluation

- Project: Dr. Muhammad AjmalDocument14 pagesProject: Dr. Muhammad AjmalAyesha AbbasPas encore d'évaluation

- 01 ISO 9001-2015 Transition Checklist C 01 Rev ADocument4 pages01 ISO 9001-2015 Transition Checklist C 01 Rev Avikkas vermaPas encore d'évaluation

- Ground Disturbance Course Materials Updates - V8 - Nov 12 2014 - As ApprovedDocument42 pagesGround Disturbance Course Materials Updates - V8 - Nov 12 2014 - As Approvedinvscd123Pas encore d'évaluation

- ISO 9001 Internal Audit ChecklistDocument14 pagesISO 9001 Internal Audit ChecklistEsterNTPas encore d'évaluation

- Quality Management With ISO 9001Document24 pagesQuality Management With ISO 9001Mardi Rahardjo100% (1)

- Internal Audit ProceduresDocument15 pagesInternal Audit ProceduresTait G MafuraPas encore d'évaluation

- 5S Audit Checklist: Sort Set in Order Shine Standardize Sustain Total Total Score No. of Questions Average ScoreDocument4 pages5S Audit Checklist: Sort Set in Order Shine Standardize Sustain Total Total Score No. of Questions Average ScoreCaroline Eliza MendesPas encore d'évaluation

- Auditor Training Module 2 - Audit ManagementDocument28 pagesAuditor Training Module 2 - Audit ManagementThant AungPas encore d'évaluation

- CAPA Corrective and Preventive Action in PharmaceuticalDocument5 pagesCAPA Corrective and Preventive Action in PharmaceuticalRainMan75Pas encore d'évaluation

- CQI-IRCA LA Online Exam Guide5Document8 pagesCQI-IRCA LA Online Exam Guide5shams aliPas encore d'évaluation

- Quality Management Strategy ExampleDocument10 pagesQuality Management Strategy Exampleselinasimpson1201Pas encore d'évaluation

- What Is The ISO 9001:2008 Audit Checklist?Document38 pagesWhat Is The ISO 9001:2008 Audit Checklist?John SoaresPas encore d'évaluation

- ISO 9001-2015 Client-Transition-Checklist - Add Your Co NameDocument11 pagesISO 9001-2015 Client-Transition-Checklist - Add Your Co NameTomBerendsenPas encore d'évaluation

- FR-198 Opening-Closing Meeting Form Rev01 3Document1 pageFR-198 Opening-Closing Meeting Form Rev01 3Erkan DilekPas encore d'évaluation

- 53 Arc 0000Document27 pages53 Arc 0000Mustafa AlHalfawiPas encore d'évaluation

- QMS Orientation TRNG - Induction Sep07Document50 pagesQMS Orientation TRNG - Induction Sep07api-3753361Pas encore d'évaluation

- Waterfall Model DocumentsDocument14 pagesWaterfall Model DocumentsNAMITA JHA100% (1)

- Audit Plan 2018 lbc1Document23 pagesAudit Plan 2018 lbc1r0wanPas encore d'évaluation

- MGT PRO-10 Control of Documented Information ProcedureDocument10 pagesMGT PRO-10 Control of Documented Information ProcedureAbla NedjmaPas encore d'évaluation

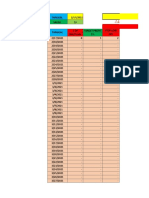

- Excel de Checklist+ISO9001Document22 pagesExcel de Checklist+ISO9001Jaime Verdugo100% (1)

- What Is Iso CertificationDocument4 pagesWhat Is Iso CertificationShailesh GuptaPas encore d'évaluation

- Introduction To ISO 9001 2015Document11 pagesIntroduction To ISO 9001 2015chrisPas encore d'évaluation

- Why ISO 9001:2015? Awareness Presentation: Subtitle or PresenterDocument15 pagesWhy ISO 9001:2015? Awareness Presentation: Subtitle or PresenterMarusia TirmicanPas encore d'évaluation

- ISO27k Nonconformity Corrective Preventive Action FormDocument3 pagesISO27k Nonconformity Corrective Preventive Action FormJasim's BhaignaPas encore d'évaluation

- M03 Risk Assessment ProcedureDocument7 pagesM03 Risk Assessment ProcedureMay Ann DuronPas encore d'évaluation

- Mini Quality ManualDocument7 pagesMini Quality Manualwici2915Pas encore d'évaluation

- APG InternalAudit2015 PDFDocument4 pagesAPG InternalAudit2015 PDFBulmaro SanchezPas encore d'évaluation

- Quality Manual 9001-2008 Elsmar 1Document13 pagesQuality Manual 9001-2008 Elsmar 1luis miguel perez cruzPas encore d'évaluation

- AAMI Quality Systems White Paper: Comparison of 21 CFR Part 820 To ISO 13485:2016Document28 pagesAAMI Quality Systems White Paper: Comparison of 21 CFR Part 820 To ISO 13485:2016Hong XuyenPas encore d'évaluation

- APG InternalAudit2015 PDFDocument4 pagesAPG InternalAudit2015 PDFBulmaro SanchezPas encore d'évaluation

- Quality JourneyDocument22 pagesQuality JourneyNishaThakuriPas encore d'évaluation

- QP7 Purchasing Control & Suppilers EvaluationDocument4 pagesQP7 Purchasing Control & Suppilers EvaluationMuhammad Shiraz KhalidPas encore d'évaluation

- Bench MarkingDocument4 pagesBench MarkingMohammad Jaid AlamPas encore d'évaluation

- Cost of QualityDocument3 pagesCost of QualityMohammad Jaid AlamPas encore d'évaluation

- Quality and ISOTS 16949Document4 pagesQuality and ISOTS 16949Mohammad Jaid AlamPas encore d'évaluation

- Customer Satisfaction (8.2.1) : What Does This Mean?Document5 pagesCustomer Satisfaction (8.2.1) : What Does This Mean?Mohammad Jaid AlamPas encore d'évaluation

- Why Bench Marking Efforts FailDocument3 pagesWhy Bench Marking Efforts FailMohammad Jaid AlamPas encore d'évaluation

- Why Quality Is Still An Exclusive Concept and What Is The RemedyDocument4 pagesWhy Quality Is Still An Exclusive Concept and What Is The RemedyMohammad Jaid AlamPas encore d'évaluation

- QMS Implementation Road MapDocument2 pagesQMS Implementation Road MapMohammad Jaid AlamPas encore d'évaluation

- Cost of QualityDocument3 pagesCost of QualityMohammad Jaid AlamPas encore d'évaluation

- Integrated Management SystemDocument5 pagesIntegrated Management SystemMohammad Jaid AlamPas encore d'évaluation

- Understanding Correction, Corrective Action and Preventive ActionDocument3 pagesUnderstanding Correction, Corrective Action and Preventive ActionMohammad Jaid Alam100% (1)

- Difference Between Quality Control & Quality AssuranceDocument4 pagesDifference Between Quality Control & Quality AssuranceMohammad Jaid Alam100% (1)

- Armand V. FeigenbaumDocument9 pagesArmand V. FeigenbaumMohammad Jaid Alam50% (2)

- Misconceptions About The ISO 9000 FamilyDocument3 pagesMisconceptions About The ISO 9000 FamilyMohammad Jaid AlamPas encore d'évaluation

- Dr. Kaoru IshikawaDocument7 pagesDr. Kaoru IshikawaMohammad Jaid Alam100% (2)

- Cause and Effect DiagramsDocument4 pagesCause and Effect DiagramsMohammad Jaid AlamPas encore d'évaluation

- Twelve Obstacles To Implementing QualityDocument4 pagesTwelve Obstacles To Implementing QualityMohammad Jaid AlamPas encore d'évaluation

- Qms Implementation: Establishing A Quality Management System (4.1)Document3 pagesQms Implementation: Establishing A Quality Management System (4.1)Mohammad Jaid AlamPas encore d'évaluation

- Pdca - Plan Do Check ActDocument5 pagesPdca - Plan Do Check ActMohammad Jaid AlamPas encore d'évaluation

- ISO Library PDFDocument643 pagesISO Library PDFhaharamesh100% (1)

- Graphology - 1st PartDocument4 pagesGraphology - 1st PartMohammad Jaid AlamPas encore d'évaluation

- MBCM771D-Marketing Management 1Document20 pagesMBCM771D-Marketing Management 1Utkarsh SinghPas encore d'évaluation

- Assignment 3. KodakDocument9 pagesAssignment 3. KodakSrabon AhmedPas encore d'évaluation

- G1 - A Guide To Writing Aim, Objectives SFS, and Structuring Coursework, v6, 15-9-22Document28 pagesG1 - A Guide To Writing Aim, Objectives SFS, and Structuring Coursework, v6, 15-9-22Dhârâñî KûmârPas encore d'évaluation

- Salience Introduction and Credentials 2018Document14 pagesSalience Introduction and Credentials 2018Graeme LowtherPas encore d'évaluation

- Alex Windle - Resume - 3Document1 pageAlex Windle - Resume - 3api-401022598Pas encore d'évaluation

- Blue Nile and Diamond Retailing: A Case Study ReviewDocument16 pagesBlue Nile and Diamond Retailing: A Case Study ReviewDaivik TandelPas encore d'évaluation

- Quality Assurance Review For Internal Audit ExcellenceDocument5 pagesQuality Assurance Review For Internal Audit ExcellencerakhasuryaPas encore d'évaluation

- C TS452 1909demoDocument4 pagesC TS452 1909demoYi-Hsien LiPas encore d'évaluation

- PMP - Short DocumentDocument101 pagesPMP - Short DocumentAndrzejPas encore d'évaluation

- STM - Grp4 - Sec - B - ThedaCare..... Ques OneDocument3 pagesSTM - Grp4 - Sec - B - ThedaCare..... Ques OneAdam MorganPas encore d'évaluation

- Chap (1) Introduction To EntrepreneurshipDocument20 pagesChap (1) Introduction To EntrepreneurshipAbdalla AbukarPas encore d'évaluation

- Tuten SMM Ch10Document22 pagesTuten SMM Ch10JannatPas encore d'évaluation

- Audit FundamentalsDocument37 pagesAudit Fundamentalsaqsa palijoPas encore d'évaluation

- Axe Deodorant in Rural MarketDocument17 pagesAxe Deodorant in Rural MarketAnimesh PhukanPas encore d'évaluation

- The DAMA Guide To The Data Management 7a 8Document61 pagesThe DAMA Guide To The Data Management 7a 8jorgepr4d4Pas encore d'évaluation

- For Sybca - Heta Desai: Student Notes On Information SystemDocument56 pagesFor Sybca - Heta Desai: Student Notes On Information SystemHeta DesaiPas encore d'évaluation

- Mohammed Seba e I CVDocument5 pagesMohammed Seba e I CVMohammed El SebaeiPas encore d'évaluation

- Axios Systems: Canadian Tire ITIL Help Desk Case StudyDocument3 pagesAxios Systems: Canadian Tire ITIL Help Desk Case StudyAxiosSystemsPas encore d'évaluation

- Target Trading HarianDocument21 pagesTarget Trading HarianNavz BlackPas encore d'évaluation

- Proposal For Services For EGB ConstructionDocument7 pagesProposal For Services For EGB ConstructionJaydwin T. LabianoPas encore d'évaluation

- Online BrandingDocument13 pagesOnline BrandingPiroPas encore d'évaluation

- HRM - 1st Week - Lecture HandoutDocument13 pagesHRM - 1st Week - Lecture HandoutProf. Jomar MariquitPas encore d'évaluation

- Management of MNCT PDFDocument303 pagesManagement of MNCT PDFKuthubudeen T MPas encore d'évaluation

- Strategic MGMTDocument44 pagesStrategic MGMTMustafa SaifeePas encore d'évaluation

- Agile PM Foundation UserguideDocument33 pagesAgile PM Foundation UserguideDarshanPas encore d'évaluation

- Integrated Case Study Complete EditionDocument34 pagesIntegrated Case Study Complete EditionWan Ramss Jr.100% (10)

- Case Study Just in Time at Eicher TractorsDocument31 pagesCase Study Just in Time at Eicher TractorsDiwakar Pasricha100% (1)

- 'NEXtCARE Corporate Profile 4Document1 page'NEXtCARE Corporate Profile 4Rajesh PotluriPas encore d'évaluation

- Green Marketing Course Syllabus Co - AB0501Document2 pagesGreen Marketing Course Syllabus Co - AB0501ANDRES VRANT100% (1)

- Module 8 Total Quality ManagementDocument9 pagesModule 8 Total Quality ManagementMary Joy Morallon CalaguiPas encore d'évaluation

- Secrets of the Millionaire Mind: Mastering the Inner Game of WealthD'EverandSecrets of the Millionaire Mind: Mastering the Inner Game of WealthÉvaluation : 4.5 sur 5 étoiles4.5/5 (197)

- The Layman's Guide GDPR Compliance for Small Medium BusinessD'EverandThe Layman's Guide GDPR Compliance for Small Medium BusinessÉvaluation : 5 sur 5 étoiles5/5 (1)

- (ISC)2 CISSP Certified Information Systems Security Professional Official Study GuideD'Everand(ISC)2 CISSP Certified Information Systems Security Professional Official Study GuideÉvaluation : 2.5 sur 5 étoiles2.5/5 (2)

- Mastering Internal Audit Fundamentals A Step-by-Step ApproachD'EverandMastering Internal Audit Fundamentals A Step-by-Step ApproachÉvaluation : 4 sur 5 étoiles4/5 (1)

- Internal Audit Checklists: Guide to Effective AuditingD'EverandInternal Audit Checklists: Guide to Effective AuditingPas encore d'évaluation

- Financial Shenanigans, Fourth Edition: How to Detect Accounting Gimmicks & Fraud in Financial ReportsD'EverandFinancial Shenanigans, Fourth Edition: How to Detect Accounting Gimmicks & Fraud in Financial ReportsÉvaluation : 4 sur 5 étoiles4/5 (26)

- Amazon Interview Secrets: A Complete Guide to Help You to Learn the Secrets to Ace the Amazon Interview Questions and Land Your Dream JobD'EverandAmazon Interview Secrets: A Complete Guide to Help You to Learn the Secrets to Ace the Amazon Interview Questions and Land Your Dream JobÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- The Game: Penetrating the Secret Society of Pickup ArtistsD'EverandThe Game: Penetrating the Secret Society of Pickup ArtistsÉvaluation : 4 sur 5 étoiles4/5 (131)

- A Step By Step Guide: How to Perform Risk Based Internal Auditing for Internal Audit BeginnersD'EverandA Step By Step Guide: How to Perform Risk Based Internal Auditing for Internal Audit BeginnersÉvaluation : 4.5 sur 5 étoiles4.5/5 (11)

- Executive Roadmap to Fraud Prevention and Internal Control: Creating a Culture of ComplianceD'EverandExecutive Roadmap to Fraud Prevention and Internal Control: Creating a Culture of ComplianceÉvaluation : 4 sur 5 étoiles4/5 (1)

- Musings on Internal Quality Audits: Having a Greater ImpactD'EverandMusings on Internal Quality Audits: Having a Greater ImpactPas encore d'évaluation

- Proof of Heaven: A Neurosurgeon's Journey into the AfterlifeD'EverandProof of Heaven: A Neurosurgeon's Journey into the AfterlifeÉvaluation : 3.5 sur 5 étoiles3.5/5 (165)

- Aruba, Bonaire & Curacao Adventure GuideD'EverandAruba, Bonaire & Curacao Adventure GuideÉvaluation : 5 sur 5 étoiles5/5 (2)

- New Zealand Adventure Travel GuideD'EverandNew Zealand Adventure Travel GuideÉvaluation : 4.5 sur 5 étoiles4.5/5 (14)

- Internal Controls: Guidance for Private, Government, and Nonprofit EntitiesD'EverandInternal Controls: Guidance for Private, Government, and Nonprofit EntitiesPas encore d'évaluation

- A Pocket Guide to Risk Mathematics: Key Concepts Every Auditor Should KnowD'EverandA Pocket Guide to Risk Mathematics: Key Concepts Every Auditor Should KnowPas encore d'évaluation